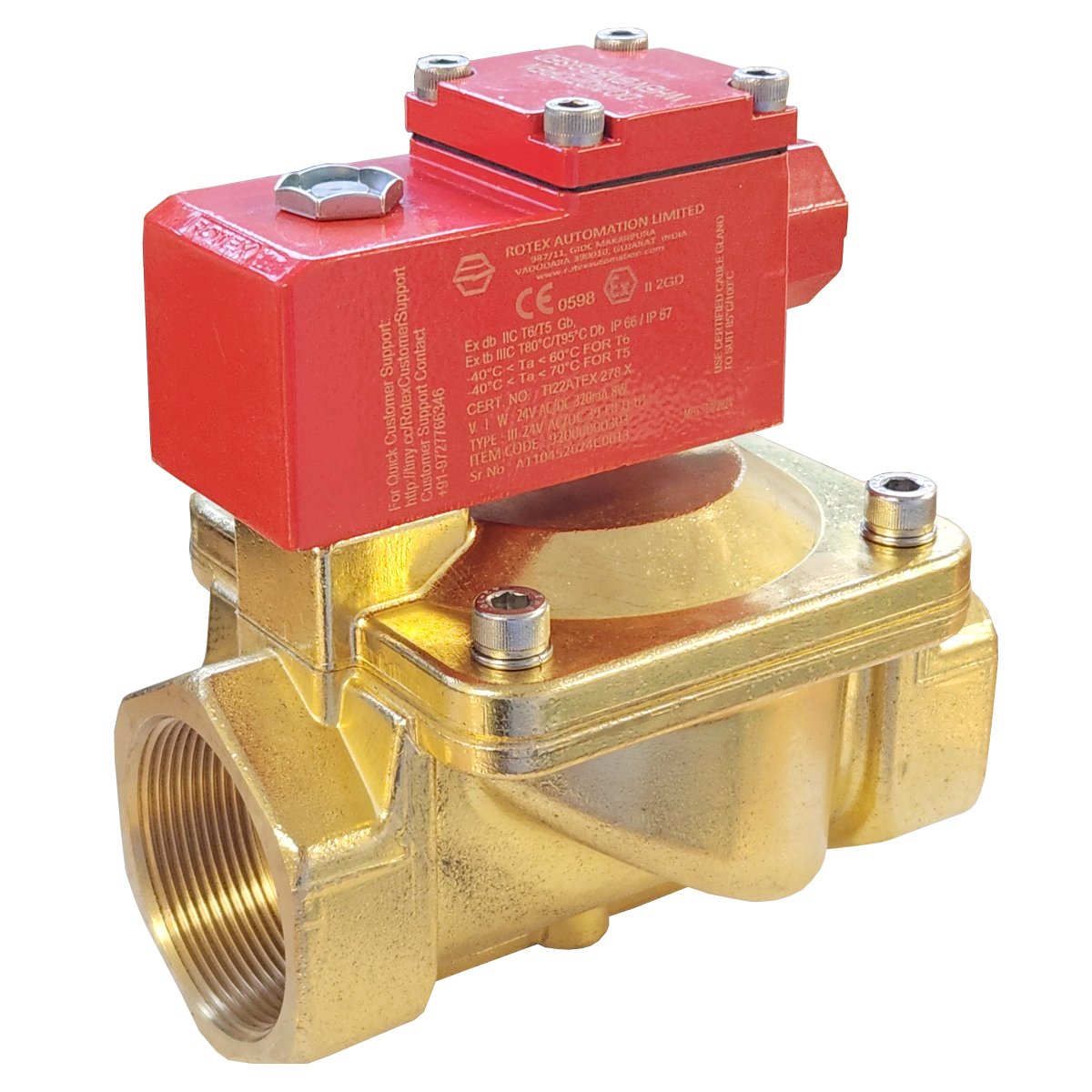

ATEX Solenoid Valves – Exm, Exd & Exia for Safety & Performance

Understanding What Really Matters in ATEX Valve Selection

Choosing the correct ATEX solenoid valves – Exm Exd and Exia options for enhanced safety and performance – is a process that goes far beyond simply matching a product code to a hazardous zone classification. Achieving true operational safety and efficiency depends on understanding the fundamental principles behind the standards. It requires a detailed analysis of how regulatory compliance translates into real-world protection strategies that secure both personnel and critical assets. This means looking past the surface-level markings on a valve to evaluate the dynamic relationship between the specific environment, the substance being managed, and the valve's core design.

Experienced safety engineers understand that genuine safety performance is achieved through this detailed appreciation, not by merely ticking a compliance box. The decision-making process must carefully balance the unique challenges of an environment against the distinct advantages of each protection method.

The Core Triangle: Zone, Gas Group, and Temperature Class

The foundation of any correct valve selection is built on three key pillars: the hazardous zone classification, the gas or dust group involved, and the maximum surface temperature. A miscalculation in any one of these areas can result in an installation that is compliant on paper but dangerously unsafe in practice.

- Zone Classification (The 'When'): This defines the frequency and duration an explosive atmosphere is present. For a Zone 0 area, where a flammable atmosphere is continuously present, an intrinsically safe (Exia) design is essential because the risk is constant. Conversely, a Zone 2 area, where an explosive atmosphere is unlikely to occur and will only exist for short periods, may be suitably protected by a different method.

- Gas/Dust Group (The 'What'): This classifies the specific substance according to its potential for explosion. A valve certified for propane (Group IIA) would be completely unsuitable and hazardous in a setting with hydrogen (Group IIC), as hydrogen requires significantly less energy to ignite.

- Temperature Class (The 'How Hot'): This specifies the maximum surface temperature the valve can reach, even under fault conditions. This temperature must always be lower than the auto-ignition point of the hazardous substance. A T6 rating (85°C) offers a substantially higher safety margin compared to a T1 rating (450°C).

Beyond the Datasheet: Real-World Considerations

Interpreting ATEX standards effectively means recognising the practical wisdom they contain. For example, the demanding requirements for Exd flameproof enclosures are not just about containing an internal explosion; they also account for the significant mechanical and thermal stresses common in heavy industrial applications. Likewise, the energy-limiting principles of Exia are intended for situations where even routine maintenance tasks could potentially introduce an ignition source.

Decisions that truly safeguard your operations must consider these underlying factors. In critical sectors across the United Kingdom, such as the North Sea oil and gas industry and emerging renewable energy projects, this level of detailed analysis is not merely best practice—it is a fundamental requirement for safe operation. The UK's strict safety regulations create a strong demand for explosion-proof solenoid valves to prevent catastrophic events in these vital industries.

Ultimately, selecting the right ATEX valve involves creating a system where the protection method is perfectly aligned with the identified risks. By developing a deeper appreciation for the intent behind this complex regulatory framework, you can make choices that provide not just compliance, but genuine confidence. You can explore more detailed guidance on our main ATEX information page.

Exm Protection: When Encapsulation Makes Perfect Sense

When comparing ATEX solenoid valves – considering Exm, Exd, and Exia options for enhanced safety and performance – the Exm protection method, or encapsulation, stands out as a superior choice for specific operational challenges. Its core principle is straightforward but highly effective: any component capable of generating a spark or heat, like the valve's coil, is completely encased in a protective resin compound. This creates a solid, impenetrable barrier, isolating the ignition source from any surrounding explosive atmosphere.

The real advantage of Exm protection becomes clear when you look at environments where it excels over other methods. For example, in facilities with high levels of moisture, corrosive agents, or fine dust—such as grain processing plants or mining operations—the complete seal from encapsulation provides an unmatched level of ingress protection. An Exd flameproof enclosure, while tough, depends on precisely machined flame paths that can be compromised by particle build-up or corrosion, requiring diligent maintenance. An Exm valve, with no such pathways to look after, is essentially a "fit-and-forget" solution in dirty or damp conditions, reducing long-term maintenance costs.

Analysing Real-World Suitability

The true measure of any protection method lies in its performance under genuine operational conditions. In pharmaceutical cleanrooms, where hygiene and sterility are critical, Exm valves are frequently chosen. Their smooth, sealed exterior is simple to clean and has no crevices where contaminants can gather, which aligns perfectly with strict cleanliness standards. These valves are also generally more compact and lighter than their Exd equivalents, which makes installation easier in tight equipment skids or intricate pipework.

However, the permanent nature of encapsulation presents a significant trade-off: it cannot be repaired. If an encapsulated component like the solenoid coil fails, the entire valve or coil assembly must be replaced. This is a stark contrast to Exd valves, where a qualified electrician can often access and swap out a faulty coil. The decision to use Exm, therefore, requires balancing its low maintenance needs against the consequence of a complete replacement upon failure. In highly reliable systems with predictable service lives, this is often a perfectly acceptable compromise.

To better understand where Exm protection delivers the most value, the following table provides a practical analysis of its performance across different scenarios.

| Application Scenario | Performance Rating | Maintenance Frequency | Environmental Suitability | Cost-Benefit Score |

|---|---|---|---|---|

| Pharmaceutical Cleanrooms | Excellent | Very Low | Excellent (easy to clean, no particle traps) | 9/10 |

| Grain/Dusty Environments | Excellent | Very Low | Excellent (impervious to fine particulates) | 9/10 |

| Offshore/Marine (High Salt) | Very Good | Very Low | Very Good (excellent corrosion resistance) | 8/10 |

| Vibrating Machinery (Mining) | Excellent | Very Low | Excellent (resists mechanical shock and vibration) | 8/10 |

| Standard Chemical Processing | Good | Low | Good (dependent on chemical compatibility of resin) | 7/10 |

| Remote/Inaccessible Locations | Good | Very Low | Very Good (ideal for 'fit-and-forget' needs) | 7/10 |

This analysis highlights that Exm's strengths in ingress protection and minimal maintenance make it a highly cost-effective and reliable solution in challenging environments, despite its lack of repairability.

Environmental Resilience and Thermal Performance

Another key advantage of Exm protection is its resilience to vibration and mechanical shock. The solid potting compound provides robust support for the internal windings of the coil, preventing damage from the constant vibrations found in heavy industrial machinery. This is a subtle but important benefit in applications such as mobile mining equipment or large-scale food processing machines.

The encapsulation compound also plays a vital role in thermal management. It effectively dissipates heat from the coil to the valve body and the surrounding air, helping to keep the surface temperature low. This can be a decisive factor in atmospheres containing substances with low auto-ignition temperatures. By understanding these specific performance details, engineers can pinpoint the scenarios where Exm's unique design solves operational problems that other ATEX protection methods cannot handle as effectively.

Exd Flameproof: Engineering That Contains the Unthinkable

While Exm encapsulation focuses on isolating components, the Exd flameproof method is built on a different principle: containment. When comparing ATEX solenoid valves – with Exm, Exd, and Exia options for enhanced safety and performance, the Exd design is engineered for pure resilience. It operates on the assumption that an internal fault could happen, so the valve's enclosure is constructed to withstand the force of an internal explosion and stop it from reaching the hazardous atmosphere outside.

This isn't just about a thick metal casing. The foundation of Exd safety is the precision-machined flame paths. These are tiny, controlled gaps where the enclosure's parts meet, like between the body and its cover. Should an internal ignition happen, the hot gases and flames are channelled through these narrow paths. As they travel, they cool down to a temperature below the ignition point of the external atmosphere, neutralising the threat before it escapes. The enclosure itself is built to contain the immense internal pressure, which can exceed 10 bar during an event. This mechanical strength makes Exd a trusted solution in demanding sectors like petrochemical processing and offshore oil and gas.

The Critical Role of Flame Path Precision

The integrity of any flameproof enclosure depends entirely on maintaining its flame paths. These are not just seals; they are finely engineered surfaces with gap dimensions and lengths defined by the gas group and the enclosure's size. For example, a valve for a hydrogen-rich area (Group IIC) will require much tighter and longer flame paths than one used for propane (Group IIA), as hydrogen flames can pass through smaller openings.

This reliance on mechanical accuracy creates a significant maintenance duty. Unlike a sealed Exm coil, an Exd enclosure can be opened for checks or repairs. However, this demands extreme care. Any scratch, bit of corrosion, or improper reassembly of the flame path surfaces can void the ATEX certification and create a route for an explosion. The bolts securing the enclosure are also vital for containing pressure; using the wrong bolts or torque can compromise the entire safety system. Field engineers often point to incorrect maintenance as a primary risk, highlighting why proper Exd handling requires specialised training.

Operational Performance and Installation Nuances

The solid build of Exd enclosures offers excellent protection against physical impacts and tough industrial environments, making them ideal where mechanical damage is a concern. This heavy-duty design, however, has practical implications. Exd solenoid valves are generally bigger and heavier than their Exm or Exia equivalents, which can make installation difficult in tight spots.

Their thermal characteristics also need careful thought. The substantial enclosure acts as a heat sink, but it also means the valve's surface temperature must be managed to remain within its certified T-class. This is especially important in high ambient temperatures or with continuous use, where heat from the coil adds to the thermal load. What looks like a simple installation is actually a detailed process involving precise mechanical assembly, choosing the right glands for cable entry, and understanding how the valve will behave thermally in its working environment. This is where the practical limits of Exd protection show, proving why it’s the right choice for high-risk, mechanically demanding jobs but might be excessive for others.

Exia Intrinsic Safety: The Gold Standard's Hidden Complexities

After looking at containment (Exd) and isolation (Exm), we now consider Exia intrinsic safety. This protection method works on a fundamentally different principle: prevention. When comparing ATEX solenoid valves – with Exm, Exd, and Exia options for enhanced safety and performance – Exia is often seen as the highest safety standard. Its design philosophy is not to contain an explosion or isolate a spark, but to ensure the electrical energy in a circuit is too low to cause ignition, even if faults occur. This makes it the only method suitable for the most hazardous environments, Zone 0, where an explosive atmosphere is continuously present.

The idea seems brilliantly simple: limit the energy and you eliminate the risk. However, the real-world application of an intrinsically safe system is far from straightforward. Unlike Exd or Exm, where safety is mostly self-contained within the valve, Exia safety relies on the entire circuit. It is a system-wide design that includes the solenoid valve, cabling, and a critical component called a Zener barrier or galvanic isolator, which is installed in the safe area. This barrier acts as a gatekeeper, carefully regulating the voltage and current entering the hazardous zone to keep it below the ignition threshold of the specific gas or dust.

The Intricacies of System-Wide Design

The complexity starts with the detailed calculations needed for the Descriptive System Document (DSD). This document is a mandatory part of any Exia installation, requiring an engineer to prove on paper that the system is safe. The calculations involve comparing the maximum capacitance and inductance of the field device (the solenoid valve) and cabling against the maximum allowable values set by the safety barrier. A seemingly small choice, like using a longer or different type of cable, can push the system's total capacitance or inductance beyond the safe limit, compromising the entire safety loop.

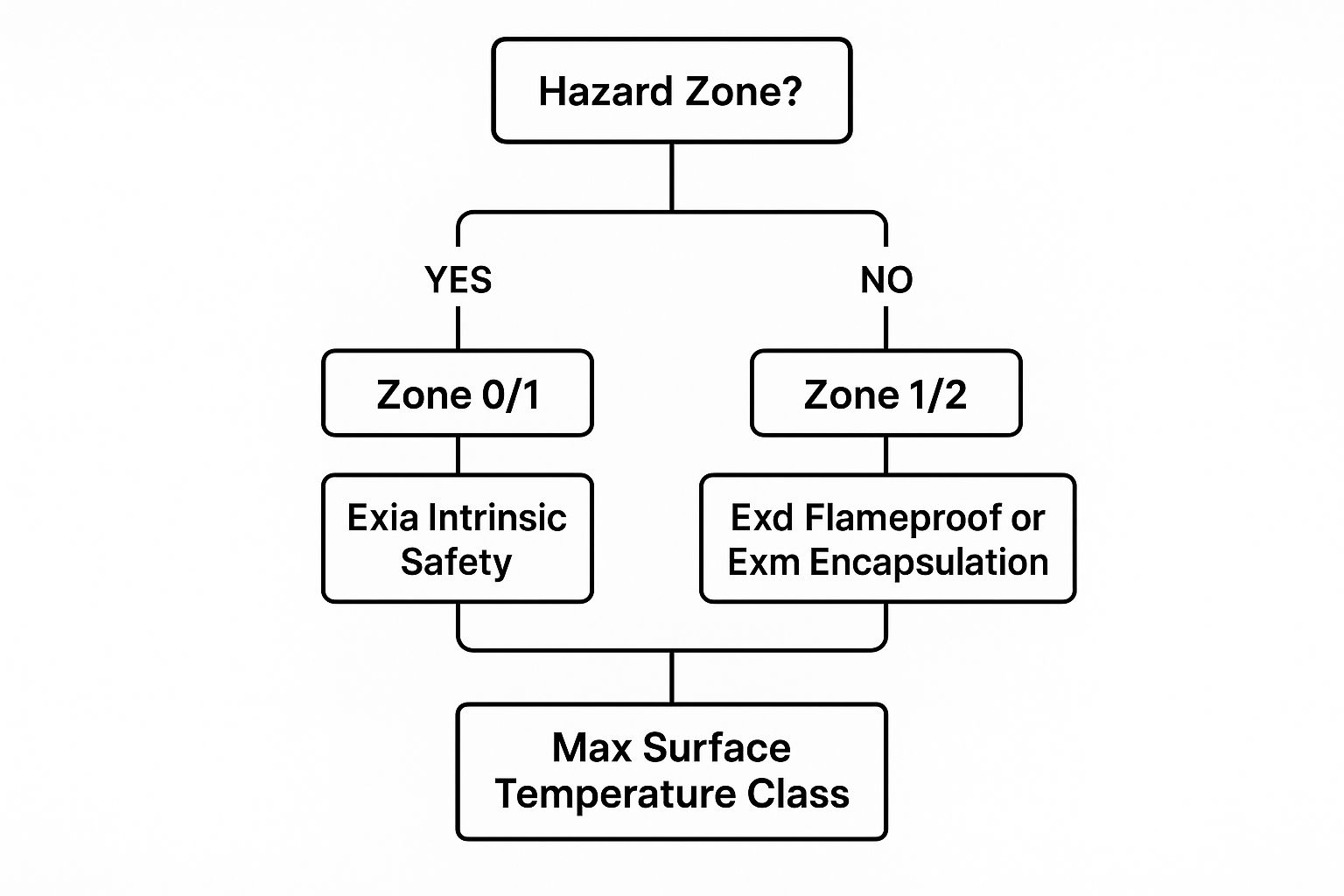

This infographic helps to visualise the initial decision-making process based on hazard zones.

As the diagram shows, the choice to use Exia is directly linked to the extreme risk in Zone 0/1 environments, which then brings further considerations like temperature class into play.

Furthermore, fault condition testing for Exia certification is exceptionally rigorous. The system must remain safe even with up to two independent faults applied at the same time. This means the valve and barrier combination must prevent ignition if, for example, a short circuit happens simultaneously with a component failure inside the barrier. This level of fault tolerance requires high-quality components and an expert understanding of their interaction.

Operational Trade-Offs and Maintenance Vigilance

The low-energy nature of Exia systems introduces practical operational trade-offs. The power available to operate an Exia solenoid valve is very limited. This can affect its performance, such as response time or its ability to operate against high differential pressures. As a result, pilot-operated valves or other specialised designs are often needed to function reliably on such low power.

To help clarify these trade-offs, the following table provides a strategic framework for comparing Exm, Exd, and Exia protection methods. It evaluates them across safety, operational needs, and overall complexity.

ATEX Protection Methods: Decision-Making Framework

Strategic comparison framework evaluating Exm, Exd, and Exia options across safety performance, operational requirements, and implementation complexity

| Protection Method | Safety Performance | Implementation Complexity | Operational Impact | Total Cost of Ownership | Best Use Scenarios |

|---|---|---|---|---|---|

| Exm (Encapsulation) | High. Isolates ignition sources by potting them in resin. Prevents any atmospheric contact with sparking components. | Low. The component is self-contained. Installation is similar to a standard component, requiring only standard wiring practices. | Minimal. No special live maintenance procedures. Component is non-repairable; replacement is the only option upon failure. | Low-Medium. Low initial installation cost. Replacement cost upon failure can be a factor. | Zone 1/2 applications where components are small, subject to vibration, and repair is not a priority (e.g., small solenoid coils, sensors). |

| Exd (Flameproof) | High. Contains an internal explosion and quenches the flame, preventing it from igniting the external atmosphere. | Medium. Requires specific certified cable glands and conduits. The integrity of the flame path (flanges) must be maintained. | High. "Hot work" permits are required for maintenance. The enclosure must be opened to access components, requiring area shutdown. | Medium-High. Higher initial component cost. Maintenance is labour-intensive and can cause significant process downtime. | Zone 1/2 applications requiring high-power equipment or where robust, physical protection is needed (e.g., large motors, control panels, high-power valves). |

| Exia (Intrinsic Safety) | Very High. Prevents ignition by limiting circuit energy to below combustible levels, even under fault conditions. The only method for Zone 0. | High. Requires a full system design (DSD), including a safety barrier, specific cabling, and detailed entity parameter calculations. | Low (for maintenance). Live maintenance is possible without hot work permits. High (for performance). Limited power can restrict valve performance (e.g., speed, power). | High. High design and engineering costs. Specialised barriers are needed. Lower maintenance downtime can offset some costs over the long term. | Zone 0/1/2 applications where the atmosphere is continuously or frequently hazardous and where live maintenance offers significant operational benefits. |

This comparison highlights that the "best" method is highly dependent on the specific application. While Exia offers the highest level of preventative safety, its complexity and performance limitations must be carefully weighed against the robust but operationally restrictive nature of Exd and the simpler, sealed protection of Exm.

Maintenance for Exia systems also demands a different type of vigilance. Although work can often be done on a live circuit without a "hot work permit"—a major advantage over Exd—technicians must be highly trained to avoid compromising the system. Using an uncertified test instrument, for example, could inject enough energy into the loop to create an ignition risk. Unlike the rugged, self-contained nature of an Exd valve, an Exia system's safety is distributed. It can be accidentally defeated by an uninformed action anywhere along the circuit. This ongoing need for specialised knowledge and strict procedures represents the hidden complexity behind intrinsic safety's gold-standard reputation.

Performance vs Safety: The Real Trade-Offs Nobody Discusses

Choosing between **ATEX solenoid valves**—with Exm, Exd, and Exia protection—often seems like a simple box-ticking exercise based on the hazardous zone classification. However, the real-world implications of this choice run much deeper than compliance, creating a delicate balance between safety integrity and day-to-day operational performance. Managers in petrochemical plants, on offshore platforms, and in pharmaceutical facilities frequently find that the specification sheet doesn't tell the full story. The true costs and compromises only surface after months of operation.

Take an Exd flameproof valve. It offers impressive mechanical protection, but its heavy, robust construction can become a significant operational hurdle. The same mass designed to contain an internal explosion also acts as a large heat sink. In applications requiring frequent cycling, this can slow down response times when compared to a lighter Exm or Exia valve. More critically, this thermal mass impacts temperature derating. In a high ambient temperature setting, an Exd valve's duty cycle may need to be limited to keep its surface temperature within its T-class rating, potentially capping production in a way that wasn't foreseen during the design phase.

Uncovering Hidden Operational Impacts

The trade-offs for intrinsic safety (Exia) are just as nuanced, though they manifest differently. While Exia systems permit live maintenance—a feature that can slash downtime compared to the shutdown procedures needed for Exd enclosures—this advantage comes with performance limits. The restricted energy allowed into the hazardous area means Exia solenoid valves often have a lower Maximum Operating Pressure Differential (MOPD). This might force you to specify a larger, pilot-operated valve to achieve the same flow control as a smaller, direct-acting Exd model, introducing new complications to the system design.

Even maintenance access can become a hidden cost. An Exd valve might be field-repairable, but its heavy, bolted flange demands considerable clearance for a technician to get in with a torque wrench. If that valve is tucked into a tightly packed skid, a "simple" repair could involve dismantling adjacent pipework, turning a one-hour task into a full day of process interruption. On the other hand, a "non-repairable" Exm encapsulated valve, while needing a full replacement upon failure, is often more compact. In a well-designed system, it can be swapped out much faster, challenging traditional ideas about the total cost of ownership.

Long-Term Realities and Economic Drivers

These operational compromises show that the selection process must consider the valve's entire lifecycle, not just its initial purchase price and safety certificate. This holistic view is becoming increasingly vital in the UK, where stringent environmental policies are a major factor. The demand for ATEX-certified solenoid valves is influenced by this focus on sustainability, with the UK market projected to grow at a CAGR of 4.3% through to 2035, driven by sectors like water treatment and offshore wind. This growth is directly tied to national commitments under directives like the Water Framework Directive, pushing for safer and more efficient industrial automation. You can find out more about the UK market trends and growth projections.

By understanding these subtle, long-term performance impacts, engineers and managers can make choices that genuinely support operational efficiency without ever compromising on the fundamental need for safety.

Industry Scenarios: Where Each Protection Method Excels

Theoretical knowledge of ATEX protection methods is a good starting point, but it's in real-world industrial scenarios that the crucial differences become clear. This is where you move from adequate selection to optimal safety and performance. The choice between ATEX solenoid valves – with Exm, Exd, and Exia options for enhanced safety and performance – is rarely straightforward and hinges on the specific operational context. By looking at case studies from different sectors, we can see how subtle environmental and operational factors guide the final decision.

Chemical Processing: The Exd Default

In a typical chemical processing plant handling flammable solvents (Gas Group IIA or IIB, Zone 1), the Exd flameproof valve is often the go-to solution. These environments are defined by robust infrastructure, a risk of mechanical impact from maintenance, and a need for high-powered valves to manage significant flow rates and pressures. An Exd enclosure provides excellent physical protection against accidental damage from tools or mobile equipment.

Furthermore, these facilities frequently use high-power coils to actuate large valves, which would be difficult to run on an energy-limited Exia system. While Exm is a possibility, the ability to repair a faulty coil within an Exd enclosure—even though it requires a hot work permit and process shutdown—is often preferred by maintenance teams who value repairability over complete replacement. The structured nature of maintenance shutdowns in these plants makes the demanding service requirements of Exd manageable.

Offshore Drilling: Exm for Reliability in Harsh Conditions

Now, let's consider an offshore oil and gas platform. Although Exd is also used here, the highly corrosive, salt-laden air and constant vibration create a unique set of challenges. This is where Exm encapsulation often becomes the superior choice for smaller, non-critical applications like pilot valves or instrumentation controls. The main threat here isn't just an explosion but long-term environmental degradation.

An Exd valve's flame paths, which are vital for its safety function, are susceptible to corrosion from saltwater spray. This can compromise their integrity over time and necessitates meticulous inspection routines. An Exm valve, however, has its coil and electronics completely sealed in resin, making it impervious to moisture and salt. Its solid construction also gives it outstanding resistance to the constant, low-level vibration found on a platform. For these smaller components, the "fit-and-forget" nature of Exm reduces difficult maintenance in exposed, hard-to-reach areas, making it a more reliable and cost-effective solution over its lifespan. When choosing components, it is wise to consider the long-term support offered; you can learn more about what to look for from a trusted solenoid valve manufacturer to ensure quality and reliability.

Pharmaceutical Manufacturing: Exia for Purity and Flexibility

In a pharmaceutical facility that produces fine chemical powders (Zone 21) or uses volatile sterile solvents (Zone 1), Exia intrinsic safety frequently becomes the preferred method. The reasons for this go beyond pure safety. Firstly, hygiene is critical. Exia systems use low-power valves that generate very little heat, which helps maintain stable conditions during temperature-sensitive processes.

More importantly, the capability to perform live maintenance on an Exia circuit without needing a hot work permit is a huge operational benefit. In a cleanroom, the process of shutting down, decontaminating an area for hot work, and then re-validating it is incredibly time-consuming and costly. The low-energy characteristic of Exia circuits removes this obstacle, allowing technicians to calibrate or replace a valve with minimal disruption. This operational flexibility often outweighs the higher initial design complexity and cost of the Exia system, making it the most efficient choice when process uptime and cleanliness are the main drivers.

Your Strategic Selection Framework: Making Confident Decisions

Choosing the right ATEX solenoid valve—whether Exm, Exd, or Exia—is more than just matching a Zone rating. It requires a structured approach that transforms technical specifications into a confident purchasing decision. Experienced engineers look beyond simple hazard classifications, using a systematic framework to balance safety requirements, operational needs, and long-term costs. This process turns complex variables into a clear, justifiable choice. It begins not with the valve itself, but with a thorough evaluation of the application, followed by a practical assessment of how each protection method will function in that environment over time.

Laying the Groundwork: Application and Hazard Profile

The first step is to create a detailed profile of the operational environment, going much deeper than the basic Zone classification. This means documenting every factor that could affect the valve's performance and safety.

- Hazard Characterisation: Look beyond the Zone, Gas Group, and Temperature Class. You must document the exact chemical makeup of the hazardous substance. Are there corrosive agents present? Is the hazard a gas or a particulate dust? These specifics directly influence material selection and the suitability of certain protection methods. For example, the flame paths in an Exd enclosure can be compromised by particulates.

- Operational Demands: Quantify the performance requirements. What is the necessary cycle frequency? What are the minimum and maximum operating pressures and temperatures? These figures are critical for deciding if an energy-limited Exia system can supply enough actuation force, or if a more powerful Exd or Exm coil is the only viable option.

- Environmental Conditions: Consider factors beyond the process media. Is the installation area subject to high vibration, frequent high-pressure washdowns, or extreme ambient temperatures? These conditions often favour the robust, fully sealed design of Exm encapsulation. The choice of valve also impacts the wider system; our guide on pneumatic solenoid valves provides more context on how these components fit into larger control setups.

The Lifecycle Cost and Maintenance Matrix

With a complete application profile, the next phase is to evaluate each protection method against the realities of long-term operation. A simple matrix helps compare how each option affects the total cost of ownership, not just the initial purchase price. Your evaluation should cover:

- Installation Complexity: Account for the cost of labour and any specialised components. Exd requires certified cable glands and precise torqueing, whereas Exia involves a system-wide design (DSD) and specific cabling. Exm is generally the most straightforward to install.

- Maintenance Burden: What do ongoing inspections and repairs entail? Exd demands periodic, labour-intensive checks of its flame paths, which often requires a full process shutdown. Exia allows for live maintenance but requires technicians with specialised training. Exm needs no routine maintenance but must be completely replaced if it fails.

- Downtime Impact: What is the real cost of taking the valve out of service? For business-critical processes, the ability to perform live maintenance on an Exia system could deliver a return on investment that far outweighs its higher initial cost.

This structured evaluation turns a potentially overwhelming choice into a series of manageable, data-supported decisions. By systematically weighing your application's specific demands against the practical trade-offs of each protection method, you can select an ATEX solenoid valve that provides both compliant safety and optimised performance for its entire service life.

For expert assistance in navigating these choices and finding the ideal valve for your application, explore the extensive range at Solenoid Valve World. With free next-day UK delivery and accessible technical support, we provide the components and knowledge you need for safe and efficient fluid control. Visit Solenoid Valve World to find your solution today.