Expert Guide to Brass Ball Valve Selection | UK

Understanding What Makes Brass Ball Valves Essential

Brass ball valves are a common sight in UK fluid control systems, and for a good reason. Their popularity comes from a blend of durability, performance, and adaptability, making them vital for various uses. But what exactly makes these components so important? This section dives into the key benefits of brass ball valves, exploring why they are the preferred choice for engineers and facility managers across the UK.

Durability and Corrosion Resistance in Demanding Environments

One of the main reasons for the widespread use of brass ball valves is their natural resistance to corrosion. The makeup of brass, mainly copper and zinc, creates a strong material that can handle the often harsh conditions found in many UK environments. This inherent durability leads to a longer lifespan, reducing the need for replacements and minimizing downtime. Additionally, brass shows excellent thermal stability, making it suitable for both hot and cold water systems.

The Efficiency of Quarter-Turn Operation

Brass ball valves are known for their simple yet effective quarter-turn operation. This design allows for quick and easy control of fluid flow, which is ideal for applications requiring fast shut-off or precise flow regulation.

- For example, in manufacturing, a quick shut-off can be crucial to prevent spills.

- In a home plumbing system, precise flow control helps regulate water temperature.

This ease of use improves system efficiency and simplifies maintenance.

Historically, brass ball valves have been important in various UK industries, including:

- Water and wastewater treatment

- Oil and gas

- Construction

While specific UK historical data isn't readily available, the global brass ball valves market has seen consistent growth. This is due to their durability and corrosion resistance, crucial for industries needing reliable fluid control. Find more detailed statistics here: DataHorizzon Research. This history highlights the long-term trust in these components.

The Impact of Proper Valve Selection

Picking the right brass ball valve has a big impact on system performance, maintenance costs, and operational safety. Choosing a valve with the wrong pressure rating could lead to early failure or system damage. Using a valve with materials incompatible with the intended media can cause corrosion and a shorter lifespan. Carefully considering factors like pressure, temperature, and media compatibility is vital for ensuring optimal performance and long-term reliability.

Material Science: Why Brass is the Smart Choice

The properties of brass make it an excellent material for demanding UK environments. Its resistance to dezincification, a type of corrosion in copper alloys, ensures longevity in water systems. The strength of brass lets it withstand high pressures, making it suitable for various uses, from home plumbing to industrial processes. This versatility combined with its robust performance makes brass a good choice for many UK fluid control systems. Understanding these advantages underscores the vital role brass ball valves play in maintaining efficient and reliable fluid control in various industries.

Choosing The Right Configuration For Your Application

Selecting the correct brass ball valve involves more than just choosing "brass." The specific configuration significantly impacts performance and cost-effectiveness. Choosing the wrong setup can lead to substantial financial losses. This section explores the performance differences between various configurations, helping you optimize your system for peak efficiency.

Understanding Port Configuration

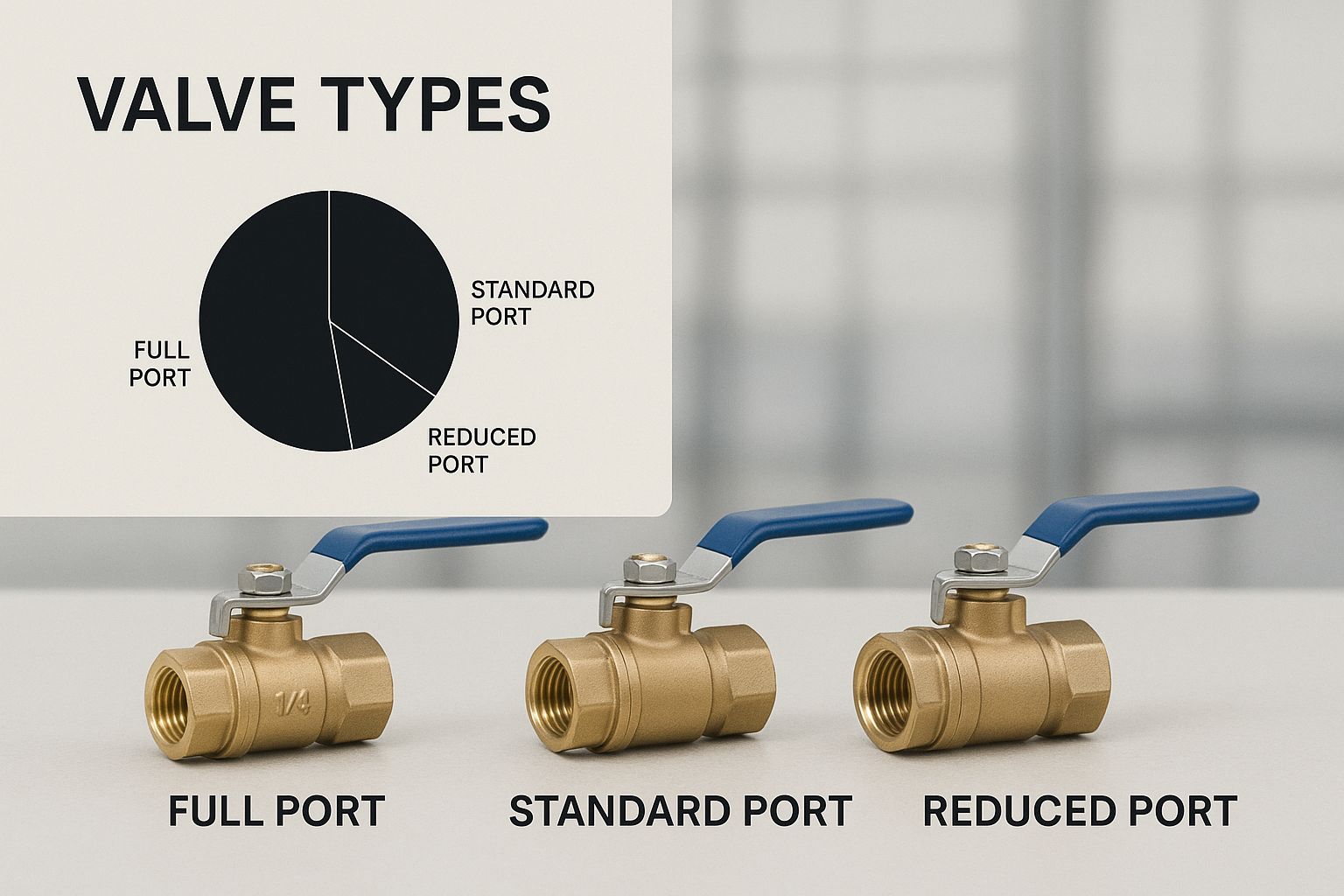

The port configuration refers to the opening size within the valve body that allows fluid to pass through. This seemingly minor detail significantly affects flow rate and pressure drop.

Full Port: The internal passage diameter matches the pipe's internal diameter. This minimizes pressure drop and maximizes flow.

Standard Port (Reduced Port): The passage diameter is one size smaller than the pipe. This results in a higher pressure drop but offers a more cost-effective solution.

Reduced Port (V-Port): Provides precise flow control.

The infographic above illustrates the three types of brass ball valves: full port, standard port, and reduced port. The internal passage size directly correlates with the potential flow rate. Choosing a full port valve maximizes flow but comes at a premium. A standard or reduced port valve may suffice for applications where a slight pressure drop is acceptable. You might find this resource helpful: How to master....

End Connection Types: Ensuring a Secure Fit

Another crucial configuration aspect is the end connection type, which determines how the valve connects to the piping system.

Threaded: Common and cost-effective, ideal for smaller diameter pipes. Easy to install and remove, threaded connections are widely used in residential and light commercial applications.

Compression: Similar to threaded connections in ease of installation, compression fittings provide a tighter seal, often preferred in applications with vibration concerns.

Flanged: Offers a robust, leak-proof connection suitable for high-pressure and high-temperature applications, commonly found in industrial settings.

The optimal choice depends on specific application needs, including pressure, temperature, and pipe size. For example, a flanged connection would be preferred over a threaded connection in a high-pressure steam system. Conversely, a threaded connection might suffice for a low-pressure domestic water supply.

Sizing: Avoiding Over-Specification

Correctly sizing a brass ball valve is essential for optimal system performance and cost efficiency. Over-sizing can increase material costs and reduce flow control, while under-sizing can cause excessive pressure drop and potential system failure.

Practical sizing involves calculating the required Cv value, a measure of a valve's flow capacity. This value depends on the system's flow rate, permissible pressure drop, and the fluid's properties. Accurately calculating the Cv value ensures the selected valve provides the necessary flow without over-specification, leading to significant cost savings, especially in large-scale industrial applications.

The following table provides a comparison of different brass ball valve types.

Brass Ball Valve Types Comparison

Detailed comparison of different brass ball valve configurations, their applications, and performance characteristics

| Valve Type | Port Configuration | Typical Applications | Pressure Rating | Flow Characteristics |

|---|---|---|---|---|

| Full Port Ball Valve | Full bore | High flow rate applications, minimizing pressure drop | Varies based on material and size | High flow capacity, minimal pressure drop |

| Standard Port Ball Valve | Reduced bore | General purpose applications where some pressure drop is acceptable | Varies based on material and size | Moderate flow capacity, some pressure drop |

| V-Port Ball Valve | V-shaped port | Fine flow control applications, throttling | Varies based on material and size | Precise flow control, moderate pressure drop |

This table highlights the trade-offs between flow rate, pressure drop, and cost for different valve types. Choosing the correct valve requires carefully balancing these factors based on the specific application requirements.

Real-World Applications Across UK Industries

From North Sea oil rigs to the latest construction projects in London, brass ball valves are essential components in numerous applications across the UK. Choosing the correct valve ensures reliable operation and prevents costly failures. Let's examine some specific examples where the right brass ball valve has made a significant impact.

Water Treatment: From Source to Tap

Water treatment facilities across the UK depend on brass ball valves. These valves are vital for controlling water flow throughout the treatment process. They manage everything from raw water intake to the distribution of treated water, ensuring consistent and dependable operation.

Their corrosion resistance is particularly important in this environment, safeguarding the purity of the water supply. This inherent resistance helps preserve water quality and extends the valve's lifespan.

Manufacturing: Where Reliability is Paramount

In UK manufacturing plants, downtime can be incredibly expensive. Brass ball valves are favored for their reliability and resilience in demanding industrial processes.

For instance, in chemical processing, brass ball valves precisely regulate the flow of potentially corrosive materials. This precise control is essential for consistent product quality and worker safety, minimizing accident risks and ensuring efficient production.

Construction and Infrastructure: Building a Solid Foundation

The UK construction industry relies on durable and dependable components. Brass ball valves are increasingly specified in new building projects for various applications, from water distribution to HVAC systems.

In infrastructure projects, such as pipeline upgrades, these valves provide efficient flow control and long-term reliability, minimizing maintenance needs and extending the infrastructure's lifespan.

Case Study: A Tale of Two Valves

A recent renovation project in Birmingham considered two different types of ball valves: brass and PVC. The cost difference was substantial, with PVC being significantly cheaper.

However, engineers chose brass ball valves due to the system's higher pressure requirements. This decision proved prudent. The brass valves have operated flawlessly for several years, while PVC valves in a similar application in another building failed multiple times within the first year. This real-world scenario demonstrates the importance of prioritizing long-term performance over initial cost savings.

Pushing the Limits: Where Brass Excels

While brass ball valves perform exceptionally well in many applications, some situations demand even greater performance. In high-pressure systems, specialized brass alloys and valve designs are necessary.

For example, in certain oil and gas applications, high-pressure brass ball valves ensure safe and efficient operation in extreme conditions. This ability to perform under pressure makes brass the ideal choice for these demanding environments.

The widespread use of brass ball valves across UK industries testifies to their versatility. Their durability, corrosion resistance, and precise control make them indispensable in countless applications. Understanding the specific requirements of each application is crucial for selecting the right brass ball valve and ensuring long-term, dependable performance.

Future-Proofing With Smart Valve Technology

UK facilities rely on the robust reliability of brass ball valves. But the future of fluid control involves more than just metal and mechanics. As industries adopt IoT integration and predictive maintenance, smart valve technology offers real-time insights without sacrificing the proven durability of brass. This allows operators to move from reactive repairs to proactive upkeep, minimizing unscheduled downtime and extending valve lifespan.

Integration Of IoT and Smart Monitoring

Smart brass ball valves combine traditional construction with electronic intelligence to provide:

- 24/7 Remote Monitoring: Sensors monitor temperature, pressure, and flow in real time.

- Automated Alerts: Receive instant notifications for leaks or deviations from pre-set parameters.

- Data Logging and Analytics: Analyze performance trends to identify wear and tear before it leads to failure.

As technology progresses, even traditional components like valves can become part of smart systems. For a similar example in home automation, consider how Motorized Blinds and Shutters Revolutionize Home Innovation.

Case Studies: Predictive Maintenance Success

Forward-thinking sites across the UK are already experiencing tangible advantages:

- A municipal water plant in Yorkshire reduced unplanned shutdowns by 30% after installing smart actuators to existing brass bodies.

- A Midlands brewery saved £15,000 annually in maintenance costs by detecting seal wear early.

- An automotive parts manufacturer saw 45% fewer valve replacements after six months of continuous monitoring.

These cases demonstrate how predictive maintenance transforms a simple valve into a data-driven asset, directly reflecting current market trends.

Speaking of market trends, brass ball valves are popular for their cost-effectiveness and reliability in managing the flow of liquids and gases, making them a common choice in many applications. Advances like IoT integration and smart valve technology further enhance the efficiency and safety of ball valves. This could boost their adoption in the UK market as industries seek more efficient and dependable solutions. Explore this topic further.

Separating Hype From Genuine Value

Not every smart feature offers the same return on investment. Proven advancements include:

- Embedded diagnostics for seal integrity.

- Cloud-based dashboards with customizable alerts.

- Modular actuators that can be retrofitted to existing valves.

Features to consider cautiously include:

- Excessively complex AI algorithms that demand high-bandwidth connections.

- Vendor lock-in packages with hidden subscription costs.

This careful evaluation sets the stage for practical implementation.

Implementing Smart Valve Systems On A Budget

To future-proof your operations affordably:

- Audit your system to pinpoint high-impact valves.

- Choose retrofit actuators compatible with your existing brass ball valves.

- Integrate a local IoT gateway for data collection.

- Set threshold-based alerts to minimize unnecessary alarms.

- Scale up gradually, focusing on critical loops first.

By following these steps, UK engineers can use smart valve technology to achieve measurable performance improvements while maintaining the robust nature of brass construction.

Traditional vs Smart Valve Comparison

| Feature | Traditional Valve | Smart Valve System |

|---|---|---|

| Monitoring | Manual inspections only | Real-time monitoring via sensor network |

| Maintenance | Reactive repairs | Proactive, predictive upkeep |

| Data Insights | Limited to downtime logs | Cloud-based analytics and trend reports |

Main takeaway: Integrating smart technology into brass ball valves provides reliable mechanics combined with actionable data – a perfect solution for UK operations seeking both resilience and innovation.

UK Market Insights And Strategic Sourcing

Understanding the UK brass ball valve market requires a deep understanding of global factors and their effects on local supply chains. Price fluctuations for raw materials like copper and zinc directly impact the cost of brass ball valves within the UK. Global events and supply chain disruptions can also affect product availability, making strategic sourcing critical for businesses dependent on these components. This section will explore how to address these challenges and develop resilient procurement plans.

Navigating Global Supply Chain Impacts

The global supply chain for brass ball valves is intricate. Changes in manufacturing locations, trade agreements, and even political instability can introduce volatility into the UK market. For example, disruptions to copper supplies from South America could lead to higher prices and extended lead times for brass ball valves in the UK. This emphasizes the need for diversified sourcing strategies.

Strategic Sourcing For UK Businesses

Finding dependable suppliers within the UK is vital for maintaining consistent quality and timely delivery. Several factors contribute to supplier reliability:

Certification and Accreditation: Seek out suppliers who meet industry standards, like ISO 9001, demonstrating their dedication to quality management.

Track Record and Experience: A history of providing quality products and excellent customer service indicates reliability.

Financial Stability: A financially sound supplier is less likely to experience disruptions that could impact your own operations.

Working with multiple suppliers can also mitigate risks associated with depending on a single source.

Check out our guide on Brass Solenoid Valves.

Optimising Inventory Management

Effective inventory management is crucial for balancing the need for readily available components with the costs of holding excess stock. Overstocking ties up capital and increases storage expenses. Understocking, however, can lead to production delays and lost revenue. Analyzing past usage patterns and forecasting future demand can help optimize inventory levels, ensuring you have the necessary brass ball valves when required.

Evaluating Total Cost Of Ownership

When sourcing brass ball valves, consider the total cost of ownership (TCO), not just the initial purchase price. TCO includes factors such as:

Installation costs: Different end connection types can influence installation time and complexity.

Maintenance costs: Higher-quality valves may require less frequent maintenance, reducing long-term expenses.

Downtime costs: Valve failures can cause costly production downtime. Selecting reliable valves minimizes this risk.

A thorough TCO analysis helps identify the most cost-effective solution in the long run. While precise figures for the UK brass ball valves market are not readily available, the global ball valves market was valued at roughly $13.6 billion in 2023. This illustrates the importance of ball valves, including brass types, in various industries worldwide. The UK, a significant part of the European market, likely contributes substantially to this global figure, particularly given the reliance of its industrial and construction sectors on robust valve technology. Discover more insights about ball valve markets here.

Managing Supplier Relationships And Market Fluctuations

Building strong supplier relationships is about more than just transactions. Open communication, collaborative planning, and shared risk management can strengthen your supply chain's resilience. Staying informed about market trends, including raw material prices and technological advancements, helps you anticipate potential fluctuations and adjust your procurement strategies accordingly. To protect the UK market and ensure secure sourcing, consider the importance of comprehensive training as outlined in Effective Security Awareness Training. By understanding market dynamics, fostering strong supplier relationships, and implementing a strategic sourcing approach, UK businesses can secure a reliable supply of brass ball valves while optimizing costs and ensuring long-term operational efficiency.

Mastering Selection Criteria For Peak Performance

Getting brass ball valve selection right hinges on understanding the factors that influence performance. This section explores proven selection methods, focusing on key criteria like pressure ratings, temperature cycling, media compatibility, and environmental conditions specific to the UK. We'll draw on the expertise of engineers who have developed systematic approaches to valve specification, minimizing failures and maximizing system efficiency.

Pressure and Temperature: Essential Considerations

Pressure and temperature ratings are arguably the most important factors in brass ball valve selection. The valve must withstand the system's maximum operating pressure and temperature. Exceeding these ratings can cause leaks, valve failure, and even system damage. In the UK, with its significant temperature fluctuations, selecting a valve with a broad temperature range is vital. This ensures reliable year-round operation, preventing problems from freezing or overheating.

Media Compatibility: Avoiding Corrosion and Contamination

The media, or the fluid flowing through the valve, also affects your choice. Certain fluids can corrode brass, leading to early failure. Highly acidic or alkaline solutions, for example, can damage standard brass alloys. In these cases, specialized brass formulations or alternative materials may be necessary, especially in industrial settings using various chemicals. The valve must also avoid contaminating the media, crucial in applications like water treatment or food processing.

Environmental Factors Specific to the UK

The UK's climate presents unique challenges. Coastal regions experience higher salinity, accelerating corrosion. Industrial areas may have elevated atmospheric pollutants, also impacting valve lifespan. Choosing a brass ball valve with appropriate coatings or materials can mitigate these issues, ensuring long-term reliability in demanding UK environments.

Balancing Performance and Budget

High-performance brass ball valves offer superior durability and reliability but come at a higher cost. Balancing performance needs with budget constraints is key. A standard brass ball valve is often sufficient. However, for critical applications where failure has serious repercussions, investing in a higher-grade valve is a worthwhile investment.

Practical Tools and Calculations

Several tools can assist in selecting the appropriate brass ball valve:

- Flow Calculators: Determine the system's required flow rate.

- Pressure Drop Calculators: Estimate the pressure drop across the valve.

- Safety Factor Calculations: Ensure the valve can handle unexpected pressure surges.

To help you make informed decisions, we've compiled a selection matrix outlining key performance criteria for different operating conditions.

This table provides a starting point for selecting the right brass ball valve for your application. Remember to consult manufacturer specifications for precise recommendations.

Brass Ball Valve Selection Matrix

Performance criteria and specifications for different operating conditions and applications

| Operating Pressure | Temperature Range | Media Type | Recommended Valve Grade | Expected Service Life |

|---|---|---|---|---|

| Low (up to 10 bar) | 0°C to 80°C | Water | Standard Brass | 10+ years |

| Medium (10-20 bar) | -10°C to 100°C | Oil | Forged Brass | 15+ years |

| High (20+ bar) | -20°C to 120°C | Gas | DZR Brass | 20+ years |

By carefully considering these factors and utilizing available tools, you can confidently select the ideal brass ball valve for your UK application, ensuring optimal performance and long-term reliability. Applying these selection criteria ensures effective, long-lasting solutions and prevents costly failures down the line.

Installation And Maintenance That Actually Works

Proper installation and maintenance can significantly extend the lifespan of your brass ball valve, potentially doubling the return on your investment. This section explores field-tested techniques used by maintenance teams who consistently achieve exceptional valve performance and longevity. We'll share best practices gleaned from years of experience, ensuring your brass ball valves provide reliable service for years to come.

Installation Practices That Prevent Failures

Correct installation is crucial for a long-lasting valve. Many common failures originate from improper installation. Let's examine some key aspects:

Pipe Preparation: Ensure pipes are clean, free from debris, and correctly aligned. Burrs or misalignment can damage seals, leading to leaks.

Valve Orientation: Install the valve in the correct flow direction, as indicated on the valve body. Incorrect orientation can hinder performance and accelerate wear.

Commissioning Procedures: After installation, thoroughly test the valve for leaks and proper operation. This crucial step is often overlooked but can prevent costly future problems.

Maintenance Schedules For Real-World Conditions

A well-defined maintenance schedule is essential for optimal valve performance. The required frequency depends on factors like operating conditions and the media flowing through the valve. Here's a general guideline:

Regular Inspection: Inspect the valve visually every six months for signs of leaks, corrosion, or damage.

Lubrication: Lubricate moving parts annually, or more frequently in harsh operating conditions.

Seal Replacement: Replace seals every two to three years, or as needed, to prevent leaks. This preventative measure offers significant long-term cost savings.

You might be interested in: How to master pressure-reducing valves.

Troubleshooting Common Issues

Even with proper installation and maintenance, occasional problems can occur. Here are some common issues and their solutions:

Leaks: Check for worn seals or loose connections. Tighten connections or replace seals as required.

Difficult Operation: Lubricate moving parts or check for obstructions in the valve body.

Reduced Flow: This could indicate a partially closed valve, debris blocking the flow path, or a piping system problem. Inspect the valve and piping to pinpoint the cause.

Optimizing Valve Performance Throughout Its Service Life

Maximizing the lifespan of your brass ball valve requires a proactive approach. Here are additional tips:

Water Quality: In water systems, maintaining good water quality prevents scaling and corrosion, extending valve life.

Operating Within Design Parameters: Avoid operating the valve outside its specified pressure and temperature ranges.

Regularly Review Maintenance Procedures: Periodically assess and adjust your maintenance schedule based on valve performance and operating conditions. This ensures your maintenance practices remain effective.

Real-World Insights From Facility Managers

Discussions with facility managers across the UK provide valuable insights into effective brass ball valve management. Many emphasize preventative maintenance over reactive repairs. Regular inspections and timely seal replacements, while seemingly minor tasks, prevent major, costly downtime. They also highlight the importance of training maintenance personnel on proper valve operation and maintenance.

For example, a facility manager at a Manchester manufacturing plant reported a 50% reduction in valve-related downtime after implementing a proactive maintenance program. This demonstrates the significant ROI of proper valve care. Another manager at a Welsh water treatment plant noted that higher-quality brass ball valves, although initially more expensive, resulted in fewer repairs and lower long-term costs. Combining these practical insights with the technical information presented here allows you to implement effective installation and maintenance strategies, ensuring your brass ball valves deliver reliable performance and maximum value.

Ready to explore solenoid valves and other fluid control solutions? Visit Solenoid Valve World today. We offer a comprehensive selection of high-quality products to meet your specific needs, backed by expert technical support and fast UK delivery.