Chemical Compatibility Guide for Solenoid Valves

Select the correct Valve Material for your application

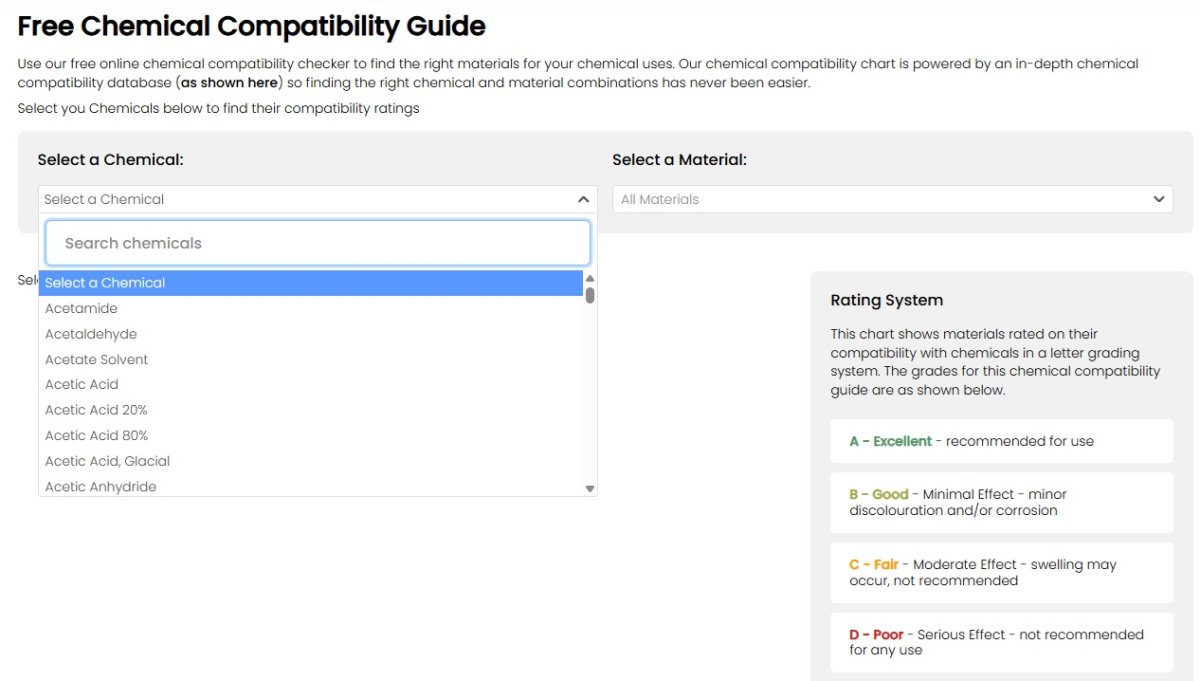

Free Interactive Chemical Compatibility Guide

Find the Right Valve Material for Your Chemical Application

Choosing the wrong material for a solenoid valve in a chemical system can lead to corrosion, leakage, or even hazardous failure. That’s why Solenoid-Valve.World provides a detailed chemical compatibility guide to help you select the right valve body and seal materials for the substances you’re working with.

Whether you’re dealing with acids, solvents, water, oils, or industrial gases, we offer expert insights into which materials resist which chemicals—ensuring safe and long-lasting performance.

Why Chemical Compatibility Matters

A solenoid valve must maintain a tight seal and structural integrity even under aggressive chemical exposure. Material degradation can cause:

Valve failure or leakage

Dangerous chemical reactions

Increased maintenance costs

Reduced system efficiency

Selecting the correct valve material from the start prevents these issues and extends the lifespan of your system.

How to Use This Chemical Guide

1. Identify the chemical flowing through your valve (e.g., sulphuric acid, acetone, ammonia).

2. Check our compatibility tables to find suitable body and seal materials (e.g., PTFE, EPDM, FKM, Stainless Steel).

3. Match your choice with one of our solenoid valve models that offer those materials.

Need a shortcut? Contact us with your media type and we’ll recommend the best option.

Common Materials and Their Resistance Profiles

Valve Body Materials:

Brass – Excellent for water, air, and non-aggressive fluids

Stainless Steel (316) – Highly resistant to acids, salts, and corrosive chemicals

PVC/PP/PTFE – Ideal for aggressive acids, alkalis, and solvents

Aluminium – Lightweight and cost-effective; limited chemical resistance

Seal Materials:

EPDM – Great for water, steam, and many alkalis

FKM (Viton®) – Excellent for oils, fuels, and many acids

NBR (Buna-N) – Suitable for oils and hydrocarbons

PTFE (Teflon®) – Universal resistance; great for harsh chemicals

Explore the Full Chemical Compatibility Guide

We’ve created a downloadable chemical resistance chart that lists hundreds of chemicals and their compatibility with common valve materials. Use it as a reference when designing or upgrading any fluid control system.

Looking for a specific chemical? Contact us for expert advice.

Application Examples

Laboratory dosing systems

Water treatment plants

Pharmaceutical production

Chemical storage tanks and transfer lines

Cleaning-in-place (CIP) systems

Need Help Choosing? We’re Here to Assist

Our technical team can match your application with the best valve materials for your chemical. Whether you need a PTFE-lined solenoid valve, acid-resistant stainless steel valve, or custom solution, we’ll guide you to the right product.

Email: sales@solenoid-valves.com

Call: 01454 334 990

Choose Chemical-Compatible Solenoid Valves with Confidence

Avoid the risk of material failure. Use our chemical compatibility guide to ensure that your solenoid valve lasts longer, performs better, and keeps your system safe.

Other Chemical Compatibility Charts

Connexion Chemical compatibility chart for

PP, 316SS, Carbon, Ceramic, PTFE, EPDM, FKM and NBR

Connexion 760 Chemical compatibility chart for

Stainless steel 302; 304; 316 and 440, Aluminium, Titanium, Hastelloy C, cast bronze, cast iron, Carbon steel, PVC, Tygon E3606, Teflon (PTFE), Noryl, Cycolac (ABS), Polyethylene, Polypropylene, Ryton, Carbon, Ceramic, Ceramagnet A, Viton, Buna N (Nitrile), Silicon, Neoprene, Ethylene Propylene (EPM), Rubber (natural) and epoxy.

Connexion 560 chemicals compatibility chart for

Aluminium, Brass, Carbon Steel, Ductile Iron, 316 Stainless steel, Alloy 20, Monel, Hastelloy C, Buna N NBR, Delrin, EPDM, Viton, Hypalon, Neoprene, Nylon and Teflon PTFE across 1000+ known chemicals.

Connexion chemical compatibility chart 1

ABS, CPVC, PP, PVC, PVDF, PEX, PPSU, PTFE, EPDM, Nitrile (buna n), Polychloroprene, FKM, Graphite, Bronze, Silicon Bronze, Aluminium bronze, Brass, Gray iron, Ductile iron, carbon steel, 3% Nickel / iron, nickel plated ductile iron, stainless steel 400, 316 stainless steel and copper.

Connexion Gas Compatibility chart 2

Brass, 303 Stainless steel, 316 stainless steel, Aluminium, Zinc, Copper and Monel, Plastics (PCTFE, Teflon, Tefzel, Kynar, PVC and Polycarbonate), and Elastomers (Kalrez, Viton, Buna-N, Neoprene and Polyurethane).

Chemical compatibility chart 3

FFKM, ETP, FKM, NBR, HNBR, EPDM, TFE/P, VQM, FVQM, AU and PTFE. Includes more of the gases typically used for refrigeration systems.

Chemical compatibility chart 4

Aluminium, Carbon Steel, Ductile Iron, 304 stainless steel, 316 stainless steel, Acetyl, Buna, CSM (Hypalon), EPDM, Fluorocarbon, Fluoroelastomer (FKM), Geolast (Buna & Polypropylene), Hastelloy C, TPE, Leather, Nitrile (TS), Nitrile (TPE), Nylon, Polychloroprene, Polypropylene, PTFE, PVDF, Santoprene (EPDM & Polypropylene), UHMWPE and Urethane against 1600+ different media types.

Chemical compatibility chart 5:

Copper and Copper alloys including Aluminium Bronze, Brass, Copper, Copper-Nickel 90/10 alloys and Gunmetal and Bronze

These lists are not a guarantee that the material or valve are compatible with the media, they are given as a guide and all special applications should be checked against the materials of construction or with your chemical supplier laboratory.