Electrical Terms Explained.

Ampere (A): International unit of measurement of the intensity of electric current.

Alternate current (AC): Electrical current flow, variable in time, both as intensity that direction. Reaches a maximum positive value and a maximum negative value, passing from zero.

Direct current (DC): Flow of electrical current, constant in time, both in intensity as that direction.

Ground connection (PE): Point of connection of the electric masses intended to be connected physically to the earth. The correct operation avoids the risk of electric shock.

Diode: Non-linear passive electronic component, whose function is to allow the passage of current flow in one direction only and lock it in the opposite direction.

Ohm (Ω): International unit of electrical resistance.

Current rectifier: It is a device consisting of diodes, capable of converting an AC voltage into a DC voltage.

Electrical resistance: Capacity of a conductor to oppose the passage of electric current, generating heat.

Transient Voltage Suppressor Diodes (TVS Diodes= Trans Voltage Suppressor): Electrical component belonging to the category of non-linear transient suppressors. It has a behaviour similar to a Zener diode, but unlike the latter, serves to protect electronic circuits against over voltage spikes and electrostatic discharge, electrical fast transient, and surge events.

Varistor (VDR = Voltage Dependent resistor): Non-linear electronic component used to protect electronic circuitry from over voltage spikes, fast and destructive.

Its behaviour can be compared to a resistor (non-linear) that, if it is exceeded the voltage for which it is designed, rapidly lowers its internal resistance so that the spike is strongly attenuated.

Volt (V): International unit of electric potential, and of the potential difference between two points of a conductor or an electric component.

Watt (W): International unit of power.

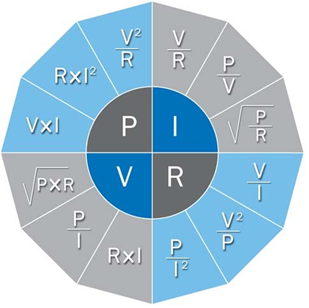

V : Voltage Volt (V)

R : Resistance Ohm (Ω)

I : Current intensity Ampere (A)

P : Power Watt (W).

How Solenoid Valve Power Consumption Varies Between AC and DC Voltage

Solenoid valves are critical components in automation, fluid control, and HVAC systems. One key factor affecting their efficiency and long-term performance is power consumption, which significantly differs depending on whether the valve is operating on alternating current (AC) or direct current (DC). Understanding these differences can help users select the most energy-efficient solenoid valves for their applications.

Power Consumption: AC vs. DC Solenoid Valves

AC Solenoid Valves

Inrush vs. Holding Power: AC solenoid valves typically draw a high inrush current at the moment of activation, which quickly reduces to a lower holding current. This results in a momentary spike in power consumption, often 2 to 3 times higher than the steady-state level.

Efficiency Concerns: The alternating nature of the current causes eddy currents and hysteresis losses in the coil core, which can increase heat and reduce efficiency.

Typical Consumption Range: AC coils may consume anywhere from 5 VA to 50 VA, depending on the size and application.

DC Solenoid Valves

Constant Power Draw: Unlike AC valves, DC solenoids maintain a constant current draw, meaning there is no inrush/holding distinction.

Lower Energy Losses: Since there's no frequency-driven core loss, DC valves are generally more energy-efficient and operate cooler.

Typical Consumption Range: Power usage is usually listed in watts (W) and tends to be between 3 W to 25 W.

Impact of Voltage on Power Consumption

Ohm’s Law explains that as voltage changes, current draw also shifts proportionally. For a fixed coil resistance, increasing voltage increases current and thus power consumption.

Voltage Rating Matters: Using a valve outside its specified voltage (e.g., applying 24V DC to a 12V DC coil) can double power consumption and risk coil burnout.

Choosing the Right Valve

For engineers and procurement specialists looking to reduce energy costs, solenoid-valve.world offers a wide range of AC and DC solenoid valves. The site provides detailed technical specifications, including voltage options and power ratings, making it easier to compare and select the most efficient model for your application.

Read our FAQ section for more information.

Discover valves by function: 2,3 + 5 way

Discover valves by thread + flange size or type.

Discover valves according to application, air, water, vacuum, steam + gas.