Pressure Transmitter: Precision and Performance in Industrial Applications

Introduction to the CNXPT Pressure Transmitter

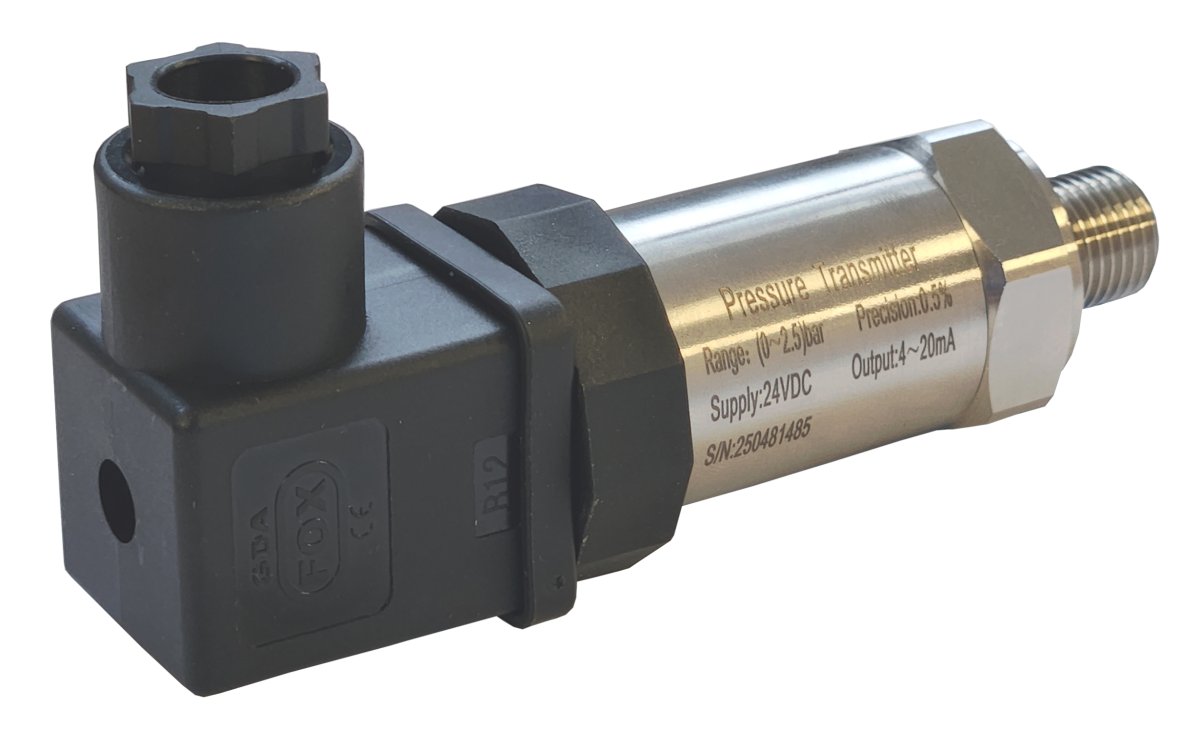

The CNXPT Pressure Transmitter by Connexion is a high-performance measurement device utilising the HT series diffusion silicon isolation oil-filled core. Designed for rugged environments, the CNXPT efficiently converts measured pressure into a standard output signal, packaged within a robust stainless-steel enclosure. Every unit undergoes stringent testing and ageing verification to ensure long-term stability and reliable performance.

1/4 BSP (G) 0-2.5 Bar Gauge

1/4 BSP (G) 0-10 Bar Gauge

1/4 BSP (G) 0-40 Bar Sealed

1/4 BSP (G) 0-100 Bar Sealed

Key Features of the Diffused Silicon Pressure Sensor

High Performance and Versatility

Wide measurement range from -1 Bar to 1000 Bar

Multiple pressure interfaces available

Adjustable zero and full-scale calibration

High accuracy levels with ±0.25% typical precision

Long-term stability of ±0.1% F.S./year

Robust Construction

Corrosion-resistant 316L stainless steel diaphragm

IP65-rated enclosure with CNEX explosion-proof Ex ia IIC T6 Ga rating

Resistant to vibration (up to 10g at 55Hz–2kHz)

Applications of the Industrial Pressure Transmitter

Wide Industry Compatibility

Industrial Use Cases

Petroleum and chemical processing

Metallurgy and power generation

Hydrology and environmental monitoring

Specialised Fields

Marine and aviation systems

Hydraulic and pneumatic control systems

This transmitter is especially suited for measuring non-corrosive gases and liquids compatible with 316L stainless steel.

Performance Specifications of the Pressure Transmitter

Electrical and Measurement Specifications

| Parameter | Specification |

|---|---|

| Pressure Range | -1 Bar to 1000 Bar |

| Pressure Type | Gauge, Absolute, Sealed |

| Accuracy | ±0.25% (typical), ±0.5% (max) |

| Output Signals | 4–20mA, 0–10mA, 0–10V, 0.5–4.5V, RS485 |

| Supply Voltage | 5–30VDC depending on output |

| Temperature Compensation | 0–70°C (≤10MPa, customisable) |

Temperature and Durability Ratings

Operating Temp: -20°C to 80°C

Storage Temp: -40°C to 120°C

Zero Drift: ±0.02% F.S./°C (≤100kPa)

Material: Housing - 304/316L; Diaphragm - 316L

Configuration and Customisation

Ordering Options

When configuring a CNXPT pressure transmitter, consider the following:

Output Signals

4–20mA (D1)

0.5–4.5VDC (S7)

RS485 Communication (custom option)

Pressure Connections

G1/4, G1/2, M20×1.5, 7/16-20UNF

Electrical Connections

Hirschman

Sealed cable

PG7 plug

Industrial casing (with or without display)

Selection Example

CNXPT 0–35Bar D1 S1 J1 B G

Translates to:

Range: 0–35 Bar

Power: 24VDC

Signal: 4–20mA

Connection: M20×1.5

Electrical: Hirschman

Pressure Type: Gauge

Best Practices for Installation and Use

Important Safety and Compatibility Notes

Do not touch the isolation diaphragm with hard objects.

Ensure grounded wiring and lightning protection for outdoor installations.

For low temperatures (below -20°C), use EPDM O-rings.Cable length defaults to 1.5m with polyethylene insulation, unless otherwise specified.

Conclusion: Why Choose the CNXPT Pressure Transmitter?

The CNXPT is an ideal choice for professionals in industrial automation, fluid control, and engineering systems seeking a durable, high-accuracy pressure transmitter. With flexible configuration options and excellent long-term performance, it stands as a reliable, customisable solution for a broad range of applications.

Understanding Pressure Measurement Types

1. Gauge Pressure (G or GP)

Measures pressure relative to atmospheric pressure. Zero gauge pressure means it's equal to the current atmospheric pressure. Common in everyday applications like car tires and water pumps.

Example: If a tire reads 35 psi (gauge), the actual pressure is 35 psi above atmospheric pressure (~14.7 psi at sea level), so the absolute pressure is 49.7 psi.

2. Absolute Pressure (A or AP)

Measures pressure relative to a perfect vacuum (0 psi). Doesn't change with altitude or weather, making it ideal for scientific research or altitude-sensitive processes.

Example: A vacuum chamber showing 0 psi (absolute) is a true vacuum. If the ambient atmospheric pressure is 14.7 psi, and a process is at atmospheric pressure, it will read 14.7 psi (absolute).

3. Sealed Gauge Pressure (SG or SGauge)

Measures pressure relative to a fixed (sealed) atmospheric pressure—usually sealed at 1 atm (14.7 psi). Works like gauge pressure but doesn't adjust with changes in local atmosphere (like elevation or weather).

Example: Bringing a sealed gauge transmitter from sea level to a mountain still assumes 1 atm = 14.7 psi, even though the actual atmosphere might be lower.

Why Choose Our Pressure Transmitters?

With a full stainless steel design, wide operating range, and field-proven sensing technology, our pressure transmitters are the go-to solution for engineers and system integrators who demand top-tier performance in real-world conditions.

For more technical specifications, certifications, or customisation options, contact us today or request a product data sheet.