Solenoid Valve Installation and Maintenance Guide

Proper installation and maintenance of a solenoid valve are essential for ensuring long-term reliability and performance. Follow this comprehensive guide for detailed instructions on mechanical setup, electrical connections, operational temperature management, and preventive maintenance.

1. Solenoid Valve Installation Guidelines

Before installing a solenoid valve, ensure compatibility with system requirements.

Verify Valve Specifications

Check the model, supply voltage (V), and frequency (Hz) to confirm they match your system's specifications.

Ensure compliance with any regulatory or industry-specific standards relevant to your application.

2. Mechanical Installation Instructions

Correct mechanical setup ensures optimal fluid control and prevents early failure.

Follow the Flow Direction

Align the valve with the flow direction indicated by an arrow or by the markings “1” (inlet) and “2” (outlet).

Remove Protective Caps

If protective caps are installed, remove them prior to assembly to avoid flow obstruction.

Prevent Contamination

During installation, avoid allowing dirt, PTFE tape, or metal shavings to enter the valve.

Correct Valve Positioning

Install the valve with the solenoid coil in an upright position for best performance.

Horizontal coil mounting is acceptable but may trap debris, reducing valve functionality.

Do not mount the coil downward.

Allow Maintenance Clearance

Ensure sufficient space around the valve for easy future servicing or coil replacement.

Avoid Improper Tightening

Do not use the coil or valve tube as leverage during installation to prevent damage.

Use Filters in Dirty Systems

Install a filter upstream of the valve in systems containing sludge, debris, or particles.

Support Mounting

Only use the pre-drilled mounting holes on the valve. Do not modify the valve body.

Welding Connections

For valves requiring welded connections, refer to the temperature and welding precautions in Section 4.

3. Electrical Connections for Solenoid Valves

Correct electrical setup is crucial for safe and efficient valve operation.

Confirm Voltage Before Wiring

Ensure the supply voltage matches the coil’s rated voltage.

Grounding

Connect the earth (ground) terminal if required.

Coil Installation Precaution

Do not energise the coil before it’s fully installed on the valve to prevent burnout.

Coil Positioning

Adjust the coil position by loosening the top nut, then secure it tightly after adjustment.

4. Temperature and Welding Considerations

Proper heat management extends valve life and prevents damage during installation.

Coil Temperature During Operation

A moderate rise in coil temperature to +40 to +90C is normal.

If smoke or a burning smell is detected, disconnect the power immediately.

Avoid External Heat Sources

Do not install near heaters, boilers, or poor-ventilated areas that may trap heat around the coil.

Do not wrap the coil in insulating materials that would trap heat generated by the coil.

High-Temperature Installations

For environments with extreme temperatures or special safety requirements, consult a technical specialist.

Welding Instructions for Valve Connections

Remove the coil before welding any valve connections.

Ensure the valve body temperature does not exceed 100°C–150°C (200°F–300°F).

Do not let the welding flame touch the valve directly.

Wrap the valve in a wet cloth to dissipate heat, or dismantle internal components if cooling is not possible.

5. Solenoid Valve Maintenance Procedures

Routine maintenance ensures operational efficiency and system safety.

Safety First

Disconnect the power supply and depressurise the system before servicing.

Cleaning and Inspection

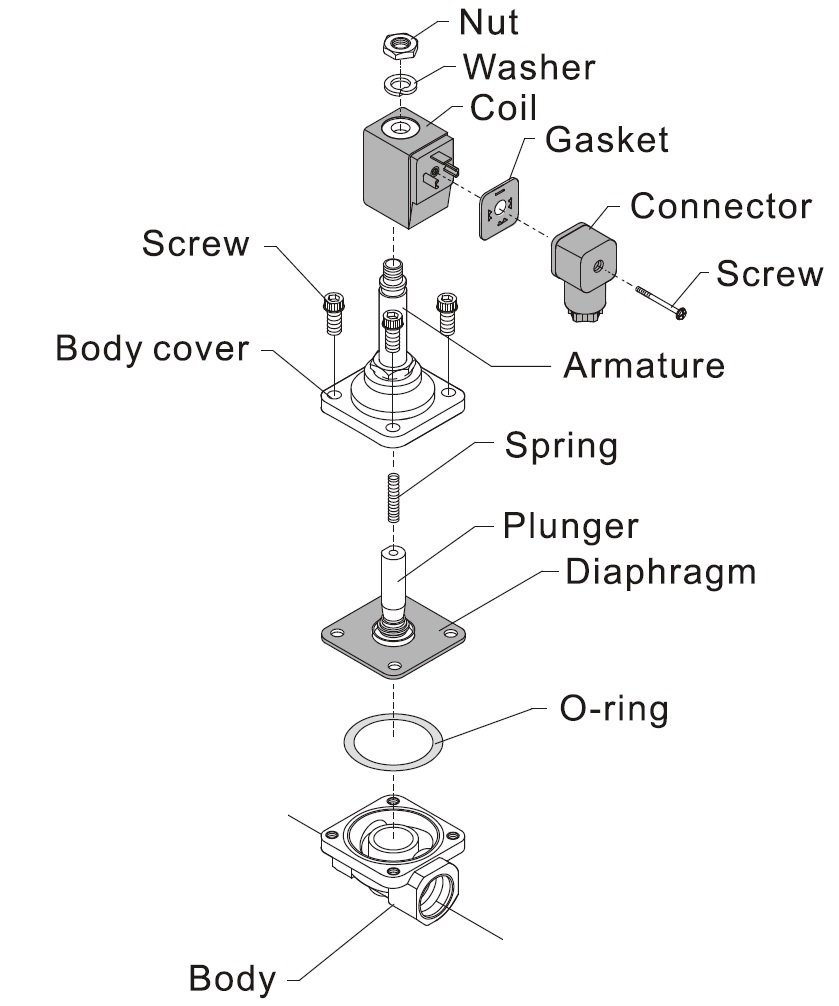

Remove, clean, and inspect all internal components.

Replace any worn parts with original spare parts.

Reassembly

Reassemble with care, ensuring all parts are correctly aligned and sealing surfaces are intact.

Final System Check

Test the valve for leaks and correct operation before returning the system to service.

6. Important Safety Warnings

General Disclaimer

These are general guidelines and do not replace manufacturer-specific installation manuals. Always consult original documentation for product-specific requirements.

ATEX Compliance

Never touch or service a valve in a potentially explosive (ATEX) area without prior risk assessment.

Consult an ATEX certified engineer before conducting any electrical work in hazardous zones.

You can download a PDF copy of our general Solenoid Valve IOM Manual