Valve Material Compatibility Chart | Find the Right Valves Easily

A valve material compatibility chart is one of the most fundamental tools in an engineer's arsenal. It's used to pick the right valve body and seal materials for whatever fluid or gas you're working with. Think of it as a detailed cross-reference, pitting materials like stainless steel, brass, and PVC against various media. This gives you a clear rating that helps predict performance and, most importantly, prevent chemical corrosion, equipment failure, and serious safety hazards. Getting this choice right from the start is absolutely critical for the longevity and safety of your entire system.

Why a Valve Material Chart Is a Critical Tool

In any industrial process, specifying the wrong valve material can lead to catastrophic failures, expensive downtime, and significant safety risks. A good material compatibility chart is your first line of defence. It provides engineers and maintenance managers with the essential data they need to make an informed decision, translating complex chemical interactions into a simple, actionable format.

You really can't overstate the importance of these charts, especially in demanding applications involving highly corrosive media or high-pressure environments. For instance, precise and reliable valve material selection in refinery plants and chemical processing facilities is non-negotiable for maintaining system integrity and preventing hazardous leaks.

The Economic Impact of Correct Material Selection

Beyond the obvious safety concerns, the financial implications are massive. An incompatible valve will inevitably corrode, seize up, or leak, forcing unplanned shutdowns for repairs and replacements. Research from UK engineering consultancies highlights that improper material selection can account for up to 20% of all valve failures in chemical processing facilities. The downtime from these incidents can cost major UK refineries anywhere from £10,000 to £50,000 per day.

Choosing a valve based solely on its initial price without consulting a compatibility chart is a false economy. The long-term costs of system failure, lost production, and potential environmental fines will always far outweigh any initial savings.

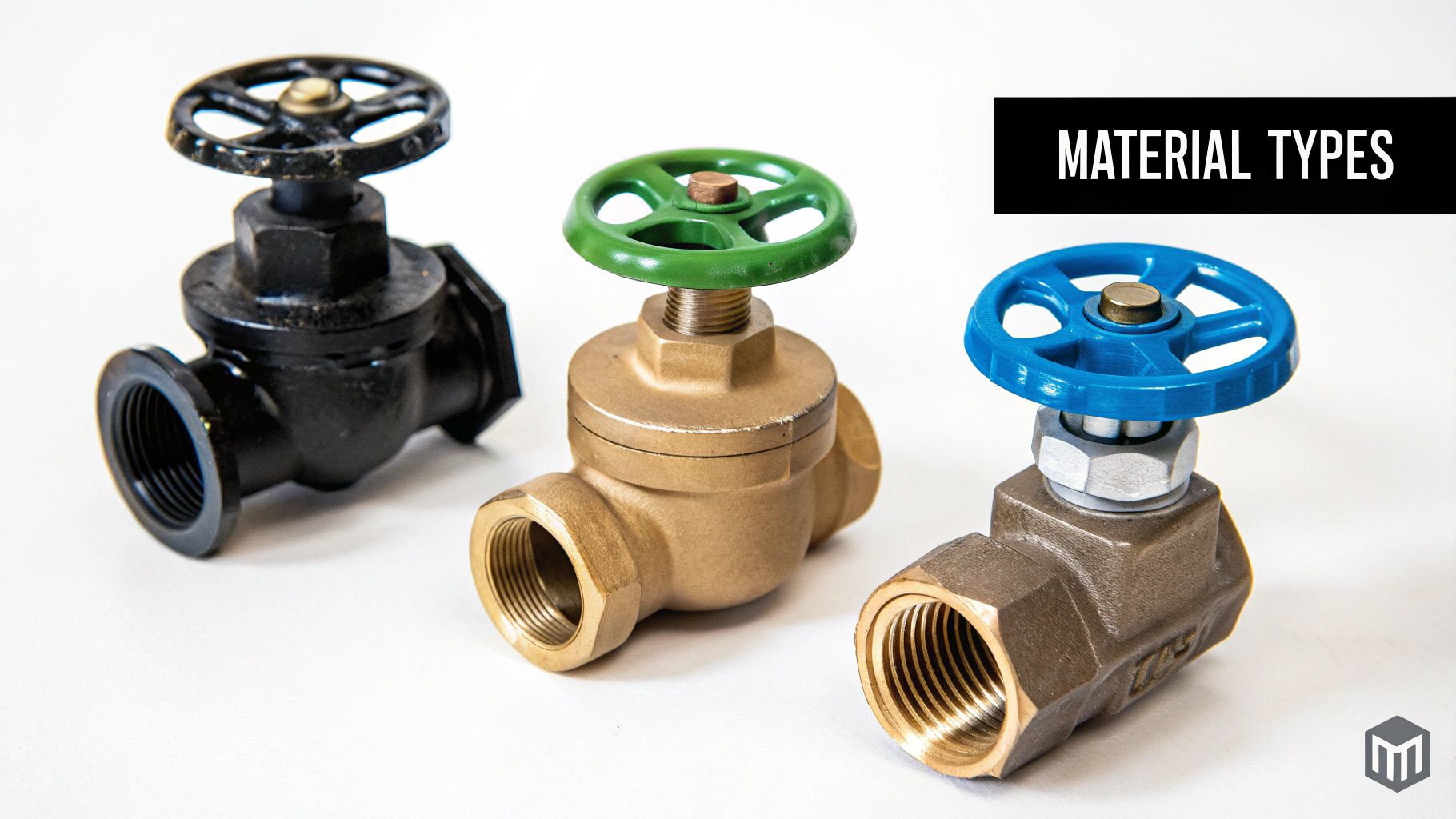

Quick Reference Material Compatibility Overview

To give you a practical feel for this, let’s create a quick reference table. It’s a simplified look, but it immediately shows how a seemingly minor choice can have major consequences.

| Material | Water | Air | Steam (Low Pressure) | Mineral Oils | Dilute Acids |

|---|---|---|---|---|---|

| Brass | Excellent | Excellent | Good | Good | Poor |

| Stainless Steel (316) | Excellent | Excellent | Excellent | Excellent | Good |

| PVC | Excellent | Good | Not Recommended | Excellent | Good |

| EPDM (Seal) | Excellent | Good | Good | Poor | Good |

| Viton (FKM Seal) | Good | Excellent | Good | Excellent | Excellent |

As you can see, the "best" material completely depends on the job at hand. This is why a detailed valve material compatibility chart isn't just a helpful guide—it's an indispensable tool. It ensures every component is fit for purpose, safeguarding both your operations and your budget.

Here’s a breakdown of the materials mentioned above to illustrate the point:

- Brass: A fantastic, cost-effective choice for water and neutral air systems. However, it will corrode quickly if it comes into contact with saltwater or even dilute acids.

- Stainless Steel (316): This is your go-to for superior resistance across a wide range of chemicals. It’s ideal for corrosive environments, but it does come with a higher price tag.

- PVC (Polyvinyl Chloride): A great budget-friendly option for many water and chemical applications, but it has strict temperature and pressure limits. Crucially, it's unsuitable for most solvents.

How to Read and Interpret a Compatibility Chart

When you first look at a valve material compatibility chart, it can feel a bit daunting. But at its core, it's just a simple grid. You'll typically find the valve materials running down the side (in rows) and the different chemicals or media listed across the top (in columns). To find what you need, you just trace your finger to where the material and the medium intersect.

That intersection gives you a compatibility rating. While every chart can be a little different, most use a straightforward key with letters or symbols. Getting to grips with this key is your first step to making a sound decision.

Understanding Common Rating Systems

Most charts you'll come across use a simple grading system to give you a quick idea of how a material will hold up. A very common format looks like this:

- A - Excellent: The material is barely affected by the chemical. It's an ideal choice for continuous, long-term service.

- B - Good: You might see some minor effects, like a bit of discolouration, but the material is generally fine for the job.

- C - Fair: Expect moderate effects here, such as a loss of strength or some swelling. You definitely wouldn't want to use this material for continuous service.

- D - Severe Effect: A hard no. This material is not recommended for any use with the chemical in question, as failure is almost guaranteed.

Key Variables That Influence Compatibility

Here's the crucial part: a rating on a chart is not the final word. It's a baseline, usually based on tests at standard room temperature (20°C) and normal atmospheric pressure. In the real world, several factors can completely change how a material behaves.

Crucial Insight: Temperature is the number one factor that can throw a chart's rating out the window. A material rated 'A' at a comfortable room temperature could easily become a 'D' once things heat up, simply because chemical reactions speed up.

You always need to think about your specific operating conditions:

- Media Concentration: Stainless steel might handle a dilute acid without any trouble, but expose it to a highly concentrated form of the same acid, and you'll see it corrode very quickly.

- Operating Temperature: Plastics are a great example here. Something like PVC has a very clear upper-temperature limit, and if you go past it, you'll lose all structural integrity.

- System Pressure: High pressure puts a lot of stress on materials, which can make them much more vulnerable to chemical attack. In these situations, balancing your system with components like specialised pressure reducing valves can be essential for stability and safety.

So, think of the chart as your starting point, not your destination. Always double-check the material against your exact operating conditions. It's the only way to guarantee a safe, reliable, and long-lasting system.

The Complete Valve Material Compatibility Chart

This is where the rubber meets the road—or perhaps more accurately, where the EPDM seal meets the acetic acid. Below you'll find the core of our guide: a comprehensive valve material compatibility chart designed for quick and reliable reference in the field.

We've cross-referenced a whole host of common valve body materials (like Stainless Steel, Brass, and PVC) and essential seal materials (including EPDM, Viton, and PTFE) against an extensive list of industrial chemicals, acids, solvents, and other fluids. Think of it as your go-to resource for making informed material selections. It’s well worth bookmarking this page for those moments you need a quick lookup to confirm your choice and ensure the long-term integrity of your system.

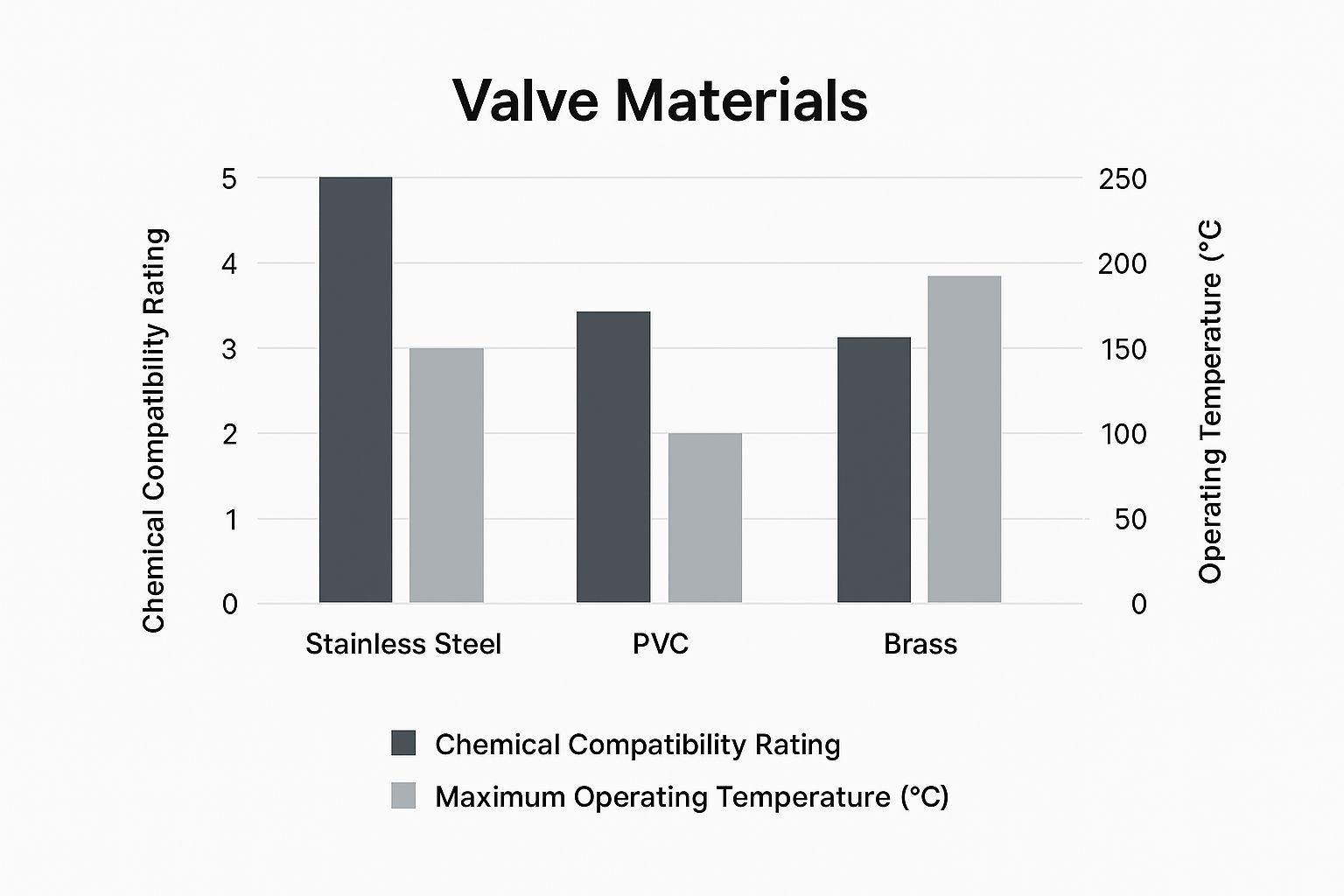

To get started, this infographic gives a great visual overview, comparing the chemical compatibility and temperature ratings for three of the most popular valve materials.

As you can see, while Stainless Steel is the clear winner for high-temperature performance, PVC often boasts exceptional chemical compatibility for specific jobs, provided you stay within its thermal limits. It’s all about matching the right material to the specific demands of the application.

Detailed Valve Material vs Chemical Media Compatibility Matrix

The table below is your detailed lookup tool. To get the information you need, simply find your chemical media in the first column, then look across that row to see how it fares against each valve and seal material. A higher rating means better resistance and a longer, more reliable service life.

| Chemical Media | Stainless Steel 316 | Brass | PVC | PTFE | EPDM Seal | Viton (FKM) Seal |

|---|---|---|---|---|---|---|

| Acetic Acid (10%) | A | C | A | A | A | B |

| Acetone | A | D | D | A | D | A |

| Air | A | A | A | A | A | A |

| Ammonia (Gas) | A | D | A | A | B | C |

| Benzene | A | D | D | A | D | A |

| Diesel Fuel | A | A | A | A | D | A |

| Ethanol | A | B | A | A | A | A |

| Hydraulic Oil (Petroleum) | A | A | A | A | D | A |

| Hydrochloric Acid (20%) | D | D | A | A | B | C |

| Hydrogen Peroxide (30%) | B | D | B | A | A | B |

| Methanol | A | D | A | A | A | D |

| Nitric Acid (10%) | C | D | A | A | B | D |

| Propane | A | A | A | A | B | A |

| Sea Water | B | C | A | A | A | A |

| Sodium Hydroxide (50%) | A | B | A | A | A | B |

| Steam | B | B | D | A | C | D |

| Sulphuric Acid (10-50%) | C | D | A | A | B | C |

| Toluene | A | D | D | A | D | A |

| Water (Deionised) | A | C | A | A | A | A |

| Xylene | A | D | D | A | D | A |

Important Note: Treat these ratings as a solid starting point. They are generally based on performance at a standard ambient temperature of 20°C. For your specific application, you must always double-check compatibility against your actual operating temperatures, pressures, and concentrations. When in doubt, nothing beats a real-world test.

How to Use the Rating System

To make things straightforward, we use a simple A-D rating system. It’s a standard way to quickly assess how a material will hold up.

- A = Excellent: The material is virtually unaffected. It's the recommended choice for continuous, long-term service.

- B = Good: There might be a minor effect, like slight corrosion or discolouration over time, but it's generally suitable for many applications.

- C = Fair: You'll see a moderate effect. This isn't a good choice for continuous use, as you could see softening, swelling, or a loss of strength.

- D = Severe Effect: The material is heavily attacked. It is absolutely not recommended for any use with this media.

This standardised key allows for a quick, at-a-glance assessment. However, for any critical applications—especially those involving aggressive chemicals, high pressures, or extreme temperatures—we can't stress this enough: performing a physical immersion test with a sample of the material is the safest and most reliable course of action. This chart is your vital first step, but real-world testing provides the ultimate confirmation.

A Detailed Guide to Metallic Valve Materials

Choosing the right metal for your valve is one of the most critical decisions you'll make for your system. Metals bring superior strength and temperature resistance to the table compared to plastics, but their chemical compatibility can be very specific. Getting this wrong can lead to premature failure, costly downtime, and even safety hazards.

Knowing the subtle but crucial differences between alloys like 304 and 316 stainless steel, or when you can safely opt for cost-effective carbon steel, is fundamental. It's about ensuring the long-term health and safety of your entire operation.

This guide will walk you through the most common metallic materials we see across UK industries. We’ll look at their properties, where they shine, and their limitations, helping you make an informed choice. After all, a valve material compatibility chart is only useful if you understand the materials on it.

Stainless Steel (304 vs 316)

Stainless steel is a fantastic, versatile material, but it's a mistake to think all grades are the same. In the world of valves, the two you'll run into most often are 304 and 316.

304 Stainless Steel: Think of this as the dependable workhorse of the stainless steel family. It provides excellent corrosion resistance against a huge range of atmospheric conditions and chemicals. This makes it a great all-rounder for general-purpose use with media like water, air, and in many food processing applications.

316 Stainless Steel: When things get more aggressive, 316 is the grade you need. It contains an important element called molybdenum, which dramatically boosts its resistance to chlorides, acids, and pitting corrosion. This quality makes it the standard for marine environments, chemical processing plants, and pharmaceutical applications where fighting corrosion is non-negotiable. If your system handles saltwater or harsh chemicals, you should be looking at 316 grade. Find out more in our guide on stainless steel solenoid valves.

In the UK, the need for detailed compatibility data grew right alongside our chemical industries, and today, manufacturers work with databases covering over 1,600 different chemicals. For instance, 316 stainless steel is a firm favourite in the UK's offshore oil and gas sector because it can effectively resist chloride stress corrosion cracking in concentrations up to 30,000 ppm at room temperature. However, it's vital to know that this resistance drops off sharply once temperatures climb above 60°C.

Carbon Steel

Carbon steel is a popular choice for valves, and for good reason. It offers great strength and durability at a relatively low cost. It performs brilliantly in non-corrosive environments, handling things like air, steam, and hydrocarbons with ease.

The trade-off? Its major weakness is a vulnerability to rust and corrosion. If it's going to be exposed to water or moisture, it absolutely needs a protective coating to last. It's an excellent, budget-friendly option for high-pressure and high-temperature work, as long as the media itself isn't corrosive. You'll see it used all the time in steam lines or for oil and gas transport.

Brass and Specialised Alloys

Brass, which is an alloy of copper and zinc, is a go-to material for smaller valves, especially in plumbing and HVAC systems. It's easy to machine and has good corrosion resistance for less aggressive media like drinking water and neutral gases.

But for the really tough jobs, you have to turn to specialised alloys. Materials like Hastelloy, a nickel-based alloy, are in a class of their own. It delivers exceptional resistance to a massive array of highly corrosive chemicals, including strong acids and chlorides, even at high temperatures where even stainless steel would fail. When nothing else will do, specialised alloys are the answer.

Plastic and Polymer Valve Materials Explained

While metal valves are the go-to for strength, there are plenty of situations where plastic and polymer valves are not just an alternative, but the only sensible choice. Their real strength lies in corrosion resistance, especially when you’re dealing with aggressive chemicals that would make short work of even high-grade stainless steel.

Getting to grips with the differences between materials like PVC, CPVC, Polypropylene (PP), and PTFE is crucial. Each has its own distinct profile of chemical resistance, temperature limits, and physical strength, which you'll find detailed in any good valve material compatibility chart. Choosing the right plastic isn't just a case of "will it dissolve?" – you have to be confident it can handle the system's pressure and temperature without failing.

PVC and CPVC

Polyvinyl Chloride (PVC) is probably the most common plastic valve material you'll come across, and for good reason. It’s affordable and stands up brilliantly to a huge range of chemicals, making it a fantastic choice for water systems, irrigation, and low-concentration chemical dosing.

The main drawback of PVC is its temperature limit. As a rule of thumb, you shouldn't use standard PVC in systems that run hotter than 60°C. This is where its close relative, Chlorinated Polyvinyl Chloride (CPVC), steps in. An extra chlorination process gives it a much higher heat tolerance, pushing its operational limit up to around 90°C. This makes CPVC the perfect upgrade for hot water lines or industrial processes where PVC's chemical resistance is ideal, but the temperature is just too high.

Polypropylene (PP) and PTFE

Polypropylene (PP) is another excellent option, known for its superb resistance to a broad spectrum of chemicals, including many acids, alkalis, and organic solvents that might give PVC a hard time. It’s a rigid but lightweight material, frequently used in chemical drainage, labs, and industrial applications.

But when you need the absolute best in chemical inertness, Polytetrafluoroethylene (PTFE) is in a class of its own. It’s resistant to almost every chemical you can throw at it and handles an incredibly wide temperature range. For this reason, it has become the gold standard for very aggressive media and high-purity applications.

This incredible performance does come with a trade-off, however. PTFE is a relatively soft material with lower mechanical strength. This means you won’t often find a valve body made entirely of PTFE. Instead, it’s most commonly used for critical internal components like valve liners, seats, and seals. Here, it acts as an inert barrier, allowing a more robust and economical material like cast iron or steel to form the main body of the valve.

Here’s a quick summary to help guide your choice:

- PVC: Best for cold-to-warm water and many common acids and alkalis. It’s the most cost-effective option but has a low temperature ceiling.

- CPVC: The one to pick when you need PVC’s chemical profile but for higher-temperature jobs.

- PP: Offers wider chemical resistance than PVC, particularly against certain solvents and organic chemicals.

- PTFE: The ultimate choice for aggressive and high-purity systems, but its mechanical properties make it best for linings and seals rather than the main valve body.

Ultimately, choosing a plastic valve over a metal one isn't a compromise. It's a strategic engineering decision driven by the specific chemical challenges of your application.

Compatibility of Valve Seals and Gaskets

You can pick the perfect valve body for your fluid, but the entire assembly can still fail if you ignore the seals and gaskets. In my experience, these components are often the first point of failure. A robust metal body means very little if the seal material degrades, leading to leaks and eventual system failure. It's a classic case of a chain being only as strong as its weakest link, which is why a holistic approach is vital when using any valve material compatibility chart.

The seal is the soft, flexible part responsible for creating the pressure-tight closure. If it’s incompatible with the media, it can swell, shrink, harden, or even dissolve completely, rendering your valve useless. This is precisely why materials like EPDM, Viton (FKM), Nitrile (Buna-N), and PTFE need just as much scrutiny as the valve body itself.

Common Seal Materials and Their Uses

Understanding the strengths and weaknesses of common seal materials is the key to preventing predictable—and often costly—failures. A classic example I see all the time is the trade-off between EPDM and Viton.

EPDM (Ethylene Propylene Diene Monomer): This is an excellent, reliable choice for applications involving water, steam, or glycol-based fluids. However, put it anywhere near petroleum oils, fuels, or most solvents, and it will perform very poorly, swelling up and degrading in no time.

Viton (FKM): On the flip side, Viton excels exactly where EPDM fails. It offers superb resistance to petroleum products, mineral oils, and a huge range of chemicals and solvents. Its Achilles' heel? Hot water and steam, where EPDM is by far the superior choice.

A common mistake is choosing a stainless steel valve for an oil-based hydraulic system without double-checking the seal. If that valve happens to be fitted with a standard EPDM seal, it is absolutely destined to fail, even though the steel body is perfectly compatible.

Choosing the right seal is a critical step that demands careful thought. For a much deeper dive into the specific properties of these materials, our comprehensive guide on seals and diaphragms offers detailed specifications to help you get it right the first time.

Other materials like Nitrile (Buna-N) offer a good, general-purpose balance for oils and water at moderate temperatures. Then there's PTFE, which provides almost universal chemical resistance, making it the go-to for the most aggressive applications, though it is less flexible than its elastomer counterparts. Always cross-reference both the body and the seal material against your specific media to ensure total system longevity and safety.

Common Mistakes in Valve Material Selection

Even with a detailed valve material compatibility chart right in front of you, it’s surprisingly easy to make a costly mistake. Getting this right is about more than just reading a chart; it’s about avoiding the common traps that can compromise the safety and lifespan of your entire system. A little foresight here will save you from dangerous failures and expensive downtime later on.

One of the most frequent slip-ups is underestimating the combined effect of temperature and pressure. A material might be perfectly rated for a chemical at room temperature, but that same compatibility can plummet as things heat up. Chemical reactions simply speed up with more heat, which can quickly turn what looked like a safe choice into a serious hazard.

For example, imagine using a PVC valve in a line that occasionally sees temperature spikes above 60°C. While PVC has fantastic chemical resistance in many situations, it softens and loses its structural strength at higher temperatures. The result? A catastrophic failure waiting to happen.

Ignoring Trace Chemicals and Focusing on Cost

Another classic oversight is getting fixated on the primary fluid and forgetting about everything else mixed in. Your main medium might be fine, but what about those small percentages of other chemicals or contaminants? These seemingly minor additions can be incredibly aggressive, leading to rapid corrosion where you least expect it.

Take a system moving deionised water, for instance. Sounds simple, right? But if that process introduces even trace amounts of chlorine, a standard brass valve—which would otherwise be a great fit—will start to corrode and eventually fail. You have to consider the entire chemical profile of your media, not just the headliner.

Choosing a valve based purely on its initial price tag is a false economy. A cheaper valve that fails in six months will end up costing you far more in downtime, labour, and replacement parts than selecting the correct, more durable option from day one.

Finally, just misreading the chart data is a common but completely avoidable error. The ratings you see are a starting point, not the final word.

- Always check the compatibility against your specific operating temperatures and pressures.

- Never assume a material is safe without confirming it can handle every single chemical in your media.

- When in doubt, test. Nothing beats a physical immersion test for ultimate peace of mind.

Frequently Asked Questions

Even with a detailed valve material compatibility chart, you're bound to run into some specific questions. We get it. Here are some straightforward answers to the queries we hear most often, designed to help you get past common sticking points and apply this guide effectively.

What Is the Main Difference Between 304 and 316 Stainless Steel for Valves?

It all comes down to one key ingredient: molybdenum. Grade 316 stainless steel includes molybdenum in its alloy, which dramatically improves its resistance to corrosion, particularly from chlorides (like saltwater) and harsh industrial chemicals.

This makes 316 the superior choice for demanding jobs in marine, chemical processing, or pharmaceutical settings. For less aggressive environments, 304 stainless steel is still a perfectly reliable and cost-effective workhorse.

How Does Temperature Affect a Material's Chemical Resistance?

Temperature is a massive factor, and overlooking it can lead to rapid failure. As temperatures rise, chemical reactions speed up, which can completely change how a material behaves. A material that's rated 'Excellent' for a specific chemical at room temperature (20°C) could easily be downgraded to 'Not Recommended' once things heat up.

We see it all the time: a system works perfectly until the process temperature increases, causing a valve or seal to fail unexpectedly. The heat simply provides the energy needed for corrosion to take hold and happen much, much faster. Always check the compatibility at your true operating temperature, not just at ambient.

When Should I Choose Viton (FKM) Seals Over EPDM?

This choice is entirely dictated by what's flowing through your valve. They are not interchangeable.

- Choose Viton (FKM) when you're dealing with petroleum oils, fuels, and a wide range of solvents. EPDM simply can't stand up to these and will swell and degrade very quickly.

- Use EPDM for systems with hot water, steam, or glycol-based fluids. In these applications, Viton is the one that tends to perform poorly.

Remember, getting the seal material right is just as critical as choosing the right valve body. A perfect valve body with the wrong seal is a guaranteed point of failure.

For expert advice and a comprehensive selection of valves for any application, explore our full range at Solenoid Valve World. Find the exact component you need with our powerful search tools and next-day UK delivery. Visit https://solenoid-valve.world today.