Water Flow Control Valve Guide: Tips & Selection

Understanding Your Water Flow Control Valve System

Water flow control valves are essential components in our plumbing systems. They work tirelessly behind the scenes, ensuring consistent water pressure and a dependable water supply throughout our homes and properties. Taking the time to understand their function is key to making informed decisions about your water system's maintenance and upgrades.

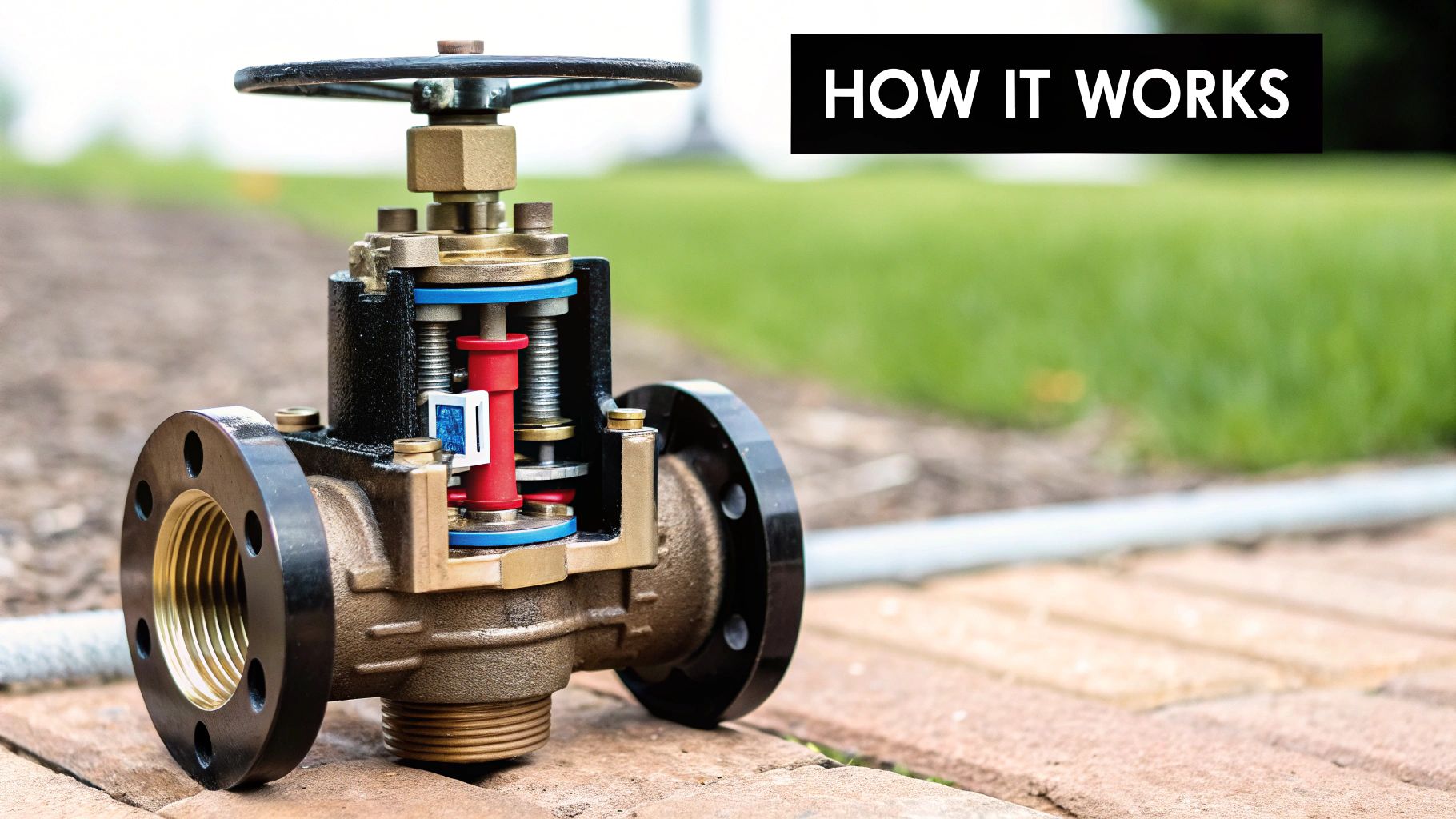

How Water Flow Control Valves Work

A water flow control valve regulates the volume of water moving through your pipes. It acts like an adjustable tap within your plumbing, fine-tuning the flow according to the system's demands. This precise regulation helps maintain a steady water pressure, which is crucial for preventing problems like water hammer. Water hammer is the sudden, jarring, and potentially damaging surge of pressure within your pipes.

The Physics of Flow Control

The fundamental principle behind a water flow control valve lies in managing the pressure differential. Water, like any fluid, flows from areas of high pressure to areas of low pressure. The greater the difference in pressure, the faster the flow. The valve introduces resistance, effectively constricting the flow and controlling the rate at which water moves through the pipes.

This careful manipulation of pressure differences is what allows these valves to effectively protect your plumbing system from pressure fluctuations.

Benefits of Proper Valve Function

Well-functioning water flow control valves offer several important benefits.

- Protection: Safeguards your plumbing from damage caused by fluctuating water pressure.

- Consistency: Ensures a reliable and steady water supply, eliminating low-pressure frustrations.

- Longevity: Contributes to the extended lifespan of appliances like washing machines and dishwashers by providing the consistent water flow they require.

The importance of these valves is reflected in the UK control valve market, valued at approximately USD 292 million in 2023. This demonstrates the significant role these devices play across various industries, from oil and gas to water treatment and even food and beverage production. You can find more detailed statistics here: Learn more about the UK control valve market

Types of Water Flow Control Valves

Different types of water flow control valves cater to specific applications. Ball valves, gate valves, and globe valves each employ unique mechanisms to manage water flow. Understanding the differences between these valve types will help you choose the correct valve for your specific needs. Selecting the appropriate valve is essential for maintaining a healthy and efficient plumbing system.

Choosing The Right Water Flow Control Valve For Your Needs

Selecting the correct water flow control valve is essential for a well-functioning and efficient plumbing system. A poor choice can result in expensive repairs, wasted energy, and even system-wide failures. This guide explores various valve types available in the UK, highlighting their advantages and disadvantages to empower you to make a well-informed decision.

Types of Water Flow Control Valves

Several types of water flow control valves exist, each designed for specific applications. Let's explore four common types:

Ball Valves: These valves utilize a rotating ball with a hole to regulate flow. Known for their rapid on/off action, they excel in shut-off applications. However, they are less suitable for fine-tuned flow adjustments.

Gate Valves: Gate valves employ a sliding gate to manage flow. They offer minimal flow restriction when fully open but are not designed for throttling. These valves are best suited for isolation purposes.

Globe Valves: Globe valves are engineered for precise flow control and throttling. They provide superior regulation compared to ball or gate valves but result in a higher pressure drop. They are frequently used in scenarios requiring variable flow rates.

Pressure-Reducing Valves (PRVs): PRVs automatically lower incoming water pressure to a preset value, protecting appliances and plumbing fixtures. They are crucial for preventing excessive water pressure, which can damage pipes and fittings.

Comparing Valve Types: A Practical Guide

The following table offers a comprehensive comparison of these valve types, detailing their applications, pressure ratings, and maintenance needs, assisting you in choosing the right valve for your project.

| Valve Type | Best Applications | Pressure Range (Bar) | Maintenance Level | Cost Range (£) |

|---|---|---|---|---|

| Ball Valve | On/Off control, Isolation | Up to 60 | Low | 10 - 50 |

| Gate Valve | Isolation, Full-flow applications | Up to 25 | Low | 15 - 70 |

| Globe Valve | Throttling, Flow regulation | Up to 40 | Moderate | 20 - 100 |

| Pressure-Reducing Valve (PRV) | Pressure regulation, Appliance protection | Varies | Moderate | 30 - 150 |

This table summarizes the key features of each valve type, providing a solid foundation for selecting the optimal option for your plumbing project. For example, if you require a valve for frequent on/off operation, a ball valve is a suitable choice. However, for precise flow control, a globe valve is preferred.

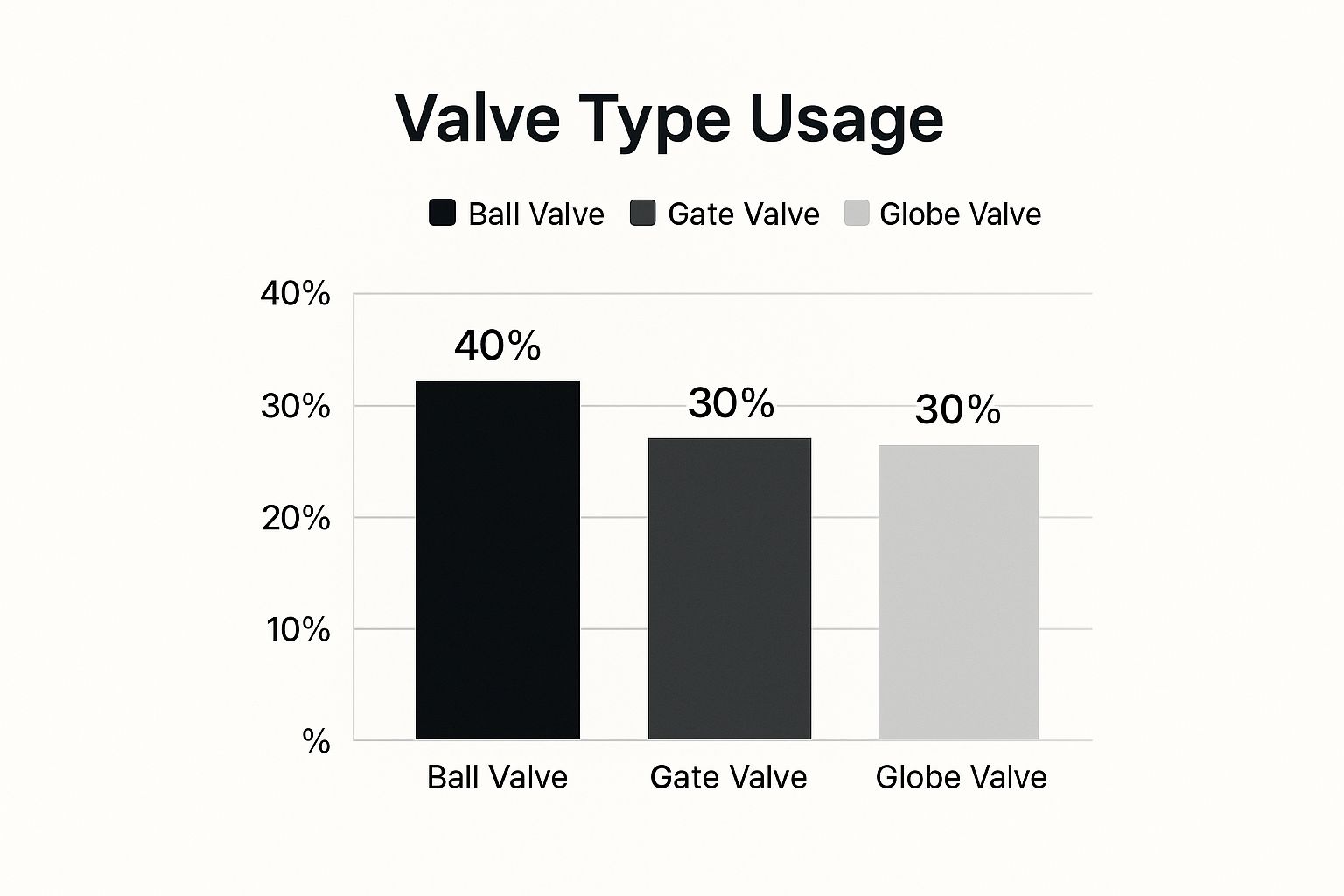

The bar chart above illustrates the typical usage distribution of three common valve types: Ball Valve, Gate Valve, and Globe Valve. Ball valves represent the most frequent choice (40%), followed by gate valves and globe valves, each accounting for 30% of typical usage. This data suggests that ball valves are commonly chosen for their simple on/off functionality, while gate and globe valves maintain significant shares due to their specialized roles in isolation and flow regulation.

Matching Valves to Specific Needs

The valve you select should align with your project's specific requirements. Consider the pipe diameter, as valves are sized according to pipe size. The pressure rating of the valve must also be compatible with your system’s pressure. Furthermore, consider the media (water, gas, oil) being handled, as valves are designed for specific media types.

Read also: How to master general purpose solenoid valves

Finally, factor in maintenance requirements. Ball valves generally require minimal maintenance, while globe valves and PRVs may need more frequent attention. By carefully evaluating these factors, you can choose the most appropriate water flow control valve, ensuring optimal performance and a long lifespan.

Making Smart Water Flow Control Valve Selection Decisions

The difference between a water flow control valve that stands the test of time and one that needs replacing after just a few years often comes down to seemingly minor selection details. This section explores those vital factors impacting valve longevity and performance. Surprisingly, everything from pipe diameter and pressure requirements to the surrounding environment can significantly influence a valve's lifespan.

Key Considerations For Valve Selection

When choosing a water flow control valve, it's helpful to research different product categories. A good starting point might be exploring available product resources, such as those found on industry blogs like Product. Understanding your system’s needs is also crucial. This means accurately assessing factors like the required flow rate and operating pressure.

For instance, a valve designed for a high-pressure system in an industrial setting will have very different specifications than one used for regulating water flow in a residential garden. Matching these demands to the correct valve specifications is paramount.

Oversizing or undersizing can lead to inefficiency and premature wear. It's much like selecting the right engine size for a vehicle. A small engine in a large truck won't perform efficiently, and a large engine in a compact car wastes fuel. Similarly, an incorrectly sized valve will strain your entire plumbing system.

Avoiding Costly Mistakes

Choosing the wrong water flow control valve can trigger a series of expensive problems. Premature failure is a common outcome, often leading to costly replacements and disrupting essential water service. Inefficient operation is another potential issue, resulting in higher energy bills and wasted water.

Furthermore, selecting the wrong valve can sometimes void warranties, leaving you responsible for the full cost of repairs. Understanding the specifics of your water system and selecting the appropriate valve can help you avoid these financial pitfalls.

A Systematic Approach To Valve Selection

A systematic approach to valve selection involves several important considerations. Water quality plays a crucial role. Some valves are better equipped to handle hard water or water containing sediment. Temperature variations also factor into the equation, particularly for outdoor installations where freezing is a concern.

Installation location also matters. A valve installed in a confined space might require a different design than one installed in an open area. Finally, budget is always a consideration, requiring a balance between desired performance and affordability.

Factors Influencing Valve Longevity

Several factors directly affect the lifespan of a water flow control valve. Material selection is key. Brass valves, for example, are renowned for their durability and corrosion resistance. Regular maintenance is essential. Routine inspections and cleaning can prevent premature wear and tear.

The operating environment also significantly impacts valve longevity. Exposure to harsh chemicals or temperature extremes can accelerate degradation. By carefully considering these factors, you can make an informed decision and choose a valve that provides years of reliable service. This systematic approach to valve selection is vital for ensuring optimal long-term performance and minimizing the risk of expensive future problems.

Professional Water Flow Control Valve Installation Techniques

Proper installation is essential for the lifespan and effectiveness of your water flow control valve. Even the highest quality valve won't perform well or will fail early if not installed correctly. This guide will walk you through professional installation practices, from evaluating your system to final testing, ensuring optimal performance right from the start.

Pre-Installation System Assessment

Before starting any work, a complete evaluation of your plumbing system is critical. This helps ensure the new valve integrates seamlessly with your current setup.

- Verifying pipe compatibility: Check that the valve's material and connections are compatible with your existing pipes. This will prevent leaks and ensure a tight seal.

- Measuring water pressure: Understanding your system's water pressure helps you choose a valve with the correct pressure rating, preventing potential damage.

- Checking water quality: Analyzing water hardness and sediment levels helps determine the best valve materials, avoiding problems like scaling or corrosion.

For further information, check out this helpful resource: How to master solenoid valve installations.

Essential Tools and Safety Protocols

Having the right tools and prioritizing safety are crucial for a smooth installation. Gather necessary tools like pipe wrenches, PTFE tape, and a pipe cutter. Always shut off the water supply before beginning any work to prevent accidental flooding. Eye protection, such as safety glasses, is also recommended.

Step-by-Step Installation Guide

Correct installation involves a series of precise steps:

- Prepare the pipes: Clean the pipe ends thoroughly, removing any burrs or debris. This ensures a good seal, much like prepping a surface before painting.

- Apply PTFE tape: Wrap PTFE tape around the male pipe threads to create a watertight seal, preventing leaks.

- Install the valve: Carefully screw the valve onto the prepared pipe ends, making sure it's facing the correct direction. The flow arrow on the valve should align with the water flow.

- Secure connections: Tighten the connections firmly with the appropriate wrenches, but be careful not to over-tighten, which could damage the valve. This is similar to tuning a guitar string – proper tension is key.

- Support the valve: Larger valves, especially in high-pressure or high-flow systems, might need support brackets. This prevents stress on the pipes and ensures long-term stability.

Testing and Commissioning

After installation, testing the valve is essential:

- Slowly turn on the water supply: Gradually restore water pressure to avoid any sudden surges.

- Check for leaks: Inspect all connections for leaks. Even a small drip can become a significant issue.

- Test valve operation: Run the valve through its full range of motion to ensure smooth and consistent water flow control.

By following these professional installation methods and safety precautions, you can ensure your water flow control valve performs efficiently and reliably for years to come. A correctly installed valve safeguards your plumbing, saves you money on repairs, and provides valuable peace of mind.

UK Water Flow Control Valve Market Growth and Innovation

The UK water control valve market is experiencing substantial growth. This expansion is driven by technological advancements and the increasing need for automation across various sectors. From water treatment plants to industrial manufacturing, these valves are essential for resource management and process optimization. Let's explore the current market trends shaping the future of water flow control valves in the UK.

The Rise of Smart Valve Technology and IoT Integration

One of the most significant trends is the growing adoption of smart valve technologies and the Internet of Things (IoT). These innovations are transforming traditional valves into advanced control systems. These new systems offer remote monitoring and automated adjustments.

For instance, IoT-enabled sensors provide real-time data on water flow, pressure, and temperature. This allows for precise control and proactive maintenance. This real-time monitoring enables early detection of potential problems. This, in turn, reduces the risk of costly breakdowns and system downtime.

This shift toward smart technology mirrors the broader trend of digital transformation in UK industries. The integration of data-driven insights allows businesses to optimize their water management strategies. Ultimately, this leads to improved efficiency and cost savings.

Digital Transformation Reshaping Valve Design and Application

Digital transformation is impacting more than just smart valves; it's fundamentally reshaping how valves are designed and used across UK industries. Digital twin systems, for example, are becoming increasingly common. These systems allow engineers to create virtual replicas of physical valves.

This allows for simulated scenarios and optimized valve performance without physical prototypes. This is especially valuable for complex systems where real-world testing can be disruptive and time-consuming.

Predictive maintenance capabilities are also gaining traction. By analyzing data from sensors and other sources, it’s possible to predict valve failures. This allows for scheduled maintenance, minimizing downtime and preventing unexpected issues. This proactive approach prevents disruptions and financial losses.

Furthermore, the UK valve industry has historically shown strong growth. Between 2010 and 2014, production almost doubled, reaching €2.1 billion. This represents an average annual growth rate of 18%. More detailed statistics can be found here: Explore the UK Valve Industry Growth

Sustainability and Energy Efficiency Driving Innovation

The increasing focus on sustainability and energy efficiency is another key driver of innovation in the UK water flow control valve market. Manufacturers are prioritizing the development of valves that minimize water waste and energy use.

This focus has spurred advancements in valve materials and designs, particularly in water treatment and industrial applications. New materials are being developed to improve durability and reduce the need for frequent replacements.

Innovative designs, such as low-flow valves and automatic shut-off mechanisms, contribute to water conservation. These improvements not only reduce operational costs for businesses but also support the UK's environmental objectives. These advancements are crucial for tackling the challenges of water scarcity and rising energy costs.

Future Trends in the UK Market

The UK water flow control valve market is set for continued growth and development. The ongoing adoption of smart technologies, coupled with an emphasis on sustainability, will drive future innovation in this essential industry.

As businesses seek ways to enhance efficiency, lower costs, and minimize their environmental impact, the demand for advanced water flow control solutions will undoubtedly increase. This creates an opportunity for manufacturers and suppliers to develop cutting-edge valve technologies. These technologies must meet the evolving needs of the UK market. This ongoing evolution is crucial for ensuring the long-term sustainability and efficiency of water management systems across the country.

Smart Technology Integration In Water Flow Control Valves

The future of water management depends heavily on smart technology, and water flow control valves are leading this change. Intelligent automation and advanced monitoring are transforming traditional valve operation into sophisticated control systems, offering remarkable precision and efficiency. This translates to more effective and cost-efficient water management.

IoT Sensors and Remote Monitoring: A New Era of Control

IoT (Internet of Things) sensors are changing how we manage water flow control valves. These sensors gather real-time data on factors like water flow, pressure, and temperature, sending this information wirelessly to central monitoring systems. This real-time data allows operators to remotely monitor valve performance, spot potential problems before they become serious, and make adjustments without needing someone on-site. For instance, a leak detected early through sensor data can be quickly fixed, minimizing water loss and preventing major damage.

Remote monitoring systems also enable proactive maintenance strategies. By analyzing trends in valve performance, these systems can predict when maintenance is needed, preventing costly failures and extending the valve's lifespan. This predictive capability reduces downtime and ensures a consistently dependable water supply.

Predictive Analytics and AI: Optimizing Water Usage

Predictive analytics and artificial intelligence (AI) are shifting water flow control valve management from reactive to proactive. AI algorithms analyze the data gathered by IoT sensors, identifying patterns in water usage and forecasting future demand. This enables systems to automatically optimize water distribution, ensuring efficient and effective use of water resources. This automated optimization leads to significant cost savings, particularly in large-scale applications.

These intelligent systems can also adapt to changing conditions, such as shifting weather patterns or variations in building occupancy. This adaptability ensures optimal performance and resource allocation in various circumstances. This responsiveness leads to greater water conservation and reduces the burden on water infrastructure. You might be interested in: How to master stainless steel solenoid valves

Integrating Smart Valves With Building Management Systems

Smart water flow control valves integrate seamlessly with existing building management systems (BMS), further improving control and efficiency. This integration allows building managers to monitor and control water usage across the entire facility, optimizing resource allocation and identifying areas for improvement. This comprehensive approach to water management streamlines operations and simplifies maintenance tasks.

The combined data from smart valves and BMS can also offer valuable insights into building performance. This data can inform strategies for energy conservation, cost reduction, and sustainability initiatives. Integrating smart valves significantly contributes to achieving broader building efficiency goals.

The Expanding UK Market and the Drive for Efficiency

The UK industrial valves market, including control valves, is expected to exceed USD 3 billion by 2028. This growth is driven by the increasing demand for energy efficiency and the ongoing digital transformation in industrial operations. Learn more about UK Industrial Valves Market growth. This expansion highlights the importance of smart valve technologies in meeting the evolving needs of the UK's industrial sector.

Smart Valve Features and Their Benefits

Smart valve technology offers a variety of functions that improve water management practices. The table below summarizes these key features and their associated advantages:

Smart Valve Features and Benefits: Overview of smart valve technologies and their operational benefits for water flow control systems

| Technology | Function | Benefits | Typical Applications | ROI Timeline |

|---|---|---|---|---|

| IoT Sensors | Real-time data collection | Leak detection, remote monitoring, predictive maintenance | Water distribution networks, industrial plants | Short-term to mid-term |

| Remote Monitoring | System oversight from a central location | Proactive maintenance, reduced downtime, improved response times | Large building complexes, irrigation systems | Short-term |

| Predictive Analytics | Forecasting future demand | Optimized water allocation, resource conservation, cost savings | Water treatment facilities, agricultural operations | Mid-term to long-term |

| AI and Machine Learning | Adaptive system control | Enhanced efficiency, responsiveness to changing conditions | Smart city infrastructure, commercial buildings | Long-term |

| BMS Integration | Unified building management | Streamlined operations, improved data analysis, enhanced control capabilities | Office buildings, hospitals, universities | Mid-term |

Smart water flow control valves are more than just a technological advancement; they are a critical step towards more sustainable and efficient water management. As the UK continues to prioritize water conservation and operational efficiency, adopting these smart technologies will become increasingly vital for businesses and industries nationwide.

Maximizing Water Flow Control Valve Performance Through Maintenance

Maintaining your water flow control valve is essential for its longevity and optimal performance. Just like regular car maintenance ensures smooth driving, proper valve care can provide decades of reliable service. This saves you from costly replacements and unexpected disruptions. This section will cover essential maintenance strategies, helping you maximize your investment.

Preventative Maintenance: Saving Money and Headaches

Preventative maintenance is the key to avoiding expensive emergency repairs and ensuring consistent performance. Think of it like scheduling regular check-ups with your doctor. Routine valve maintenance can catch small issues before they become major problems. This proactive approach not only extends the life of your valve but also minimizes the risk of unexpected system failures.

Regular Inspections: Inspect your valve regularly for signs of wear and tear, leaks, or corrosion. This simple check can often prevent more significant problems.

Cleaning: Periodically clean your valve to remove debris or buildup that could restrict flow or damage internal components.

Lubrication (if applicable): Some valves need lubrication for smooth operation. Consult your valve’s manual for specific lubrication instructions.

These simple steps can significantly extend the lifespan of your water flow control valve and keep your water systems operating efficiently.

Troubleshooting Common Valve Problems

Even with diligent maintenance, issues can sometimes arise. Knowing how to troubleshoot these issues can save you time and money. Understanding technological advancements, like those discussed on Technology, can provide insight into future trends and potential solutions.

Leaks: Leaks are often due to worn seals or loose connections. Tightening connections or replacing seals usually resolves the issue.

Reduced Flow: Reduced flow can be caused by debris buildup, a partially closed valve, or a malfunctioning actuator. Cleaning the valve, checking its position, or troubleshooting the actuator can often restore proper flow.

Unusual Noises: Unusual noises, such as banging or whistling, can indicate internal problems or excessive pressure. Investigating the noise source and addressing the underlying issue is crucial.

These are just a few examples of common valve problems. Consult your valve’s manual or contact a qualified plumber for more complex issues.

Professional Maintenance Techniques

While some maintenance tasks are suitable DIY projects, others require professional expertise. Understanding this difference is crucial.

Seal Replacement: Replacing seals in some valves can be complex and requires specialized tools. A professional plumber can ensure the job is done correctly, preventing future leaks.

Calibration: Some valves, especially pressure-reducing valves, need periodic calibration for accurate operation. Professional calibration ensures your system maintains the correct pressure.

Internal Component Repair or Replacement: If internal components are damaged, professional repair or replacement is often the most cost-effective solution.

Knowing when to call a professional can prevent further damage and ensure proper valve repair.

Seasonal Maintenance Checklists and Schedules

Creating seasonal checklists and schedules helps you stay on top of essential tasks. For instance, winterizing outdoor valves is vital in colder climates to prevent freezing damage.

Spring: Inspect valves for winter damage, clean debris, and test operation.

Summer: Check for leaks and ensure efficient operation during peak water usage.

Autumn: Prepare outdoor valves for winter by insulating or draining them as needed.

Winter: Monitor indoor valves for proper function and address any issues promptly.

By implementing these strategies and seeking professional help when needed, you can extend your valve's life, prevent costly repairs, and enjoy years of trouble-free operation.

Ready to explore high-quality water flow control valves? Visit Solenoid Valve World today. Whether you're an engineer or a DIY enthusiast, Solenoid Valve World offers the right products and expert advice to manage your water systems efficiently.