What Is a Solenoid Valve?

A solenoid valve is an electromechanical control device that uses an electrical coil (solenoid) and a movable plunger to quickly open or close a fluid passage. They are ideal for fast on/off flow control of liquids or gases, and are used across industries from irrigation systems to industrial automation

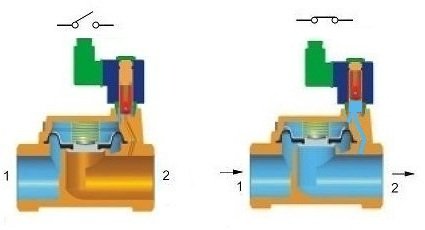

2/2 Way Normally Closed - failsafe closed

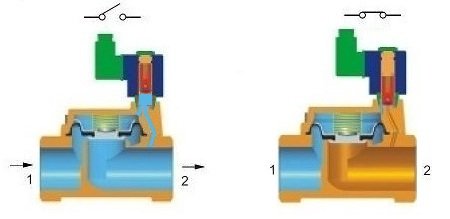

2/2 Way Normally open - failsafe open

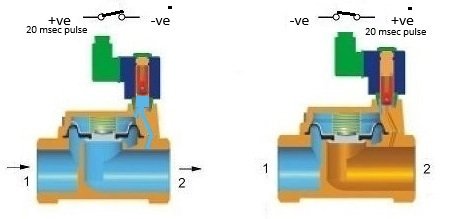

2/2 Way Latching - power pulse open + close

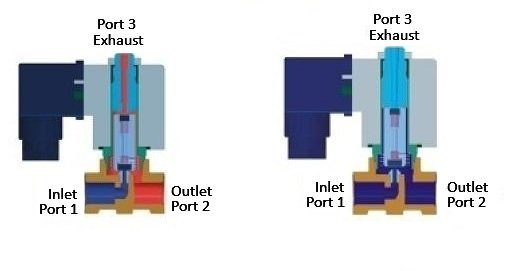

3/2 Way Normally closed, Open or Universal

How Does It Work?

Solenoid valves operate by energising a coil, creating a magnetic field that pulls the plunger against a spring, thereby opening (or closing) a passage. When power is removed, the spring returns the plunger to its original position .

Types:

Normally Closed (NC): Closed without power.

Normally Open (NO): Open without power.

Latching (Bi-stable) : Power pulse stay open - reverse polarity pulse stay closed.

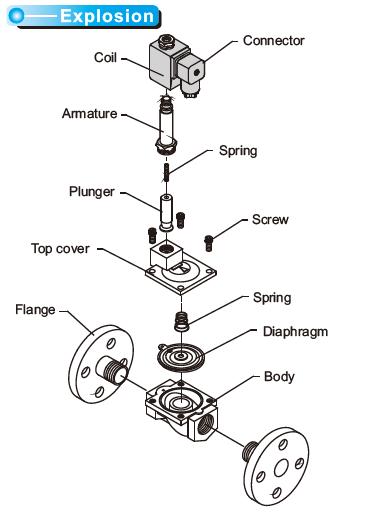

Main Components

Solenoid Coil: – creates electro magnetic field when powered.

Armature tube: Retains media + plunger allows fitment of solenoid coil

Plunger: – moves to open/close valve.

Spring – returns plunger to rest position.

Valve Body: – defines flow path; constructed in brass, stainless steel, or plastic depending on application

Diaphragm: Main seal for media, can be NBR, EPDM, VITON, HNBR

Configurations & Variants

2-way valves: Simplest design—one inlet, one outlet.

3-way / 5-way valves: Used to switch or direct flow between multiple channels .

Latching (bi-stable): Maintains position without continuous power—ideal for battery-powered setups

Common Applications

Irrigation & water treatment: Automated watering and valve control in plumbing.

HVAC and industrial systems: Managing air, oil, gas, and chemicals.

Domestic appliances: Dishwashers, washing machines .

Speciality systems: Paintball markers, test benches, pneumatic/hydraulic actuators .

Advantages & Considerations

Pros:

Fast switching (milliseconds)

Compact and reliable

Low power usage, especially pilot-operated and latching types

Cons:

Limited orifice size (larger valves need stronger coils or pilot support)

Sensitive to dirty media—clogs can prevent operation

Requires matching coil voltage and pressure range to specific application

Installation & Maintenance Tips

Always confirm coil voltage, thread type, and seal material match the system and media

Install filter before valve to prevent debris buildup.

Check electrical wiring and grounding carefully.

Perform routine checks for leaks, coil heat, and clogging.

Follow recommended service intervals from the manufacturer.

Conclusion

Solenoid valves are versatile, efficient, and precise fluid controllers that utilise electromagnetic actuation to manage flow. With configurations suited for a wide range of pressures, media types, and system demands, choosing the right variant (NO/NC, pilot or direct, latching) ensures optimal performance in your application.