Why You Need a Silver Shading Ring in a Solenoid Valve for Pure Water Applications

Solenoid valves play a critical role in fluid control systems, especially in high-purity environments like reverse osmosis (RO), demineralised, or ultra-pure water systems. A key component ensuring their smooth and reliable operation is the shading ring—and when it comes to pure water, silver shading rings offer unmatched advantages, that are essential for 50/60Hz alternating current.

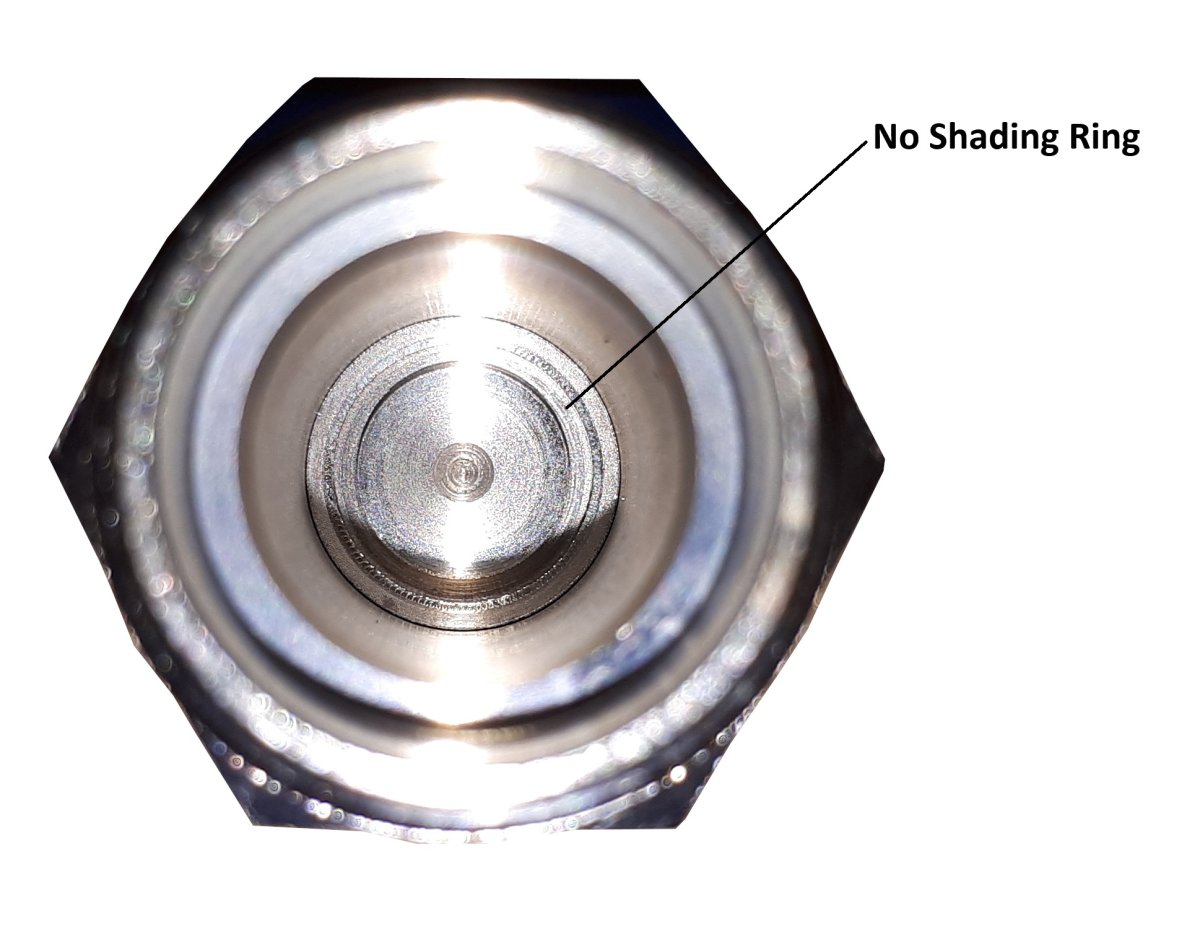

Shading rings are not however required for DC voltage supplies because the current is stable (not alternating), in this instance for aggressive media applications an armature assembly without any shading ring can be used. These are typically less expensive than silver rings.

Helpful hint: By using a fully bridge rectified DIN43650 electrical connector to convert AC (50/60Hz Alternating Current) to DC (Direct Current), so a DC coil can be used in conjunction without a shading ring even with an initial AC supply.

What Is a Shading Ring in a Solenoid Valve?

A shading ring, also called a phase ring or shading coil, is a small metallic ring embedded in the solenoid valve’s armature or tube assembly. Its primary role is to stabilise the magnetic field when the valve is powered by alternating current (AC)—especially important at 50/60 Hz frequencies.

Without a shading ring, AC-powered solenoid valves are prone to noise, vibration, and premature wear. In high-purity water systems, the material of the shading ring becomes even more important.

Benefits of Using a Silver Shading Ring in Solenoid Valves

Prevents Chatter and Vibration in AC-Powered Systems

In AC systems, the current drops to zero 50 or 60 times per second. This causes fluctuations in the magnetic field, which can make the plunger vibrate or “chatter”, leading to noise and mechanical wear.

Silver shading rings act as a secondary conductor, creating a small, continuous magnetic field even during these zero-crossings. This stabilises the plunger, resulting in:

Quieter operation

Reduced wear and tear

Longer valve life

Provides Superior Corrosion Resistance in Pure Water

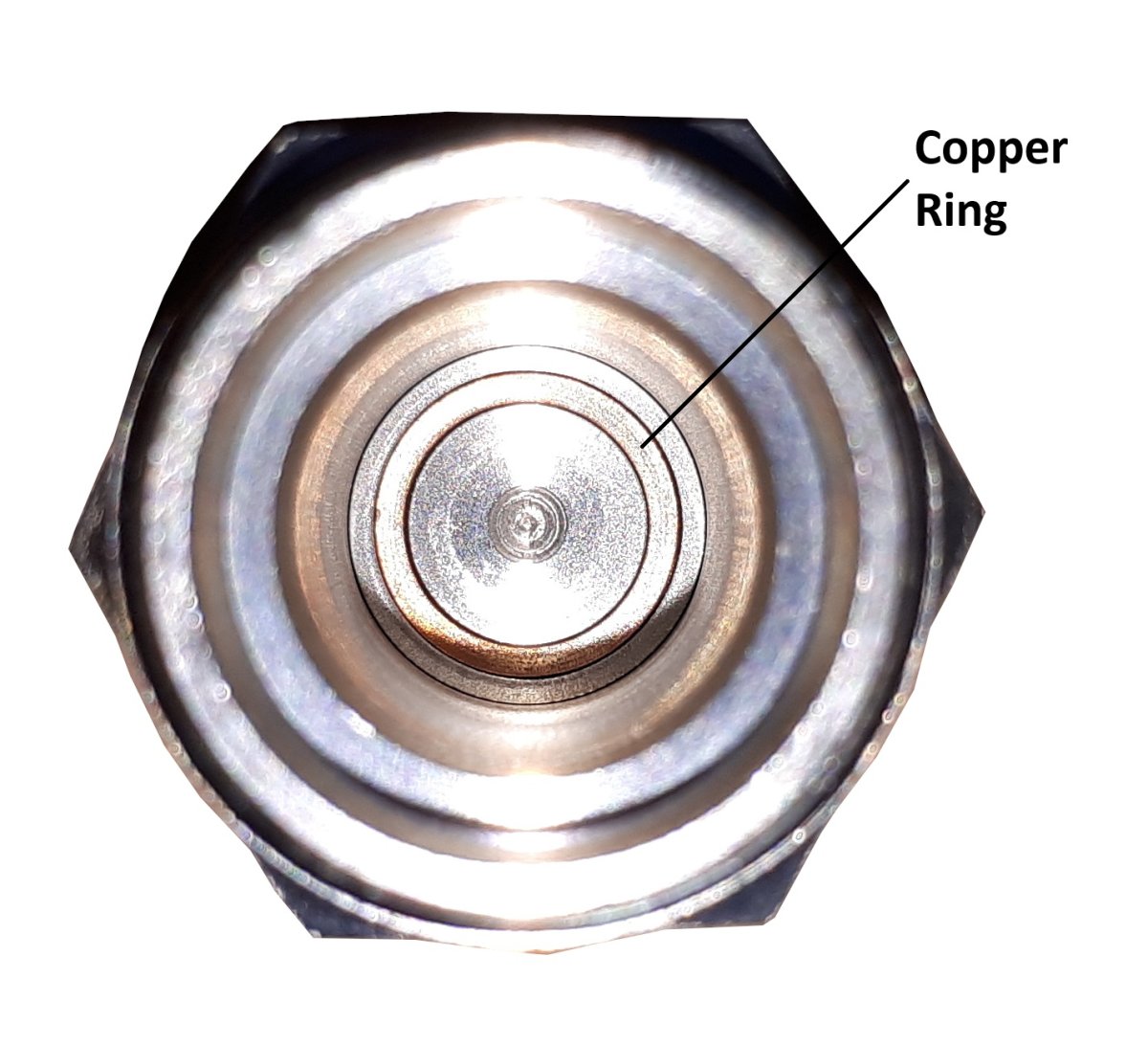

RO and demineralised water aggressively leach ions from metallic surfaces due to their lack of dissolved minerals. Traditional shading rings made from copper or brass are especially vulnerable.

Silver offers significant advantages:

Excellent resistance to corrosion and oxidation

Long-term stability in aggressive water environments

Reduced risk of component degradation

For this reason, silver is the preferred material for solenoid valves in ultra-pure water systems.

Avoiding Contamination in High Purity Systems

Why Copper Rings Are a Risk in Pure Water

Applications such as:

Pharmaceutical processing

Semiconductor manufacturing

Laboratory water systems

Medical-grade water delivery

require extremely low levels of contamination.

Copper-based shading rings can leach metal ions into the water, affecting quality and performance. In contrast, silver is chemically stable and does not leach, making it the ideal choice for:

Maintaining ultra-high water purity

Complying with strict industry standards

Note: If no shading ring is used, the solenoid must operate with DC coils or rectified AC via DIN connectors, limiting flexibility.

Improves Reliability and Extends Valve Life

Long-Term Durability in Demanding Environments

Pure water isn’t just corrosive—it can also lead to:

Oxidation of metallic surfaces

Accumulation of scale or deposits

Mechanical sticking of moving parts

A silver shading ring:

Minimises oxidation and surface damage

Prevents plunger sticking and valve seizure

Reduces the need for frequent maintenance

The result: improved operational reliability and extended service life of the solenoid valve.

Summary: Why Silver Shading Rings Are the Best Choice

Choosing a silver shading ring in your solenoid valve ensures:

Silent, chatter-free performance in AC-powered systems

Maximum corrosion resistance in pure or de-ionised water

Protection against contamination in high-purity applications

Reliable, long-lasting performance

Minimal risk of seizing or component failure