Your Guide to the Backflow Preventer Valve

A backflow preventer valve is a crucial safety device, acting as a one-way gate for your water supply. At its core, its only job is to stop contaminated water from flowing backwards into the clean, potable water system. Think of it as an essential traffic controller for your plumbing, ensuring water only ever travels in the correct direction.

Understanding the Danger of Backflow

To really get why these valves are so important, you first have to understand the problem they solve. Backflow is the unwanted reversal of water flow, a situation that can introduce hazardous materials like pesticides, chemicals, and even human waste into the public drinking water.

This dangerous reversal happens because of two specific hydraulic conditions.

The Two Causes of Backflow

Backflow incidents are almost always triggered by one of two situations:

- Backsiphonage: This happens when the pressure in the main water supply line drops suddenly and significantly. Imagine drinking through a straw—the suction you create pulls liquid up. A sudden pressure drop in a water main, maybe from a nearby fire hydrant being used or a major break in the line, creates a similar vacuum. This can siphon contaminated water from a connected system right back into the clean supply. A classic example is a garden hose left submerged in a bucket of soapy water or a paddling pool.

- Backpressure: This occurs when a connected system, like a commercial boiler or a high-pressure irrigation system, is operating at a greater pressure than the main water supply. This stronger pressure can literally push non-potable water backwards through the connection, forcing it into the public mains.

Key Takeaway: Both backsiphonage and backpressure create a direct path for contaminants to enter the clean water supply. A backflow preventer valve is engineered to automatically slam that path shut the moment these conditions arise.

Why This Is a Serious Issue in the UK

Protecting public health is exactly why backflow prevention is a legal requirement. In the UK, water authorities are rightly concerned about backflow incidents, as any contamination event can lead to serious public health crises and expensive damage to water infrastructure.

Because of this, the use of devices like Reduced Pressure Zone (RPZ) valves and double check valves is a critical line of defence. Official regulations state that the prevention method must match the fluid category risk and be able to stop both backpressure and backsiphonage. For a deeper dive, you can find more details in the official documentation about regulator specifications.

This isn't just a theoretical problem; it's a very real threat that these valves are designed to eliminate. Without a properly installed and functioning backflow preventer, a simple drop in municipal water pressure could have severe consequences for everyone. This makes this small device one of the most important components in any modern plumbing system.

How a Backflow Preventer Valve Actually Works

At its core, a backflow preventer valve is a brilliantly simple gatekeeper, built for one single purpose: to make sure water only flows one way. The easiest way to picture how it works is to imagine a series of one-way security doors inside your pipes that only open for outbound traffic—that is, fresh water coming into your building.

When your water pressure is stable and everything is working as it should, these internal doors, known as check valves, stay open. This lets fresh water move without any fuss from the mains right where you need it. But they are engineered to slam shut the instant they detect a pressure change that hints at a backflow problem.

This basic principle—reacting to pressure changes—is what makes all backflow prevention possible. Of course, the exact mechanics get a bit more clever, especially when we’re dealing with high-risk situations where contamination is a serious concern.

The Role of Internal Check Valves

The most fundamental part of a backflow preventer valve is one or more check valves. Think of a simple swing door held shut by a spring. When water flows in the right direction, it has enough push to force the door open and pass through easily.

But what happens if the pressure on the other side suddenly spikes (a condition called backpressure), or if the pressure from the mains drops (backsiphonage)? The water tries to flow backwards. This reverse force, helped by the spring, slams that door shut. It creates a solid, physical barrier that stops any contaminated water from getting back into the clean supply. A single check valve offers a decent layer of protection, but for real peace of mind, you need something more robust.

Double Check Valves: A Two-Tiered Defence

Just as the name implies, a Double Check Valve Assembly (DCVA) packs two of these spring-loaded check valves one after the other. It’s like having a two-tiered security system.

- First Line of Defence: The first check valve creates the initial block against any reverse flow.

- Second Line of Defence: Should that first valve ever fail—maybe it gets jammed open by a piece of debris—the second check valve is right there to act as a critical backup.

This built-in redundancy makes DCVAs far more reliable than a single check valve alone. You'll often find them used where the contamination risk is moderate but still a public health threat. The logic is simple: if one security door is breached, the second one is there to hold the line.

A backflow preventer is fundamentally a safety device that operates on pressure differentials. It doesn't require electricity or manual intervention; it reacts automatically to the physics of your water system to prevent contamination before it starts.

The Reduced Pressure Zone: A Clever Buffer

When you get to the highest-risk scenarios, you need the top-tier solution: a Reduced Pressure Zone (RPZ) valve. An RPZ takes the double-check-valve design and adds a truly ingenious safety measure—a reduced pressure zone nestled between the two check valves.

This middle chamber is kept at a lower pressure than the incoming water supply. Critically, it also has a relief valve that can open up and drain to the atmosphere.

Here’s how it delivers such superior protection:

- Normal Flow: Water passes through the first check valve, enters the reduced pressure zone, and then continues through the second check valve into your system.

- Backflow Condition: In the unlikely event that both check valves fail at the same time, the relief valve instantly opens.

- Draining Away Danger: Instead of letting contaminated water push through, the relief valve dumps it safely out of the system, usually onto the ground below.

This buffer zone is the ultimate failsafe. It guarantees that even in a worst-case scenario where both internal check valves are compromised, no backflow can get through. The relief valve essentially creates an emergency exit for any hazardous water. While these valves are critical for safety, other types of valves, such as those used in vacuum systems, operate on different principles. If you're interested in related technologies, our guide on the vacuum solenoid valve provides further insight into fluid control under negative pressure.

Exploring the Main Types of Backflow Preventers

Picking the right backflow preventer isn't a one-size-fits-all job. The device you need is dictated entirely by the level of risk you're dealing with. Here in the UK, we define this risk using a system of Fluid Categories. A harmless garden hose and a high-hazard industrial chemical line obviously require vastly different levels of protection.

It’s a bit like choosing a lock. You might use a simple latch for a bedroom door, but you’d want a robust, multi-point system for your front door. It’s the same principle: the more dangerous the potential contaminant, the more sophisticated the backflow preventer valve has to be.

Let's walk through the most common types you’ll come across, from basic protection to the high-security options.

Double Check Valve Assembly (DCVA)

The Double Check Valve Assembly, or DCVA, is your first proper step up from a simple, single check valve. It offers a solid layer of protection for low to medium-hazard situations, which fall under Fluid Categories 2 and 3.

As the name suggests, a DCVA contains two independently acting, spring-loaded check valves, one after the other. This setup creates built-in redundancy.

- First Check Valve: This is the primary wall of defence against any reverse flow.

- Second Check Valve: This one acts as a backup, ready to slam shut if the first valve fails to close properly, maybe because a bit of grit got stuck in it.

This two-stage defence makes the DCVA a go-to choice for applications like fire sprinkler systems (as long as they don't have chemical additives) and large-scale irrigation. It's great at stopping both backpressure and backsiphonage where the backflow would be a nuisance but not a direct toxic threat.

Pressure Vacuum Breaker (PVB)

Next up is the Pressure Vacuum Breaker (PVB), a specialist device designed for one job and one job only: protecting against backsiphonage. It’s important to know that it offers no protection against backpressure. Think of a PVB as a one-way guard that’s hyper-sensitive to any vacuum-like pull from the main supply.

A PVB has a check valve and an air inlet valve. If the water pressure suddenly drops in the supply line, that air inlet valve pops open. This lets air rush into the system, which breaks the vacuum and instantly stops any potentially dirty water from being sucked backwards.

A crucial detail for PVBs is that they must be installed higher than any downstream pipes or outlets they protect. This is why you'll often see them on raised pipes feeding lawn irrigation systems—a classic application for this type of valve.

Reduced Pressure Zone (RPZ) Valve

When the risk of contamination is severe and poses a direct threat to public health (Fluid Category 4), you need the best protection available. This is where the Reduced Pressure Zone (RPZ) valve comes in. It's the most secure and reliable mechanical backflow preventer on the market.

An RPZ takes the DCVA design and adds a critical third element: a differential pressure relief valve. This is housed in a central chamber known as the "reduced pressure zone."

This design creates a virtually failsafe system. If backpressure builds and the second check valve starts to leak, the relief valve will open and dump the water out to the atmosphere before it can even get near the first check valve. In a worst-case scenario where both check valves fail, that relief valve acts as the ultimate emergency exit, flushing the contaminated water out of the system entirely so it never reaches the clean supply.

This unmatched level of security is precisely why RPZ valves are a mandatory requirement in the UK for high-risk spots like commercial kitchens, hospitals, and industrial processing plants.

To help visualise how these valves stack up, the table below compares their key features, protection levels, and common applications here in the UK.

Comparison of Common Backflow Preventer Valve Types

| Valve Type | Protection Level | Mechanism Principle | Common UK Applications |

|---|---|---|---|

| Double Check Valve Assembly (DCVA) | Low to Medium Hazard (Fluid Category 2-3) | Two independent, spring-loaded check valves in series provide redundancy. | Fire sprinkler systems (without additives), large irrigation, internal building supplies. |

| Pressure Vacuum Breaker (PVB) | Backsiphonage ONLY | A check valve paired with an air inlet that opens on pressure drop to break the vacuum. | Lawn irrigation systems, hose bibbs, laboratory taps. |

| Reduced Pressure Zone (RPZ) Valve | High Hazard (Fluid Category 4) | Two check valves plus a central differential pressure relief valve for failsafe discharge. | Hospitals, chemical plants, commercial kitchens, mortuaries, industrial processing. |

As you can see, the choice of valve is directly linked to the specific risk it needs to mitigate, from nuisance protection with a DCVA to safeguarding public health with an RPZ.

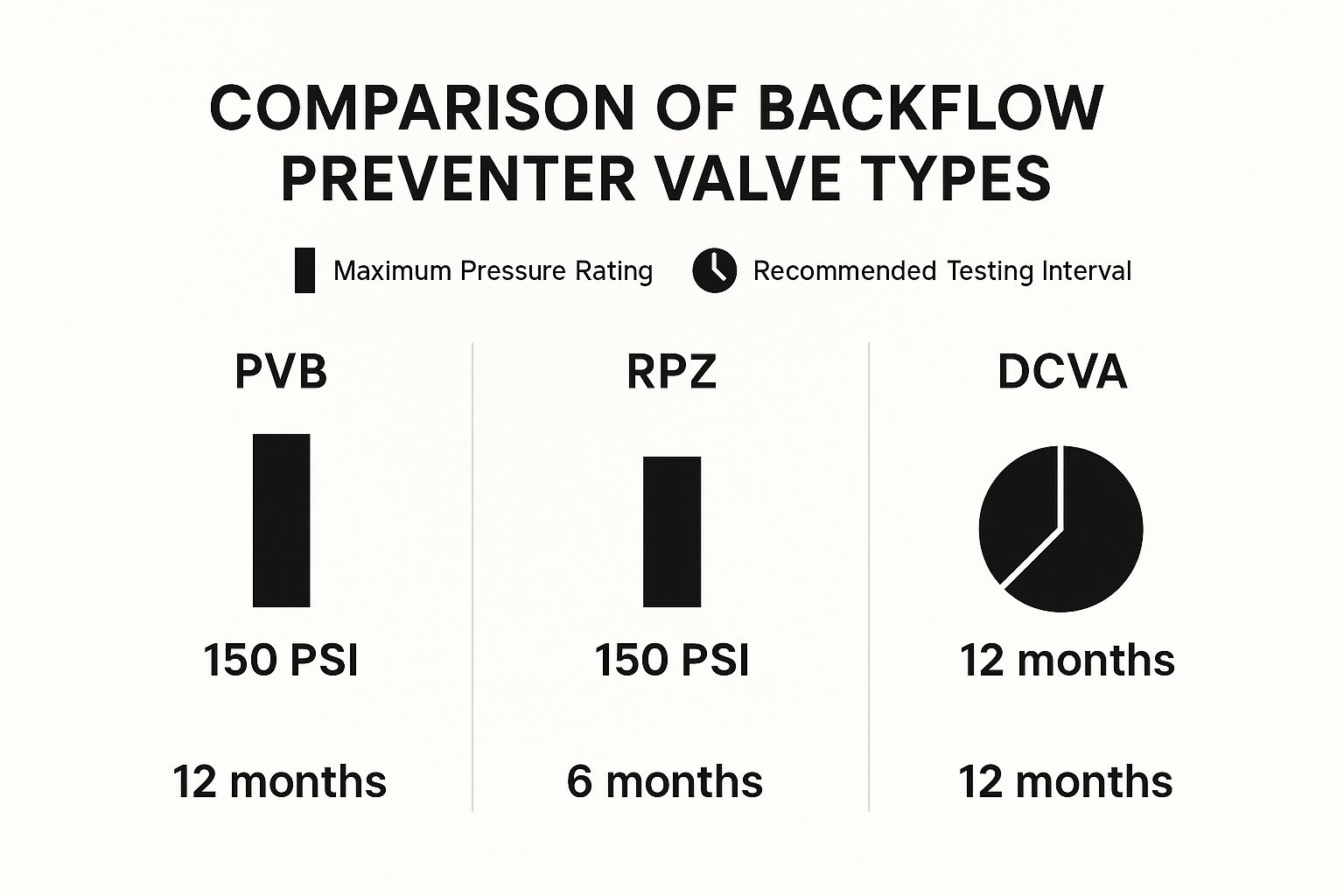

This infographic breaks down the typical pressure ratings and recommended testing intervals for these common valve types.

It clearly shows that while all three can handle significant pressure, the recommended testing frequency for an RPZ valve is much shorter. This reflects its critical role in high-hazard environments where failure is simply not an option.

Navigating UK Backflow Prevention Regulations

Making sure a backflow preventer valve is installed correctly isn’t just about good engineering practice; it's a legal necessity in the UK. The Water Supply (Water Fittings) Regulations 1999 are in place for one critical reason: to protect public health by keeping our drinking water supply completely free from contamination.

These regulations aren't optional guidelines. They're the law, and they place a direct responsibility on property owners, installers, and anyone managing a water system to prevent any chance of backflow. Getting to grips with these rules is crucial for staying compliant and avoiding some very serious penalties.

The entire regulatory framework is built around a risk classification system. Essentially, it assesses the danger posed by any liquid that could potentially find its way back into the public water supply. This system is known as the Fluid Categories.

Understanding the Five Fluid Categories

The regulations lay out five distinct Fluid Categories, with each one representing a greater level of risk to human health. The category that applies to your water system will dictate exactly what type of backflow prevention you are legally required to fit.

It’s a simple sliding scale of risk:

- Fluid Category 1: This is wholesome, clean water supplied directly by the water company. It’s perfectly safe to drink and poses no risk.

- Fluid Category 2: Still safe to drink, but its taste, smell, or colour might have been affected. A good example is water that has passed through a water softener or has been heated.

- Fluid Category 3: This category represents a slight health hazard. Think of water in a central heating circuit or from a domestic shower hose that could drop into bathwater.

- Fluid Category 4: Here the risk becomes significant. This fluid contains toxic substances that pose a substantial health hazard, such as water mixed with pesticides, industrial detergents, or certain chemicals.

- Fluid Category 5: The most serious risk. This category is for fluids containing pathogens or radioactive materials that present a very serious health hazard. You’d find this in places like mortuaries, abattoirs, and specialised medical or veterinary facilities.

For those in the food service industry, it's worth noting how these water safety rules fit into broader sanitation standards, like the NSF/ANSI Standard 2 for food equipment.

The Role of WRAS Approval

To make compliance a bit more straightforward, the Water Regulations Advisory Scheme (WRAS) tests and approves plumbing products. When a product is WRAS-approved, it means it has passed rigorous independent testing to confirm it meets the high standards of the regulations.

Key Takeaway: When you're choosing a backflow preventer or any water fitting, always check for the WRAS-approved mark. It's your guarantee that the product is fit for purpose in UK water systems and meets all safety and quality requirements.

Fitting non-approved parts isn't just a compliance risk; it could also void your insurance. For anyone involved with potable water systems, specifying components from a trusted range of WRAS-approved valves is a non-negotiable step for a safe and legal installation.

High-Risk Categories and RPZ Valves

The regulations are, quite rightly, strictest when dealing with high-risk applications. For any system classified as Fluid Category 4, UK law demands a specific type of backflow preventer valve: a Reduced Pressure Zone (RPZ) valve.

These devices are the gold standard for protecting public water from significant health risks. An RPZ valve creates a buffer zone of reduced pressure that physically prevents contaminated water from flowing backwards, offering fail-safe protection.

Because the stakes are so high, you can't just install one. You must notify your local water supplier before installation, and the work is governed by strict Approved Installation Methods (AIM). The valve itself must, of course, be WRAS-approved. This is a clear legal duty for property owners and their installers, reinforcing the need to use certified professionals and follow the correct procedures to the letter.

Installation and Maintenance Best Practices

A backflow preventer valve is only as good as its installation and maintenance. Fitting the device is just the start; its ongoing care is what guarantees it will work when you need it most. You can't just fit it and forget it—this is a crucial piece of safety kit that needs regular attention.

A backflow preventer valve is only as good as its installation and maintenance. Fitting the device is just the start; its ongoing care is what guarantees it will work when you need it most. You can't just fit it and forget it—this is a crucial piece of safety kit that needs regular attention.

If you skimp on either the fitting or the upkeep, even the most sophisticated valve is rendered useless. This creates a dangerous false sense of security, leaving your water supply wide open to contamination. Let's walk through a practical checklist for getting it right, from the initial setup to long-term care.

Key Installation Factors

Getting the installation spot-on from day one will save you a world of headaches and ensure you stay on the right side of the regulations. While different devices have specific needs, a few golden rules always apply.

- Correct Orientation: Every backflow preventer is designed to sit a certain way, usually horizontally. If you install it vertically or upside down, the internal check valves simply won't work correctly and will fail.

- Sufficient Clearance: The valve has to be accessible. A technician needs enough room to get their test gear hooked up, carry out repairs, and perform simple visual checks. Don't box it in.

- Freeze Protection: Here in the UK, a frozen valve is a broken valve. Freezing temperatures can easily crack the valve body, making it completely useless. If you're fitting a device outdoors or in an unheated space, it absolutely must be properly insulated or put inside a heated enclosure.

Proper fitting is a specialised job. For a more detailed guide on the process, you'll find everything you need in our guide to https://www.solenoid-valve.world/backflow-preventer-installation.

Creating a Simple Maintenance Plan

Once it's installed, your backflow preventer needs a regular maintenance schedule. This isn't just a friendly suggestion—for higher-risk devices in the UK, it's a legal requirement. A straightforward plan involves regular visual checks and, most importantly, professional testing.

The potential health and economic fallout from a backflow incident really hammers home why these devices are so vital for protecting UK water quality. Contamination can lead to expensive clean-ups and outbreaks of nasty waterborne diseases. This is why the UK water industry insists on verifiable protection, like RPZ valves. Modern innovations, such as integrated stop valves, are also making life easier by simplifying maintenance and avoiding building-wide shutdowns during servicing.

Regulatory Mandate: In the UK, any system protected by an RPZ valve (which covers Fluid Category 4 risks) must be formally tested by an accredited professional at least once a year. The successful test certificate must then be sent to your local water supplier to prove compliance.

The Importance of Professional Testing and Repair

While having a quick look yourself is a good habit, it can't tell you if the internal mechanics are functioning. Only a formal test with calibrated gauges can truly verify that the check valves are sealing tightly and the relief valve is ready to do its job.

This is why all testing and repairs must be handled by a certified technician. These professionals have the specific training and equipment to diagnose faults accurately and ensure any fix meets the strict standards. Trying a DIY repair on a high-risk device isn't just a bad idea—it's illegal and can land you with serious penalties.

Of course, beyond the valve itself, good general plumbing health is key. Having resources for troubleshooting common plumbing issues is always a bonus for property managers. At the end of the day, investing in professional upkeep for your backflow preventer is a direct investment in safety, compliance, and public health.

Common Backflow Preventer Questions Answered

Even when you've got a good grasp of the theory, the practical side of backflow preventer valves always throws up a few questions. We often hear from property owners and site managers who are trying to navigate the specifics of compliance, safety, and what to do when things look like they might be going wrong.

Here are the answers to some of the most common questions we get, designed to give you the confidence to make the right call.

How Do I Know If I Need a Backflow Preventer Valve?

The short answer is, you almost certainly need one if your property has any point where non-potable (non-drinkable) water could mix with the clean mains supply.

In the UK, it’s a non-negotiable requirement for virtually all commercial and industrial sites where the risks are naturally higher.

For domestic properties, a backflow preventer is usually needed for specific systems like garden irrigation, swimming pools, or homes using a private well. The golden rule is to consider any potential for a cross-connection to introduce contaminants. While your local water supplier can carry out a formal risk assessment, your best first step is to speak with a WRAS-approved plumber. They can tell you exactly what you need to comply with the Water Supply Regulations.

How Often Must a Backflow Preventer Be Tested?

In the UK, the testing schedule is all about the level of risk. For high-risk scenarios, like those in many commercial and industrial settings using a Reduced Pressure Zone (RPZ) valve, the rules are very strict.

For these high-risk RPZ installations, annual testing by an accredited tester is a legal requirement. The test results must be properly logged and sent to your local water supplier.

For devices protecting against lower risks, such as double check valves, there may not be the same strict annual mandate. However, getting them professionally checked regularly is still a very smart move. A faulty valve is no better than having no valve at all, and failing to test and report can lead to enforcement action from the water authority.

Can I Install a Backflow Preventer Myself?

For almost every situation, and especially for any system classed as medium or high-risk, the answer is a firm "no".

Installing critical safety devices like RPZ valves in the UK is a regulated job. It must be carried out by an accredited, WRAS-approved professional. These installers have the specialist training needed to fit the valve perfectly according to strict standards, making sure it works as intended and is accessible for future testing.

An improper installation doesn't just fail to protect your water supply; it also voids the device's function, creates a public health risk, and can land the property owner with serious legal and financial trouble. For safety and compliance, always bring in a certified professional.

What Are the Warning Signs of a Failing Valve?

Knowing what to look for can help you catch a small problem before it spirals into a major incident. Keep an eye out for these tell-tale signs:

- Continuous Dripping or Discharge: This is the most obvious red flag. A constant or regular drip from the relief valve port means the internal pressure is off and the valve isn't sealing properly.

- Visible Leaks: Any water weeping from the valve body, its seals, or where it connects to the pipework needs immediate attention.

- Changes in Water Quality: If your water looks discoloured or has an unusual taste or smell, it could be a serious warning of an active backflow event.

- Sudden Pressure Drop: A significant and unexpected drop in water pressure across the property can sometimes be traced back to a faulty backflow device.

While these signs are useful, many internal faults are completely silent. They can only be found during a proper test using calibrated equipment. This is precisely why routine professional testing is so important—it finds the hidden dangers before a contamination can happen.

At Solenoid Valve World, we provide a comprehensive range of WRAS-approved backflow prevention devices and expert support to ensure your system is safe, compliant, and reliable. Explore our selection of valves today at https://solenoid-valve.world to find the right solution for your application.