Butterfly Valve vs Ball Valve: The UK Engineer's Guide

Understanding What Really Separates These Valve Types

This image illustrates the straightforward design of a butterfly valve. Its disc, situated directly in the flow path, rotates to modulate media flow. This simplicity results in a compact, lightweight valve, ideal when space is at a premium.

While both butterfly and ball valves share the same quarter-turn operation, their internal mechanisms and performance characteristics differ substantially. Focusing solely on this shared action can be misleading. Simply put, comparing only the "open" and "closed" positions doesn't provide a complete understanding.

Disc Position and Flow Turbulence

The interaction of the disc (or ball) with the flow is a crucial distinction. Even when fully open, a butterfly valve's disc remains within the flow path. This inherent obstruction generates turbulence and a higher pressure drop compared to a fully open ball valve, where the ball is entirely removed from the flow. In a water management system, for instance, this increased pressure drop translates to higher energy consumption to maintain the desired flow.

The image above visually demonstrates this principle – even in the open position, the disc partially obstructs the flow. For a deeper dive into butterfly valve specifics, explore further details here.

Seat Material: The Unsung Hero

Another critical, often overlooked, element is the seat material. The seat, the interface between the disc/ball and the valve body, is vital for a tight seal, preventing leaks and influencing valve lifespan. In harsh environments, such as those encountered in UK chemical processing, seat material selection is paramount.

A standard EPDM seat, suitable for water, deteriorates rapidly when exposed to certain hydrocarbons. In such cases, a more resilient material like PTFE or FKM is essential, despite potentially higher upfront costs. This underscores the importance of considering long-term operational expenses over initial purchase price.

Torque Requirements and Maintenance

Operational torque is another key factor influencing maintenance. Butterfly valves typically require less torque, especially in larger sizes, but this can vary significantly with disc position. Peak torque often occurs near the closed position, precisely when the valve is working hardest against the flow. Understanding this variability is crucial for proper actuator sizing and preventing premature wear. Conversely, ball valves exhibit more consistent torque across their operational range, simplifying actuator selection and minimizing maintenance in automated systems.

Performance Under Pressure

Design differences also impact performance under high-pressure conditions. Ball valves, with their robust construction and fully enclosed ball, are generally better suited for high-pressure applications, like oil and gas pipelines. The spherical ball effectively withstands high forces. Butterfly valves, due to the disc's exposure to flow and potential deflection, are typically limited to lower pressures. While high-performance butterfly valves are available, they often incorporate specialized design features and come at a higher cost, emphasizing the need for careful selection based on operational requirements. These subtle yet significant differences can dramatically affect valve longevity and overall system reliability.

Where Each Valve Type Dominates UK Industry

Choosing between butterfly and ball valves in the UK isn't a simple matter of checking a generic chart. Practical application often trumps theory. Operational priorities heavily influence the final decision.

For instance, organizations like Thames Water, responsible for extensive water networks, prioritize cost-effectiveness and straightforward maintenance. This naturally leads them towards butterfly valves for large diameter pipelines. The lower torque requirements of butterfly valves translate to smaller, less expensive actuators and reduced maintenance costs.

However, consider the harsh conditions of North Sea oil and gas platforms. Here, reliability under extreme pressure and temperature trumps cost. The rugged build and tight shut-off of ball valves become crucial, even with a higher upfront investment. The cost of a potential valve failure in such critical applications dwarfs any initial savings.

Supply chain resilience has also become a key factor, particularly in the post-Brexit landscape. UK manufacturers now prioritize readily available spares and local maintenance expertise. This practicality can sway decisions towards valve types with strong local support, even if it means deviating from traditional choices. Long-term maintainability has become as important as the initial purchase price. You might be interested in: high-pressure solenoid valves.

Emerging Applications and Shifting Preferences

Interestingly, some sectors are bucking the trend. The increasing focus on energy efficiency in UK manufacturing has prompted a reassessment of butterfly valves for specific low-pressure applications. Their lower pressure drop, even when partially open, can lead to significant energy savings over time, potentially offsetting the higher initial cost compared to a ball valve. Driven by this emphasis on efficiency, the UK industrial valves market (encompassing both butterfly and ball valves) is predicted to exceed USD 3 billion by 2028. Discover more insights into the UK industrial valve market.

Furthermore, emerging fields like hydrogen transport and carbon capture present entirely new challenges. These applications demand valves that can handle extreme temperatures and pressures, potentially disrupting the traditional dominance of ball valves in high-performance scenarios. The development of advanced butterfly valve designs, using innovative materials and sealing technologies, adds another layer of complexity to the selection process. It highlights the dynamic nature of valve technology in the UK.

To understand how these factors play out across different UK industries, let's examine the table below:

| Industry Sector | Primary Valve Choice | Key Drivers | Typical Pressure Range |

|---|---|---|---|

| Water Management | Butterfly | Cost-effectiveness, ease of maintenance | Low to Medium |

| Oil & Gas | Ball | Reliability, tight shut-off | High |

| Chemical Processing | Ball | Chemical compatibility, leak tightness | Medium to High |

| Power Generation | Butterfly/Ball | Application specific, varies widely | Low to High |

| Food & Beverage | Butterfly | Hygienic design, ease of cleaning | Low |

The table above illustrates how valve selection is influenced by the specific needs of each industry. While water management prioritizes cost and maintenance, oil and gas favors reliability under extreme conditions. Chemical processing demands chemical compatibility, while power generation uses a mix depending on the specific application. The hygienic requirements of food and beverage processing often lead to butterfly valves.

Clearly, choosing between butterfly and ball valves requires careful consideration of operational needs, lifecycle costs, and long-term maintenance. A thorough evaluation of these factors is essential for navigating the evolving industrial landscape in the UK.

When System Reliability Cannot Be Compromised

Critical applications truly push valve designs to their limits. This section compares butterfly and ball valves in demanding environments where failure isn't an option—think North Sea oil platforms, chemical processing plants, or power stations.

High-Stakes Environments: Where Reliability Matters Most

Imagine the brutal conditions on a North Sea oil platform: constant saltwater exposure, fluctuating temperatures, and extreme pressures. These conditions demand exceptionally reliable valves. Here, the robust design of ball valves often shines. Their fully enclosed ball and robust seat create a tight seal, minimizing leak risk even with significant pressure fluctuations.

However, in specific lower-pressure areas of these platforms, strategically placed butterfly valves offer distinct advantages. Their compact design and lighter weight simplify installation and maintenance in cramped offshore spaces. Choosing the right valve becomes a strategic balancing act: reliability versus practicality.

Maintenance Realities in Demanding Applications

Maintenance reveals further differences. In chemical processing, where media compatibility is paramount, butterfly valves often require more frequent seat replacements. The disc's constant exposure to corrosive substances takes its toll. This increased maintenance translates to higher downtime and costs.

Ball valves, with their internal ball and seat protected from direct media contact, boast a longer service life in these harsh chemical environments. This means fewer maintenance interventions and less operational disruption, making long-term cost a key factor in valve selection.

Temperature Cycling and Pressure Surges: Unveiling Design Strengths and Weaknesses

Temperature cycling, common in power generation, stresses valve components. Butterfly valves, with their exposed disc, can be susceptible to warping or distortion under extreme temperature swings, compromising the seal and potentially leading to catastrophic failures in high-temperature steam lines.

Ball valves, with their encased ball and robust seat, typically handle temperature cycling more effectively. Their consistent performance under thermal stress enhances system reliability in critical power generation applications.

Similarly, pressure surges, prevalent in many industrial processes, expose another aspect of valve performance. Butterfly valves, being lighter, may experience greater stress during pressure spikes, leading to accelerated wear and premature failure. For insights on the European butterfly valve market and its growth, explore European market trends here.

Ball valves, inherently stronger due to their enclosed spherical design, are better equipped to handle pressure surges without significant damage. This resilience translates into greater reliability in systems prone to pressure fluctuations.

To summarize the key performance differences, let's examine the following table:

Performance Comparison: Critical Service Parameters

Head-to-head comparison of butterfly and ball valve performance metrics

| Parameter | Butterfly Valve | Ball Valve | Impact on Selection |

|---|---|---|---|

| Leak Tightness | Good in lower pressure applications, can be compromised in high-pressure or high-temperature environments | Excellent, even under high pressure and temperature fluctuations | Crucial for applications with stringent leak requirements |

| Maintenance | Higher in corrosive environments due to exposed disc | Lower due to protected internal components | Significant factor in overall cost of ownership |

| Temperature Cycling Resistance | Lower, susceptible to warping or distortion | Higher, more robust design withstands temperature fluctuations | Essential in power generation and other high-temperature applications |

| Pressure Surge Resilience | Lower, higher stress on lighter components | Higher, robust design absorbs pressure spikes | Critical for systems prone to pressure fluctuations |

| Size and Weight | Smaller and lighter | Larger and heavier | Influences installation and handling in confined spaces |

| Cost | Generally lower initial cost | Generally higher initial cost | Balanced against long-term maintenance and reliability considerations |

The table highlights the strengths and weaknesses of each valve type concerning critical service parameters. As you can see, the choice between a butterfly and a ball valve often depends on the specific application and its unique demands, especially in environments where reliability is paramount.

The Real Economics: Beyond Purchase Price

This image provides a glimpse inside a ball valve. Notice the robust ball and seat mechanism. This enclosed design is a key factor in its durability and suitability for high-pressure applications. This sturdy construction often translates to lower maintenance needs compared to a butterfly valve.

While the initial price tag of a valve matters, the real cost reveals itself over its entire lifespan. For facilities in the UK, this lifecycle cost includes installation, energy use, and ongoing maintenance. What initially seems like the cheaper choice can often lead to higher expenses in the long run.

Installation Complexity: Labour Costs Add Up

Installation complexity significantly impacts the total cost. Butterfly valves, typically lighter and smaller, are usually faster to install, requiring less specialized labour. This results in lower installation costs, especially in intricate piping systems.

Ball valves, often heavier and larger, sometimes need more involved installation procedures. These may require specialized tools and skilled workers, particularly for larger sizes. In tight spaces or areas with difficult access – common in UK facilities – this added complexity can significantly increase installation costs.

Energy Consumption: The Hidden Cost of Pressure Drop

Energy consumption is a recurring operational cost directly affected by valve design. Even when fully open, butterfly valves inherently restrict flow because of the disc positioned within the flow path. This creates a higher pressure drop, meaning more energy is needed to maintain the required flow rate. Over time, this adds up, especially in systems that run continuously, like those found in many UK water management and processing plants.

On the other hand, ball valves, with their completely unobstructed flow path when open, minimize pressure drop. This translates to lower energy consumption and lower operational costs throughout the valve's life. These long-term energy savings can often balance out the higher initial cost of a ball valve.

Maintenance Frequency: Downtime Impacts the Bottom Line

Maintenance frequency is another crucial factor in long-term cost considerations. The exposed disc in a butterfly valve is vulnerable to wear and tear, particularly in harsh environments. This often leads to more frequent maintenance and part replacements, which means increased downtime, lost production, and higher maintenance expenses.

Ball valves, with their protected internal components, usually require less frequent maintenance. The robust construction and enclosed design contribute to a longer operational life, minimizing downtime and reducing the cost of replacement parts and labour. This lower maintenance frequency can be a real advantage, particularly in critical applications where unexpected downtime is costly.

Practical Cost Frameworks: Beyond the Sticker Price

Procurement managers in the UK are increasingly focusing on total cost of ownership. A clearer cost picture emerges by assessing installation complexity, energy efficiency, and predicted maintenance needs. This comprehensive approach to valve selection considers the long-term financial implications, enabling UK facilities to make smart investments and improve operational efficiency. Considering these long-term costs leads to better decisions that meet budget requirements and performance goals.

Making Confident Valve Selection Decisions

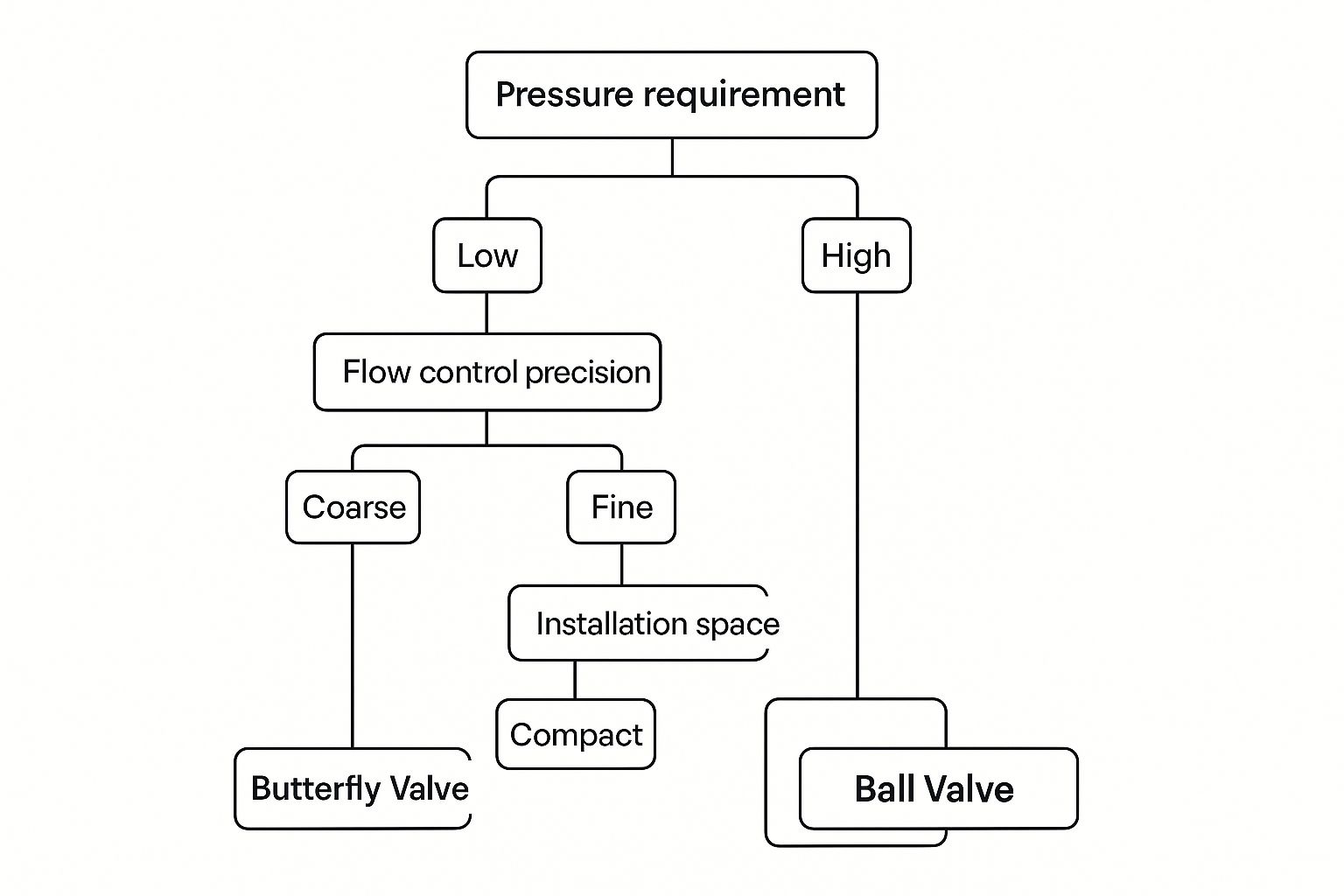

This infographic offers a quick visual guide for choosing between butterfly and ball valves. It considers key factors like pressure, flow control needs, and space limitations. Following the branches helps narrow down the best valve type. For instance, a ball valve is suggested for precise flow control in a spacious environment, while a butterfly valve might be better for coarse control in tight quarters.

However, real-world valve selection is more nuanced than a simple chart. It often involves juggling competing priorities. Experienced UK engineers regularly grapple with tough decisions: compact size versus easy maintenance, efficient flow versus tight shut-off, and low upfront cost versus long-term reliability.

Navigating Competing Priorities in Valve Selection

Space is a premium in many UK facilities. Butterfly valves offer a compact footprint, but their in-line maintenance can disrupt operations. Ball valves, although larger, often simplify maintenance with less system downtime thanks to their two-piece body design. This underscores the importance of considering long-term maintenance access, not just the initial installation space. For a deeper dive into valve selection best practices, check out our selection guide.

Flow efficiency is another critical factor. Ball valves minimize pressure drop when fully open, maximizing flow. Butterfly valves, even fully open, introduce some flow restriction. This can increase energy costs over time, especially in systems with continuous flow. However, for applications requiring throttling or modulating flow, the superior control of a ball valve often makes it the preferred choice, even with a higher initial investment.

Justifying Valve Decisions to Stakeholders

Justifying valve choices to stakeholders often requires a strong economic argument. Butterfly valves typically have a lower upfront purchase price. However, long-term costs like higher energy consumption and potentially more frequent maintenance can tip the scales in favor of ball valves. Clearly presenting these lifecycle costs is crucial when discussing valve selection with budget-conscious stakeholders.

Future-Proofing Your Valve Selection

Forward-thinking engineers also consider future system changes and evolving regulations. A valve chosen solely for today's needs could become a limitation tomorrow. Anticipating potential system expansions, changes in the process media, or stricter environmental rules can influence the decision toward a more versatile and robust valve, even at a higher initial cost. This proactive approach prevents expensive valve replacements down the line. Choosing between a butterfly valve vs ball valve demands careful evaluation of multiple factors.

Implementation That Delivers Expected Performance

Choosing between a butterfly valve and a ball valve is just the first step. Even the perfect valve can underperform, or even fail, if implemented poorly. This includes everything from the initial specifications and installation to ongoing operational practices. Let's explore common pitfalls and best practices for successful valve implementation.

Specification Errors: Avoiding Costly Mistakes

When selecting a valve, consider every factor, including the platform or system it will be integrated with. For example, if you're working with an e-commerce setup, the Pros and Cons of Shopify might influence your valve choice, particularly if integration is a major concern. A common mistake is oversimplifying valve specifications. Focusing only on the nominal pressure rating without considering pressure spikes or temperature fluctuations can lead to premature failure. Similarly, neglecting actuator sizing based on the valve's peak torque requirements can cause operational issues and increased wear.

Installation Mistakes That Compromise Performance

Proper installation is critical. Misaligned pipework, incorrect flange bolting torque, and inadequate pipe support can stress valve components and shorten their lifespan. For butterfly valves, improper centering of the disc within the pipe can cause uneven wear and leakage. With ball valves, poor alignment of the ball within its seats can lead to sealing issues and premature wear.

Operational Practices: Maximising Valve Lifespan

How you operate your valves has a significant impact on their performance. Rapid cycling of a butterfly valve, especially near the closed position where torque is highest, accelerates wear. For ball valves, frequent throttling (using the valve in a partially open position) can damage the ball and seat, increasing the risk of leaks. Regular inspection and planned maintenance are essential to catch potential problems early.

Actuator Sizing: More Important Than You Think

Proper actuator sizing is crucial for reliable valve operation. Undersized actuators might not be able to overcome valve torque, especially when closing against high pressure. Oversized actuators can apply excessive force, damaging the valve. Carefully consider the valve's torque requirements, including variations due to pressure and temperature.

Warning Signs: Spotting Potential Issues Early

Proactive maintenance relies on recognizing potential problems. Unusual noise during operation, increased vibration, or difficulty achieving a tight shut-off can indicate emerging issues. Regularly monitoring valve performance metrics, such as pressure drop and actuator current draw, can provide early warning signs, allowing for timely intervention. By focusing on these key implementation aspects, facilities can ensure their chosen butterfly or ball valve delivers the expected performance and reliability.

Your Path To The Right Valve Choice

Choosing between a butterfly valve and a ball valve goes beyond simply comparing specifications. It's about understanding how each valve performs under real-world conditions and aligning that performance with your project's specific needs. This guide distills years of practical engineering experience into actionable advice for UK applications.

Key Decision Criteria: Matching Valves to UK Applications

For UK water management projects, the butterfly valve often presents an attractive initial option. Its compact design and lower cost, coupled with lower torque requirements (meaning smaller, cheaper actuators), can be particularly appealing for large diameter pipelines where budget is a primary driver. However, it's important to consider the inherent pressure drop caused by the disc within the flow path. This can lead to increased energy consumption over time, especially in systems that operate continuously.

The ball valve, while carrying a higher upfront cost, frequently offers a better long-term return on investment. Its unobstructed flow path minimizes energy loss, and its typically robust construction translates to less frequent maintenance. This is especially valuable in critical applications, like offshore platforms in the North Sea, where downtime carries a significant financial penalty.

Implementation Steps: Ensuring Long-Term Performance

Successful valve implementation hinges on thorough planning. Accurately mapping pressure and temperature profiles is crucial. Don't rely solely on nominal ratings; consider potential pressure spikes and temperature fluctuations that can stress the valve. This is particularly relevant in the demanding environmental conditions often encountered in UK projects.

Actuator sizing is another critical, yet often overlooked, aspect. An undersized actuator may struggle to operate the valve effectively, while an oversized one can cause damage. Carefully match the actuator to the valve's torque requirements, accounting for variations caused by pressure and temperature changes.

Performance Benchmarks: Measuring Success

Monitoring valve performance is essential for identifying potential problems early. Track key metrics like pressure drop across the valve and actuator current draw. Any deviations from expected values can signal developing issues such as wear or blockage. Early detection prevents costly failures and ensures your chosen valve performs as expected throughout its lifespan.

For a comprehensive range of solenoid valves, actuated ball valves, and other fluid control equipment tailored for UK applications, visit Solenoid Valve World. We provide expert technical support and a wide selection to meet your specific needs, from WRAS-approved water systems to ATEX-certified gas valves.