Solenoid Valve Coils – AC/DC Replacement Coils for Industrial and Commercial Use

Premium Solenoid Valve Coils – Versatile, Reliable & Ready to Ship

At Solenoid-Valve.World, we supply a complete range of replacement solenoid valve coils compatible with our own valves and many popular brands. Whether you're replacing a worn coil or building a new system, we provide high-performance AC and DC coils that ensure precise actuation and long-term reliability.

Key Features of Our Solenoid Coils

AC & DC Voltage Options: 6V, 12V, 24V, 110V, 230V, 380V AC/DC

DIN & Flying Lead Connections

In Stock & Ready to Ship

High Temperature & IP65-IP68 Rated Coils Available

Strong Electromagnetic Force for Consistent Valve Operation

Overheat and Short-Circuit Resistant Design

Our coils are engineered to deliver optimal performance under continuous use, even in demanding industrial environments.

Find the Right Coil by Voltage and Size

AC Coils

Commonly used in systems with a steady power supply

Ideal for continuous-duty solenoid valves

Available in 12V, 24V, 110V and 230V 50-60Hz

DC Coils

Suited for battery-powered or low-voltage systems

Offer quieter and more energy-efficient operation

Options: 3V, 6V, 12V and 24V DC

Connector Types

DIN 43650-A/B/C – The industry standard for fast, secure connections

Flying Lead – Ideal for custom or waterproof set ups.

View and buy our range of electrical DIN connectors online.

Not sure which coil you need? Contact our technical team for help to match the right coil based on your valve model and specs.

Common Applications

Solenoid valve coils are a critical component in systems across many sectors:

HVAC systems

Compressed air and pneumatic tools

Water treatment and irrigation

Gas safety systems

Industrial automation and machine control

Whether you're maintaining existing equipment or building new systems, our coils ensure fast, precise valve actuation every time.

Tips for Selecting the Right Solenoid Coil

1. Check the voltage rating (AC or DC)

2. Confirm connector type (DIN or leads)

3. Match size and power with valve specs

4. Use only certified replacements for safety and performance

Fast Shipping, Expert Support

We ship solenoid coils throughout Europe and internationally, with most models in stock for same-day dispatch. Our support team is ready to assist you with technical queries, compatibility questions, or custom coil needs.

Browse & Order Solenoid Valve Coils Now

Don’t risk downtime with worn-out or incompatible coils. Order genuine solenoid coils that meet performance and safety standards.

Commonly used solenoid coils.

What is a solenoid coil?

A solenoid valve coil is designed to convert electrical energy into lateral motion. The coil usually consists of copper wire wound around a hollow bobine or tube, so when electric current flows through the coil, a magnetic field is generated. By placing a solenoid valve coil over a ferromagnetic core (usually magnetic 430F stainless steel armature) the magnetic field generated causes the plunger to slide further up towards the magnetic field (into the coil) thus allowing an opening to be created. This in turn can be utilised to either to control direct acting solenoid valves, Assisted Lift Solenoid Valves or Servo/ Pressure Assisted solenoid valves.

Solenoid valve coils come in a huge range of sizes, voltages, IP protection levels, temperature ratings and power levels.

Care needs to be taken when replacing solenoid valve coils because all these factors must be considered.

Solenoid Coil Sizing.

When measuring a coil, you need to measure accurately the internal diameter of the coil (as above). Some solenoid coils may be fitted with a top plate with a reduced diameter to aid secure fitment to the armature / core tube. Then the depth of the internal core needs to be measured. If this matches up, you are at the first step of finding the right coil. Helpful hint - when buying solenoid valve coils, try to replace according to brand.

Solenoid Coil Voltages.

Coils are manufactured for specific voltages, it is very rare that a coil will work on more than 1 voltage, whether it be AC or DC. There are some instances of "Dual voltage coils" which can work on for example 12vDC and 24vAC, 48vDC and 24vAC or even 110vDC and 230vAC but these are quite rare and this cannot be relied on to overcome spares shortfalls.

Helpful hint - check your supply voltage rather than guessing or trying to read the coil voltage.

Solenoid Coil Temperature Ratings.

Coil winding's have several temperature classes and are usually designed depending on the media, ambient temperatures and duty cycle (duty cycle being the power on time and power off cool downtime) as all coils generate heat when energised a bit like a light bulb the more power they consume the hotter they will get.

Standard coils are available for insulation classes E, F and H. The insulation class determines the coil maximum operating temperature for a specific life expectancy.

Class H: 30 000 hours-Class F: 20 000 hours

Class F coils are rated to 155°C, basically the copper wire windings can withstand a working temperature up to but not exceeding 155°C. These are the most common form of solenoid coil used in the pneumatic industry and are ideally suited to working ambient temperatures up to 20°C and media up to 100°C.

Class H coils are rated to 180°C, basically the copper wire windings can withstand a working temperature up to but not exceeding 180°C. These are the most common form of solenoid coil for higher temperature applications such as steam or hot oil with working ambient temperatures up to 50°C and media up to 180°C.

Class N coils are rated to 200°C, basically the copper wire windings can withstand a working temperature up to but not exceeding 200°C. These are the most common form of solenoid coil for extreme applications such as super heated steam and ambient temperatures up to 80°C and media up to 200°C.

Helpful hint - replace brand like for like if experiencing short solenoid coil life, check supply voltage and application temperature parameters and make sure none of the internals where the coil sits are stuck or contaminated.

Power Levels for solenoid coils

Solenoid coils come in a range of power levels, DC coils are measured in Watts, AC coils measured in VA (Volt Amps) and will have a higher Inrush current and lower Holding Current. It is a bit like weight lifting, lifting a weight requires more energy than holding it up with arms locked.

Helpful hint Watts = Volts x Amps.

You need to pay attention to the power ratings, underrated coils will over load and burn out and too higher power rating may well do the same.

Helpful hint - try to stay with the same power level unless the coil fails quickly then check voltage supply and current availability then if need be consult your supplier.

Why do solenoid coils burn out?

Solenoid coils are designed to convert electrical energy into mechanical movement by means of a magnet field, which means as they consume power like a light bulb for example they will become hot, and the higher the wattage or power consumption or the longer they are switched ON the hotter they can become.

If the coil becomes too hot or above its temperature rating (copper winding class rating) the copper or insulating material can fail to short circuit.

Other reasons include high media or ambient temperatures preventing the coil from cooling sufficiently, water ingress between armature and coil or if the coil is removed whilst energised!!

Why does a coil get burnt when removed from valve?

This is because with AC 50/60Hz coils you are reducing the impedance or resistance of the coil, as the shading ring within the armature or stem generates resistance within the coil. By removing the coil whilst powered the resistance is reduced thus the power consumption can easily increase above the coil winding class limits causing over heating.

Solenoid Coil Duty Rating.

Duty rating (duty cycle being the power on time and power off cool down time).

The duty cycle of a solenoid coil is expressed as a percentage of the coil power off time (cooling time) divided by the time powered ON + time power off (cooling) x 100 to give a percentage.

Duty Cycle = Time OFF / (Time ON + Time Off) x 100

Example: Coil powered ON for 15 seconds and then switched / powered OFF (cooling time) for 45 seconds before powered ON again then the cycle time is calculated as:- Duty cycle = 45 seconds / (15 ON + 45 OFF) x100 Duty Cycle = 45 / 60 x 100 Duty Cycle = 75%

Example: Power ON 2 minutes then power off 2 Minutes. Duty Cycle = 2 / (2+2) x 100 Duty Cycle = 50%

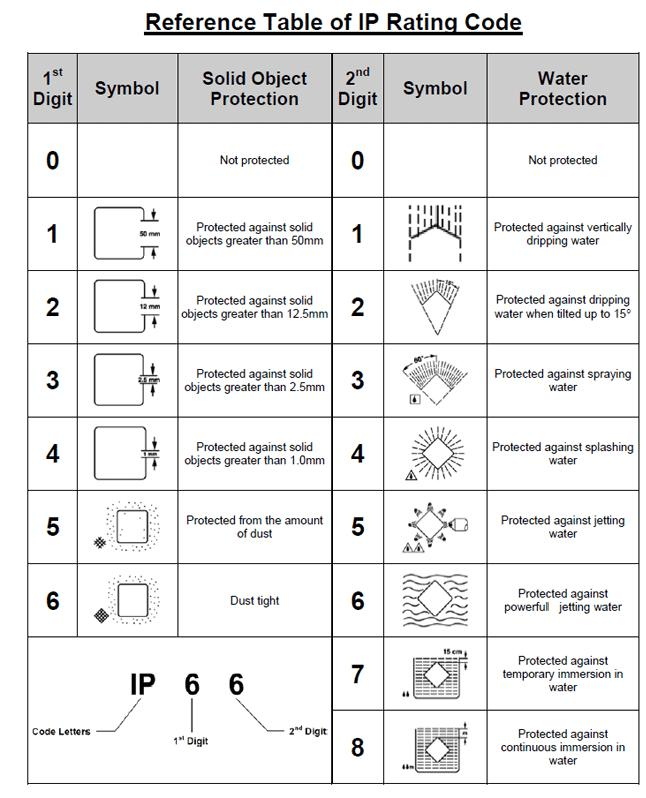

Solenoid Coil IP Protection Levels

Solenoid coils come with a wide range of IP (Ingress Protection) ratings according to general protection and Dust and Water Ingress. Please find below a basic IP Protection chart.