A Guide to Compressed Air Leak Detection

Compressed air leak detection is simply the process of finding and pinpointing where your system is unintentionally losing air. These leaks are a huge source of wasted energy and money. They quietly drain a company’s profits by forcing compressors to work much harder than they need to.

The True Cost of Invisible Air Leaks

In many UK industrial plants, compressed air is basically the "fourth utility"—it’s just as vital as electricity, water, and gas. The problem is, it's often the single biggest source of unmanaged energy waste. That quiet hiss from a tiny leak might not seem like a big deal, but when you have dozens of them across a facility, they add up to a serious financial drain.

This constant loss means your compressors have to run longer and more often. This not only pushes your electricity bills through the roof but also increases your company’s carbon footprint. It’s a silent, invisible cost that chips away at your bottom line, day in and day out.

The Financial Drain of Air Leaks

Think about it like leaving a tap running. Except instead of water, you’re just pouring money into thin air. The financial hit is almost always much bigger than managers realise.

Believe it or not, industry estimates suggest that as much as 30% of all compressed air generated in the UK is lost through leaks. That’s a staggering figure, translating into millions of pounds in wasted electricity across the country every single year.

The Carbon Trust has pointed out that a single, tiny 3mm hole in a compressed air line can cost a business an extra £1,000 per year in electricity alone.

Most industrial sites in the UK are running with leakage rates over 20%, usually because of old pipework, poorly kept fittings, or bad connections. The problem doesn't get fixed because you can't hear these leaks over the normal noise of the plant floor.

Beyond Energy Costs: The Wider Impact

The fallout from air leaks goes well beyond high energy bills. This constant, unnecessary demand puts a huge strain on your core equipment. Everything from filters and regulators to dryers has to work harder. You can learn more about how these parts work in our detailed guide on essential compressed air equipment.

Here’s how leaks can hurt your operations beyond your electricity bill:

- Increased Wear and Tear: Your compressors and all the related components work overtime to make up for the pressure loss. This leads to more frequent breakdowns and a shorter operational lifespan for your equipment.

- Reduced Equipment Efficiency: Tools and machines that need compressed air might get inconsistent pressure. This can cause poor performance, problems with product quality, and even production delays.

- Higher Maintenance Bills: The accelerated wear on your system naturally leads to more frequent and expensive repairs. It's a vicious cycle of fixing components that are only failing because they're being overworked by leaks.

By changing how you look at it, you can stop seeing leaks as just a cost of doing business. A proactive compressed air leak detection programme isn't an expense—it's an investment. It turns a major liability into a real opportunity for efficiency gains and a tangible return.

Choosing Your Leak Detection Tools

Before you can start plugging those costly air leaks, you've got to have the right kit for the job. Finding where all that expensive compressed air is escaping isn't a guessing game—it requires moving beyond old-school methods and grabbing the tech built for today's busy industrial sites.

For years, the go-to method was spraying soapy water on joints and fittings and looking for bubbles. It's simple and cheap, sure, but it's just not practical for a full-system survey. It's messy, painfully slow, and totally useless for any leaks you can't easily reach or in spots where spraying liquids is a non-starter.

Embracing Ultrasonic Leak Detection

This is where ultrasonic leak detection comes in. Honestly, this technology is a complete game-changer. It doesn't rely on you seeing bubbles or hearing a hiss over the factory noise. Instead, it "listens" for the high-frequency sound—the ultrasound—that's created when pressurised air escapes through a small opening.

Even a tiny pinhole leak creates a distinct ultrasonic signature. A good detector can pick this out from the general clatter of a production floor, meaning you can hunt for leaks during normal working hours. That’s a massive advantage because you find the leaks as they happen, under real-world operating pressures. You can see the kinds of components that are often the culprits in our deep dive into pneumatics.

Here's the best part: modern ultrasonic detectors don't just find leaks; they can quantify them. By estimating the flow rate, the device helps you calculate the annual cost of that one specific leak. Suddenly, a routine maintenance task becomes a powerful tool for slashing your operating costs.

To help you decide which approach is best for your facility, here’s a quick comparison of the common methods available.

Comparison of Air Leak Detection Methods

| Method | Effectiveness | Environment | Cost | Best For |

|---|---|---|---|---|

| Soapy Water | Low | Quiet areas only. Impractical for large systems or hard-to-reach spots. | Very Low | Spot-checking a single, easily accessible fitting. Not for system-wide audits. |

| Audible Listening | Low | Only works in very quiet environments for large, obvious leaks. | Very Low | A last resort when no other tools are available. Extremely unreliable. |

| Ultrasonic Detection | High | Excellent. Works in noisy, active industrial settings without production downtime. | Medium to High (initial investment) | The industry standard. Finding and quantifying all leaks, large and small, across an entire facility. |

This table makes it clear why ultrasonic detection has become the preferred choice for any serious efficiency programme.

In-House Team or Professional Survey?

Once you’re sold on ultrasonic technology, the next question is who actually does the work. You've really got two paths here, and the best one depends on your facility's needs.

Hiring a Professional Survey Team

- Pros: These teams live and breathe leak detection. They arrive with top-of-the-line equipment and a ton of experience. They can get a large, complex site surveyed quickly and hand you a detailed report, complete with prioritised repairs and estimated savings.

- Cons: It's a bigger upfront cost, no doubt about it. It’s also a snapshot in time—a periodic check-up rather than a continuous health monitor.

Equipping Your In-House Maintenance Crew

- Pros: Putting the tools in your team's hands builds a culture of proactive maintenance. It means more frequent, ongoing checks and quicker repairs, stopping small leaks before they waste thousands.

- Cons: There’s the initial outlay for the equipment and the time needed to train your staff properly. Your first full audit might take a bit longer to complete.

For most small to medium-sized facilities, equipping your own crew is usually the more sustainable, long-term play. But if you're running a massive, multi-building site or just want a rapid, expert assessment to get started, a professional survey provides incredible value. The choice really comes down to your resources, the complexity of your air system, and your long-term efficiency goals.

Conducting Your First Leak Survey

Alright, you’ve got the right tools in hand. Now comes the interesting part: hunting down those costly leaks. The real secret to a successful compressed air leak survey isn’t just about having a fancy detector; it’s about being methodical. Trust me, wandering around the plant floor hoping to stumble upon leaks is a waste of time. You need a solid plan to make sure nothing gets missed.

Before you even think about starting, a bit of prep work will make all the difference. Get your basic safety checks out of the way for any areas you'll be surveying. More importantly, make sure your compressed air system is running at its normal operating pressure. If you try to do this during a shutdown or when the pressure is low, you won’t get a true picture of where the real-world leaks are. It's a recipe for inaccurate results.

Breaking Down the Survey into Zones

The best way to tackle a full-facility survey without feeling overwhelmed is to break the job down. Divide the entire plant into logical zones. This turns a massive task into a series of smaller, more manageable ones. I’ve always found the most sensible approach is to follow the path the air takes, from the compressor right through to the end-use equipment.

Here’s a practical way to structure your survey zones:

- Zone 1: The Compressor Room: This is where it all begins. Start by checking every component in the compressor room itself. We're talking aftercoolers, receivers, dryers, and the main filtration bank. Pay very close attention to all the connections, drain traps, and relief valves in this area.

- Zone 2: Main Distribution Piping: Next, trace the main headers and distribution lines that pipe the air across your facility. These are often tucked away overhead, making them easy to forget about. That’s exactly why they’re prime suspects for hidden leaks.

- Zone 3: Point-of-Use Drops: Finally, zero in on what some of us call the "dirty thirty"—that last 30 feet of piping leading to your machinery. This is where you’ll find an enormous percentage of your leaks, often over 80%. This section includes all the regulators, hoses, connectors, and fittings that are constantly being handled and adjusted.

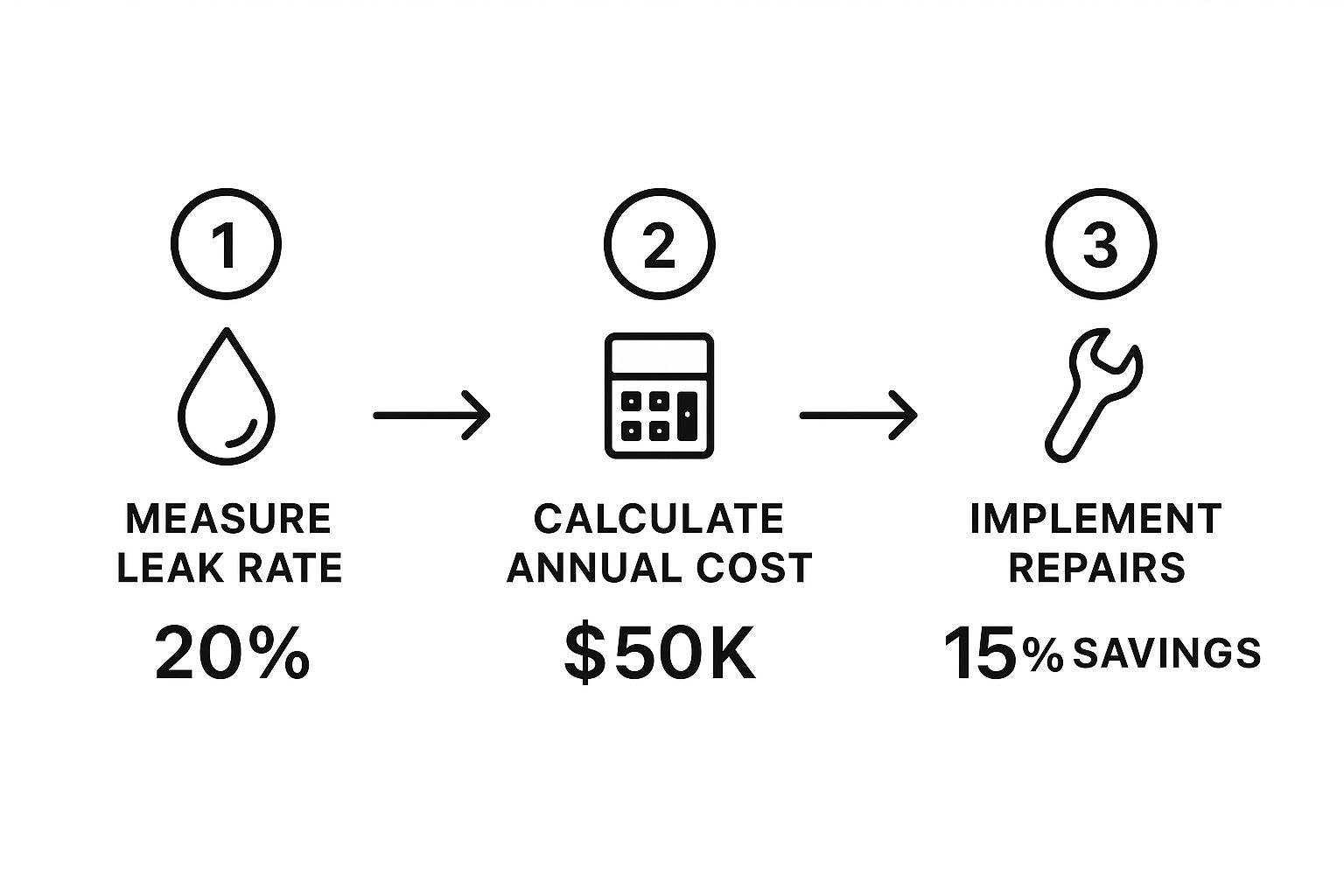

This image really drives home how finding and fixing these leaks gives you a clear return on your effort.

As you can see, you can directly translate a measured leak rate into an annual cost. This makes it incredibly easy to justify the repair work and show clear savings.

Tagging and Logging Every Leak

Finding a leak is only half the job. If you don't document it properly, it's as good as not found—it’ll likely never get fixed. This is where a simple but solid tagging and logging system becomes absolutely critical. Every single leak you find, no matter how tiny, needs to be tagged and recorded.

Your aim is to create a crystal-clear roadmap for your maintenance team. A simple, brightly coloured tag placed right at the source of the leak is the first step. Each tag needs a unique number that matches an entry in your survey log.

A great tagging system doesn’t just point out a leak; it gives your team all the information they need to prioritise and carry out the repair efficiently. Without this data, your survey is just an interesting walk-around with no real outcome.

Your log, which can be a basic spreadsheet or a dedicated app, needs to capture a few key details for every leak you tag.

What to Record for Each Leak

- Tag Number: The unique ID that corresponds to the physical tag.

- Location: Be specific. Don't just write "machine #3." Instead, try "Inlet fitting on the FRL unit for CNC Machine #3, Bay 2."

- Component Type: Note exactly what is leaking. Is it a pipe weld, a quick-connect coupling, a valve stem, or a regulator?

- Leak Severity: Use your ultrasonic detector to estimate the leak rate (usually in CFM or l/min). This is vital for deciding which repairs to tackle first.

- Photo: A quick snap on your phone provides priceless context. It helps the repair team find the exact spot without wasting time searching.

By diligently following this process—prepare, zone, scan, and log—you turn your first compressed air leak detection survey from a simple inspection into a powerful diagnostic tool. This detailed record is the foundation for an effective repair strategy that will start saving your facility money almost immediately.

Prioritising and Fixing Your Air Leaks

You’ve done the hard work of surveying your system and now you've got a detailed log of every leak. That's the first battle won. Now for the satisfying part: actually fixing the problems and watching your energy bills drop.

It's tempting to just start fixing whatever you find first, but that’s rarely the best use of your team’s time. A little bit of strategy goes a long way. The key is to tackle the most damaging leaks first to get the biggest and fastest return on your efforts.

After all, a huge leak on a main airline is a much bigger problem than a tiny hiss from a tool that's only used once a week. You need to weigh up the leak size, its impact on your operations, and how easy it is to get to. We always recommend starting with the "low-hanging fruit"—those large, easy-to-reach leaks that give you a quick, morale-boosting win.

A Smart Prioritisation Strategy

To keep things organised, it helps to categorise every leak you’ve tagged. Think of it like a triage system for your air network. This simple step helps you send your maintenance crew where they can make the biggest difference right away.

We find a three-tier system works best for most facilities:

- Priority 1 (Urgent): These are your biggest offenders. They're usually found on main distribution lines or critical production equipment and are responsible for a massive chunk of your wasted air. These need to be fixed as soon as possible, even if it means scheduling a brief shutdown.

- Priority 2 (High): This category covers medium-sized leaks on equipment that’s used a lot or in areas that are fairly easy to access. Get these scheduled for repair within your next maintenance cycle.

- Priority 3 (Routine): These are the small leaks, or those on non-critical tools that only see occasional use. They still need attention, of course, but you can roll them into your regular preventative maintenance schedule.

By focusing on the Priority 1 leaks first, you can often eliminate 50% or more of your total leakage volume with just a handful of targeted repairs. It's an approach that delivers immediate, measurable results and builds momentum for the whole programme.

Addressing the Root Causes of Leaks

Fixing a leak is one thing, but making sure it doesn’t come back is another. A quick patch-up might solve the problem for a week, but a lasting repair means figuring out why the part failed in the first place. From what we see in the field, most leaks boil down to a few common culprits.

Common Leak Sources and Their Fixes

- Loose Fittings and Connections: This is often the easiest fix. Constant vibration can work threaded connectors loose over time. A simple tighten-up is often all that's needed.

- Worn Seals and O-Rings: Seals and O-rings in valves, cylinders, and regulators don't last forever. They degrade with age and exposure. Replacing them is a cheap and effective repair that stops a surprising amount of air loss.

- Failed or Poorly Installed Regulators: A regulator that’s set too high or is starting to fail can create what’s called "artificial demand"—essentially pushing way more air through the system than is actually needed. Getting your system pressure right is crucial, and you can find solid guidance on choosing and using the correct pressure reducing valves for air and water to manage it properly.

- Damaged Hoses and Tubing: Look out for kinks, abrasion, or just old, cracked hoses. Don't be tempted to just wrap them in tape; that’s a temporary fix at best. Cut out and replace the damaged section entirely.

By following this methodical process, you move your leak detection work from a one-off project to a sustainable management strategy. It’s the final, crucial step in reclaiming lost energy and boosting your facility’s efficiency and bottom line.

Making the Business Case for Leak Management

You’ve done the hard work, crawling around the plant and meticulously tagging every hiss and whistle. But armed with your survey data, the next job is just as critical: getting management on board for a proper, sustained leak management programme.

Just telling the people upstairs you have leaks won't cut it. You need to speak their language, and that language is money. It’s all about translating your technical findings—those CFM or l/min figures—into a clear, undeniable financial argument based on costs, savings, and return on investment (ROI).

Your survey log is the foundation. Tally up the estimated leak rates for every tag to get a total volume of wasted air. From there, you can put a real pound sterling figure on it by factoring in your compressor's efficiency and what you actually pay for electricity.

Calculating Your Return on Investment

A strong ROI calculation is the heart of your business case. It shows exactly how quickly the initial spend—whether on your team’s time or a third-party service—and the repair costs will be paid back through energy savings.

The numbers here can be genuinely staggering. We've seen cases where a single 3mm hole in a compressed air line wastes over £1,000 in electricity every single year. For bigger sites with dozens of leaks, those losses can easily climb into the tens of thousands. If you want to dig into how these figures are worked out, there’s a great insightful post on air leak surveys that breaks it down.

The core message to management is simple: the upfront cost of finding and fixing leaks is almost always paid back within a few months. After that, every penny saved drops straight to the bottom line, boosting profitability year after year.

Highlighting Broader Business Benefits

While the cost savings are compelling, don't stop there. A well-managed system delivers benefits that resonate with wider company goals. This isn't just about cutting the electricity bill; it's about creating a more reliable, efficient, and productive operation.

Make sure to highlight these other key advantages:

- Reduced Carbon Footprint: Wasting less electricity directly lowers your CO₂ emissions. This is a big win for corporate sustainability targets and strengthens the company’s green credentials.

- Improved System Reliability: Fixing leaks eases the load on your compressors. That means less wear and tear, fewer unexpected breakdowns, lower maintenance bills, and a longer life for that expensive bit of kit.

- Enhanced Production Quality: When air pressure is stable and consistent, your pneumatic tools and machinery work exactly as they should. This can significantly reduce product defects and improve overall quality.

By framing this initiative as a strategic investment in efficiency, not just another maintenance cost, you build a powerful, multi-faceted argument that management will find very hard to ignore.

Your Air Leak Detection Questions Answered

Even with the best intentions, a few practical questions always come up when you kick off a compressed air leak detection programme. Getting these queries sorted from the start helps build confidence and gets the whole team on board with just how valuable this is for the long run.

How Often Should We Be Looking for Leaks?

For most industrial sites, a full-system survey once a year is a solid starting point. Think of it as an annual health check for your pipework and equipment.

However, if your plant has a lot of vibration or you’re working with older pipework, you'd be wise to check things every six months. Consistency is what really matters here – it’s about catching small leaks before they have a chance to grow into a massive drain on your energy bill.

Can We Do a Survey While the Plant Is Running?

Absolutely! In fact, you should be doing it during normal operations. The system has to be at its typical operating pressure for leaks to show themselves under real-world conditions.

Ultrasonic detectors are brilliant for this. They are designed specifically to work in noisy factory environments, honing in on the unique high-frequency hiss of a leak while filtering out all the background noise from machinery. This means you don’t have to shut anything down.

This is a huge benefit. Your compressed air leak detection can happen without ever having to pause production.

What's a Realistic Leakage Rate to Aim For?

Let's be realistic – a system with zero leaks is the holy grail, but it's practically impossible to achieve. Don't waste time chasing perfection.

Instead, a great target is a leakage rate below 10% of your total compressor output. This is what you’ll see in best-in-class facilities. When you consider that many plants are running with leaks wasting over 20-30% of their air, getting under that 10% mark means you have a seriously efficient and well-maintained setup. Hitting that goal delivers some pretty substantial energy savings.

Ready to get your system under control? The team at Solenoid Valve World has the expertise and the components you need to fix leaks and improve efficiency. Explore our range of high-quality valves, fittings, and pressure control equipment at https://solenoid-valve.world.