A Guide to Double Regulating Valves in the UK

At its heart, a double regulating valve (DRV) is a specialised bit of kit that pulls double duty, giving you both precise flow control and a dependable shut-off function, all wrapped up in a single body. Think of it like a high-end stereo where you can dial in the perfect volume, lock it in place, and then switch the power off knowing you won't lose that sweet spot. It's this dual role that makes them so critical for balancing modern HVAC systems.

What Are Double Regulating Valves and Why Do They Matter?

In any big heating or cooling system, getting the right amount of hot or cold water to every single part is crucial for efficiency and comfort. This whole process is known as hydronic balancing, and double regulating valves are the main tools for the job. Without them, you end up with messy, unbalanced systems where some areas are flooded with flow and others are left starving.

Picture a large office building with rows of radiators. It’s only natural that the ones closest to the boiler get the lion's share of hot water, leaving the radiators at the far end of the circuit lukewarm at best. This not only creates annoying "cold spots" for the people working there but also forces the entire system to run harder, guzzling a huge amount of energy in the process.

The Two Jobs: Regulation and Isolation

A double regulating valve tackles this problem head-on by performing two distinct, yet connected, functions.

Precise Flow Regulation: An engineer can carefully fine-tune the valve to let a very specific flow rate through. This makes sure every part of the system gets exactly the amount of conditioned water it needs—no more, and no less. This procedure, known as commissioning, is the foundation of any well-designed system.

Lockable Memory Setting: This is the "double" in double regulating. Once that perfect flow rate is set, the valve's position can be locked in place with a mechanism often called a 'memory stop'. This simple but clever feature stops anyone from accidentally knocking it out of whack, preserving the system's delicate balance.

The real magic of a double regulating valve is its ability to be fully closed for maintenance and then reopened to the exact preset position. This 'memory' ensures that a perfectly balanced system isn't ruined every time a bit of servicing is needed.

This combination of regulating flow and providing a reliable shut-off is why DRVs are a true cornerstone of modern HVAC design here in the UK. They save space by merging two components into one, cut down on potential leak points, and, most importantly, deliver serious energy savings. By getting the flow just right, they help make buildings comfortable, efficient, and cheaper to run. They're far more than just another piece of pipework.

The Evolution of Modern Flow Control Technology

To really get to grips with what modern double regulating valves do, it’s helpful to look back at the engineering headaches they were designed to fix. The search for precise flow control isn't new; it's a story that’s been unfolding for over a century, all driven by the need to tame the powerful forces inside large-scale pipe systems.

As far back as the early 20th century, engineers were already wrestling with how to stabilise flow and manage the massive dynamic pressures found in industrial pipework. Their early efforts created the foundational designs that paved the way for the valves we all rely on today.

The Balancing Act Begins

The core ideas behind the modern DRV have surprisingly deep roots. Believe it or not, the concept of a balanced valve first appeared in the early 1900s to counteract the huge forces acting on a valve's plug. Designs like the double-seated valve, even showing up in a 1906 catalogue, introduced the idea of balancing these forces to improve stability in pipe sizes from 50mm to 300mm.

This was a massive leap forward. Pioneers in the US, like the folks at Fisher Governor, pushed this work through the 1920s and 30s, figuring out ways to stop instability and solve the persistent problem of valve oversizing. These early American breakthroughs eventually spread across the globe, influencing valve design and how we use them right here in the UK. You can read more about the origins of control valves and their early development to see just how far we've come.

These early innovators realised a fundamental truth that is still critical today: a stable system needs more than just a way to open and close a pipe. It demands a valve that can actively manage the forces within it.

From Instability to Precision Control

Let's be honest, early flow control was often a bit of a blunt instrument. Many old valves had a simple "quick-opening" action, meaning they went from fully closed to nearly wide open with just a small turn of the handwheel. Great for basic on/off jobs, but a complete disaster for regulation.

This overly simple approach created two nagging problems that just wouldn't go away:

- System Instability: That sudden surge of flow would send pressure fluctuations through the system, creating unstable and unpredictable behaviour.

- Chronic Oversizing: Without good ways to calculate flow, engineers would often play it safe and pick a valve that was far too large for the job, making any fine-tuning almost impossible.

The development of double regulating valves was a direct answer to these shortcomings. By cleverly combining a precision regulation mechanism with a memory stop and an isolation function, they finally gave us the stable, repeatable, and accurate performance that modern UK industrial and HVAC systems can't do without.

How a Double Regulating Valve Actually Works

To really get why double regulating valves are so valued in the field, we need to pop the bonnet and look at the clever design that lets them do two jobs so well. From the outside, a DRV might not look much different from other industrial valves, but what’s going on inside is purpose-built for precision and consistency.

Think about it this way: you’re commissioning a large heating system. The goal is perfect hydronic balance, making sure every single radiator or air handling unit gets the exact flow rate it was designed for. This is where the DRV’s first job, simple regulation, comes in. As you turn the handwheel, you're moving an internal part called the valve plug (or disc). This plug moves towards or away from the valve seat, making the opening for water to pass through smaller or larger. It’s this action that gives you incredibly fine control over the flow.

The All-Important Memory Stop

Now, for the clever bit. What really makes a double regulating valve special is its memory stop feature. This is the "double" part of the regulation. Once an engineer has carefully dialled in the perfect flow rate using the handwheel, they can lock this maximum open position.

This is usually done with an Allen key, tightening a small, often hidden, locking screw inside the handwheel. Once that memory stop is set, the valve can be fully closed for maintenance and then reopened. Critically, it will only open as far as that pre-set position, stopping anyone from accidentally opening it too far and throwing the whole system out of balance.

The memory stop is like the valve's "muscle memory." It ensures that once a system is balanced, it stays balanced. It takes the guesswork and risk out of maintenance, guaranteeing those crucial commissioning settings are never lost.

This turns what could be a complex re-balancing act into a simple, repeatable task, which is absolutely vital for the long-term health and efficiency of any HVAC system.

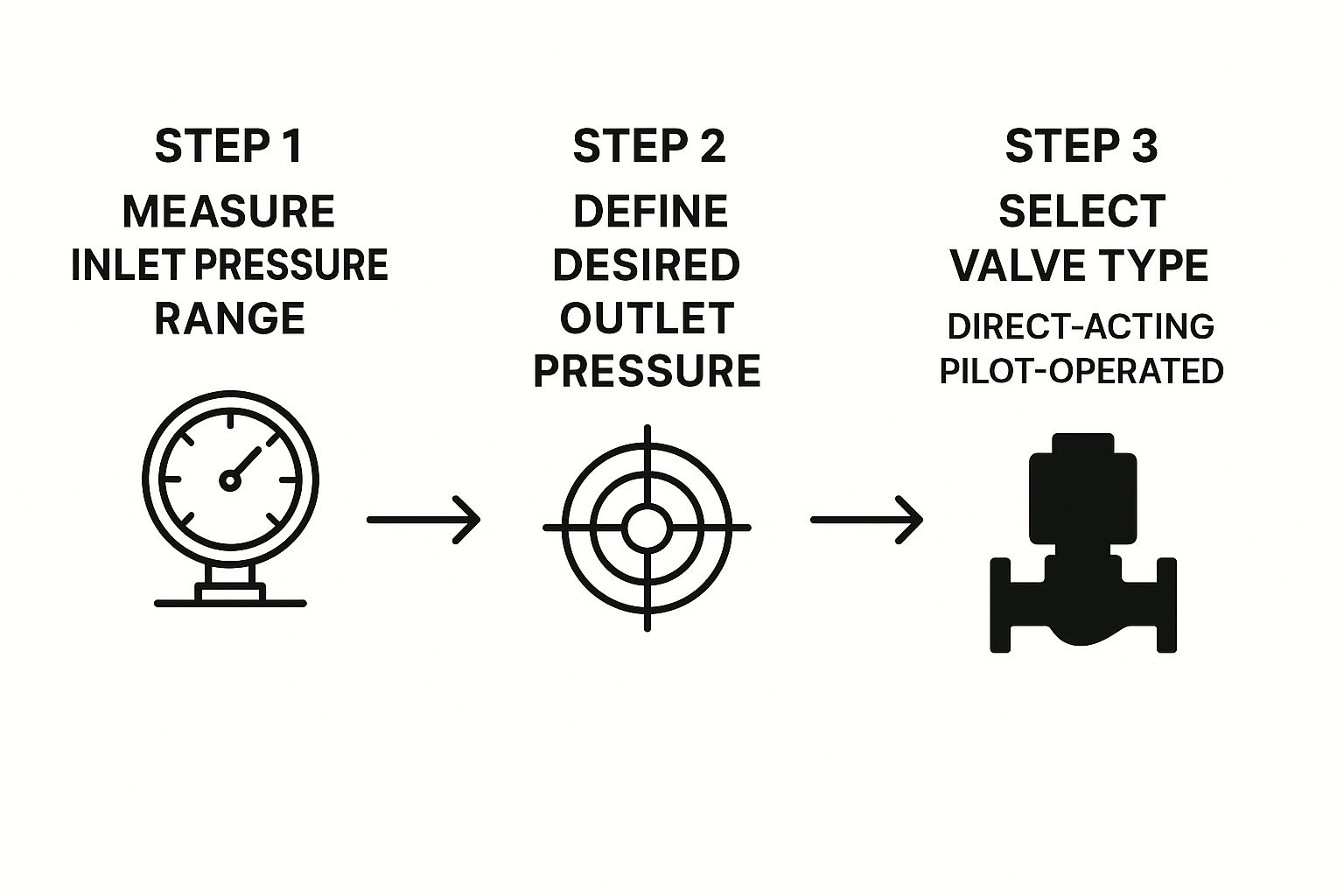

This infographic lays out a straightforward, three-step process for choosing the right regulating valve based on your system's pressures.

The main point here is that you have to understand your system's pressure requirements first. It’s the foundational step before you can even think about selecting a valve accurately.

Core Components Working Together

Several key parts work in harmony to give you this dual-functionality of regulating and isolating. Let's break them down:

- Handwheel: This is how you interact with the valve. Turning it moves the stem up and down to control flow. Most have a clear position indicator so you can see exactly how open it is at a glance.

- Stem: The stem is the threaded rod that connects the handwheel to the valve plug. As you turn the handwheel, the stem moves the plug with real precision.

- Bonnet: This is the housing that contains the stem and the memory stop mechanism. It creates a leak-proof seal with the main body of the valve, keeping all the important internals protected.

- Valve Plug and Seat: This is where the magic happens. The specific shape of the plug and seat is engineered to give a predictable flow rate as the valve is opened and closed.

Put them all together, and you have a robust piece of kit that can handle both meticulous flow adjustment and a tight shut-off for isolation. This means a single double regulating valve can do the job of two separate components—a balancing valve and a stop valve. That saves space, cuts down on costs, and reduces the number of potential leak points in the pipework.

The Key Benefits of Using DRVs in HVAC Systems

Moving past the nuts and bolts of how they work, the real magic of double regulating valves shines through when you see their impact on a building's performance. These aren't just bits of brass in a pipeline; they are a strategic investment in efficiency, comfort, and the long-term health of your system. The benefits really do ripple out.

The biggest win is a massive improvement in energy efficiency. In an unbalanced system, some circuits get far too much flow while others are left high and dry. This classic problem forces the pumps to work much harder, desperately trying to push water to the starved areas and wasting a huge amount of energy in the process.

By getting the hydronic balancing just right, DRVs ensure every part of the system gets the precise flow it was designed for. This stops the pumps from running flat out, which directly slashes energy consumption and brings down those operational costs.

Enhanced Comfort and System Stability

This level of precise control also translates into a much more comfortable building for the people inside. When the flow is properly balanced, you can say goodbye to those annoying hot and cold spots that plague so many buildings. Every room stays at the temperature it's meant to, creating a consistently pleasant environment.

That stability helps the system itself, too. A balanced flow means less noise, fewer vibrations, and a lot less wear and tear on components like pumps and control valves. While DRVs are built for water and similar fluids, it's useful to understand how different valves manage pressure in other contexts. For example, a high pressure solenoid valve is engineered specifically to handle much more demanding conditions in other types of systems.

A properly balanced system isn't just more efficient; it's a quieter, more reliable, and longer-lasting system. Double regulating valves are foundational to achieving this state of equilibrium.

Simplified Maintenance and Reduced Costs

The clever dual-function design of a double regulating valve brings a host of practical benefits that save time, space, and money, both when you're installing it and when you're maintaining it down the line.

- Smaller Installation Footprint: By rolling a balancing valve and an isolation valve into a single unit, you simply need fewer components. This is a lifesaver in cramped plant rooms and makes for much tidier pipework.

- Fewer Potential Leaks: Every joint in a pipeline is a potential failure point. Fewer valves mean fewer connections, which inherently lowers the risk of leaks in the future.

- Guaranteed Recommissioning: That 'memory stop' feature is an absolute game-changer for maintenance work. A technician can completely shut off a circuit to fix or replace a part, then just open the DRV back to its preset position. The system's balance is instantly restored without any fuss or specialist recommissioning tools.

When you add it all up, it's clear that opting for double regulating valves is a proactive move. It’s an investment that pays dividends over the entire life of the system through better performance, sustainability, and happier building occupants. A bit of planning upfront goes a very long way.

Where You'll Find Double Regulating Valves in the UK

We've covered the theory, but where do these valves actually live and work? Far from being just a concept on a schematic, double regulating valves are the unsung heroes in countless buildings across the United Kingdom. They're the workhorses that keep systems running smoothly and efficiently, and their popularity has shot up right alongside the growing demand for energy efficiency and perfectly commissioned buildings.

The Double Regulating Valve (DRV) is a quintessentially British piece of engineering. It became a standard part of hydronic heating systems in the later 20th century, and its design is perfectly suited to UK commissioning methods. The genius is in its dual function: an engineer can set a precise flow rate and then lock it in with the memory stop. This makes it indispensable for both fine-tuning flow and isolating parts of a system for maintenance. You’ll see them in all sorts of sizes, from a small 15mm up to a hefty 200mm.

Whether it's a bustling city office or a new-build apartment block, DRVs are the key to achieving perfect hydronic balance.

Critical Roles in Heating and Water Systems

You'll most often find double regulating valves in hydronic heating and cooling circuits. They’re a familiar sight in plant rooms and tucked away in ceiling voids, doing the vital job of balancing flow to make sure every corner of a building gets the heating or cooling it needs. Their flexibility means they're used across a huge range of systems common in the UK.

Here are some of their key applications:

- Low, Medium, and High Temperature Hot Water (LTHW, MTHW, HTHW): In everything from radiator circuits and underfloor heating to large air handling units, these valves are essential. They ensure that each part of the system gets exactly the right amount of hot water.

- Ring Main Piping Circuits: A common setup in UK commercial buildings, ring mains depend on DRVs. By fitting a valve on each branch off the main loop, engineers can balance the entire system. This stops the classic problem where circuits close to the pump get all the flow, leaving the ones at the end starved.

- Clean Cold Water Systems: While we often think of them for heating, DRVs also play a role in boosted cold water systems. They are used to balance flow between different floors or zones, guaranteeing consistent water pressure and supply throughout a building.

The rise of the double regulating valve went hand-in-hand with stricter UK building regulations and energy performance standards. Their ability to deliver a precise, lockable, and verifiable flow rate made them an essential component for hitting modern efficiency targets.

Their widespread use is a testament to their value. If you want to get into the nitty-gritty of their specifications and operation, it's worth learning more about the double regulating valve and how it slots into different system designs. At the end of the day, their unique dual functionality has cemented their place as a standard piece of kit for high-performance building services in the UK.

How to Select and Install DRVs for Peak Performance

Choosing the right double regulating valve and installing it properly is what separates a chaotic, inefficient system from a perfectly balanced one. Nailing these details from the outset prevents countless headaches, from poor performance and sky-high energy bills to expensive recommissioning work down the road. It all starts with understanding what your system truly needs.

The selection process is about more than just matching the pipe size. You need to get a trio of critical factors right to make sure you've picked the best tool for the job. Get these specifications correct, and you're already on the path to reliable and precise flow control.

Key Selection Criteria for Your DRV

When you’re selecting a DRV, your decision must be guided by the system's real-world operational demands. The main parameters to confirm are the valve size, its pressure rating, and its all-important flow characteristics.

Valve Size (DN): This is the nominal diameter of the pipework the valve will be fitted into. It might seem simple, but it’s crucial to ensure the valve size aligns with the system design to avoid creating unwanted flow restrictions or turbulence.

Pressure Rating (PN): This number tells you the maximum pressure (in bar) the valve can handle safely. Choosing a DRV with the right PN rating is non-negotiable for system safety and integrity, especially in high-pressure circuits.

Flow Coefficient (Kv): This is arguably the most critical factor for regulation. The Kv value represents the volume of water (in m³/hr) that will pass through the valve with a pressure drop of one bar. Always check the manufacturer's flow charts to pick a valve that gives you the right level of control for your target flow rate.

While DRVs are masters of flow regulation, other components like pressure reducing valves are designed specifically to manage system pressure. Knowing the distinct roles of each part is fundamental to a well-designed hydronic system.

Installation Best Practices for Accurate Performance

Once you've selected the perfect valve, a proper installation is the final piece of the puzzle. A poorly installed DRV, no matter how well-specified, will never deliver accurate readings or stable regulation. The golden rule here is all about the pipework immediately surrounding the valve.

Think of it like this: the straight pipe before the valve is a calming runway for the water. It smoothes out the turbulent flow created by bends and fittings, allowing the DRV to take a clean, accurate measurement and provide predictable control.

To ensure the valve can do its job, you must give it a clean, stable flow of water. This is achieved by installing it with sufficient straight pipework before and after.

The following table summarises the key technical specifications and installation requirements common in the UK. Adhering to these guidelines is essential for any installer aiming for accurate commissioning and reliable long-term performance.

DRV Technical Specification and Installation Checklist

| Parameter | Common Range / Requirement | Reason |

|---|---|---|

| Common Valve Sizes | DN15 to DN200 | Covers the vast majority of commercial and industrial applications. |

| Typical Pressure Rating | PN25 (25 bar) | Provides a robust safety margin for most UK heating and cooling systems. |

| Upstream Straight Pipe | 5x the pipe diameter (minimum) | Ensures laminar (smooth) flow enters the valve for accurate measurement. |

| Downstream Straight Pipe | 2x the pipe diameter (minimum) | Prevents turbulence from affecting components immediately after the valve. |

| Industry Usage | Standard in ~70% of balancing projects | Highlights its role as a fundamental component in modern hydronics. |

| Data Source | Manufacturer Flow Charts | Essential for matching the valve’s Kv characteristics to the system’s needs. |

Following these selection and installation rules sets the stage for a system that is not only easy to commission but also stays efficient and dependable throughout its operational life.

Got Questions About DRVs? We’ve Got Answers.

As you get more familiar with double regulating valves, a few questions tend to pop up. Let's clear up some of the most common ones.

What’s the Real Difference Between a Static Balancing Valve and a DRV?

It's a great question, and the answer lies in one critical feature: the 'memory stop'. While a standard static balancing valve can regulate flow, it doesn't remember its setting.

A double regulating valve, on the other hand, lets an engineer find that perfect flow rate, set it, and then lock it in place. This means you can fully close the valve for maintenance, and when you reopen it, it hits that exact pre-set position every single time. No guesswork, no re-balancing—the system's integrity is perfectly preserved.

Can I Just Use a DRV as a Stop Valve?

Yes, you absolutely can. In fact, that's one of their biggest advantages. A core part of a DRV's design is its ability to create a tight, reliable shut-off.

This means it doubles up as an isolation valve (or stop valve) whenever you need to perform maintenance. This clever dual-functionality often means you need fewer valves in the pipeline, which simplifies the system and can save on costs.

For all your fluid control needs, from precision regulation to reliable isolation, you can trust the experts at Solenoid Valve World. Take a look at our extensive range of valves and fittings today at https://solenoid-valve.world.