Emergency Gas Shut Off Valve: Your Complete UK Safety Guide

Understanding Emergency Gas Shut Off Valves (And Why They Matter)

Emergency gas shut off valves are your home's first defense against gas leaks. More than just a regulatory requirement in the UK, they're a critical safety feature for every homeowner. These valves quickly stop the flow of gas, preventing potentially dangerous situations. Understanding how they work is essential for protecting your family and your home.

How Emergency Gas Shut Off Valves Work

These devices are usually installed on the main gas line entering your property. They interrupt the gas supply when activated, similar to how a tap stops water flow. This prevents gas from reaching appliances and potentially igniting. Imagine a gas hob malfunctioning and causing a leak. The shut off valve can prevent a fire or even an explosion.

Types of Emergency Gas Shut Off Valves

Several types of emergency gas shut off valves are available in the UK. Manual valves require someone to physically turn them off. Automatic valves, on the other hand, activate in response to specific triggers, like seismic activity or excess flow. Some valves are even designed for specific appliances, offering targeted protection. If you're interested in learning more about valve technology, you might find this resource helpful: How to master solenoid valves.

Why These Valves Are Important

Emergency gas shut off valves are crucial for several reasons. They dramatically reduce the risk of gas leaks and fires, offering valuable peace of mind. They can also help you avoid costly damage associated with gas-related incidents. Plus, these valves are key to complying with UK gas safety regulations. A comprehensive emergency response plan is also crucial, particularly for gas-related events. For guidance on developing one, check out this resource on creating an Emergency Action Plan.

Integrating Valves Into Your Home's Gas Supply

The emergency gas shut off valve is a key part of your home's gas supply system. It sits at the junction between the external supply and your internal pipework. When activated, the valve isolates your home from the gas source, stopping any further flow. This controlled isolation minimizes potential hazards.

What Happens During an Emergency

In an emergency, the valve is either triggered automatically or manually activated. This immediately stops the gas supply to your home. This rapid response can prevent a minor leak from becoming a major incident. However, it's important to remember that after activation, a qualified Gas Safe registered engineer must restore your gas supply.

Understanding how emergency gas shut off valves work is the first step to ensuring your home’s safety. By learning about the different types, their importance, and how they function during an emergency, you’re better equipped to make informed decisions about your gas safety systems. This knowledge helps you protect your family and property from potential gas-related dangers.

Navigating UK Legal Requirements (Without The Headaches)

UK gas safety regulations are designed to protect you, your family, and your property. Understanding the legal framework around emergency gas shut off valves is crucial for homeowners, landlords, and business owners. This knowledge helps ensure your property meets required safety standards.

The Gas Safety (Installation and Use) Regulations 1998

The foundation of UK gas safety legislation is the Gas Safety (Installation and Use) Regulations 1998. This legislation sets requirements for gas installations and appliances to prevent accidents and ensure safe gas usage in all premises. For instance, it mandates readily accessible emergency controls, meaning an accessible emergency gas shut off valve is a legal requirement. Learn more about gas safety regulations.

Responsibilities for Homeowners and Landlords

Homeowners must ensure their gas installations, including emergency shut off valves, are inspected and maintained by a Gas Safe registered engineer. Landlords have additional responsibilities, including annual gas safety checks by a Gas Safe registered engineer.

They must also provide tenants with a copy of the gas safety record. Furthermore, landlords are responsible for ensuring provided gas appliances are safe and meet current standards. This framework ensures high gas safety levels across rented properties.

Commercial Property Obligations

Commercial property owners also have a duty of care. They must ensure regular inspections and maintenance of gas systems and emergency shut off valves. Specific requirements vary depending on the business and the gas installation's complexity. However, prioritizing gas safety and compliance remains vital.

Penalties for Non-Compliance

Non-compliance with gas safety regulations has serious consequences. Landlords could face substantial fines or imprisonment. Homeowners also face penalties for failing to maintain gas systems and installations. These penalties highlight the UK government's emphasis on gas safety, making compliance crucial for property owners and managers.

How Gas Safety Laws Interact With Broader Safety Legislation

The Gas Safety (Installation and Use) Regulations 1998 work alongside other safety legislation, like the Health and Safety at Work etc. Act 1974, to create a comprehensive safety net. This ensures a consistent approach to safety across various sectors. Gas safety is integral to a broader commitment to public well-being.

Understanding these regulations helps you avoid legal issues and protect your property and loved ones. Learning about these requirements is a proactive investment in everyone's safety and well-being.

Technical Standards That Actually Make Sense

Behind every emergency gas shut off valve installation are important technical standards. These requirements ensure your safety and aren't just arbitrary rules. Let's explore why specifics like placement, accessibility, and how the valve turns matter.

Why Positioning and Accessibility Are Key

The emergency gas shut off valve should be easy to access in a hurry. Imagine a situation where you need to shut off the gas quickly—you don't want to be hunting for it. Accessibility is paramount. The valve needs to be free from obstructions like furniture, allowing quick and easy access, even under stress. The valve's height should also be convenient for everyone in the household.

The Importance of Rotation Angles

How the valve turns from "on" to "off" is also standardized. This consistency prevents confusion during emergencies. For example, The Gas Industry Standard in the UK sets specific requirements for emergency control valves. The lever on emergency control valves should rotate 180 degrees from "on" to "off," while gas emergency security valves require a 90-degree rotation. Learn more about gas shut off valve standards. This detail ensures predictable operation and prevents accidental activation or difficulty shutting off the gas.

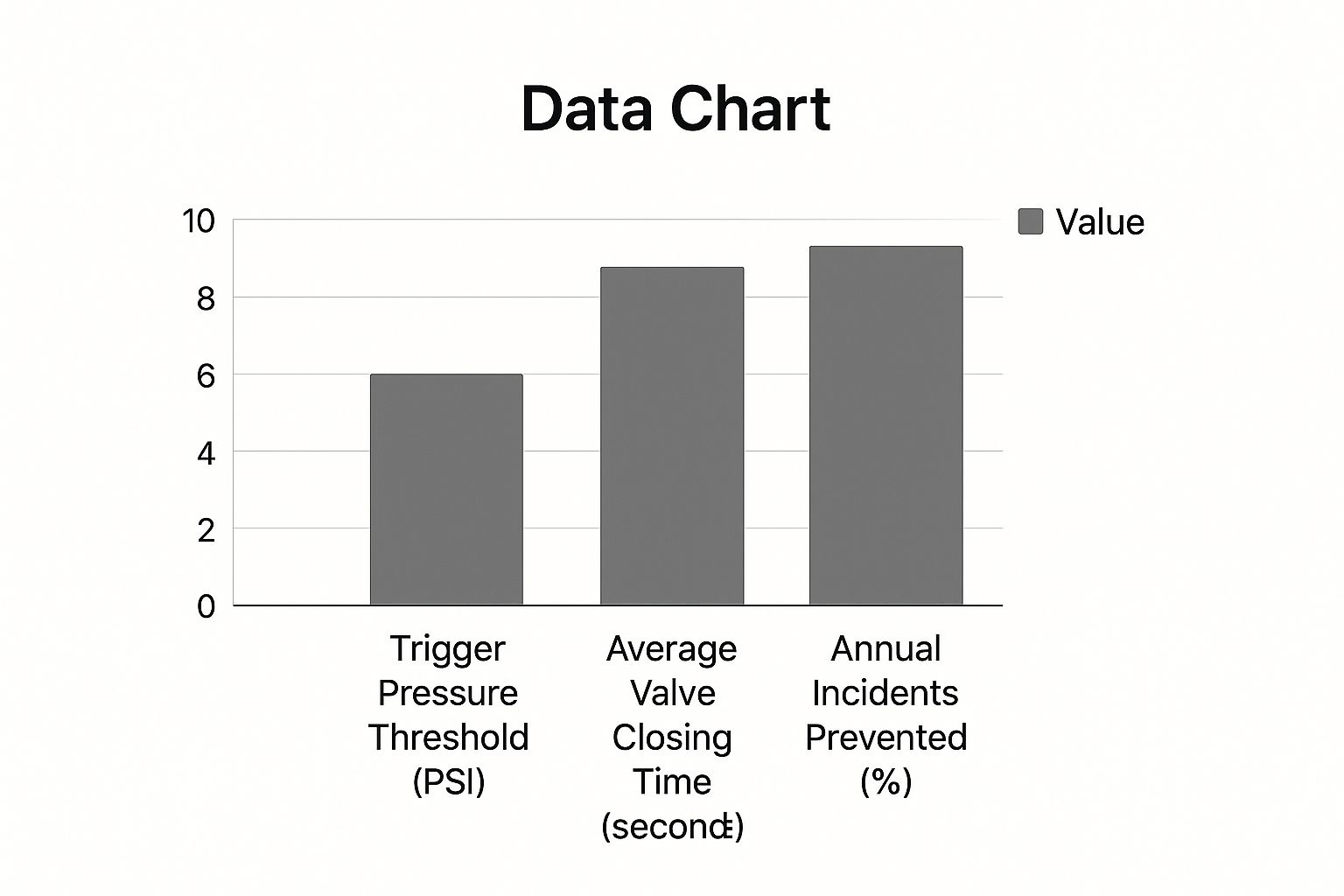

Visualizing Key Performance Data

The infographic below shows key performance metrics for emergency gas shut off valves. It clearly compares Trigger Pressure Threshold, Average Valve Closing Time, and the percentage of Annual Incidents Prevented.

As the infographic shows, the trigger pressure and closing time are designed to minimize potential damage, significantly reducing gas-related incidents. Proper documentation is also crucial. For more information, explore document management best practices to ensure your gas safety system documentation is well-maintained and readily available.

Understanding Different Valve Types and Standards

Different emergency gas shut off valves have various technical specifications. To illustrate these differences, let's look at the following table:

Emergency Gas Valve Technical Specifications

Comparison of technical requirements for different types of emergency gas shut off valves

| Valve Type | Rotation Angle | Installation Height | Access Requirements |

|---|---|---|---|

| Emergency Control Valve | 180 degrees | Accessible to all household members | Unobstructed access |

| Gas Emergency Security Valve | 90 degrees | Accessible to all household members | Unobstructed access |

This table highlights the key difference in rotation angles between the two main types of emergency shut off valves, while emphasizing the shared requirement for easy access.

These standards govern factors such as maximum operating pressure, the pressure the valve can safely handle; temperature range, the specific temperatures within which the valve can operate; and material compatibility, ensuring the valve's materials are compatible with the gas used.

These technical details are important for the effectiveness of your emergency gas shut off valve. They ensure reliable performance when you need it most, protecting against gas leaks. Understanding these standards helps you communicate with gas engineers and make informed decisions about your safety.

Working With HSE and Professional Installation Services

Ensuring the safety of your home and family is paramount, especially when dealing with gas appliances. In the UK, the Health and Safety Executive (HSE) sets and enforces crucial gas safety regulations. Understanding their role, and the importance of professional installation, provides peace of mind.

The HSE's Role in Gas Safety

The HSE enforces gas safety legislation, including regulations related to emergency gas shut off valves. These regulations are designed to protect lives and property by ensuring installations meet stringent standards. This oversight helps prevent gas-related incidents and provides an essential layer of safety. The HSE's authority stems from the Health and Safety at Work etc. Act 1974, which outlines legal obligations for ensuring safety. Explore this topic further.

Why Professional Installation Is Essential

Professional installation isn't just a good idea—it’s a legal requirement for gas appliances in the UK. Gas work is complex and potentially hazardous if not handled correctly. Using a Gas Safe registered engineer is crucial for installing your emergency gas shut off valve. These registered engineers have the necessary qualifications and experience to ensure a safe and compliant installation.

Gas Safe Registration: A Mark of Competence

The Gas Safe Register is the official list of gas engineers legally authorized to work on gas appliances in the UK. This registration provides assurance that engineers have undergone rigorous training and assessment. It acts as a verification of their competence and ability to work safely with gas, much like a driver's license. Choosing a Gas Safe registered engineer means choosing a professional who meets stringent national standards.

What HSE Inspectors Look For

HSE inspectors play a crucial role in upholding gas safety standards. During inspections, they focus on several key aspects related to emergency gas shut off valves:

Correct Installation: The valve must be installed according to manufacturer guidelines and relevant regulations, including proper positioning and accessibility.

Proper Function: The valve must operate effectively, shutting off the gas supply rapidly when activated. Inspectors may test the valve's operation.

Appropriate Signage: Clear signage should indicate the valve's location and operation instructions, enabling quick access in an emergency.

Maintenance Records: Regular maintenance and testing are essential. Inspectors often look for records of proper valve maintenance.

The Importance of Gas Safe Registered Engineers

Choosing a Gas Safe registered engineer safeguards homeowners and the public alike. It ensures the installation adheres to all safety regulations, minimizing the risks of gas leaks and other hazards. This commitment to professionalism is central to the UK's focus on gas safety. A correctly installed emergency gas shut off valve offers peace of mind, knowing your home is protected by a system installed and verified by a qualified expert. Professional installation also helps avoid future costs associated with repairs or replacements due to incorrect initial setup. By adhering to these standards, you contribute to a safer environment for your family and community.

Choosing The Right Valve For Your Property

When it comes to emergency gas shut off valves, finding the perfect fit for your property is crucial. Several factors play a role in this decision, including the type of property and its specific gas usage. Taking the time to carefully consider these aspects will ensure you select the most appropriate valve.

Different Valves for Different Needs

A variety of emergency gas shut off valves are designed to cater to different needs. Manual valves offer a straightforward and budget-friendly option. They require someone to physically shut them off in an emergency, making them well-suited for smaller properties with easily accessible gas lines.

Automatic valves, on the other hand, provide automated protection. These include excess flow valves, which detect unusual surges in gas flow, and seismic valves, which trigger during earthquakes. Seismic valves are particularly important for properties located in earthquake-prone regions. For further information about valves specifically designed for natural gas, refer to our guide on natural gas approved valves.

Matching Valves to Property Types

The type of property significantly influences the choice of valve. A small apartment, for example, may only necessitate a basic manual valve. A larger detached house, however, might benefit from an automatic system due to the increased complexity of its gas network.

Commercial properties, with their higher gas consumption and potential impact on a greater number of occupants, often require more complex systems. Restaurants, for instance, frequently incorporate automatic shut-off systems integrated with their kitchen hood suppression systems to ensure comprehensive fire safety.

To further illustrate the different valve applications based on property type, the following table provides a helpful guide:

To help you understand the various valve types available, here's a quick guide:

Emergency Gas Valve Applications Guide

Overview of different valve types and their recommended applications.

| Property Type | Recommended Valve Type | Key Features | Maintenance Requirements |

|---|---|---|---|

| Small Apartment/Flat | Manual Valve | Simple, cost-effective, easy to operate | Periodic visual inspection |

| Large Detached House | Automatic (Excess Flow) | Detects unusual gas flow increases, automatic shut-off | Annual inspection and testing |

| Restaurant | Automatic (Seismic/Excess Flow) | Earthquake or excess flow activated, integrates with fire suppression | Regular inspection and testing as part of the fire safety system |

| Industrial Facility | Multiple Automatic Valves (Excess Flow, Manual) | Multi-layered protection, redundancy for critical systems | Frequent inspection and testing based on industry regulations |

This table highlights the importance of considering property type and potential hazards when selecting an emergency gas shut off valve. Choosing the right valve enhances safety and ensures appropriate protection for various scenarios.

Factors Influencing Valve Selection

Several crucial factors influence the selection of an emergency gas shut off valve:

- Property size: Larger properties might require multiple shut-off valves for thorough protection.

- Gas Consumption: Higher gas usage often necessitates a valve with a greater capacity.

- Household Needs: Families with young children or elderly individuals may prioritize automatic valves for enhanced safety.

- Accessibility: The valve location should be easily accessible to all occupants in case of an emergency.

Learning From Different Industries

Examining the practices of various industries can offer valuable insights. Industrial settings, with their intricate gas networks, often employ multiple layers of shut-off valves for optimal safety. This redundant approach minimizes the risk of large-scale incidents.

Learning from these diverse applications can help homeowners make well-informed choices. Selecting a valve that aligns with specific needs and adheres to relevant safety regulations ensures both compliance and effective protection.

Understanding Your Specific Requirements

By understanding the available valve types and the factors that influence their selection, you can choose a system tailored to your individual requirements. This proactive approach promotes optimal safety and compliance with UK regulations, offering peace of mind for years to come. Consulting with a Gas Safe registered engineer is always recommended for personalized advice and professional installation.

Maintenance And Testing That Keeps You Safe

Your emergency gas shut off valve is a critical safety feature in your home, acting as a first line of defense against gas leaks. But just like any other safety device, regular maintenance and testing are essential to ensure it’s ready to perform when you need it most. A properly maintained valve gives you peace of mind, knowing it's ready for a crisis.

Routine Inspection: A Simple Yet Crucial Step

Regular visual inspections are the foundation of proper emergency gas shut off valve maintenance. Aim to perform a quick check every few months. Look for visible signs of damage, such as rust, corrosion, or physical obstructions. Also, ensure the area around the valve is clear for easy access in an emergency. This simple habit can identify and address potential problems before they become major issues.

Recognizing Warning Signs

In addition to routine checks, it's important to recognize the warning signs of a potential valve malfunction. A hissing sound near the valve, the smell of gas, or dying houseplants could all indicate a leak. Difficulty turning the valve or a loose handle are also signs that the valve needs attention. If you notice anything unusual, contact a Gas Safe registered engineer immediately.

Safe Testing Procedures: Knowing What To Do

Testing your emergency gas shut off valve is simple yet essential. Before beginning, inform everyone in your household about the test to avoid any confusion. Locate all gas appliances and make sure they are turned off. Next, turn the shut off valve to the "off" position. The pilot lights on your appliances should go out, confirming the gas supply has been interrupted. Afterwards, turn the valve back "on" and relight your pilot lights. If you experience any problems, contact a qualified professional. For more information on valve maintenance, you might find this resource helpful: How to master solenoid valve installations and maintenance.

When Professional Help Is Necessary

While basic visual inspections and testing can be done by a homeowner, certain situations require the expertise of a professional. If you detect any damage, leaks, or have trouble operating the valve, contact a Gas Safe registered engineer. They have the training and experience to diagnose and fix any problems, ensuring your valve is operating safely and correctly.

Documentation and Compliance

Keeping records of your valve’s maintenance and testing history is important, especially for compliance. A logbook detailing inspection dates, any repairs performed, and the contact information of the Gas Safe registered engineer is recommended. This documentation demonstrates your commitment to maintaining your gas safety systems.

Common Maintenance Issues and Prevention

Common problems with emergency gas shut off valves include corrosion from exposure to the elements, seizing due to infrequent use, and physical damage. Preventing these problems is relatively simple. Protect the valve from weather, operate it periodically to prevent seizing, and keep the surrounding area clear of obstructions.

Creating a Realistic Maintenance Schedule

A practical maintenance schedule balances convenience and safety. A quarterly visual inspection and an annual test by a Gas Safe registered engineer are generally sufficient for most homes. However, if your house is older or has a more complex gas system, more frequent checks might be needed. Consulting with a qualified professional can help you establish a schedule tailored to your specific needs. This proactive approach helps ensure your valve remains a reliable safety feature, protecting your home and family. By following these maintenance and testing guidelines, you can rest assured that your emergency gas shut off valve will function properly in an emergency. This vigilance turns your safety system from a passive device into an active safeguard.

Emergency Response Planning That Actually Works

Having an emergency gas shut off valve installed is a crucial first step in home safety. However, it’s only one piece of the puzzle. A well-defined emergency response plan ensures everyone in your household knows what to do if a gas leak occurs, maximizing the effectiveness of your safety measures and minimizing potential harm.

Creating a Plan For Everyone

Your emergency response plan should be clear, concise, and easy for everyone to understand, regardless of their technical knowledge. Think of it like a fire drill – everyone needs to know their role. This includes identifying a leak, activating the shut off valve, and safely evacuating. Simplicity is key in stressful situations.

Recognizing the Signs of a Gas Leak

Knowing how to recognize a gas leak is vital. The characteristic “rotten egg” smell added to natural gas is your primary indicator. Other signs might include a hissing sound near gas appliances or pipes, discolored vegetation around the gas meter, or bubbling water near the gas line. If you suspect a leak, do not attempt to locate it yourself. Follow your emergency plan immediately.

Step-by-Step Emergency Procedures

Your plan should detail the correct sequence of actions for different scenarios:

- Suspected Leak: Turn off the gas supply at the emergency shut off valve. Open windows and doors to ventilate the area, and evacuate everyone immediately.

- Confirmed Leak (with no ignition): Follow the same steps as a suspected leak, and notify the gas emergency service from a safe location, such as a neighbor’s house.

Communication is Key

Effective communication is essential during a gas emergency. Your plan should include designated contact persons and their phone numbers. Everyone in the household should know who to contact and how. Establish clear communication with neighbors, too, in case you need to evacuate quickly.

Evacuation Procedures: Getting Out Safely

A well-defined evacuation route is critical. Identify safe exit points and a designated meeting place outside your property. Practice the evacuation route regularly with everyone in your household. This practice can save valuable time in a real emergency.

Post-Emergency Actions: What To Do After Evacuation

After evacuating, do not re-enter the property until the gas emergency service gives the all-clear. Even if the smell dissipates, there could still be a dangerous gas concentration. Once the gas supply is deemed safe, a Gas Safe registered engineer must inspect your system and re-establish the gas supply.

Turning Your Valve Into a Comprehensive Safety Strategy

Combining an emergency gas shut off valve with a comprehensive emergency response plan transforms a simple device into a powerful safety system. This proactive approach protects your home and loved ones, offering genuine peace of mind. For a wide selection of valves, visit Solenoid Valve World. They offer solutions for various applications, helping you find the right fit for your needs.