A Guide to High Temperature Solenoid Valves

When you're dealing with extreme heat in an industrial process, a standard valve just won't cut it. This is where a high temperature solenoid valve becomes essential. Think of it as a specialised, heat-resistant traffic controller for your pipelines, designed to reliably manage the flow of media like steam, hot oil, or corrosive chemicals without failing under pressure.

Understanding the Core Role of High Temperature Solenoid Valves

Picture this: you try to use a regular plastic tap to control the flow of superheated steam from a boiler. What happens? The intense heat would quickly warp, melt, and utterly destroy it, leading to a catastrophic failure. This is precisely the problem a high temperature solenoid valve is engineered to solve. It guarantees safe, automated, and precise fluid control even under extreme thermal stress.

These devices aren't just minor upgrades; they are fundamental components for safety and efficiency in any process involving serious heat. Their ability to operate without a hitch prevents dangerous leaks, protects sensitive downstream equipment, and maintains the integrity of the entire system. Without them, many modern industrial processes would be either too dangerous or simply impossible to automate.

Why Are These Valves so Crucial?

The need for these specialised valves comes directly from the industrial world's push for greater automation and safety. In the UK, the move towards advanced automation is a major driver for market growth. This is part of a broader European trend where the solenoid valve sector accounted for about 38.91% of the global market revenue in 2024. This hefty figure underscores just how critical these valves are to the region's powerful industrial backbone, from manufacturing plants to power generation facilities.

Their true value lies in a powerful combination of durability and precision:

- Safety Assurance: They are the first line of defence against the uncontrolled release of high-temperature media, safeguarding personnel and valuable assets.

- Process Reliability: Their consistent operation ensures that processes like sterilisation, moulding, or industrial heating run smoothly and without interruption.

- Operational Efficiency: Automating control with these valves reduces the need for manual oversight, streamlining workflows and cutting operational costs.

At its heart, a high temperature solenoid valve creates a dependable barrier between extreme heat and precise control. This makes it a cornerstone of modern industrial safety and automation.

Ultimately, these valves are specified for applications where failure is simply not an option. A key differentiator is their construction, which often features robust materials like stainless steel. If you're interested in material choices, our guide on the https://www.solenoid-valve.world/stainless-steel-solenoid-valve offers deeper insights into why certain metals are vital for such demanding environments. This foundational knowledge is the perfect starting point for understanding exactly how they work.

How These Valves Master Extreme Heat

To get a real feel for how a high-temperature solenoid valve survives in brutal conditions, you have to look under the bonnet. At its heart, the operation is a surprisingly elegant dance between electromagnetism and mechanics. When you send an electrical current to the valve, it energises a copper wire coil, creating a powerful magnetic field.

This magnetic force instantly yanks on a movable ferromagnetic core, known as the plunger or armature. As the plunger moves, it lifts a seal off an opening (the orifice), letting fluids like hot steam or oil rush through. Cut the power, and the magnetic field collapses. A spring immediately snaps the plunger back into place, sealing the orifice and stopping the flow. This entire sequence can happen in just a few milliseconds.

While this basic principle is common to all solenoid valves, the real magic of a high-temperature solenoid valve is found in its clever heat management strategies. A standard valve would quickly overheat and fail, so these specialised units use some brilliant design tricks to protect their most vulnerable parts.

Shielding the Electronics from Searing Heat

The number one challenge is protecting the electrical coil. If that coil gets too hot, its insulation can melt, leading to a short circuit and total valve failure. To stop this from happening, manufacturers employ several key engineering techniques.

One of the simplest yet most effective methods is physical separation. Many high-temperature designs place the coil further away from the hot valve body, connecting them with an extended tube. This creates an air gap that acts as a thermal break, drastically cutting down the heat that transfers from the hot fluid to the coil assembly.

On top of that, the coils themselves are built to endure. They often feature:

- Heat-dissipating fins on their outer casing to increase the surface area and shed heat more effectively into the surrounding air.

- High-grade insulating materials like Class H or Class N enamels that can withstand temperatures up to 180°C or even 200°C without breaking down.

- Encapsulation in specialised epoxy or resin compounds, which not only shields against moisture and vibration but also helps pull heat away from the copper windings.

The goal is simple: isolate and protect. By creating distance and using superior materials, the design ensures the sensitive electrical parts stay at a safe operating temperature, even when the valve body is handling media hot enough to boil water.

Built-in Robustness for Unfailing Operation

It’s not just about protecting the coil; the entire valve is engineered for thermal resilience. The valve body, which is in direct contact with the high-temperature media, is typically forged from tough materials like stainless steel or brass. These metals hold their shape and resist corrosion even when put through constant heating and cooling cycles.

The internal parts are just as crucial. The plunger and spring are made from specific grades of stainless steel that resist warping and keep their mechanical properties at high temperatures. This ensures the valve operates reliably every single time, without sticking or failing to seal properly.

It's this combination of smart heat management and durable construction that allows a high-temperature solenoid valve to master extreme environments and deliver dependable performance where ordinary components would simply falter.

The Building Blocks of Thermal Resilience

A high-temperature solenoid valve's ability to operate flawlessly in scorching conditions isn't magic; it's pure material science. The secret to its durability lies in a careful selection of materials for two key areas: the main valve body that contains the intense heat and the crucial seals that prevent leaks. Choosing the wrong material for either component guarantees swift and often dangerous failure.

Think of the valve body as the furnace wall. It has to be strong enough to withstand high pressures while remaining structurally stable at punishing temperatures. This is why materials like Stainless Steel and Brass are the top contenders for constructing a high temperature solenoid valve.

The Foundation of Strength: Valve Body Materials

Stainless steel is often the premium choice, particularly for its fantastic corrosion resistance and high melting point. This makes it ideal for handling aggressive media like certain chemicals or superheated steam, where lesser metals would quickly degrade. Brass, a robust and cost-effective alloy, also performs admirably in many hot water and oil applications, offering excellent thermal conductivity.

The choice between them often comes down to balancing performance requirements with budget and the specific chemical properties of the fluid being controlled. For instance, a food processing plant using hot water for sterilisation might choose stainless steel for its purity and resistance to corrosion over time.

This focus on robust materials is critical as industries push for components that can handle ever-more-demanding conditions. The increasing complexity and demand for ultra-high temperature solenoid valves highlight a growing industrial requirement in the UK for parts that operate reliably in extreme environments. This is particularly relevant for the UK’s expanding renewable energy and advanced manufacturing sectors, where precision and high-temperature resistance are fundamental. You can discover more insights about the growth of the ultra-high temperature valve market on datainsightsmarket.com.

The Unsung Heroes: Seal Materials

While the body provides the structural integrity, the seals are the unsung heroes responsible for preventing leaks. A seal in a high-temperature application must remain flexible and create a tight closure without becoming brittle or melting. Standard seal materials like NBR (Nitrile) would fail almost instantly above 100°C.

The seal is often the first point of failure in an improperly specified valve. Matching the seal material to the temperature and media type is arguably the most critical decision in ensuring long-term reliability.

This is where specialised elastomers and polymers come into play. Each has a distinct temperature range and chemical compatibility profile, making the selection process absolutely vital.

Comparing High-Temperature Seal Options

| Seal Material | Common Name | Typical Max Temperature | Best For |

|---|---|---|---|

| FKM | Viton® | ~200°C | Hot oils, fuels, and many industrial chemicals. |

| PTFE | Teflon® | ~230°C | Aggressive media, steam, and food-grade uses. |

| EPDM | EPDM | ~150°C | Hot water, steam, and glycol-based fluids. |

Let’s break down these choices with some practical examples.

FKM (Viton®) is the go-to choice for systems handling hot hydraulic oils or engine fuels. Its excellent resistance to hydrocarbons makes it perfect for automotive and manufacturing machinery where petroleum-based fluids are common.

PTFE (Teflon®) is a real powerhouse when it comes to chemical resistance. Its incredibly low-friction surface and ability to handle aggressive substances make it indispensable for chemical processing plants or applications involving pure, high-temperature steam.

EPDM really shines in applications involving water or steam, such as in industrial boilers, district heating systems, or autoclaves. However, it performs poorly with oils and solvents, which would cause it to swell and degrade quickly.

Ultimately, constructing a resilient high-temperature solenoid valve is a two-part strategy. It requires a tough, heat-resistant body to form the foundation and a precisely chosen seal material to guarantee a leak-proof and reliable operation, cycle after cycle.

Choosing the Right Valve for Your Application

Picking the right high-temperature solenoid valve can feel overwhelming. There are so many options. But if you break it down into a few key decisions, the process becomes much clearer. You can go from feeling uncertain to being confident you've specified a valve that’s not just good enough, but a perfect fit for the job.

This isn't about taking a wild guess. It's about methodically matching the valve’s capabilities to what your system actually needs. Get this right, and you’re setting yourself up for a safe, efficient, and long-lasting installation. Let’s walk through the critical steps.

Define Your Operating Conditions

First things first: you absolutely must know the environment your valve will be living in. This is the foundation of your decision. If you get this part wrong, even the most expensive and well-built valve is destined to fail. You need to pin down some precise data.

Start with these fundamentals:

- Media Type: What exactly is going to be flowing through the valve? Is it hot water, superheated steam, thermal oil, or something more aggressive like a corrosive chemical? The fluid itself is the number one factor that determines the body and seal materials you’ll need. For steam in particular, you need a valve specifically designed for its unique challenges. We have a dedicated guide on high-temperature solenoid valves for steam systems that digs into these special requirements.

- Temperature Range: What’s the minimum and maximum temperature the valve will face? Don’t just think about the fluid temperature; you also need to account for the ambient temperature of the surrounding environment.

- Pressure Range: What are the inlet and outlet pressures in your system? You need to know both the minimum and maximum pressure, as this directly impacts whether a direct-acting or pilot-operated valve is the right choice.

Think of it this way: media, temperature, and pressure are the three pillars of your selection. Every other choice you make rests on getting this information right.

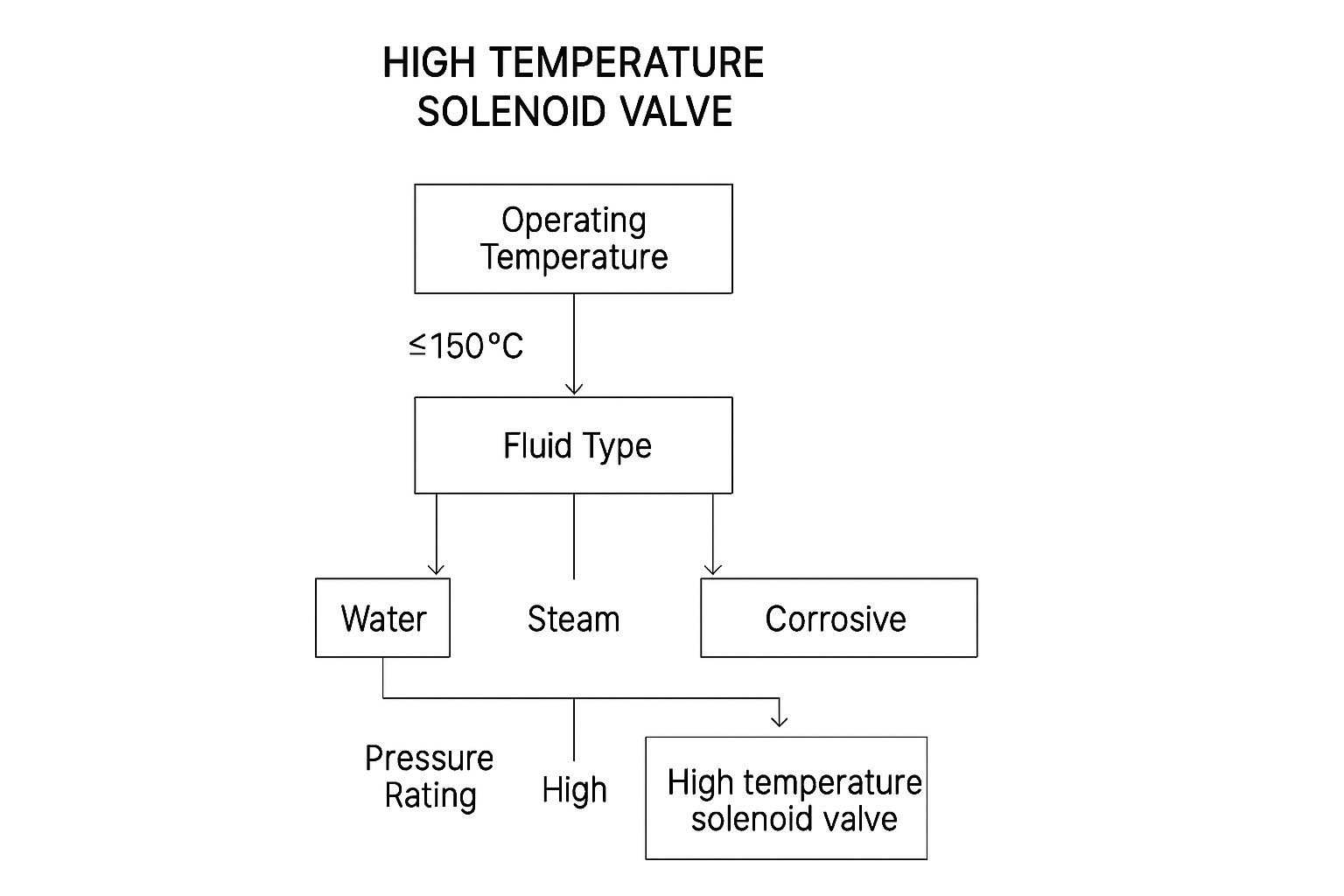

This decision tree gives you a great visual for how these core factors steer you towards the right valve family.

As you can see, filtering by operating temperature, the type of fluid, and the pressure rating immediately narrows down the field, making your choice a lot simpler.

Determine the Valve’s Function and Operation

Once you’ve nailed down your operating conditions, you can think about what you need the valve to do. This boils down to its default state and how it opens and closes.

The most basic choice is between a Normally Open (NO) and Normally Closed (NC) valve. The vast majority of applications use Normally Closed valves. They stay shut, blocking flow, until you send power to the coil to open them. This is a brilliant fail-safe for many systems because if the power cuts out, the valve automatically closes and stops the flow.

A Normally Open valve does the opposite. It stays open, letting fluid pass through, until you energise it to shut. This is handy for applications that need to vent or drain safely in the event of a power failure.

Next, you need to think about the operating principle, which is tied directly to your system's pressure.

- Direct-Acting Valves: Here, the solenoid coil does all the work, directly lifting the plunger to open the valve. They are perfect for low-pressure systems or even vacuums because they don’t rely on system pressure to work.

- Pilot-Operated Valves: These clever designs use the pressure already in your pipework to help open a much larger main orifice. This allows them to control significantly higher flow rates and pressures, but there’s a catch: they need a minimum pressure difference between the inlet and outlet to operate correctly.

Your High Temperature Solenoid Valve Selection Checklist

Working through these technical details systematically is the key to success. This checklist will help you gather all the necessary information in one place, ensuring you don't miss a critical parameter when specifying your valve.

| Parameter | Question to Answer | Example |

|---|---|---|

| Media Type | What fluid will pass through the valve? | Saturated Steam |

| Temperature | What is the minimum and maximum media/ambient temperature (°C)? | 150°C media, 40°C ambient |

| Pressure | What is the minimum and maximum operating pressure (bar)? | Min 0.5 bar, Max 10 bar |

| Function | Does it need to be open or closed without power? | Normally Closed (fail-safe close) |

| Operation | Is there enough pressure differential for a pilot valve? | Yes, pressure drop is >0.5 bar (Pilot-Operated) |

| Port Size | What is the size of the connecting pipework? | 1" BSP |

| Flow Rate (Cv) | What flow rate is required for the system to perform correctly? | Required Cv value of 12 |

| Voltage | What power supply is available for the coil? | 24V DC |

| Certifications | Are any specific approvals needed (e.g., ATEX, WRAS)? | Not required for this application |

By answering each of these questions, you build a complete technical profile of the exact valve you need, taking all the guesswork out of the equation.

Sizing and Flow Rate Considerations

Finally, you have to make sure the valve is the right size to handle the volume of fluid your system demands. This comes down to two things: its port size and its flow coefficient (Cv). The port size is straightforward—it should match your pipework to prevent creating a bottleneck and restricting flow.

The Cv value is a critical number that tells you how much fluid the valve can pass at a specific pressure drop. A higher Cv value means a higher flow rate. Choosing a valve with the right Cv is absolutely vital. If it's too small, it will starve your system. If it's too big, you'll not only waste money but could also end up with poor control and "water hammer" issues.

Getting this selection process right is more important than ever. The global solenoid valve market is growing steadily and is predicted to hit around USD 4.99 billion by 2025. In the UK, this growth is fuelled by industrial upgrades and a major push for energy efficiency, especially in sectors like heating and power generation that depend on specialist components like a high-temperature solenoid valve.

Real-World Applications in Industry

Theory and specs are one thing, but where a high temperature solenoid valve really proves its worth is out in the field, solving tough industrial problems. These aren't just abstract components on a schematic; they are the dependable workhorses at the core of critical processes in countless industries. Looking at how they perform in specific situations helps connect the technical details to real, tangible results.

From hospital sterilisation to heavy manufacturing and power generation, these valves deliver the precise, automated control needed to keep things safe and efficient whenever heat is a factor.

Ensuring Sterility in Healthcare and Pharmaceuticals

In any hospital or pharmaceutical plant, perfect sterilisation is a life-or-death matter. Autoclaves are the go-to tool for this, using superheated steam under high pressure—often between 121°C and 134°C—to wipe out every last microbe on surgical tools and lab gear. The whole process hinges on absolute precision.

A high-temperature solenoid valve acts as the gatekeeper for this steam. It has a critical job to do:

- It must open reliably to let in the exact volume of steam needed for sterilisation.

- It has to maintain a perfect seal under constant heat and pressure for the entire cycle.

- Then, it needs to snap shut instantly for the vacuum and drying phases.

If that valve doesn't open properly, the equipment isn't sterile. If it leaks, pressure drops, the cycle is compromised, and patient safety is on the line. This is why a stainless steel, steam-rated solenoid valve with PTFE seals is the right choice—it offers the chemical resistance and thermal stability to perform flawlessly, time and time again.

Managing Hot Oil in Industrial Manufacturing

Picture a huge industrial press, the kind used for moulding composites or laminating wood. These machines often have a network of channels running through them, filled with circulating hot thermal oil to heat the press platens to a consistent temperature, which can easily top 200°C. Hitting and holding that exact temperature is vital for product quality.

The challenge here is controlling the flow of this incredibly hot, viscous oil. A high temperature solenoid valve is essential for this task. It manages the circulation, diverting or stopping the flow as required to regulate the platen temperature with pinpoint accuracy.

You can think of the valve as the thermostat for the entire machine. Its quick response time ensures the mould never gets too hot or too cold, which prevents defects and cuts down on wasted material.

For this kind of job, a valve with a tough brass or stainless steel body and FKM (Viton®) seals is the ideal setup. FKM is brilliant at resisting hot oils and fuels, which stops the seals from breaking down and ensures a long, leak-free life, even when it’s constantly heating up and cooling down.

Controlling High-Pressure Steam in Power Generation

Power plants, especially those with steam turbines, are home to some of the most extreme conditions you can imagine. Boilers create steam at immense pressures and temperatures to spin the turbines that generate our electricity. Managing this high-energy steam requires components built with zero compromises on strength and reliability.

High temperature solenoid valves are dotted throughout the auxiliary systems in a power plant. They might control the steam for soot blowers that keep boiler tubes clean, or manage steam tracing lines that prevent other pipes and instruments from freezing in cold weather.

In this environment, the failure of just one valve can have massive knock-on effects, from a drop in efficiency to a full-blown, expensive shutdown. That’s why the valves used here have to be engineered not just for extreme heat but also for incredibly high pressures, often demanding specialised designs that go far beyond standard, off-the-shelf parts.

Installation and Maintenance for Peak Performance

A high-quality high temperature solenoid valve is a fantastic investment in your system's reliability. But its long-term performance? That comes down entirely to getting the installation right and sticking to a proactive maintenance schedule.

Nailing these two things prevents premature failure, sidesteps costly downtime, and keeps your operations safe. A botched installation can cause immediate headaches, while skipping maintenance is a guaranteed way to shorten a valve’s working life.

Think of it like fitting a high-performance engine. You wouldn't just drop it in and cross your fingers; you'd make sure every connection, alignment, and fluid line was absolutely perfect. The same care applies here. Get it right, and your valve will operate at its peak for years.

Nailing the Installation Process

Correct installation is your first, and best, chance to lock in reliability. While the specific steps can change depending on the model, a few universal rules always apply. It's overlooking these fundamentals that causes most valve failures I see in the field.

Key installation practices include:

- Correct Mounting Orientation: Most solenoid valves are designed to be mounted with the coil pointing straight up. Installing one on its side or upside down can stop the plunger from moving freely, leading to annoying operational issues or a failure to close properly.

- Upstream Filtration: Debris is the absolute enemy of a solenoid valve. You must install a Y-strainer just before the valve’s inlet port—it's non-negotiable. This simple bit of kit catches pipe scale, rust, and other gunk that could score the valve seat or jam the plunger, causing critical leaks.

- Verify Electrical Supply: Always, always double-check that the voltage and current you're supplying match the specs printed on the coil. The wrong voltage can either stop the coil from actuating or, far more dangerously, cause it to overheat and burn out completely.

For a more detailed walkthrough, you can find excellent guidance in our dedicated article covering solenoid valve installation and maintenance instructions. It’s a great checklist for any technician.

Proactive Maintenance for Longevity

Once your valve is up and running, a simple maintenance schedule is your best friend for catching small problems before they become big ones. This isn't about waiting for something to break; it's about doing regular checks that keep your system healthy and prevent those unexpected, middle-of-the-night failures.

A regular maintenance routine transforms valve management from a reactive headache into a controlled, predictable process. It's the difference between scheduling a quick inspection and managing an emergency shutdown.

Your routine can be straightforward. A few key sensory checks—what you can see, hear, and feel—are often all it takes to spot the early warning signs of trouble. This simple "look, listen, and feel" approach is remarkably effective.

A Simple Maintenance Checklist

- Look for Leaks: Every so often, inspect the valve body and pipe connections for any weeping or moisture. Even a tiny external leak is a clear sign that a seal is starting to degrade and needs looking at.

- Listen for Abnormal Sounds: A healthy, energised valve gives off a faint, steady hum. If you hear a loud, excessive buzzing or chattering, it often points to a problem like low voltage, incorrect pressure, or internal debris that's stopping the plunger from seating correctly.

- Feel for Overheating: The body of a high temperature solenoid valve will naturally be hot because of the media running through it. The coil, however, shouldn't be excessively hot to the touch. An unusually hot coil is a classic red flag for an incorrect voltage supply or an internal short circuit.

Frequently Asked Questions

Even after you get your head around the technical side of high temperature solenoid valves, a few practical questions always pop up. It happens to everyone, from engineers on the floor to the technicians keeping everything running.

Here are some straight answers to the most common queries we get. Getting these details right is often the difference between a system that runs like a dream and one that causes expensive headaches.

Can I Use a Standard Valve for a High Temperature Application?

We hear this one a lot, and the answer is a firm and absolute no. Trying to shoehorn a standard solenoid valve into a high-temperature job isn't just a bad idea—it’s a serious safety risk.

The problem comes down to the seals. Your typical standard valve uses materials like Nitrile (NBR), which is perfectly fine for moderate temperatures, usually up to about 80°C. But once you expose it to hot oil or steam, that seal will degrade with frightening speed. It becomes brittle, cracks, and ultimately fails, leading to dangerous leaks, equipment failure, and potentially far worse.

How Long Does a High Temperature Solenoid Valve Last?

There's no single answer to this; a valve's lifespan really depends on the job it's doing. How often does it open and close? What's flowing through it? A valve controlling clean, hot water that cycles once an hour will have a much easier life than one wrestling with aggressive steam every few seconds.

That said, a high temperature solenoid valve is built for the tough stuff. When you've picked the right one for the temperature, pressure, and media—and you've protected it with a filter upstream—it's designed to give you millions of reliable cycles. Think of proper maintenance as the key to unlocking that full operational life.

A correctly specified and maintained valve isn't just a component; it's a long-term investment in your system's reliability. Proper selection is the first and most important step towards ensuring a long service life.

What Are the Warning Signs That My Valve Is Failing?

Keeping your senses sharp is the best way to catch a problem before it causes a full-blown shutdown. You can often see, hear, or feel the signs that a high temperature valve is on its way out.

Look out for these classic symptoms:

- External Weeping or Leaks: This is a big one. Any moisture or residue around the valve body or where the coil meets the valve is a dead giveaway that an internal seal has failed.

- Failure to Actuate: The valve gets stuck open or doesn't seal properly when it closes. This could be anything from a bit of grit inside to a worn-out spring or a dying coil.

- Sluggish Operation: If the valve seems lazy or slow to respond when you power it on or off, you could be looking at internal wear and friction, or a coil that's losing its strength.

- Unusual Coil Noise or Heat: A healthy coil should just have a faint hum. If you hear a loud, angry buzzing sound, it could be a voltage issue or something physically stopping the plunger from seating correctly. And if the coil is too hot to comfortably touch, that’s a major red flag—it’s likely on its last legs.

At Solenoid Valve World, we have the expertise and the high-quality parts you need to keep your systems running safely and efficiently. Take a look at our huge range of high-temperature valves and find the perfect fit for your application.