Finding the Perfect Gas Solenoid Valve

Need to control gas flow precisely and safely? This listicle presents six top-performing solenoid valves for gas applications, helping you choose the ideal solution. We'll cover key features, pros, and cons of each valve, including options like the ASCO 8210, Parker 7100, Burkert Type 6213 EV, Danfoss EV220B, and SMC VX2 Series. We’ll also highlight Solenoid Valve World as a valuable resource for sourcing your solenoid valve for gas. This guide simplifies your selection process, whether you require a solenoid valve for gas in a domestic boiler or a complex industrial system.

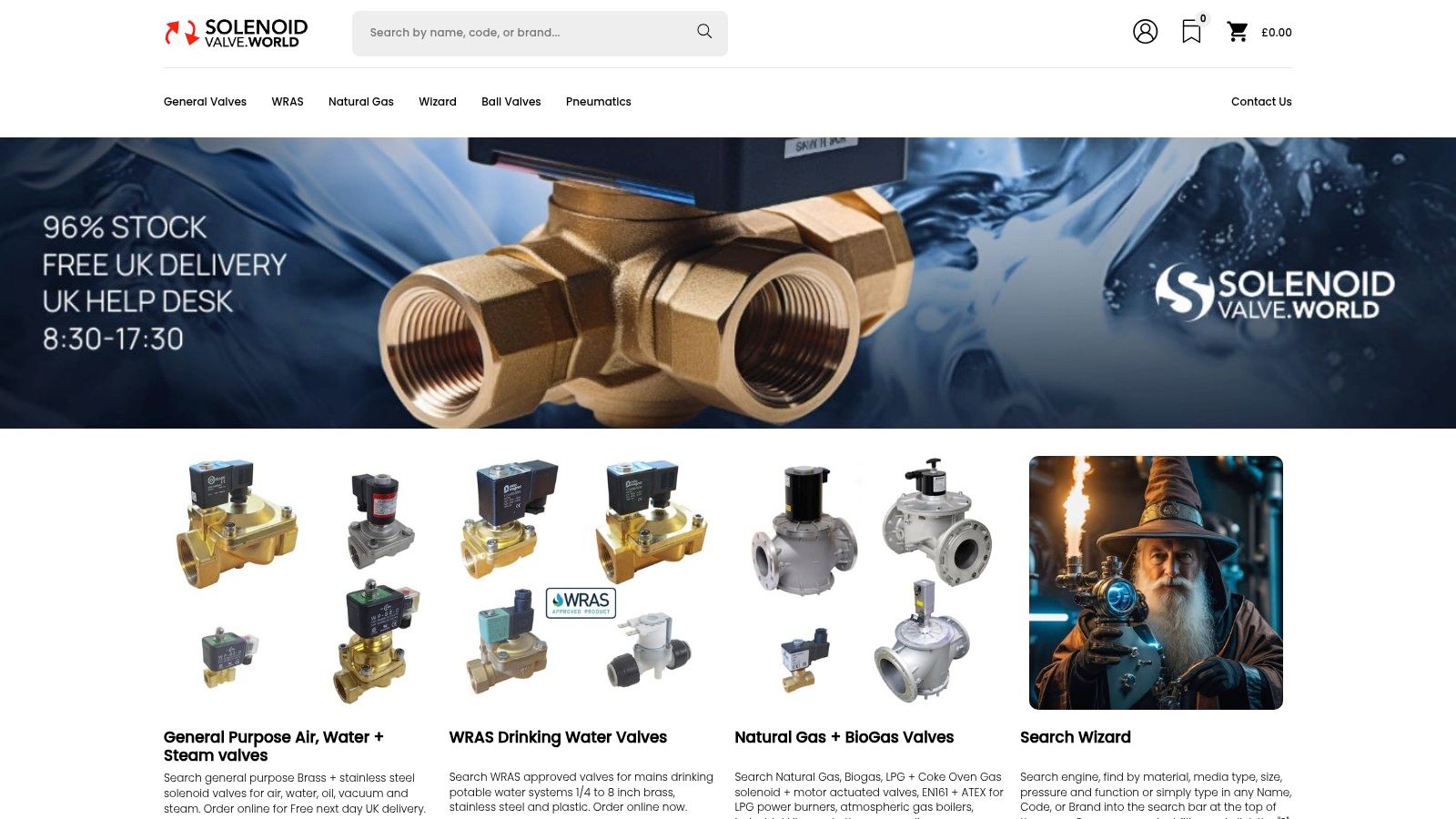

1. Solenoid Valve World

For UK-based professionals seeking a reliable source of solenoid valves for gas applications, Solenoid Valve World stands out as a comprehensive online retailer. They offer an extensive range of high-quality solenoid valves, actuated ball valves, and related pneumatic components specifically designed for handling various media, including natural gas, biogas, and LPG. Their stock caters to diverse needs, from industrial kilns and gas appliances to more general gas control systems. A key strength lies in their offering of EN161 and ATEX-certified valves, ensuring compliance with stringent safety standards required for gas applications. This commitment to quality and regulation makes them a particularly attractive option for engineers and manufacturers prioritizing safety and adherence to industry best practices.

Solenoid Valve World simplifies the product selection process with an intuitive search engine and comprehensive filters. Users can quickly refine their search by media type (specifically "gas"), size, pressure rating, function (e.g., normally closed, normally open), and even brand. This allows mechanical and process engineers, as well as HVAC and gas appliance installers, to efficiently locate the precise solenoid valve for their specific gas control requirements. Beyond individual valves, their catalog extends to include associated components like pneumatic fittings, filters, regulators, and relief valves, providing a one-stop shop for complete system solutions. Learn more about Solenoid Valve World and their general-purpose offerings.

While specific pricing isn't readily available on the website, requiring contact for quotes, the benefit of free next-day delivery within the UK is a significant advantage for time-sensitive projects. This rapid turnaround, combined with flexible payment options including PayPal and major credit cards, contributes to a streamlined procurement process. Furthermore, their UK-based technical support, available during standard business hours, provides expert assistance and addresses any technical queries, bolstering customer confidence. This dedicated support is invaluable for installers and maintenance teams needing guidance on installation, troubleshooting, or selecting the appropriate valve for a specific gas application.

Pros: Wide selection of WRAS and ATEX-certified valves suitable for various gas applications; user-friendly website for easy navigation; free next-day UK delivery; flexible payment options; UK-based technical support.

Cons: Limited international shipping; pricing requires individual quotes.

This focus on UK customers, while beneficial for local businesses, may limit accessibility for international buyers. However, for those within the UK, Solenoid Valve World offers a compelling combination of product quality, regulatory compliance, and efficient service, making it a valuable resource for sourcing solenoid valves for gas applications.

2. ASCO 8210 Series Solenoid Valve

The ASCO 8210 Series earns its spot on this list as a premium, highly reliable solenoid valve for gas applications, perfect for demanding environments encountered by UK engineers and operators. If you prioritize dependability and longevity over initial cost, the 8210 Series deserves serious consideration. This robust solenoid valve is specifically engineered to control the flow of various gases, including natural gas, propane, and other compatible media, making it a versatile choice for a wide range of industrial and commercial settings.

This series shines in applications requiring precise and dependable gas control. Imagine a critical safety shutoff system for a gas burner: the 8210's fast response time becomes essential for preventing hazardous situations. Similarly, in industrial process control where precise gas flow is crucial for maintaining product quality and consistency, the 8210's accuracy and reliability are invaluable. From controlling gas flow in commercial heating systems to regulating gas supply in industrial furnaces, the 8210 Series provides the robust performance you can rely on. It's also frequently found in power generation facilities, gas distribution networks, and even complex manufacturing processes.

The ASCO 8210 offers a range of configurations, with normally closed and normally open options available. This flexibility ensures it can be integrated into diverse control systems and meet specific application requirements. Furthermore, the availability of explosion-proof enclosures makes the 8210 Series suitable for hazardous locations, adhering to stringent UK safety regulations.

Key Features and Benefits:

- Wide Range of Sizes and Pressures: Handles pressures up to 200 PSI (depending on the specific model) and is available in pipe sizes from 1/8" to 2", accommodating a wide spectrum of gas systems. This versatility simplifies system design and integration within UK infrastructure.

- Durable Construction: Constructed with a robust brass or stainless steel body, ensuring long service life even in challenging operational conditions. The choice of materials allows you to select the optimal configuration for your specific gas and environment, minimizing corrosion and maximizing longevity.

- Certified for Safety and Reliability: UL and CSA certified for both natural gas and LP gas applications, providing assurance of its safety and performance in accordance with UK standards.

- Wide Temperature Range: Operates effectively within a temperature range of -40°F to 180°F (-40°C to 82°C), suitable for the varied climatic conditions experienced in the UK.

- Fast Response Time: Critical for safety applications, the 8210's rapid response ensures quick and effective control of gas flow.

Pros:

- Exceptional reliability and a long service life, minimizing downtime and maintenance costs.

- Fast response time, vital for safety-critical applications.

- Variety of body materials ensures compatibility with a wide range of gases.

- Industry-leading quality, backed by extensive certifications.

Cons:

- Higher price point compared to some competitors. However, the long-term cost savings from increased reliability and reduced maintenance often justify the initial investment.

- Requires careful voltage matching for optimal performance. Consult the specifications and ensure your electrical system is compatible.

- Some models may require additional maintenance in extremely dusty environments.

Implementation Tips:

- Ensure correct voltage supply and wiring configuration as per the manufacturer's specifications. Incorrect wiring can lead to malfunction and potential hazards.

- Consider the specific gas and environmental conditions when selecting the appropriate body material (brass or stainless steel).

- Regular inspection and maintenance are recommended, particularly in harsh environments, to ensure optimal performance and longevity.

Pricing: Pricing for the ASCO 8210 Series varies depending on the specific configuration, including body material, pipe size, and pressure rating. Contacting a distributor or visiting the Emerson website is recommended for detailed pricing information for the UK market.

Website: https://www.emerson.com/en-us/catalog/asco-series-8210

The ASCO 8210 Series stands as a premium choice for a solenoid valve for gas applications where reliability, durability, and safety are paramount. While the initial cost might be higher, the long-term benefits of reduced maintenance, minimized downtime, and enhanced safety make it a worthwhile investment for critical gas control systems in the UK.

3. Parker 7100 Series Solenoid Valve

The Parker 7100 Series is a robust and versatile solenoid valve for gas, making it a strong contender for various gas control applications. Its direct-acting design ensures precise and reliable on/off control, a crucial factor for engineers and technicians dealing with critical gas systems. This solenoid valve for gas excels in providing fast and dependable performance, particularly suited for demanding environments.

This series shines in applications requiring precise gas control, such as gas burner systems, gas analyzers, and industrial process control. Its compact design, coupled with multiple mounting options, makes it ideal for installations where space is at a premium. For instance, in a packaged gas burner system, the 7100 Series can easily be integrated into the control manifold, simplifying installation and reducing overall system footprint.

The 7100 Series' brass body and specifically chosen elastomer seals ensure compatibility with a range of gases. This versatility extends to varying flow requirements, thanks to the availability of multiple orifice sizes and connection options. From controlling natural gas flow in a commercial heating system to regulating specialty gases in a laboratory setting, this solenoid valve for gas adapts to diverse needs. For UK users, this adaptability is especially relevant given the diverse applications of gas across various industries.

Key features of the Parker 7100 Series include:

- Direct-acting design: Provides positive on/off control without the need for a minimum pressure differential.

- Pressure ratings up to 150 PSI: Suitable for a wide range of gas pressures.

- Compact design: Facilitates installation in confined spaces.

- ATEX and IECEx approvals (available): Ensures safe operation in potentially hazardous environments, crucial for compliance in many UK industrial settings.

- Low power consumption models available: Contributes to energy efficiency.

- Multiple voltage options (12V, 24V, and 110V): Offers flexibility in system integration.

Pros:

- Excellent life cycle durability and proven reliability: Reduces downtime and maintenance costs.

- Fast switching times: Enables responsive control in dynamic systems.

- Compact footprint: Simplifies installation in tight spaces.

Cons:

- Limited to smaller pipe sizes compared to some competitors: May not be suitable for high-flow applications.

- Higher power consumption in standard models: Consider low-power options for energy-sensitive applications.

- May require more frequent maintenance in high-cycle applications: Factor this into preventative maintenance schedules.

While pricing information isn't readily available, contacting Parker directly can provide specific quotes. Learn more about Parker 7100 Series Solenoid Valve for installation and maintenance guidelines. This resource is particularly helpful for UK-based engineers and technicians seeking best practices for installation and upkeep.

When comparing the 7100 Series to competitors like ASCO or Burkert solenoid valves for gas, the Parker valve often stands out due to its robust construction and reliability. While other valves may offer larger pipe size options, the 7100 Series excels in applications where precision, durability, and compact size are paramount.

For implementing the Parker 7100 Series, ensure proper sizing based on your gas flow and pressure requirements. Pay close attention to voltage compatibility and consider environmental factors, such as ambient temperature and potential exposure to hazardous substances. Correct installation is crucial for optimal performance and safety. You can find more information on the Parker website: https://www.parker.com/portal/site/PARKER/menuitem.223a4a3cce02eb6315731910237ad1ca/

4. Burkert Type 6213 EV Solenoid Valve

When reliability and performance are paramount in gas control applications, the Burkert Type 6213 EV Solenoid Valve stands out as a premium choice. This servo-assisted solenoid valve is specifically designed for use with gas, making it a strong contender for various applications across the UK. From heating systems and gas burners in domestic settings to demanding industrial gas control scenarios, the 6213 EV earns its spot on this list due to its robust construction, high flow capacity, and comprehensive certifications.

This solenoid valve for gas features a durable brass body, ensuring longevity even in challenging environments. The seals, available in NBR or FKM, offer broad compatibility with various gases, further enhancing its versatility. The clever servo-assisted design allows for impressive flow rates with a minimal pressure drop, translating to greater efficiency in your system. This is particularly beneficial in applications where maintaining consistent gas pressure and flow is crucial.

Key Features and Benefits:

- High Flow Capacity: The servo-assisted operation enables the 6213 EV to deliver exceptional flow characteristics with a significantly lower pressure drop compared to direct-acting solenoid valves. This is particularly important for applications requiring high gas flow rates.

- Energy Efficiency: Despite its high performance, the 6213 EV boasts low power consumption, contributing to reduced operational costs over time.

- Wide Pressure Range: The valve operates effectively across a broad pressure range, from 0 to 145 PSI (depending on the orifice size), making it suitable for both high and low-pressure gas applications.

- DVGW Approval & Certifications: Crucially for the UK market, the 6213 EV holds DVGW approval, signifying its suitability and safety for natural gas applications. It also boasts other international certifications, ensuring compliance and acceptance across various global standards.

- Flexible Installation: The coil can be rotated 4 x 90°, providing flexibility during installation and allowing it to fit seamlessly into various system configurations.

- Available Sizes: The valve is available in sizes from G1/4 to G2, catering to a range of pipe sizes and flow requirements.

Pros:

- Exceptional flow characteristics with low pressure drop

- Highly energy-efficient with low power consumption

- Suitable for both high and low pressure gas applications

- Extensive certification for global use, including DVGW for natural gas

- Flexible installation options

Cons:

- Premium pricing compared to more basic solenoid valves for gas. This is often offset by the increased efficiency and reliability it offers.

- Requires a minimum pressure differential for reliable operation, which needs to be considered during system design.

- Limited compatibility with certain specialized gas mixtures. Consult the datasheet to ensure compatibility with your specific application.

Technical Requirements and Implementation Tips:

- Ensure the minimum pressure differential requirement is met for your chosen valve configuration and application. Refer to the Burkert documentation for specific values.

- Select the appropriate seal material (NBR or FKM) based on the gas being used.

- Consider the orifice size and its impact on flow rate and pressure drop when selecting a valve.

- Utilise the rotatable coil feature to simplify installation and optimise space.

Pricing: Pricing for the Burkert 6213 EV varies depending on configuration and supplier. Contacting Burkert directly or authorised distributors in the UK is recommended for accurate pricing.

Website: https://www.burkert.com/en/products/solenoid-valves/servo-assisted-solenoid-valves/type-6213

For engineers and professionals seeking a top-tier solenoid valve for gas applications where reliability and performance are non-negotiable, the Burkert 6213 EV is a worthy investment. While it commands a premium price, its robust construction, high flow capacity, and comprehensive certifications, including DVGW approval, make it a compelling choice for demanding applications in the UK.

5. Danfoss EV220B Solenoid Valve

The Danfoss EV220B earns its spot on this list as a top-tier solenoid valve for gas, specifically designed for heavy-duty, industrial applications requiring robust performance and reliability. If you're a mechanical or process engineer overseeing large-scale gas systems, an industrial maintenance manager, or involved in gas appliance manufacturing in the UK, this valve deserves a closer look.

This servo-operated solenoid valve boasts a durable brass body and specialized sealing materials, ensuring compatibility with various gas types, including natural gas and LPG. This makes it a versatile choice for diverse applications such as industrial burners, gas distribution networks, and large HVAC systems. Learn more about Danfoss EV220B Solenoid Valve for its approved usage with natural gas.

One of the key advantages of the EV220B is its excellent flow characteristics. It provides high flow rates, up to 31 m³/h depending on the specific model, with minimal pressure loss, ensuring efficient gas delivery even in high-demand systems. This efficiency translates to lower operating costs and improved overall system performance. The valve operates within a broad pressure range of 0.3 to 16 bar (4.3 to 232 PSI), catering to a wide range of industrial requirements. However, it's important to note that the EV220B requires a minimum differential pressure for operation, a factor to consider during system design.

The modular design of the Danfoss EV220B is a significant advantage for maintenance. The valve body and coil can be serviced independently, simplifying maintenance procedures, reducing downtime, and ultimately lowering maintenance costs. This modularity also allows for easy replacement of individual parts, extending the overall lifespan of the valve.

While the Danfoss EV220B represents a higher initial investment compared to simpler, direct-acting solenoid valves, its robust construction and durable components ensure a long service life, justifying the cost in the long run. The larger physical footprint of the EV220B compared to direct-acting alternatives might require some consideration during system design and installation.

Key Features and Benefits:

- High Flow Capacity: Flow rates up to 31 m³/h with minimal pressure drop.

- Durable Construction: Robust brass body and gas-compatible seals ensure long-lasting performance.

- Modular Design: Easy maintenance and part replacement, reducing downtime and costs.

- Wide Pressure Range: Operates effectively from 0.3 to 16 bar (4.3 to 232 PSI).

- Universal Coil System: Offers multiple voltage options for flexible integration.

- IP65 Enclosure Rating: Provides protection against harsh environmental conditions.

- Manual Override Option: Available for emergency operation and system control.

Pros:

- Exceptionally durable construction for long service life

- Modular design allows for easy maintenance and part replacement

- High flow capacity with minimal pressure drop

- Compatible with multiple gas types including natural gas and LPG

Cons:

- Requires minimum differential pressure for operation

- Larger physical footprint compared to direct-acting alternatives

- Higher initial investment compared to simpler valves

Implementation Tips:

- Ensure the system meets the minimum differential pressure requirements for optimal valve operation.

- Consider the valve's larger footprint during system design and allocate sufficient space for installation.

- Consult the Danfoss product documentation for specific technical requirements and installation guidelines.

Pricing for the Danfoss EV220B varies depending on the specific model and configuration. Contact a Danfoss distributor in the UK for detailed pricing information and availability. For more information, visit the official product page: https://www.danfoss.com/en/products/valves/dcs/solenoid-valves/solenoid-valves-for-industrial-applications/ev220b/

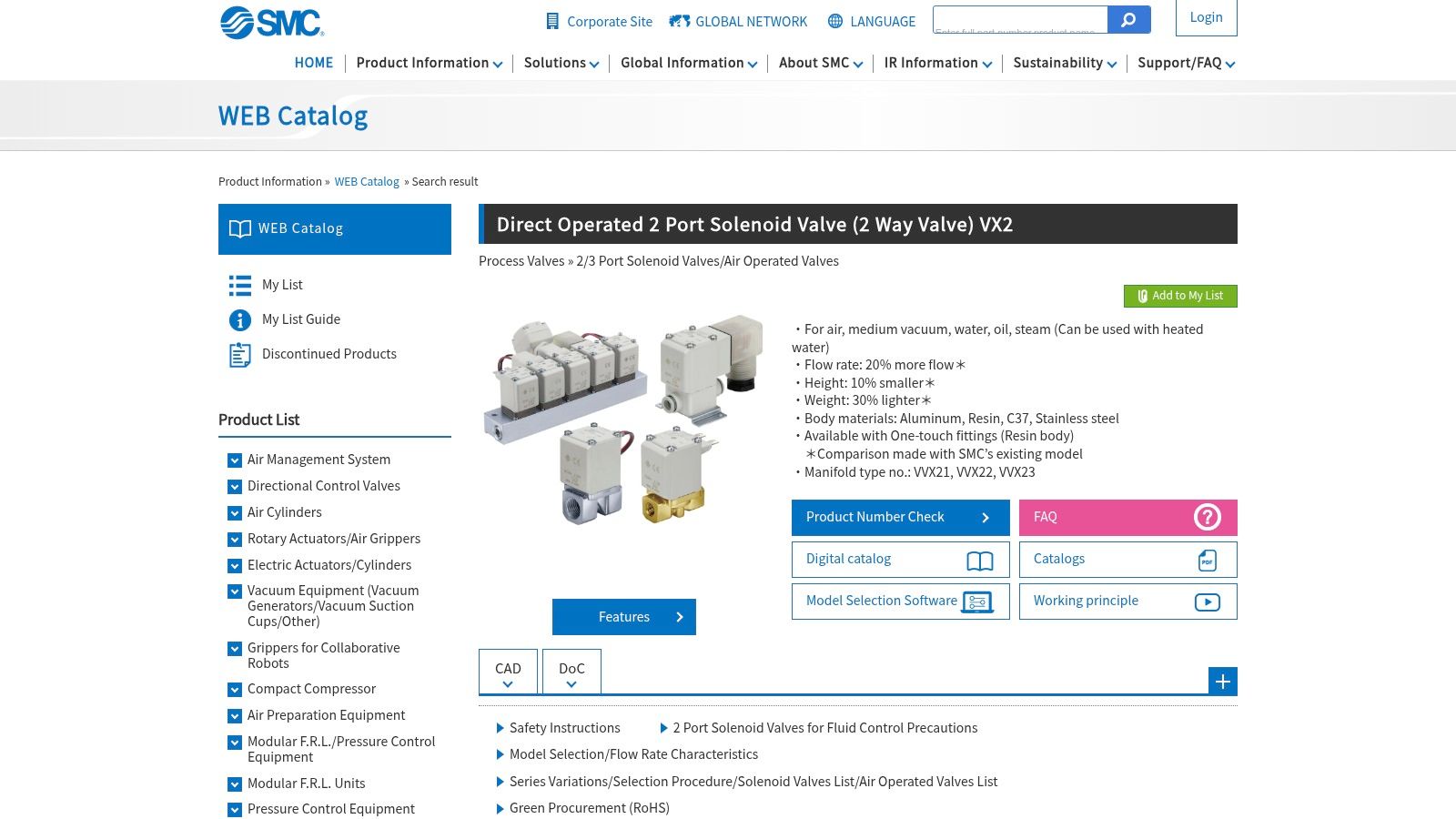

6. SMC VX2 Series Solenoid Valve

The SMC VX2 Series stands out as a high-performance solenoid valve for gas control, specifically designed for applications demanding precision and rapid response. Its direct-operated mechanism ensures an immediate reaction to control signals, making it ideal for critical processes where timely gas flow regulation is paramount. This makes it a strong contender for inclusion in this list, especially for applications requiring precise and dynamic gas control. This valve is particularly suited for use in the UK due to its compliance with relevant gas safety regulations and its availability through SMC's UK distribution network.

From analytical instruments in laboratories to complex gas burner systems in industrial settings, the VX2 series offers a reliable and efficient solution. Think of applications like gas chromatography, flame ionization detectors, or controlling the fuel supply to burners in industrial ovens. The compact and lightweight aluminium body allows for easy integration even in space-constrained environments, a significant advantage for retrofits or complex installations. Furthermore, the availability of explosion-proof configurations broadens its applicability to hazardous environments commonly found in the oil and gas, petrochemical, and pharmaceutical industries in the UK.

The VX2 series boasts flow rates up to 1,600 L/min depending on the chosen model and handles operating pressures from 0 to 1 MPa (0 to 145 PSI). Multiple port sizes, ranging from M5 to 1/2", provide flexibility for various applications. The low power consumption, available in both DC and AC voltage options, contributes to lower operating costs and minimizes heat generation, enhancing overall system efficiency. Unfortunately, pricing information isn't readily available online and often requires contacting SMC directly for a quote based on specific configuration requirements. This allows for tailored pricing based on features like voltage, port size, and explosion-proof requirements.

Pros:

- Extremely fast response time: Critical for applications requiring precise and dynamic gas control.

- Compact design: Facilitates installation in tight spaces.

- High reliability and long service life: Ensures consistent performance even in demanding high-cycle applications.

- Energy-efficient operation: Reduces operating costs and heat generation.

Cons:

- Limited flow capacities: Compared to servo-operated valves, the VX2 series is better suited for smaller flow requirements.

- Sensitivity to particulate contamination: Proper filtration is essential to prevent performance issues.

- Less suitable for very high-pressure applications: Consider alternative solutions for pressures exceeding 1 MPa.

Implementation Tips:

- Ensure proper filtration: Install an appropriate filter upstream of the valve to protect it from particulate contamination and ensure optimal performance.

- Select the correct voltage and port size: Carefully consider your application requirements to choose the appropriate valve configuration.

- Consult with SMC for hazardous environment applications: If your application involves potentially explosive atmospheres, ensure the selected VX2 model complies with all relevant safety regulations and certifications.

For more detailed technical specifications, datasheets, and information on available configurations, visit the official SMC website: https://www.smcworld.com/products/en/get.do?type=GUIDE&id=VX2-E

Solenoid Valve Model Comparison

| Product | Core Features/Certifications ✨ | User Experience/Quality ★ | Value Proposition & Price | Target Audience | Unique Selling Points |

|---|---|---|---|---|---|

| Solenoid Valve World | Wide selection including WRAS, EN161, ATEX certified valves; brass, SS, plastic types; filters & actuated valves | Intuitive search & filters; UK-based expert support; free next-day delivery ★★★★ | Flexible PayPal/card payments; comprehensive catalog; pricing on request | Industrial, municipal, HVAC, gas appliance pros | One-stop specialist retailer; certified, reliable, fast service ✨ |

| ASCO 8210 Series Solenoid Valve | Brass/SS body; UL/CSA certified; explosion-proof options; up to 200 PSI | Long service life, fast response, industry-standard ★★★★ | Premium pricing; requires correct voltage; high reliability | Industrial/commercial gas control systems | Explosion-proof; robust & certified for gas safety ✨ |

| Parker 7100 Series Solenoid Valve | Direct-acting; ATEX & IECEx certified; up to 150 PSI; low power models | Fast switching; compact; multi-voltage options ★★★ | Mid to high price; smaller pipe sizes; size efficient | Industrial, commercial, medical gas applications | Compact; fast response; ATEX/IECEx approved ✨ |

| Burkert Type 6213 EV Solenoid Valve | Servo-assisted for high flow; DVGW approved; sizes G1/4 to G2 | Energy-efficient; excellent flow; global certification ★★★★ | Premium pricing; needs minimum pressure differential | Heating, burners, industrial gas systems | Servo-assisted design; low pressure drop; flexible coil rotation ✨ |

| Danfoss EV220B Solenoid Valve | Servo-operated; modular design; IP65 rated; 0.3-16 bar (4.3-232 PSI) | Durable; easy maintenance; high flow; multi-gas compatible ★★★★ | Higher initial cost; larger footprint; modular saves maintenance costs | Heavy industrial gas systems | Modular coil/body; manual override; IP65 rated ✨ |

| SMC VX2 Series Solenoid Valve | Direct-operated; aluminum body; explosion-proof option; up to 145 PSI | Extremely fast response; compact; energy-efficient ★★★ | Competitive pricing; limited flow; sensitive to contamination | Analytical, burner systems, hazardous gas | Fastest response; lightweight; explosion-proof available ✨ |

Making the Right Choice

Selecting the right solenoid valve for gas applications is crucial for ensuring safety, efficiency, and reliability in your systems. Throughout this article, we've explored several leading options, including the ASCO 8210 Series, Parker 7100 Series, Burkert Type 6213 EV, Danfoss EV220B, and SMC VX2 Series. Each of these valves offers unique features and capabilities suited for specific gas control needs. Key takeaways include understanding the importance of pressure and flow rate compatibility, the specific gas media compatibility, and the voltage requirements for your intended application. When implementing these tools, remember to prioritize safety by adhering to UK gas regulations and ensuring proper installation and maintenance procedures. For instance, selecting a valve with appropriate ATEX certification is vital for hazardous environments commonly found in gas applications. Properly sizing the valve for your specific application is another critical aspect ensuring optimal performance and preventing potential issues.

Choosing the optimal solenoid valve for gas necessitates a thorough understanding of your project requirements. Consider the operating pressure, required flow rate, the type of gas being controlled (natural gas, propane, etc.), and the environment in which the valve will operate. Don't forget to factor in future maintenance needs and the availability of spare parts within the UK.

Finding the perfect solenoid valve for gas is an investment in the safety and efficiency of your operations. Ready to explore a wider range of high-quality solenoid valves tailored to your specific needs? Visit Solenoid Valve World, a comprehensive resource for everything solenoid valve related, and discover the ideal solution for your gas control application. They offer expert advice and a vast selection to help you make the best choice for your project.