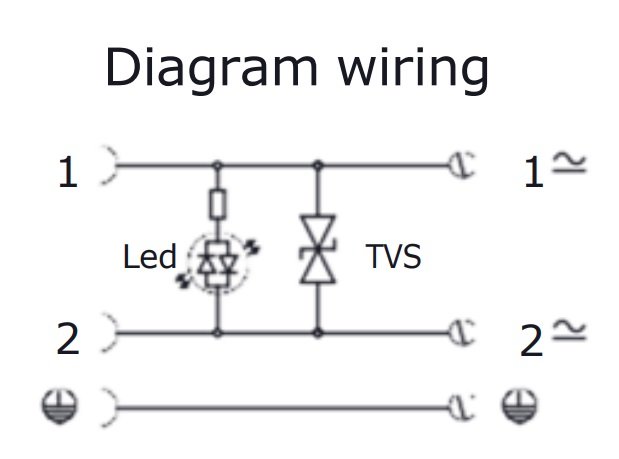

TVS suppressors to protect from voltage spikes (kick backs) from solenoid valves.

Using the EN 175301-803 A (DIN 43650A) electrical connector with Yellow LED + TVS suppressor for solenoid valves offers several technical advantages, particularly in industrial and automation environments.

Here are the key benefits:

1. Surge Protection with TVS (Transient Voltage Suppressor)

TVS suppressor (Vbr max 37.8V, 400W peak) protects connected electronics from voltage spikes (inductive kickback) caused when the solenoid is de-energised.

Increases solenoid and controller lifespan, and protects sensitive PLC or I/O devices.

2. Visual Status Indication with Yellow LED

The built-in yellow LED provides clear visual feedback when the solenoid is energised.

Aids in quick diagnostics and troubleshooting without the need for a multi meter.

3. Standardised & Compatible Interface

Compliant with EN 175301-803 Type A / DIN 43650A, a widely adopted connector standard.

Ensures interoperability with most solenoid valves used in industrial pneumatics, hydraulics, and fluid control.

4. Robust Mechanical and Environmental Design

IP65 protection when correctly assembled offers resistance to dust and water spray, making it suitable for harsh environments.

Wide operating temperature range (-20°C to +80°C) supports diverse industrial applications.

PA12 and PA6 GF materials provide good chemical resistance and mechanical strength.

5. Easy & Secure Assembly

Screw terminals simplify installation without soldering.

Central M3 fixing screw and NBR gasket ensure a secure seal and vibration resistance.

Torque-controlled contact screws (0.5 N·m) help avoid over-tightening and ensure reliable electrical contact.

6. Cable Flexibility

Suitable for cable diameters from 5mm to 7mm, accommodating standard industrial cable sizes.

Versatile for various wiring setups in control panels or field wiring.

7. Earth Pin for Safety

The 2 + Earth configuration ensures protective grounding, enhancing electrical safety in metallic-bodied solenoids.

Summary of Use Case Advantages:

| Feature | Benefit |

|---|---|

| TVS Suppressor | Protects from voltage spikes |

| LED Indicator | Visual operation check |

| Standard EN 175301-803 A | Broad solenoid compatibility |

| IP65 Protection | Industrial durability |

| Easy Mounting | Quick installation and maintenance |

| Grounding Pin | Improved safety |

Detailed comparison of the EN 175301-803 A (DIN 43650A) connector with other common industrial solenoid valve connector types, covering functionality, protection, and application suitability.

1. EN 175301-803 A (DIN 43650A)

(Your Product)

Shape: Square

Contacts: 2+Earth

Pin Spacing: 18mm

Voltage/Current: 24V AC/DC, 4A

Features: LED, TVS suppressor, screw terminals

Protection: IP65 (with gasket and proper assembly)

Best For: Solenoid valves in pneumatics, hydraulics, fluid control systems.

2. EN 175301-803 B / C (DIN 43650B/C)

Shape: Rectangular (smaller than Type A)

Contacts:

Type B: 3-pole or 2+Earth, 11mm pin spacing

Type C: Compact, 8mm pin spacing

Voltage/Current: Similar ranges

Protection: Typically IP65

Pros:

Smaller size for compact devices

Used in more space-constrained systems

Cons:

Less robust for heavy industrial applications

Lower current capacity than Type A

Best For: Smaller solenoids, sensors, pilot valves

M12 Circular Connectors (A-coded)

Shape: Circular, threaded

Contacts: Typically 3, 4, or 5 pins

Voltage/Current: Up to 250V, ~4A

Features: Compact, IP67+ rated, vibration-resistant

Connection: Screw or snap-lock

Pros:

Higher ingress protection (IP67+)

Fast connection/disconnection

Common in field-bus & sensor systems

Cons:

Requires matched M12 cable

More expensive

Harder to wire in-field (less DIY-friendly)

Best For: Mobile machinery, automation with tight space or high wash down requirements

Deutsch DT Connectors

Shape: Rectangular, sealed

Contacts: 2 to 12 pins

Voltage/Current: High capacity, up to 13A/pin

Protection: IP67–IP69K (very high), UV/chemical resistant

Pros:

Excellent sealing, vibration resistance

Ideal for outdoor/heavy-duty mobile equipment

Cons:

Requires crimp tooling

Not standard on solenoid valves

Best For: Agriculture, construction equipment, harsh outdoor use

Terminal Blocks / Screw Terminals (non-pluggable)

Shape: No connector—direct wiring to device

Protection: Varies

Ease of Use: Low

Cons:

No plug-and-play

Harder maintenance

No in-line protection (TVS/LED)

Best For: Fixed installations where cost must be minimal

Comparison Summary Table

| Feature / Type | EN 175301-803 A | DIN 43650 B/C | M12 | Deutsch DT | Screw Terminal |

|---|---|---|---|---|---|

| Protection Rating | IP65 | IP65 | IP67–IP69K | IP67–IP69K | Varies |

| Size | Medium | Small | Compact | Compact | N/A |

| Ease of Field Wiring | Easy (screw) | Easy (screw) | Harder | Medium (crimp) | Low |

| Integrated LED/TVS | ✅ (available) | ✅ (less common) | ❌ | ❌ | ❌ |

| Best For | Solenoids, general | Small solenoids | Sensors, I/O | Harsh outdoor | Fixed systems |

| Cost | Low to medium | Low | Medium–High | Medium–High | Low |

Why Choose EN 175301-803 A (with LED + TVS)?

Best balance of price, durability, visibility, and electrical protection

Ideal for solenoid valve installations in most industrial, OEM, or process automation applications

Tool-free wiring, standard compliance, and LED + TVS make it field-service friendly