Your Guide to Temperature Control Valves

At its core, a temperature control valve is a clever device that automatically manages the temperature of a fluid. It achieves this by carefully controlling the flow of a heating or cooling medium—like steam, hot water, or chilled glycol—to hold a specific, pre-set temperature within a system.

How a Temperature Control Valve Actually Works

Think of a temperature control valve as your system's tireless thermostat, constantly working behind the scenes to keep conditions just right. Its main job is to hit and maintain a target temperature by precisely adjusting the flow of a heating or cooling fluid. It’s not unlike how a radiator valve in your home keeps a room comfortable, or a car's thermostat maintains the engine temperature. This valve is the key to stability.

The entire process hinges on three essential components working together in a seamless feedback loop.

The Three Core Components

To really get a handle on how these valves operate, let’s break down the main parts. Each one has a specific job, and they all need to work in perfect harmony to deliver accurate temperature control.

To make this even clearer, here's a quick look at the primary parts of a typical temperature control valve and what they do in simple terms.

Core Components and Their Real World Functions

| Component | Primary Function | Simple Analogy |

|---|---|---|

| The Sensor | This is the "eyes" of the operation. It constantly measures the process fluid's temperature. It can be a bulb filled with an expansive liquid, a bimetallic strip, or an electronic sensor. | A thermometer telling you if it's too hot or too cold. |

| The Actuator | This is the "muscle." When the sensor detects a temperature change, it signals the actuator, which provides the physical force to open or close the valve. | Your hand turning the tap to adjust the water flow. |

| The Valve Body | This is the "gate." It houses the internal parts (like a plug or disc) that physically move to increase or decrease the flow of the heating or cooling medium. | The tap itself, which contains the mechanism that controls the water. |

These three parts work together beautifully. For instance, in a hot water tank, if the sensor finds the water is too cool, it signals the actuator. The actuator then opens the valve wider, letting more steam or hot water flow into the heating coils. As soon as the water hits the target temperature, the sensor tells the actuator to throttle the valve, reducing the flow.

At its heart, a temperature control valve operates on a simple principle: sense the temperature, compare it to a set point, and adjust the flow to correct any difference. This closed-loop system is the foundation of automated temperature regulation in countless applications.

While the basic principle is straightforward, the control logic can get quite advanced. For high-precision and dynamic systems, it's worth delving into the principles of Mastering PID Temperature Controllers.

The demand for these devices is a clear indicator of their importance. In fact, the UK control valve market, where temperature control valves are a vital segment, is set to grow at a compound annual growth rate (CAGR) of around 14.145% between 2025 and 2035. This growth is fuelled by their expanding use across key UK industries. This ongoing expansion really highlights just how fundamental these components have become to modern industrial processes.

Navigating the Different Types of Control Valves

Now that we've got the core concepts down, we can dive into the different kinds of temperature control valves you'll actually come across in the field. The easiest way to think about them is by what powers them. This single factor tells you almost everything you need to know about their application, complexity, and capabilities. This splits them neatly into two main camps: self-actuated valves that run on their own, and externally powered valves that need to be part of a bigger system.

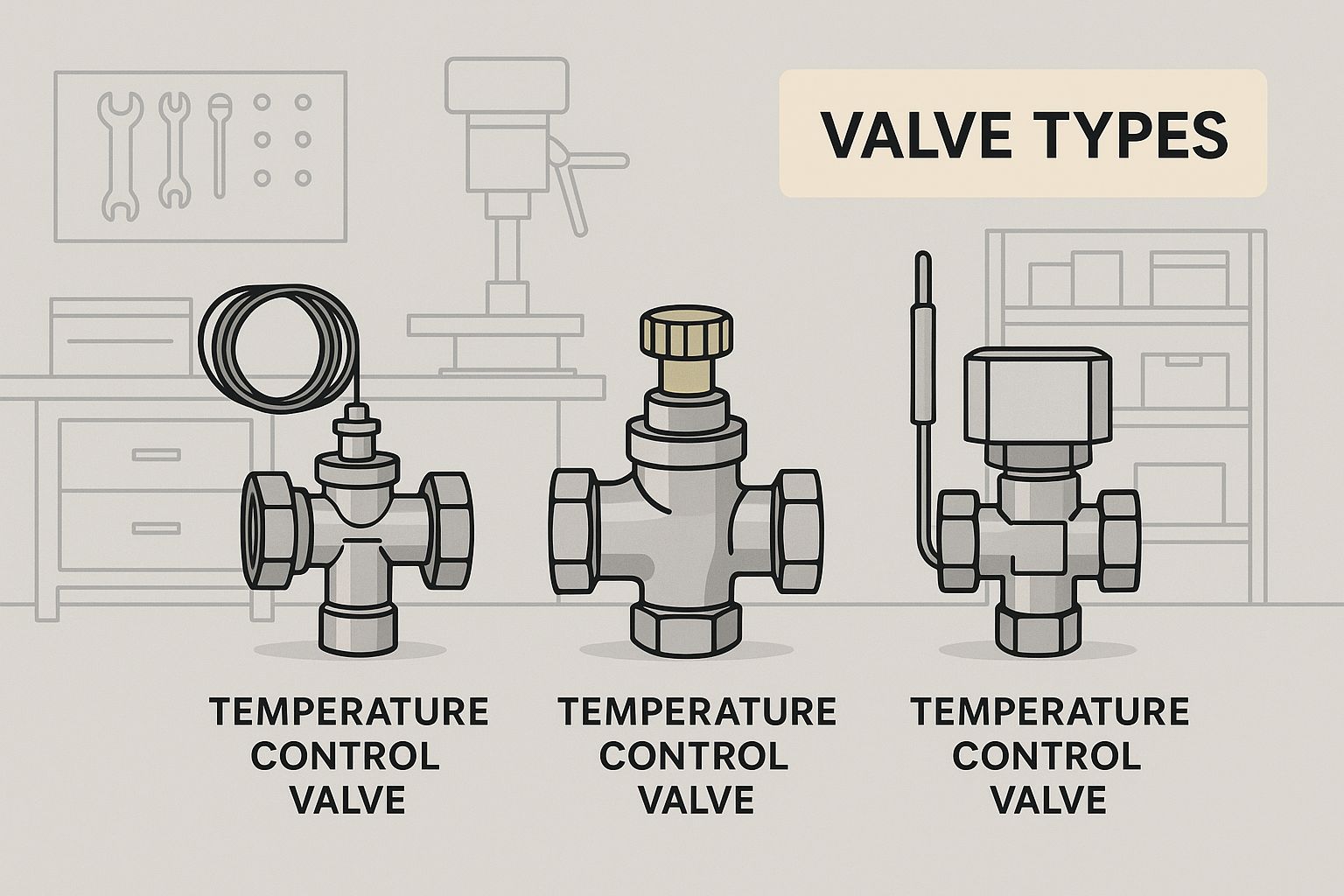

The infographic below lays out the three main types of temperature control valves you'll find in both commercial and industrial settings.

This visual guide shows the distinct models, from the simple, self-powered thermostatic units to the more advanced actuated valves, which should help clarify where each one fits in.

Self-Actuated Thermostatic Valves

Self-actuated valves are the real workhorses of temperature regulation. They are completely self-contained, meaning they operate without any outside help from electricity or compressed air. It's an ingenious design that makes them incredibly reliable and cost-effective for a huge range of jobs where you just need something simple and dependable.

How do they work? It all comes down to a fundamental principle of physics: thermal expansion. Tucked inside the valve's sensor is a special material—often a wax pellet or a liquid-filled bulb—that’s been precisely calibrated to expand or contract at a specific temperature. When the fluid around it heats up or cools down, this material expands or contracts, physically pushing the valve stem to open or close the valve.

Think of it just like the thermostat in your car engine. There are no wires, no computers, nothing but a pure, mechanical reaction to heat. This makes them perfect for remote locations or systems where you can't guarantee a power supply.

Key Takeaway: Self-actuated valves are the ultimate "set-it-and-forget-it" solution. Their mechanical simplicity delivers robust performance in places like remote storage tanks, engine cooling circuits, and basic hot water systems. The trade-off? Their set points are usually fixed at the factory and can't be easily changed on the fly.

Externally Powered Actuated Valves

When your application needs more finesse—like pinpoint precision, remote adjustments, or integration with a central control system—then you'll be looking at externally powered valves. Unlike their self-sufficient cousins, these valves need an external power source like electricity, pneumatic air, or hydraulic fluid to move the actuator. This clever separation of sensor and actuator opens the door to much more sophisticated control.

These valves are always part of a bigger control loop, which typically includes:

- An external sensor (like a thermocouple or RTD) to measure the temperature.

- A controller (like a PLC or a dedicated PID controller) that acts as the brain, processing the sensor's readings.

- The actuated valve itself, which gets its marching orders from the controller to adjust the flow.

This setup allows for incredibly tight temperature control, often down to a fraction of a degree. It also means operators can change set points from a control room, react to fast-changing process conditions, and even automate complex temperature profiles without ever touching the valve.

Common Types of Actuated Valves

The choice of external power source really defines the valve's personality and where it works best.

Electric Actuated Valves: These use an electric motor to drive the valve open or closed. They're known for their precision and are a common sight in HVAC systems, water treatment plants, and any application where clean operation is a must. They offer fantastic control but can be a bit slower to react than pneumatic types.

Pneumatic Actuated Valves: Powered by compressed air, these valves are prized for their lightning-fast response times and serious muscle, making them ideal for large-scale industrial processes. They are also inherently safe for hazardous environments where an electric spark could be disastrous. You'll find them everywhere in the chemical, oil and gas, and pharmaceutical industries.

Hydraulic Actuated Valves: By using pressurised liquid (usually oil), these actuators generate immense force, making them the heavyweights of the valve world. They are reserved for the most demanding jobs, like controlling massive dampers or high-pressure steam lines in power generation plants.

Choosing the Right Materials for Your Valve

Picking a temperature control valve involves more than just getting the flow rates and power supply right. The materials the valve is made from are just as crucial for its performance, safety, and how long it will last.

Think about it this way: you wouldn't use a paper cup to hold hot acid. By the same logic, you can't expect a standard brass valve to hold up in a highly corrosive or extreme-temperature environment. The choice of material for the valve body, its internal parts, and the seals will ultimately decide if it’s the right tool for the job.

The valve body is the main housing, the outer shell that contains the pressure and protects all the internal components. Your decision on what material this body should be made from comes down to the fluid type, its temperature, and the operating pressure. Get this wrong, and you could be looking at anything from a minor leak to a catastrophic system failure.

Common Materials for General Use

For many everyday jobs, common and cost-effective metals offer more than enough strength and reliability. These are the go-to options for systems that aren't dealing with harsh chemicals or extreme conditions.

- Brass: An alloy of copper and zinc, brass is a popular choice for smaller valves you’d find in plumbing, HVAC systems, and applications with non-corrosive liquids. It’s easy to work with, relatively inexpensive, and resists corrosion well when used with water and other neutral fluids.

- Bronze: An alloy of copper, typically with tin as the main additive, bronze is a bit tougher and more resistant to corrosion than brass—especially from saltwater. This makes it a dependable workhorse for marine applications and some low-pressure steam systems.

While these materials are excellent for general utility services, they have their limits. When the stakes get higher, you need to step up to more robust solutions.

Robust Materials for Demanding Environments

When you’re dealing with food products, pharmaceuticals, or corrosive media, the material requirements become much more stringent. This is where stainless steel and other specialised alloys shine, offering superior performance and safety.

Stainless steel is a fantastic choice for its excellent durability and resistance to corrosion, especially in environments where temperature control is critical. Its widespread use across various industries really highlights how vital these valves are for maintaining precise regulation within the UK's industrial infrastructure.

Key Insight: The magic of stainless steel lies in its passivation layer—a thin, inert film of chromium oxide that forms on the surface. If this layer gets scratched, it actually repairs itself, providing continuous protection against rust and chemical attacks. This makes it perfect for sanitary applications.

When your system is operating under extreme pressure, the valve’s design is just as important as its material. For these intense conditions, a specially engineered https://www.solenoid-valve.world/high-pressure-solenoid-valve is often required to handle the load safely.

High-Performance Alloys for Extreme Conditions

Some industrial processes push materials to their absolute breaking point, using highly aggressive chemicals or temperatures that would completely destroy standard metals. For these extreme duties, engineers turn to specialised "superalloys."

- Monel: This nickel-copper alloy is exceptionally resistant to corrosion from seawater, acids, and alkalis. It's often specified for marine engineering and in chemical processing plants that handle substances like hydrofluoric acid.

- Hastelloy: As a family of high-performance nickel alloys, Hastelloy offers incredible resistance to a wide range of severe corrosives, including hydrochloric and sulphuric acids. It also keeps its strength at high temperatures, making it essential for equipment like chemical reactors and pollution control systems.

Material Selection Guide for Common Applications

To help you navigate these choices, here's a quick comparison of how different materials stack up for various industrial jobs. This table provides a snapshot of their properties, ideal uses, and relative costs.

| Material | Key Properties | Ideal Applications | Cost Comparison |

|---|---|---|---|

| Brass | Cost-effective, good machinability, moderate corrosion resistance. | Water, air, neutral fluids, HVAC, general plumbing. | £ |

| Bronze | Stronger than brass, good wear and saltwater corrosion resistance. | Marine environments, low-pressure steam, slurries. | ££ |

| Stainless Steel | Excellent corrosion resistance, hygienic, high strength, good temperature range. | Food & beverage, pharmaceutical, chemical processing, high-purity systems. | £££ |

| Monel | Exceptional resistance to acids, alkalis, and seawater. | Marine engineering, chemical plants (e.g., hydrofluoric acid), oil refining. | ££££ |

| Hastelloy | Superior resistance to aggressive chemicals and high temperatures. | Chemical reactors, waste treatment, pollution control, severe corrosive services. | £££££ |

Choosing the right material is a fundamental first step. It’s what ensures your temperature control valve will operate safely, reliably, and effectively for its entire service life.

Where Temperature Control Valves Are Used Most

Understanding the mechanics of a temperature control valve is one thing, but seeing them in action is where you really grasp their value. These devices are the unseen heroes in countless systems, working away quietly to ensure safety, efficiency, and quality across a huge range of industries. Their impact is everywhere, from the food we eat to the air we breathe in large buildings.

This widespread use is a major driver of market growth. The global market for all control valves, where temperature control valves hold a significant share, was valued at around USD 9.99 billion. Projections show this figure is expected to climb to USD 17.07 billion by the end of the decade. This expansion reflects just how essential these components are in modernising key sectors.

Let's move from theory to practice and explore the real-world environments where these valves are most critical.

Optimising Comfort and Efficiency in HVAC Systems

In large commercial buildings like office blocks, hospitals, and shopping centres, keeping the indoor climate comfortable and consistent is a massive undertaking. The Heating, Ventilation, and Air Conditioning (HVAC) systems are the beating heart of these facilities, and the temperature control valve is absolutely central to their efficient operation.

Their main job here is to regulate the flow of hot or chilled water through coils in air handling units (AHUs) and fan coil units (FCUs). As air passes over these coils, it’s either heated or cooled before being sent out into the building. A temperature control valve modulates this water flow precisely, making sure each zone gets just the right amount of conditioning.

This isn’t just about comfort; it's about significant energy savings. By preventing over-heating or over-cooling, these valves ensure the building’s boilers and chillers aren't working harder than they need to. This can lead to substantial cuts in energy consumption and running costs.

Ensuring Safety and Quality in Food and Beverage Production

The food and beverage industry operates under incredibly strict standards, where precise temperature management is completely non-negotiable. Here, the temperature control valve is a cornerstone of processes that guarantee product safety and consistency.

Take pasteurisation, a critical step for milk, juices, and other products.

- Heating Phase: The product is rapidly heated to a specific temperature (e.g., 72°C for 15 seconds for milk) to kill harmful bacteria. A temperature control valve manages the flow of steam or hot water to the heat exchanger with pinpoint accuracy, achieving the target temperature without scorching the product.

- Cooling Phase: Immediately after, the product has to be cooled down quickly to preserve its quality and flavour. Another valve takes over, controlling the flow of chilled water or glycol to bring the temperature down efficiently.

Any deviation can compromise the whole batch, leading to waste and potential safety risks. The reliability of a temperature control valve is therefore essential for both public health and the manufacturer's bottom line.

A Real-World Scenario: A dairy plant noticed its pasteurisation temperatures were fluctuating, putting product safety at risk. The culprit was a slow-acting pneumatic valve. They upgraded to a fast-response, electrically-actuated temperature control valve and achieved rock-solid temperature stability, ensuring compliance and product integrity.

Critical Process Control in Chemical and Pharmaceutical Manufacturing

Nowhere is temperature control more critical than in chemical and pharmaceutical manufacturing. In these sectors, even a minor temperature fluctuation can have dramatic consequences, affecting reaction yields, creating impurities, or, in the worst-case scenario, causing a dangerous runaway reaction.

Inside a chemical reactor, a temperature control valve meticulously regulates the flow of a heating or cooling medium to the reactor's jacket. This holds the process at the optimal temperature needed for the chemical synthesis to proceed correctly. For instance, if a reaction is exothermic (produces heat), the valve will continuously adjust coolant flow to draw that excess energy away and keep the process stable.

These environments often handle hazardous materials, so other valve types are also crucial. For example, our guide on pressure relief valves explains how these safety devices work alongside control systems to prevent over-pressurisation. Understanding the environments where temperature control is paramount is key, such as in the detailed guide to morgue cooler temperature, where precision is equally vital. The precision offered by a modern temperature control valve is what allows for the safe and repeatable production of everything from complex polymers to life-saving medicines.

How to Select the Perfect Temperature Control Valve

Picking the right temperature control valve is much more than just a line item on a purchase order. It's a fundamental engineering decision that directly affects how efficiently, safely, and reliably your entire system will run. Get it wrong, and you're looking at poor performance, early component failure, or even dangerous operating conditions.

Think of it like choosing the right engine for a car. You wouldn’t put a tiny, 1-litre engine in a heavy-duty lorry and expect it to work. In the same way, your valve has to be perfectly matched to the job you're asking it to do.

Define Your Operational Parameters

Before you even glance at a product catalogue, you need to do your homework. This first step is non-negotiable: you have to collect hard data on your system's exact operating conditions. Without this, you're just guessing.

You need a crystal-clear picture of:

- Fluid Properties: What’s flowing through the valve? Is it clean water, high-pressure steam, oil, or a corrosive chemical? The nature of the fluid is the first filter for choosing the right materials.

- Temperature Range: What are the absolute minimum and maximum temperatures the valve will have to handle? This directly impacts your choice of body material and, just as importantly, the internal seals.

- Operating Pressures: You must know the maximum inlet pressure and the expected pressure drop across the valve. This information is vital for ensuring the valve not only performs correctly but operates safely.

This data is the technical blueprint for your decision. Once you have these numbers nailed down, you can get into the finer details of sizing and functionality.

The Importance of Correct Valve Sizing

Proper valve sizing is probably the single most critical step in the entire process. There's a common and costly misconception that "bigger is always better." In the world of control valves, both undersizing and oversizing can cause major headaches.

An undersized valve creates a bottleneck. It simply can't pass enough heating or cooling fluid to keep up with demand, leading to sluggish temperature control and a system that’s always fighting to hit its setpoint.

Ironically, an oversized valve is often a bigger problem. It will spend most of its time barely cracked open, leading to a phenomenon called "chattering" where it rapidly cycles on and off. This causes wildly erratic control, introduces instability into your process, and hammers the valve’s internal components, drastically shortening its life.

The sweet spot is to choose a valve that will operate comfortably within 25% to 75% of its total open range. This ensures you get stable, responsive control and the longest possible service life.

Understanding Flow Coefficient and Safety Features

To size a valve correctly, you need to calculate the required Flow Coefficient (Cv). This industry-standard value tells you the volume of water (in US gallons per minute) that will flow through the valve with a pressure drop of one PSI. Every valve manufacturer provides Cv ratings for their products, allowing you to precisely match a valve’s capacity to your system's needs.

Beyond sizing, you have to think about what happens when things go wrong. A critical safety consideration is the valve's fail-safe position. This determines the valve's state if its power—be it electric or pneumatic—is lost.

- Fail-Open: The valve automatically opens fully on power loss. You’d use this for a cooling system on critical machinery, where you need flow to continue to prevent overheating and damage.

- Fail-Close: The valve automatically shuts tight on power loss. This is the standard choice for systems like steam or fuel lines, where an uncontrolled flow could be hazardous.

Deciding between fail-open and fail-close is a crucial part of your risk assessment, focused on protecting both your equipment and your people. As energy costs rise, these choices are also increasingly linked to efficiency and regulatory compliance. As detailed in a recent report on the control valve market from researchandmarkets.com, optimising energy use is a major driver in valve technology today.

Finally, don't overlook the smaller parts. The materials used for seals and internal trim are just as important as the main valve body. For a closer look at this topic, our guide on solenoid valve seal materials offers some excellent insights that are relevant to many different valve types.

Installation and Maintenance to Prevent Failure

Even the best-specified temperature control valve can't do its job properly if it’s installed incorrectly or left neglected. Getting the installation right sets the stage for reliable performance, and routine maintenance is what keeps it operating safely and efficiently for years to come. These two steps are absolutely critical to getting the most out of your investment.

It's surprising how many performance issues trace back to simple installation mistakes. Rushing the job or skipping basic steps can cause immediate problems, or worse, lead to hidden damage that results in a premature failure down the line.

Critical Installation Best Practices

To sidestep the common traps, the installation process needs to be handled with care. A methodical approach ensures the temperature control valve is set up for success right from the start.

Verify Flow Direction: Most valve bodies have a cast-in arrow showing the correct direction of flow. Installing a valve backwards is a recipe for disaster, often causing severe chattering, poor performance, and damage to the internal parts. Always double-check this before you fit anything.

Protect from Pipe Strain: The pipework connecting to the valve must be properly aligned and supported. If you have to force pipes to meet the valve, you’re creating mechanical stress (pipe strain). This can warp the valve body, leading to leaks and stopping the internal plug from seating correctly.

Install Upstream Filtration: Debris is the enemy of any control valve. Things like pipe scale, bits of weld, or grit can easily score or damage the delicate internal seating surfaces. A simple strainer or filter installed just upstream of the valve is a low-cost, high-impact way to protect it.

A Practical Maintenance Checklist

Once your valve is installed, a proactive maintenance schedule is your best friend for long-term reliability. Regular checks help you spot small issues before they snowball into major failures, preventing expensive downtime and keeping your process stable.

A well-maintained temperature control valve doesn't just last longer; it also holds its control accuracy. This directly impacts your product quality and energy use. Skimping on maintenance is a false economy that almost always leads to higher running costs.

Your routine inspection should cover these key points:

- Check for Leaks: Look carefully at all gaskets, packing nuts, and flange connections for any hint of weeping or an active leak.

- Verify Actuator Movement: Make sure the actuator moves smoothly through its full travel. It shouldn't stick, jump, or hesitate at all.

- Calibrate the Sensor: From time to time, check the temperature sensor against a calibrated reference thermometer to ensure it's still reading accurately. A sensor that has drifted will completely throw off your temperature control.

Troubleshooting Common Issues

Even with a perfect setup, problems can sometimes crop up. One of the most common complaints is a valve that is "hunting"—where it constantly cycles open and closed, unable to settle. This is often the sign of an oversized valve, where even a tiny movement causes too big a change in flow.

Another frequent issue is a failure to hold temperature. This could be down to a damaged valve seat that isn't closing tightly anymore, a faulty or miscalibrated sensor, or a problem with the actuator. By following a logical troubleshooting process, starting with calibration and a good visual inspection, you can systematically track down and fix most common faults, keeping your system running smoothly and reliably.

Frequently Asked Questions

This section gets down to the nitty-gritty, answering the most common practical questions we hear about putting a temperature control valve to work.

Can a Temperature Control Valve Reduce Energy Costs?

Yes, absolutely. By precisely matching the flow of heating or cooling fluid to what’s actually needed, a temperature control valve stops the system from overheating or overcooling.

This prevents boilers and chillers from working harder than necessary. For large-scale HVAC and industrial processes, the energy savings can be substantial.

What is Valve "Hunting" and How Do I Fix It?

"Hunting" is the term for a valve that constantly cycles open and closed, never quite finding a stable position. It’s a classic sign of an oversized valve.

Even a tiny adjustment causes a massive change in flow, forcing the controller to constantly overcorrect. The fix is to make sure the valve is correctly sized for your system's required flow rate (Cv).

A properly sized valve should operate comfortably between 25% and 75% of its open range. If your valve is always hovering near the closed position, it’s a dead giveaway that it’s too big for the job, leading to poor control and accelerated wear.

How Often Should I Service My Temperature Control Valve?

The ideal service schedule really depends on how hard the valve is working. For critical systems or those handling aggressive fluids, an annual inspection is a wise investment.

For less demanding jobs, like a standard HVAC system, a check-up every two years is often enough. Regular checks for leaks, smooth actuator movement, and sensor accuracy are your best defence against unexpected failures.

For expert advice and a comprehensive range of high-performance valves for any application, explore the options at Solenoid Valve World. Find the perfect solution for your fluid control needs at https://solenoid-valve.world.