Three Way Ball Valve Guide: Essential UK Installation Manual

Understanding Three Way Ball Valve Fundamentals

A three way ball valve differs from standard valves because of its ability to control fluid flow through three separate ports. This isn't simply opening or closing; it's directing the flow between multiple pathways. Imagine a railway junction, guiding trains (liquids or gases) along different tracks. This precise control is vital in many UK industrial applications, from complex chemical processing to temperature control in HVAC systems.

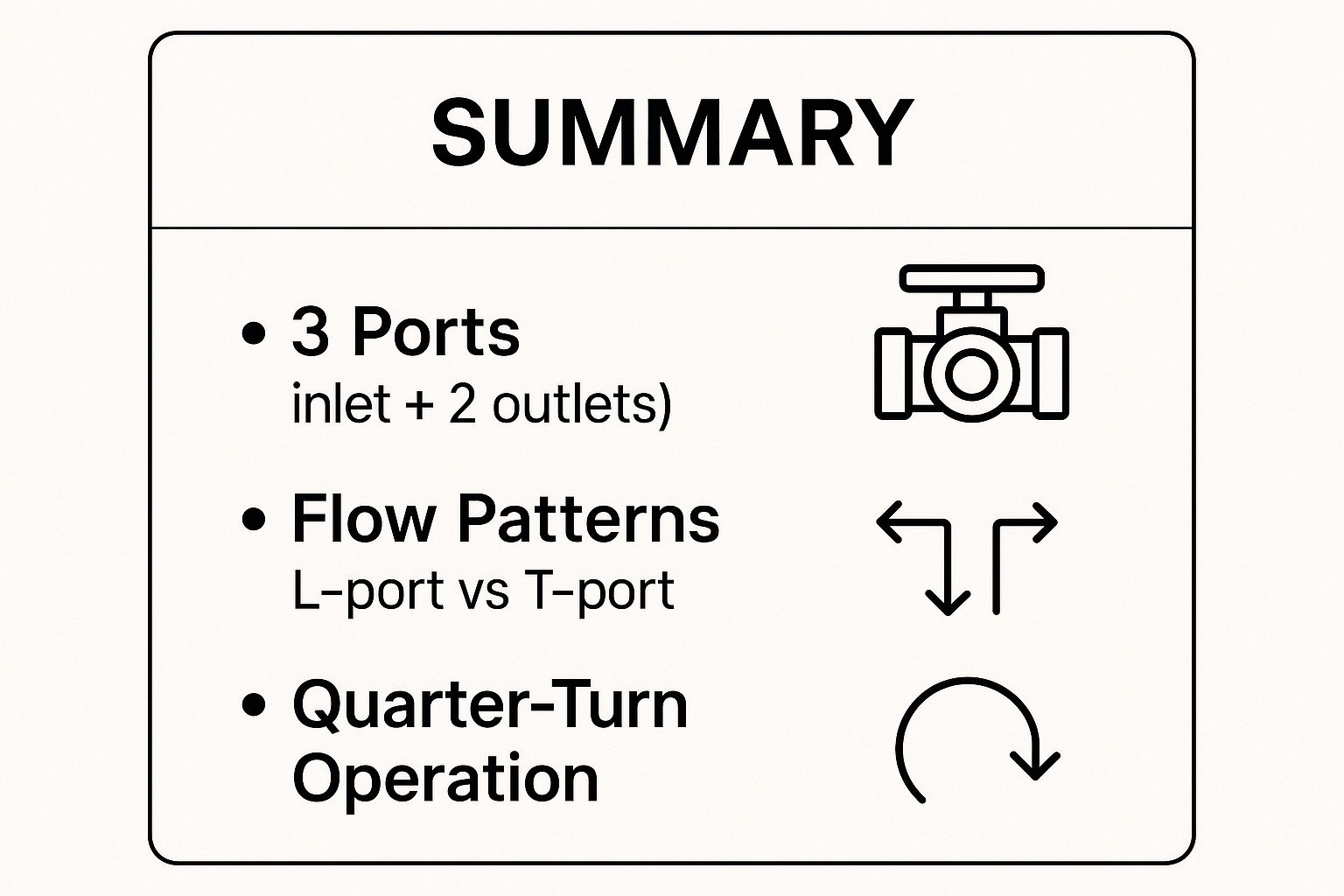

The infographic above illustrates the key components of a three way ball valve: its three ports, the flow patterns created by L-port and T-port configurations, and the efficient quarter-turn operation. The three-port design allows for both diverting and mixing fluid streams. The quarter-turn mechanism ensures rapid and precise control. This simple yet effective functionality distinguishes the three way ball valve from traditional two-way valves.

Exploring T-Port and L-Port Configurations

The internal design of a three way ball valve dictates its flow capabilities. Two main configurations exist: T-port and L-port. The T-port, shaped like a "T," allows fluid from a single inlet to be distributed to two outlets at the same time. It can also divert flow between any two ports.

For instance, a T-port valve can mix hot and cold water to reach a specific temperature or divert flow to a bypass during maintenance. The L-port, resembling an "L," connects two ports at a 90-degree angle. This configuration effectively diverts flow between two outlets from a single inlet or combines two inlets into one outlet. This is particularly useful in systems needing flow diversion for redundancy or for mixing different fluids.

To further clarify the differences between these two configurations, let's examine the following table.

Three Way Ball Valve Types Comparison: This table compares T-port and L-port three way ball valve configurations, showing their applications and flow patterns.

| Valve Type | Flow Pattern | Primary Application | Advantages |

|---|---|---|---|

| T-port | Distributes one inlet to two outlets, or diverts between any two ports | Mixing fluids (e.g., hot and cold water), diverting flow for maintenance | Versatile flow control, allows for simultaneous mixing and diverting |

| L-port | Diverts flow between two outlets from one inlet, or mixes two inlets to one outlet | Flow diversion for redundancy, mixing different fluids | Simple and effective for diverting or mixing, compact design |

As the table shows, the T-port excels in applications requiring both mixing and diverting, while the L-port offers a compact solution primarily for diverting or mixing.

Operational Advantages in UK Industries

Three way ball valves offer considerable benefits across various UK industries. Effective Document Approval Workflow documentation is crucial for successful implementation. Their compact design and quarter-turn operation save space and enhance efficiency. Their robust construction and reliable sealing minimize leakage, improving safety and reducing maintenance.

These advantages are boosting their use in sectors like chemical processing, pharmaceutical manufacturing, and energy production throughout the UK. In these sectors, precise and dependable flow control is essential for product quality, operational efficiency, and compliance with British safety standards.

UK Market Landscape and Industry Applications

The UK's industrial sector is increasingly incorporating three-way ball valves due to their advanced flow control capabilities. These valves go beyond basic on/off functionality, allowing for the precise diverting and mixing of fluids, which is crucial for complex industrial processes. Let's delve into the specific UK industries reaping the most benefits from these valves.

Chemical Processing and Pharmaceutical Manufacturing

Precise flow control is essential in chemical processing. Three-way ball valves play a key role in directing chemical streams for reactions, ensuring accurate ingredient mixing, and diverting flows for essential cleaning and maintenance. Similarly, the pharmaceutical industry, with its strict requirements for product purity and precise ingredient combinations, utilizes these valves to guarantee accurate dosing and sterile processing, contributing to the high quality of UK pharmaceutical products.

The robust construction of these valves makes them well-suited for handling corrosive chemicals common in both industries. Their reliable sealing minimizes leakage, enhancing safety and reducing environmental impact. This is particularly important in the UK, where facilities must adhere to stringent environmental regulations.

Energy Production and Renewable Energy Systems

Three-way ball valves also find diverse applications in the UK's energy sector, from conventional power generation to the rapidly expanding field of renewable energy. In traditional power plants, these valves manage steam and water flow, optimizing efficiency and ensuring safe operations. Their role in renewable energy is also expanding, particularly in systems like solar thermal, where they regulate the flow of heat transfer fluids to maximize energy capture. For more on flow control, check out our guide on general-purpose solenoid valves.

The increasing focus on biogas production in the UK provides another application area. These valves contribute to efficient biogas processing by precisely controlling the flow of digestate and biogas within anaerobic digestion systems. This adaptability underscores their importance in supporting the UK's transition to sustainable energy.

Return on Investment and Regulatory Compliance

Across various sectors, the adoption of three-way ball valves is increasingly justified by a clear return on investment. Reduced downtime due to improved flow control and minimized leakage translates to significant cost savings. Their extended lifespan, thanks to robust design and reliable operation, further enhances the cost-benefit analysis. The UK ball valves market, encompassing three-way ball valves, is segmented by type, material, and size. It forms part of the broader Western European market, which is experiencing considerable growth fueled by industrial expansion and infrastructural development. The global ball valve market, valued at USD 12.43 billion in 2021, is projected to grow at a CAGR of 4.3%. You can find detailed market statistics here.

Regulatory compliance is also a key factor in valve selection across UK industries. Three-way ball valves meet stringent British standards for safety and performance, ensuring installations comply with industry best practices. This not only promotes safe operations but also helps businesses avoid penalties and maintain a strong reputation. This naturally leads us to the increasing integration of smart technology into these essential components.

Smart Technology Integration And Automation Trends

While basic automation is commonplace, real transformation happens with intelligent systems. Forward-thinking UK manufacturers are seeing measurable improvements by utilizing smart three-way ball valves. This goes beyond simply installing the valves; it involves integrating them into broader automation strategies. For instance, connecting these valves with sensors and control systems allows for dynamic flow adjustments based on real-time conditions. This represents a significant advancement over simple timed or manual adjustments.

IoT Integration and Predictive Maintenance

The Internet of Things (IoT) is reshaping industrial processes, and three-way ball valves are no exception. By integrating these valves with IoT platforms, UK facilities gain valuable operational insights. Sensors embedded within or attached to the valve can track factors like pressure, temperature, and flow rate, transmitting this data instantly. This facilitates remote monitoring and control, empowering operators to make informed decisions based on live system data.

This data also powers predictive maintenance. By analyzing operational trends, potential problems can be identified before they cause failures. This minimizes unplanned downtime, a costly issue for any industrial operation. Imagine a system predicting a valve's impending seal failure based on subtle pressure changes – maintenance can be scheduled proactively, averting a costly production stoppage.

Industry 4.0 Alignment and Operational Benefits

Integrating smart three-way ball valves aligns perfectly with the tenets of Industry 4.0, which emphasizes interconnected systems and data-driven decisions. This interconnectedness fosters a more responsive and efficient production environment. This translates to quicker responses to changing demands, optimized resource utilization, and increased overall system resilience.

Successful UK installations are showing significant downtime reductions, often in the double digits. Moreover, automation features like remote control and automated shut-off offer the best return on investment, maximizing the technology's benefits. The UK's three-way ball valve market is closely linked to broader European and global trends in the valve industry. The UK benefits from progress in automation and smart technologies, leading to improved operational efficiency and reduced maintenance expenses. The incorporation of IoT capabilities allows for real-time monitoring and predictive maintenance, contributing to a vibrant market. Find more detailed statistics here.

Implementing Smart Valve Technologies

Implementing smart valve technologies doesn't have to be complex or prohibitively expensive. A phased approach lets facilities gradually incorporate these features, focusing initially on key areas with the highest potential returns. For example, a chemical plant could start by integrating IoT monitoring on critical valves handling hazardous materials, then gradually expand the system as budget permits.

By prioritizing areas where smart technology has the biggest impact, businesses can achieve tangible results within realistic timelines and budgets. This ensures that smart technology investments deliver genuine value, contributing to improved safety, efficiency, and profitability in the UK industrial sector.

Selection Criteria And Specification Guidelines

Choosing the correct three way ball valve for a project in the UK requires careful planning. Selecting the wrong valve can result in costly downtime, premature failures, and even safety hazards. This guide outlines the key criteria for specifying a three way ball valve that will meet your project's unique demands and provide reliable, long-term performance.

Material Compatibility and Pressure Ratings

Material compatibility is a primary concern. The valve's material needs to be resistant to the medium flowing through it. Highly corrosive chemicals, for instance, demand valves constructed from materials like stainless steel or specialized alloys. For less demanding applications, brass or PVC may be sufficient. However, the operating environment also factors into material selection. High temperatures or pressures often require stronger materials, even for non-corrosive fluids.

The valve's pressure rating is equally important. This rating signifies the maximum pressure the valve can safely withstand, and should always include a safety margin. A valve with a pressure rating below the system's peak pressure risks dangerous failures. Conversely, a significantly higher pressure rating than necessary can inflate project costs.

British Standards Compliance and Manufacturer Claims

Compliance with relevant British Standards is essential. This adherence assures a minimum level of quality and safety, vital for both legal and operational compliance. Look for certifications such as BS EN ISO 17292 for industrial valves. This specific standard demonstrates that the valve has undergone rigorous testing and quality control procedures.

It's also crucial to verify manufacturer claims. Don't solely rely on marketing materials. Independent testing or consultation with trusted industry resources can help confirm that a valve's stated performance holds up in real-world applications. Requesting test certificates directly from manufacturers is also recommended.

Total Cost of Ownership and Future-Proofing

The total cost of ownership goes beyond the initial purchase price. It encompasses installation, maintenance, and potential replacement costs. A less expensive valve may require more frequent maintenance or have a shorter lifespan, increasing the overall cost in the long run. Factors such as the valve's anticipated lifespan, maintenance needs, and the cost of replacement parts should all inform your decision.

To help guide your material selection, the table below offers a comparison of common three way ball valve materials and their suitability for various UK industrial settings. Remember that specific temperature and pressure ranges will vary based on the valve's design and manufacturer.

Material Selection Guide for UK Applications:

| Material | Temperature Range | Pressure Rating | Best Applications | UK Industry Use |

|---|---|---|---|---|

| Brass | Moderate | Moderate | Water, air, oil | General plumbing, HVAC |

| Stainless Steel | Wide range | High | Corrosive fluids, high-temperature applications | Chemical processing, pharmaceutical manufacturing |

| PVC | Limited | Low | Non-corrosive, low-temperature fluids | Irrigation, water treatment |

| Carbon Steel | High | High | High-temperature, high-pressure applications | Power generation, oil and gas |

This table provides a starting point for material selection. Consulting with industry experts or suppliers is recommended for specific application guidance.

Finally, consider the future when selecting a valve. Future-proofing your choice involves anticipating potential changes in system requirements. Could the system pressure or temperature increase? Might you need to handle different media? Opting for a valve with slightly higher specifications can be a cost-effective strategy in the long term if it accommodates future changes, avoiding the expense of replacing the valve down the line. This forward-thinking approach is crucial for making informed decisions that contribute to safe and efficient operations.

Installation Best Practices And Maintenance Strategies

Proper installation and diligent maintenance are essential for optimal performance and longevity of your three-way ball valve. This guide, drawing on the expertise of seasoned UK technicians, outlines best practices to ensure efficient and dependable valve operation, from initial setup to ongoing care.

Installation Procedures and System Compatibility

Before starting the installation process, confirm system compatibility. Ensure the valve's pressure and temperature ratings align with your system's specifications. It's also crucial to verify the valve's material compatibility with the intended fluids to prevent corrosion or degradation. For water systems, our guide on solenoid valves for water might be helpful.

During installation, proper pipe alignment is vital to avoid undue stress on the valve body. Use a suitable sealant on threaded connections to prevent leaks, being careful not to over-tighten, which could damage the valve. For flanged connections, use the correct gasket material and follow the recommended bolt tightening sequence for a secure and even seal. After installation, thoroughly test the system for leaks before commencing full operation.

Maintenance Schedules and Troubleshooting

A regular maintenance schedule is key to preventing costly failures and maximizing valve lifespan. This schedule should include periodic inspections, lubrication, and functional tests. Inspect the valve for any signs of wear, corrosion, or leakage.

Lubricate moving parts, such as the stem and ball, with an appropriate lubricant for smooth operation. Functional testing confirms the valve's ability to control flow correctly in all positions, ensuring complete shut-off when closed and accurate flow diversion in other positions.

Should problems arise, a systematic troubleshooting approach is best. Begin by checking for simple issues like debris or loose connections. For more complex problems, consult the manufacturer's troubleshooting guide or contact a qualified technician.

Safety Considerations and UK Regulations

Prioritize safety during all installation and maintenance procedures. Always isolate the valve from the system and depressurize the line before starting any work. Wear appropriate personal protective equipment (PPE), including gloves and eye protection.

Adherence to all relevant UK regulations and safety standards is mandatory. This includes following British Standards for valve installation and complying with any industry-specific safety guidelines. The demand for three-way ball valves in the UK is influenced by the country's evolving industrial infrastructure and economic policies. The UK's focus on sustainability further drives demand for efficient valves with minimal environmental impact. As the UK continues to develop its industrial sector, the need for specialized valves like these will likely increase. Learn more about this trend here.

Spare Parts Strategies and Documentation

A well-defined spare parts strategy is essential for minimizing downtime. Keeping frequently replaced parts, such as seals and gaskets, readily available facilitates quick repairs. For less common failures, a reliable supplier with fast delivery can be a more cost-effective solution.

Maintain thorough records of all maintenance activities, including dates, parts replaced, and any encountered issues. This documentation proves invaluable for troubleshooting and demonstrating compliance during audits. Detailed records also help optimize your maintenance schedule over time, enabling proactive identification and resolution of potential problems.

Key Considerations For UK Procurement Teams

Procuring three-way ball valves requires a strategic approach. It's more than just finding the lowest price. UK procurement teams need to consider several factors to ensure the valves meet quality standards, perform reliably over time, and offer a good return on investment. This guide helps navigate these essential considerations.

Supplier Evaluation and Quality Assurance Protocols

Evaluating potential suppliers is critical. Don't just focus on price. Consider the supplier's reputation, experience, and quality certifications like ISO 9001, which shows a commitment to quality management. Also, assess their manufacturing processes, including quality control and testing.

Robust quality assurance is essential. Request detailed product specifications and ensure compliance with relevant British Standards. Request samples for independent testing. This ensures the valves meet or exceed expectations.

Total Cost of Ownership and Contract Negotiation

Consider the total cost of ownership. This includes the initial purchase price, installation, maintenance, and potential replacements. A more expensive valve with a longer lifespan and lower maintenance could be more cost-effective over time. For related insights, check out our guide on solenoid valves for gas.

Contract negotiation should cover warranties, service level agreements, and delivery schedules. Clearly define acceptance criteria and penalties for non-compliance. A well-structured contract protects your organization.

Warranty Evaluation and Service Support Requirements

Carefully review warranty terms, including duration, coverage, and the claims process. A strong warranty offers peace of mind and protects against unexpected costs from early valve failures. For more information, see this helpful cabinet installation guide.

Think about your service support needs. Does the supplier offer on-site technical support? What's their response time? Reliable service support minimizes downtime and ensures quick issue resolution.

Delivery Scheduling and Inventory Management

Align delivery schedules with project timelines. Account for manufacturing and shipping lead times. Establish clear communication with the supplier to manage potential delays. This prevents project setbacks.

Create an efficient inventory management strategy. Avoid overstocking while ensuring enough valves are available. This might involve setting minimum stock levels and using a just-in-time delivery system.

Procurement Best Practices and UK Standards

Following UK procurement regulations and best practices is vital. Ensure compliance with relevant legislation, including public procurement guidelines, and maintain thorough records. This promotes ethical procurement and builds trust.

Choose suppliers committed to sustainability. Look for certifications like ISO 14001, which indicates adherence to environmental management systems. This aligns with UK sustainability goals.

By considering these points, UK procurement teams can confidently purchase three-way ball valves, getting high-quality solutions that meet their needs and contribute to long-term success.

Looking for reliable valve solutions? Visit Solenoid Valve World for a wide range of high-quality valves designed for UK applications.