A Guide to Industrial Valve Noise Reduction

To get a handle on valve noise reduction, you first have to play detective. You can't fix a noise if you don't know what's causing it, and different sounds point to wildly different problems—from simple mechanical rattles to seriously destructive fluid dynamics.

Diagnosing the Source of Valve Noise

Before you jump to a solution, you absolutely must pinpoint the noise's origin and type. This is the most crucial step. A misdiagnosis means wasted time, money spent on the wrong fix, and a problem that just won't go away. The only way to get it right is to methodically listen and observe the valve under its various operating conditions.

Industrial noise is a serious issue, and valves are often the main culprits, especially control valves wrestling with high-pressure drops. The racket they make usually comes from one of three places: physical vibration of internal parts, turbulent gas flow (aerodynamic noise), or the damaging effects of liquid cavitation (hydrodynamic noise). For a deeper dive, Emerson.com offers some great insights into these core mechanisms. Getting your head around these three is fundamental to quieting any valve.

Unpacking Mechanical Noise

Mechanical noise is usually the easiest one to spot. If you hear rattling, clanking, or a metallic grinding, that's your sign. It's the sound of physical parts inside the valve that aren't sitting right or are simply worn out.

You're likely dealing with:

- A loose plug, disc, or cage rattling around inside the valve.

- Worn-out guides or bushings that can no longer hold components steady.

- Vibrations from nearby equipment, like a pump, travelling down the pipework.

This kind of noise often comes and goes, maybe only appearing when the valve is partially open. It’s a dead giveaway that the valve needs a good inspection and some maintenance.

Identifying Aerodynamic Noise

Aerodynamic noise is the signature sound of gas or steam systems. Think of a high-pitched hiss or a deafening roar, almost like a jet engine. This sound is pure turbulence, created when gas shoots through the valve at high speed, especially when there’s a big pressure drop.

The sheer intensity of this noise is tied directly to gas velocity. When the flow goes supersonic (breaking Mach 1) inside the valve, it creates shockwaves. These generate an intense, high-frequency sound that can easily blow past workplace safety limits.

Imagine air screaming out of a punctured tyre—the bigger the pressure difference, the louder the hiss. Inside a valve, this chaos happens at the vena contracta, the narrowest point of flow right after the valve's opening, where velocity is at its absolute peak.

The Dangers of Hydrodynamic Noise

Hydrodynamic noise is a problem exclusive to liquid systems, and it's by far the most destructive. It sounds like a low-frequency rumbling, like gravel churning through the pipes, or even sharp cracking noises. This is the tell-tale sign of cavitation.

Cavitation kicks off when the liquid's pressure dips below its vapour pressure as it squeezes through the valve. This pressure drop literally boils the liquid, forming tiny vapour bubbles. As the liquid moves downstream and the pressure recovers, these bubbles violently collapse—or implode.

These implosions create tiny but incredibly powerful pressure spikes that act like miniature jackhammers, eating away at the valve and pipe materials. Over time, this causes severe damage. Flashing is a related issue where the bubbles don't collapse, creating a noisy, two-phase flow that’s also a problem.

To help you get a better sense of what you're hearing, this table breaks down the common culprits.

Identifying Common Valve Noise Sources

| Noise Type | Primary Cause | Typical Sound Profile | Commonly Affects |

|---|---|---|---|

| Mechanical Noise | Internal part vibration or wear | Rattling, clanking, metallic grinding | Any valve type, especially older ones |

| Aerodynamic Noise | High-velocity gas/steam turbulence | High-pitched hiss or loud roar | Gas, steam, or vapour systems |

| Hydrodynamic Noise | Cavitation or flashing | Rumbling, gravelly sound, sharp cracking | Liquid systems with high-pressure drops |

Use this as a quick reference to diagnose your valve noise based on what it sounds like and when it's happening.

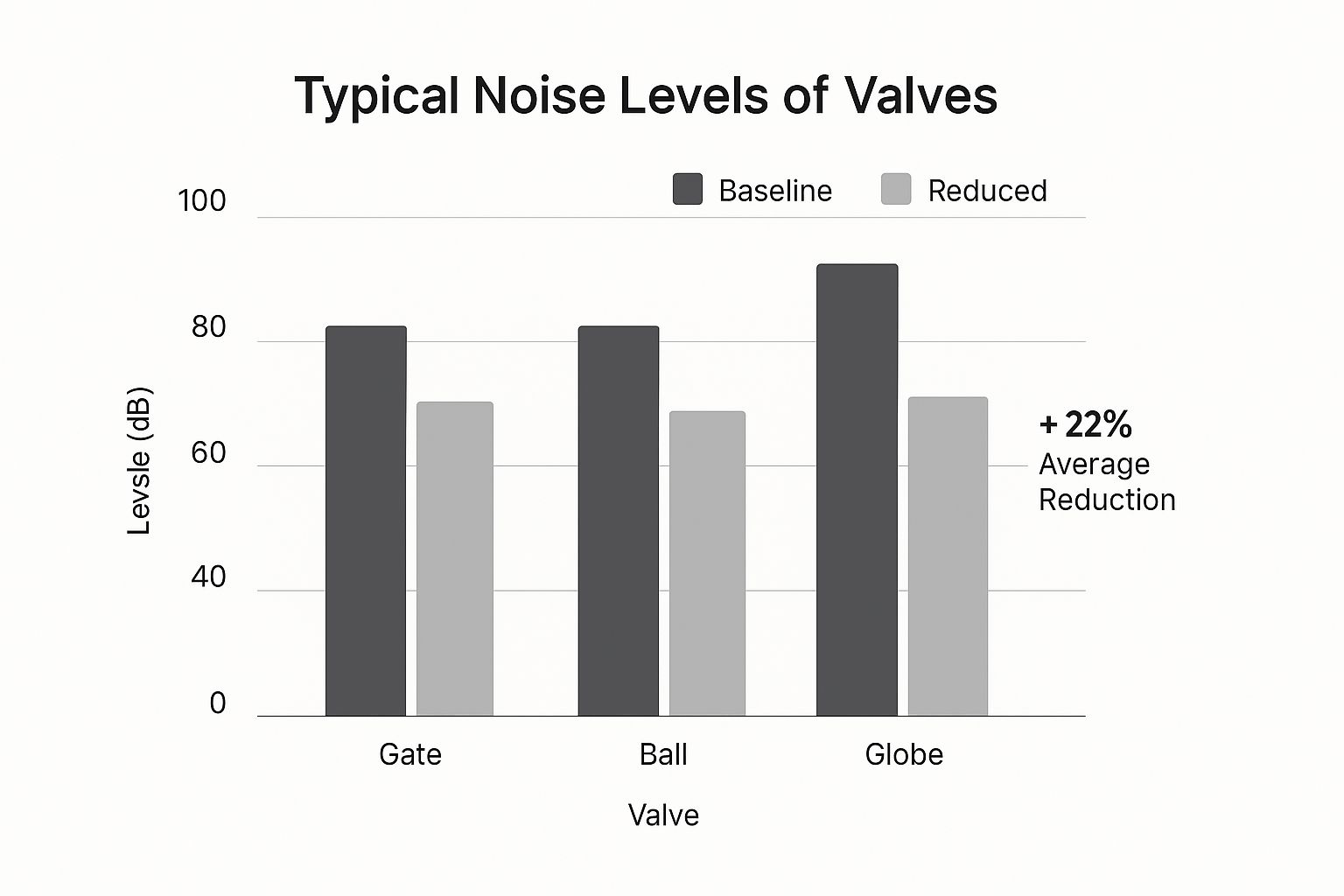

The infographic below shows just how much of a difference the right treatment can make.

As the chart shows, targeted solutions can bring decibel levels way down. Globe valves, with their more complex flow paths, often see the biggest improvements. By correctly identifying whether your problem is mechanical, aerodynamic, or hydrodynamic, you can choose the fix that will actually work.

Controlling Noise at the Source

Once you've diagnosed exactly what kind of noise is plaguing your system, the most direct strategy is to tackle the problem right where it starts. It’s always better to treat the source than the path. Why? Because you’re preventing the acoustic energy from ever being created, rather than just trying to muffle it after the fact.

This approach means selecting or retrofitting valves with specialised internal components, all designed to proactively manage the fluid dynamics causing the ruckus. By focusing on the valve's internal trim, you can achieve a massive reduction in noise without sacrificing the valve's core job of controlling flow.

The Role of Specialised Noise-Reduction Trims

The real magic of a source-based noise solution happens inside the valve's trim—specifically, the cage, plug, and seat. Your standard valve trim often shoves fluid through a single, harsh restriction. This creates a huge pressure drop and high-velocity flow, which are the perfect ingredients for generating noise.

Noise-attenuation trims, on the other hand, are engineered with a lot more finesse. Their design is built on two key ideas:

- Dividing the Flow Path: Instead of one big opening, these trims use a cage riddled with tiny, specially shaped holes. This breaks the main flow into dozens of smaller, lower-energy jets. Not only do these little jets produce less noise on their own, but they also interact in a way that helps cancel each other out.

- Creating Tortuous Paths: The pathways are often intentionally complex or "tortuous." This design forces the fluid to zig and zag, making it change direction multiple times. This dissipates energy gradually and keeps the pressure drop under control, directly tackling the conditions that cause excessive noise.

This method is incredibly effective for quieting down aerodynamic noise in gas and steam applications. By keeping the velocity in check and stopping the flow from hitting supersonic speeds, these trims can turn a deafening roar into a much more acceptable hiss.

Tackling Pressure Drops with Multi-Stage Designs

For really severe situations, especially those with the kind of high-pressure drops you see in demanding liquid and gas systems, a single-stage trim just won't cut it. This is where multi-stage valve designs earn their keep. Think of a multi-stage valve as having several valves built into one body.

Instead of one huge, noisy pressure drop, the total drop is split into a series of smaller, more manageable steps. Each "stage" has its own set of restrictions and flow paths, gently lowering the pressure as the fluid passes through. A valve might use two, three, or even more concentric cages to pull this off.

By breaking down a single, large pressure drop into multiple smaller ones, a multi-stage valve keeps the fluid velocity below critical thresholds at every point. This is the single most important factor in preventing both high-intensity aerodynamic noise and destructive liquid cavitation.

This staged approach is a game-changer. It ensures the pressure never dips below the liquid's vapour pressure, which completely eliminates the root cause of cavitation. In gas systems, it works by keeping velocities subsonic, preventing the shockwaves that produce that extreme noise. While many systems are fine with standard parts, you can explore how specialised pneumatic solenoid valves are used in complex industrial setups where this level of precision is non-negotiable.

Selecting the Right Source-Control Solution

Choosing the right source-control valve is about more than just finding a model with a "low-noise" sticker on it. You have to match the technology to the specific problem you identified earlier.

Here's what to keep in mind when you're making a selection:

- For Aerodynamic Noise: Your priority should be trims with a high number of small-diameter flow paths. The aim here is to shrink the scale of the turbulence and push the noise frequency higher, where it's easier to absorb.

- For Hydrodynamic Noise: It's all about cavitation control. Look for multi-stage trims that are explicitly designed to manage the pressure profile and stop it from ever dropping below the liquid's vapour pressure.

- For Dual-Concern Scenarios: In some high-pressure gas applications, you get hit with a double-whammy of noise and vibration. A multi-stage trim is often the perfect fix, as it manages energy dissipation more smoothly through the entire valve body.

Putting your money into a valve with engineered source control technology, like the well-regarded Fisher WhisperFlo™ or similar designs, is often the most permanent and effective solution for serious noise problems. It gets to the heart of the physics behind the noise, leading to a quieter, safer, and more reliable operation all around.

Managing Noise Along the Pipeline Path

Let's be realistic—sometimes, swapping out a noisy valve just isn't on the cards. Budget constraints, the headache of operational downtime, or sheer system complexity can make a full replacement impractical. When you find yourself in this situation, your focus for valve noise reduction has to shift. Instead of tackling the source, you need to manage the noise as it travels down the pipe. We call this path treatment.

This approach is all about containing the acoustic energy after it's been created, stopping it from radiating out from the pipework and into the surrounding plant. It might not be as fundamental as source control, but for existing systems where noise has become a real problem, path treatment offers some incredibly effective, real-world solutions.

The two main weapons in your arsenal for path treatment are acoustic insulation (also known as lagging) and the installation of silencers. Each has its own strengths, depending on the specific noise you're dealing with and the physical layout of your system.

The Practicalities of Acoustic Insulation and Lagging

The most common path treatment by far is applying acoustic insulation, or lagging, directly onto the outside of the valve and the downstream pipework. Think of it like throwing a heavy blanket over a speaker—it doesn't stop the noise from being made, but it does a fantastic job of absorbing the sound energy before it can escape.

The effectiveness of lagging comes down to two things: the materials you use and how well you install them. A proper, high-performance lagging system is built in layers:

- An inner absorbent layer: This is typically a soft, porous material like high-density fibreglass or mineral wool. Its job is to soak up high-frequency sound waves.

- A heavy outer barrier: Next comes a dense, non-porous layer, often a mass-loaded vinyl (MLV). The sheer mass of this layer is what blocks the lower-frequency noise from punching through.

- A protective outer jacket: To finish it off, an aluminium or stainless steel cladding protects the insulation from physical damage, moisture, and the weather.

For any of this to work, you absolutely cannot have any gaps. Even a tiny opening in the lagging can seriously undermine its acoustic performance, creating a weak spot for sound to leak out. A continuous, perfectly sealed application is critical for success.

Using Inline and Vent Silencers

When insulation isn't quite enough, or it's just not practical for the application, an inline silencer or vent silencer is your next best bet. These are essentially industrial-strength mufflers that you install directly into the pipeline itself.

An inline absorptive silencer, fitted downstream from the noisy valve, works a bit like acoustic lagging but in a much more compact, engineered package. The gas or liquid flows through a central passage that’s surrounded by sound-absorbing packing material. This is brilliant for dampening the high-frequency "hiss" you often get from gas control valves, such as those found in systems using pressure reducing valves.

Vent silencers, on the other hand, are designed for a specific, and often deafening, scenario: where a gas or steam line vents straight to the atmosphere. That sudden, massive pressure drop creates an incredible roar. A vent silencer uses a combination of diffusion (to slow the fluid down gently) and absorption to muffle the sound before it exits. The results can be dramatic. For instance, a steam blow-off valve that screams at 140 dB can be brought down to a much safer 85 dB with a correctly sized vent silencer.

Choosing the Right Path Treatment for Your System

So, how do you decide between insulation and silencers? It all comes down to the noise characteristics and your operational setup.

- Acoustic Lagging is best for: High-frequency noise (that classic aerodynamic "hiss"), situations where you're tight on space, and when you need to retrofit existing pipework with minimal fuss.

- Silencers are ideal for: Tackling both low and high-frequency noise, especially in venting applications or anywhere you need a significant, single-point noise reduction.

It's vital to remember that path treatments manage the symptom, not the cause. If the noise is coming from severe cavitation, lagging the pipe will muffle the sound, but it won’t stop the destructive implosions from eroding your valve and pipework from the inside out. For extensive issues requiring major changes, it may be worth exploring professional piping and repiping solutions.

Meeting UK Industrial Noise Regulations

Tackling valve noise reduction isn't just good practice for creating a better work environment or staving off mechanical wear. It's a legal necessity. Here in the UK, failing to get a grip on industrial noise can bring serious consequences, from hefty fines and operational shutdowns to lasting damage to your company's reputation.

Getting your head around your legal duties is the first, most crucial step towards building a compliant and sustainable operation. It’s about more than just a decibel reading at the fence line; it requires a proactive, documented approach to noise management that keeps your team safe and minimises disruption to your neighbours.

Industrial sites in the UK, especially those with complex valve systems generating significant noise, fall under the Pollution Prevention and Control (PPC) Regulations 2000. These rules are clear: operators must use the Best Available Techniques (BAT) to reduce noise. For a full picture of your duties, it’s worth reviewing the complete government guidance on environmental protection.

What Does "Best Available Techniques" Mean in Practice?

The term "Best Available Techniques" might sound a bit vague, but it boils down to something quite practical. It means you must use the most effective and feasible methods available to stop or minimise noise emissions. It's not about installing the most expensive gear imaginable. Instead, it’s about a well-rounded strategy that blends technology, smart operational procedures, and thoughtful site management.

When it comes to valve noise, this means you need to be able to justify your decisions. For instance, if you choose cheaper, noisier valves and just wrap the pipes in lagging, you might be asked to prove why a source-based fix, like a low-noise trim, wasn't a "best available technique" for your situation. It forces a more considered, long-term approach to noise control.

A key principle of BAT is its focus on prevention. The regulations strongly favour controlling noise at its source rather than simply blocking its path with barriers. This lines up perfectly with engineering best practice for valve noise, pushing us to prioritise low-noise valve trims and multi-stage designs wherever we can.

The Power of Smart Site Layout

One of the most powerful—and frequently overlooked—elements of BAT is strategic site planning. Where you physically place your noisy equipment can make a world of difference to your site's overall noise footprint.

When planning new builds or modifying existing layouts, keep these principles in mind:

- Distance is your friend: Put the loudest kit, like big control valve stations or atmospheric vents, as far as possible from sensitive locations like offices or the site boundary.

- Use what you've got: Can you position noisy processes so that other buildings or large structures act as natural sound barriers?

- Plan for maintenance: Always leave enough space around valves and pipework to install and maintain acoustic lagging and enclosures properly. A cramped installation almost always leads to gaps and weak spots in the acoustic seal.

Barriers, Bunding, and Enclosures

When controlling noise at the source and using clever site layout still isn't enough, physical barriers become your next line of defence. This is where we move beyond simple pipe lagging and into more significant engineering controls.

Acoustic enclosures are, in essence, sound-proof boxes built around a particularly noisy valve or machine. A well-designed enclosure can achieve a significant noise reduction of 15-25 dB. However, they need careful design to manage heat build-up and, crucially, to allow for maintenance access.

Bunding and acoustic barriers are simply walls placed strategically between the noise source and the listener. While they are less effective against high-frequency noise which can travel over the top, they are fantastic for blocking the direct path of mid-frequency sound. Their success depends entirely on their height, density, and placement. Thinking about this during the design phase is always cheaper than trying to retrofit a solution later.

Getting Your Noise Prediction Models Right

Getting a reliable noise forecast is the bedrock of designing effective controls, especially when you're dealing with high-pressure industrial environments. An accurate prediction means you can select the right valve noise reduction technology from day one, saving a whole lot of time and money down the line. But as anyone with field experience knows, predicting valve noise is a lot more nuanced than the textbooks might suggest.

Standard semi-empirical models are a decent starting point, but they can fall short. While they give you a solid baseline, they don't always capture the complex physics at play, particularly at the extreme ends of the valve size and pressure spectrum. Relying on them too heavily can lead to a false sense of security or, just as bad, unnecessary over-engineering.

The Limits of Standard Models

Experience has taught us that these standard models have a knack for getting it wrong for the really big and really small valves. This gap between prediction and reality only gets wider as the pressure ratio climbs.

A detailed experimental analysis in the UK, which looked at valve noise at pressure ratios all the way up to 11 bars, put a spotlight on this exact problem. The findings were clear: for larger valves, the noise was often under-predicted by about 2 decibels. On the other hand, for smaller valves, the models could over-predict the noise by as much as 4 decibels. If you want to get into the weeds, you can review the full experimental analysis on valve noise characteristics to see the data for yourself.

This might not sound like a huge deal, but in the world of acoustics, a few decibels is the difference between a compliant system and a noisy, problematic one. It really hammers home the need to look beyond the basic formulas and consider how fluids behave in the real world.

A model that under-predicts noise for a large valve can trick you into choosing an inadequate abatement solution. That means even after you've spent the money and done the work, the system could still fail to meet legal noise limits, forcing you into costly rework.

It's Not a Straight Line: Understanding Non-Linear Noise

There's a common assumption that as you crank up the pressure, noise just increases in a simple, straight line. That's a myth. The relationship between pressure ratios and the noise they create is anything but linear, particularly in gas and steam systems.

As the pressure drop across a valve increases, the gas velocity shoots up. Then you hit a critical point where the flow reaches sonic velocity (Mach 1), which creates shockwaves inside the valve and the downstream pipework. This is where the noise level spikes, often dramatically.

Pushing the upstream pressure even higher won't make the flow any faster—it's physically choked at that point. Instead, it just intensifies the shockwaves, changing the noise profile in complex ways that basic models can really struggle to account for.

Moving Towards More Precise Predictions

To get beyond rough estimates, we need to supplement those standard models with a deeper understanding of what's physically happening inside the valve. It's about taking a more granular approach to the analysis.

Here are a few practical steps you can take to sharpen your noise forecasting:

- Factor in Valve Geometry: Pay close attention to the specific trim design. A multi-hole cage trim generates noise completely differently to a single-port globe valve, even if the process conditions are identical.

- Analyse the Vena Contracta: You have to model the pressure right at the vena contracta—the point where the flow is most constricted. This is the birthplace of cavitation in liquids and where sonic flow kicks off in gases.

- Consider Downstream Effects: The noise doesn't just vanish at the valve outlet. The piping setup immediately downstream, including any elbows and expanders, can either amplify or dampen the noise generated by the valve.

Taking this level of detailed analysis is what separates a rough guess from a truly engineered solution. These same complex fluid dynamics also lead to other problems like water hammer, a destructive phenomenon that needs careful management. For those interested, we have a helpful guide explaining the crucial role of water hammer arrestors in system protection.

By appreciating the limitations of the go-to models and digging into the non-linear realities of fluid dynamics, you can make far more precise predictions. This ultimately gives you the confidence to select the most appropriate and cost-effective valve noise reduction strategy for your specific application.

Common Questions on Valve Noise Reduction

When you start digging into a valve noise reduction project, practical questions always crop up. Knowing the answers before you start can make troubleshooting on the fly much easier and give you the confidence to apply the right fix. Let's tackle some of the most frequent queries we hear from plant managers and engineers in the field.

These aren't just textbook problems; they're the real-world challenges that surface when you're trying to diagnose an issue or put a solution in place. Getting clear, straightforward answers is what bridges the gap between technical theory and a successful result on the plant floor.

How Can I Tell If Valve Noise Indicates a Safety Risk?

Being able to tell a simple nuisance noise from a genuine safety risk is a critical skill. While any noise above regulated limits is a health hazard for your personnel, some sounds are a direct warning of an immediate mechanical danger to the system itself.

Loud, erratic noises are your biggest red flag. If you hear a distinct rattling, clanking, or grinding, it could point to severe mechanical wear. This often means internal parts like the valve plug or cage are loose and might be on the verge of failure.

The most critical warning sign is any sudden change or sharp increase in the noise level from a valve. This almost always means a component's condition has rapidly worsened. Hydrodynamic noise from cavitation, in particular, is incredibly destructive. That tell-tale gravelly rumbling sound means the valve and surrounding pipework are actively being eroded, which poses a serious long-term integrity risk.

Is Acoustic Lagging or a Low-Noise Trim More Effective?

This is a classic "path vs. source" debate. Fundamentally, a low-noise trim is more effective because it attacks the problem at its root, preventing the acoustic energy from being generated in the first place. Acoustic lagging is a path treatment—it only contains the noise after it has already been made.

Think of it this way: a low-noise trim is like re-engineering a car engine to run quietly. Acoustic lagging is like stuffing sound-dampening material under the bonnet. Both can reduce what you hear, but only one truly fixes the source of the problem.

Here’s how to decide in practice:

- Low-Noise Trim: This is the superior long-term solution. It's the best choice for new installations or major upgrades where you have the chance to specify the right valve from day one.

- Acoustic Lagging: This is an excellent and often necessary fix for existing systems. When replacing a valve is just not feasible because of cost or operational downtime, lagging is a powerful alternative.

Ultimately, the best choice really hinges on your specific situation. For a brand-new project, engineered source control should always be the goal. For a problematic existing valve, high-performance lagging is a perfectly valid and effective fix.

Can Routine Maintenance Reduce Existing Valve Noise?

Yes, absolutely—but only for certain kinds of noise. Regular, thorough maintenance is incredibly effective at tackling mechanical noise. This is the sound caused by loose connections or worn internal components like plugs, stems, guides, or seals.

During a maintenance check, simply tightening up packing bolts, lubricating moving parts where needed, and replacing worn-out seals can dramatically cut down on rattling and vibration. It’s often surprising just how much quieter a valve can get after a bit of basic care.

However, it's crucial to know the limits of maintenance. It will have no effect on aerodynamic or hydrodynamic noise. These noises are created by the physics of the fluid flow, not by loose parts. No amount of tightening or lubrication is going to stop cavitation or turbulent gas flow. Those issues demand an engineered solution, like installing a different trim or a downstream silencer.

At Solenoid Valve World, we provide the specialised components needed to tackle noise at the source. From pressure control equipment to actuated valves, our technical team can help you select the right solution for your application. Explore our comprehensive range at https://solenoid-valve.world.