Coaxial Valves: Comprehensive Guide to Solenoid & Air Pilot Coax Valves

Introduction

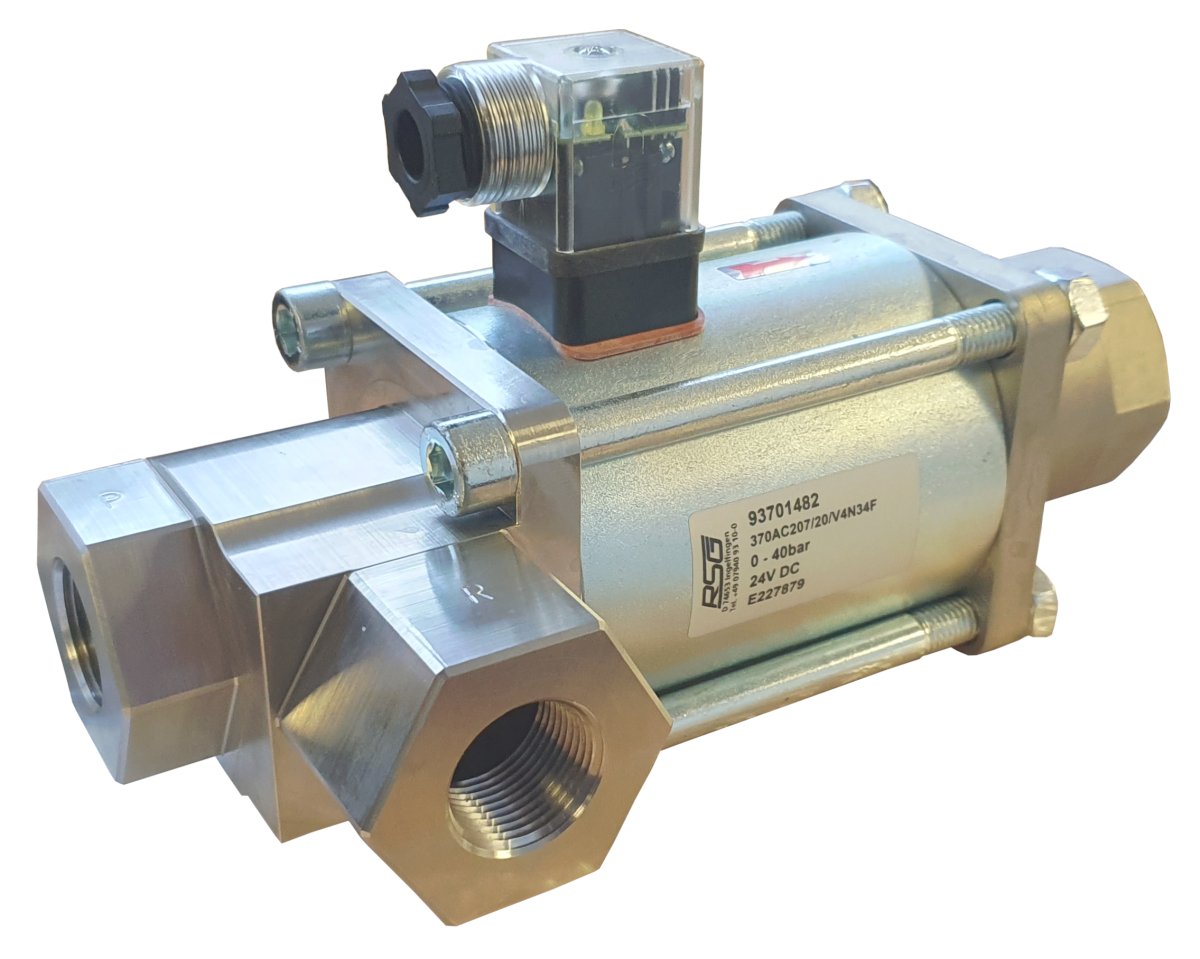

Explore what coaxial valves are, how they work, and their industrial applications. Coaxial valves are direct‑acting, pressure‑balanced valves featuring an internal stainless steel tube that enables flow control or diversion, acting from zero pressure and resisting back‑pressure from downstream equipment.

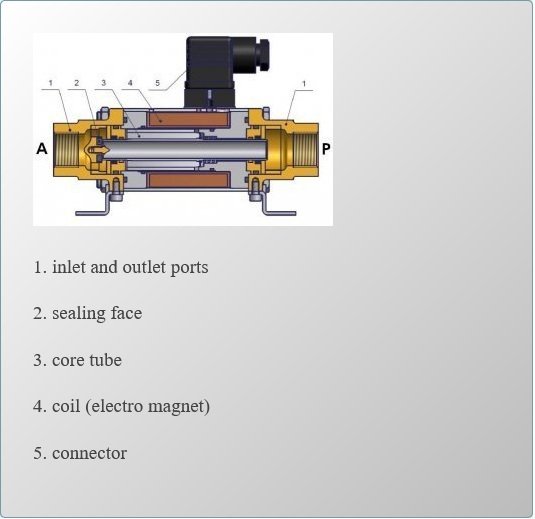

What Is a Coaxial Valve?

Design & Materials

316 stainless steel coaxial tube – Offers corrosion, wear, and chemical resistance

O‑ring seals – Typically PTFE, NBR, EPDM, or FKM, which allow tube movement while maintaining fluid integrity

Pressure‑Balanced Operation

Completely pressure‑balanced design—functioning from 0 bar and unaffected by inlet vs. outlet pressure differences

Can handle up to 16 bar back‑pressure at the valve seat; some pneumatic/hydraulic drives can handle full line pressure

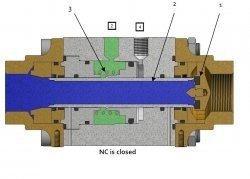

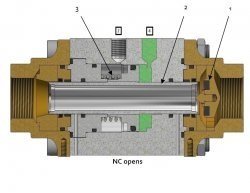

Types of Coaxial Valves

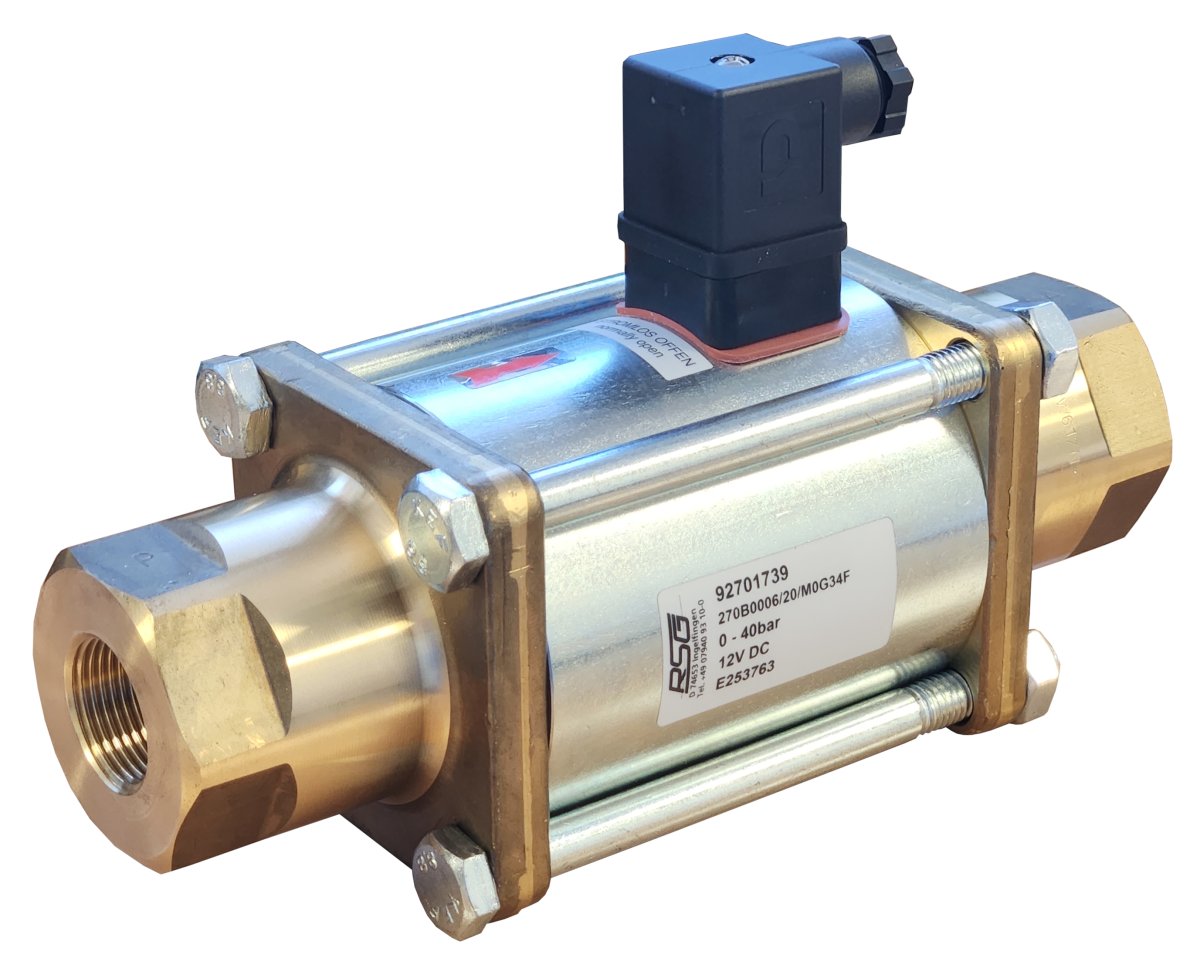

2/2 Way Coax Solenoid Valves

Function: Two ports (inlet P, outlet A); normally open (NO) or normally closed (NC).

Operation: Electromagnet moves the internal tube to open/close flow; spring returns it to default

Options: BSP/NPT threads, flange connections, orifice sizes (10–50 mm), body materials (brass, stainless steel), seals (FKM, NBR, EPDM, PTFE)

Technical information and buy 2/2 coaxial solenoid valves.

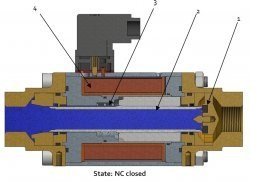

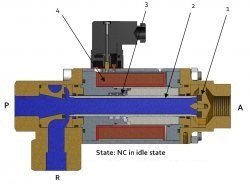

2/2 Way Normally Closed coaxial valve is in the fail-safe closed state.This 2 way normally closed coaxial valve is in the rest or fail-safe position. The control tube (2) through which the media (Blue) will flow and is pressed by a compression spring (3) into the valve seat (1). The coaxial valve is in the closed state - no flow.

|

|

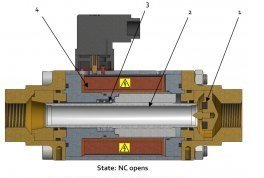

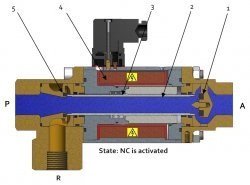

2/2 Way Normally Closed Coaxial Valve in the energised open state.This 2 way normally closed coaxial valve is in the energised position. By energising the electro magnet (4) an electromagnetic field is generated which moves the control tube (2) in an axial direction away from the valve seat (1) and so opens the flow passage. Due to the axial movement of the tube (2) a compression spring (3) is compressed. When the electrical supply is removed and the electro magnet de-energised (4), the compressed spring (3) pushes against the control tube (2) back into ins initial position against the valve seat (1). The coaxial valve is again closed and there is no flow of media. |

|

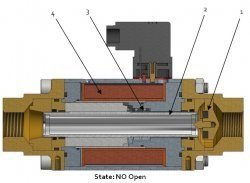

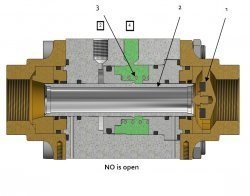

2/2 Way Normally Open coaxial valve is in the fail-safe open state.This 2 way normally open coaxial valve is in the rest or failsafe position. In the fail-safe rest position, the control tube (2) through which the media flows, has the compression spring (3) mounted on the right hand side, keeping the tube (2) away from the seat seal (2), allowing the flow of media through the valve. |

|

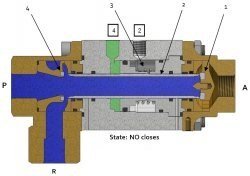

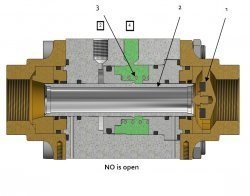

2/2 Way Normally Open coaxial valve is in the energised closed state.This 2 way normally open coaxial valve is in the energised position. With electrical power to the solenoid magnet (4) of an applied voltage, an electromagnetic field is generated, which pulls the control tube (2) in an axial direction against the valve seal (1) and thus closes the passage preventing the flow of media. At the same time the tube (2) compresses the spring (3) further. With electrical power removed and the electro magnet (4) without power to generate electro magnetic field, the compression spring (3) pushes the control tube (2) back to its fail safe (original) position away from the valve seat (1). The valve opens again. |

|

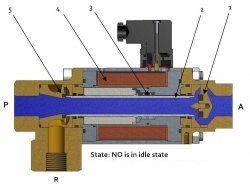

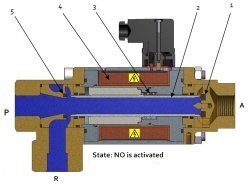

3/2 Way Coax Solenoid Valves

Function: One inlet, two outlets (A + exhaust R); two states (open/closed).

Operation: Electromagnetic coil shifts tube to direct flow; spring resets .

Options: Same port/thread options, orifice sizes, materials, and additional features like vacuum versions, manual overrides, and position feedback

Technical information and buy 3/2 coaxial solenoid valves.

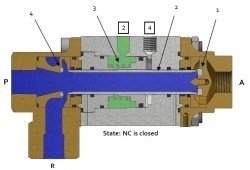

3/2 Way Normally Closed coaxial valve in the fail-safe closed state.This 3 way normally closed coaxial valve is in the rest or fail-safe position. With the control tube (2) through which the media (Blue) flows and is pressed against a compressed spring (3) against the valve seat (1). The valve is constantly closed from inlet P to outlet A. Flow is allowed from port P to exhaust port R. |

|

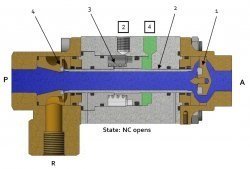

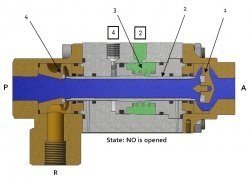

3/2 Way Normally Closed coaxial valve in the energised open state.This 3 way normally closed coaxial valve is in the energised position. By energising the electro magnet (4) an electromagnetic field is generated that in turn moves the control tube (2) in an axial direction away from the valve seat (1) and so opens the flow passage from Inlet P to outlet A. The opposite side of the control tube (2) is pressed against the 3/2 valve seat (5) and closes the flow passage from A to R. Due to the axial movement of the tube (2) a compression spring (3) is compressed. When you turn off the magnet i.e. remove the electrical supply and de-energise the electro magnet (4), the compressed spring (3) pushes against the control tube (2) back into its rest position against the valve seat (1). The coaxial valve is again closed from P to A and flow from P to R is thus open again. |

|

3/2 Way Normally Open coaxial valve in the fail-safe open state.This 3 way normally open coaxial valve is in the failsafe or rest position. When a 3/2 way coaxial valve is in the rest or fail-safe position the control tube (2) through which the media (blue) will pass, is forced to the left by a compressed spring (3) against the 3/2 way valve seat (5), which in turn opens the passage from P to A and closes the flow path P to R. |

|

3/2 Way Normally Open coaxial valve in the energised closed state.This 3 way normally open coaxial valve is in the energised position. With electrical power to the solenoid magnet (4) of an applied voltage an electromagnetic field is generated, which moves the media control tube (2) in an axial direction (right) away from the 3/2 valve seat (5) and opens the flow path from P to R. The other side of the control tube is pressed against the valve seat (1) and thus closes port A. Due to the shift of the tube (2) the return spring (3) is compressed further. When you turn off the electrical power supply the electro magnet (4) allows the compression spring (3) to push the control tube (2) (left) back to its fail safe original position back against the 3/2 way valve seat (5) closing the connection from P to R and at the other end the tube moves against the valve seat (1) closing port A. |

|

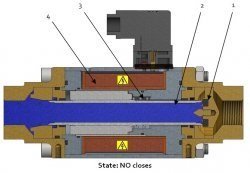

2/2 Way Coax Pneumatic Valves

Function: Pneumatic pilot valve actuates the coax valve—fail‑safe open or closed.

Operation: Compressed air (3–8 bar) shifts control tube; spring resets

Options: BSP/NPT/flange, orifice ranges (10–50 mm), body materials and seals

Technical information or buy 2/2 way Coaxial air pilot valves

2/2 way normally closed air piloted coaxial valve in the failsafe closed state.This 2 way normally closed air actuated coaxial valve is in the rest or fail position. The control tube (2) through which the medium (blue) flows is

pressed by a compression spring (3) against the seal of the valve seat

(1). The valve is thus permanently closed. |

|

2/2 way normally closed air pilot coaxial valve in the actuated open state. This 2 way normally closed air actuated coaxial valve is in the actuated position. By supplying the control air at the port 4, the space in the cylinder is set under pressure, which pushes the control tube (2) in the axial direction away from the valve seat (1) and so releases the passage allowing flow. The space at port 2 is exhausted to atmosphere. Due to this shift in the valve tube, a compression spring (3) is compressed further. When port 4 is vented to atmosphere, the compression spring (3) pushes the control tube (2) back to its initial position against the valve seat (1). The valve is then closed again - no flow. |

|

2/2 way normally open air pilot coaxial valve in the failsafe open state. This 2 way normally open air actuated coaxial valve is in the rest or failsafe position. When the Normally Open valve is in the rest position, the control tube (2)

through which the medium flows, is pressed by a compression

spring (3), to the left and results in an open passage for flow of

media. The valve is thus permanently opened. |

|

2/2 way normally open air pilot coaxial valve in the energised state. This 2 way normally open air actuated coaxial valve is in the actuated position. If the space in the cylinder is filled through the port 4 with the control air (green), the control tube (2) moves in the axial direction towards the sealing of the valve seat (1), thus closing the passageway. The space at port 2 is vented to atmosphere. Due to this shift in the valve, the compression spring (3) is compressed further. When air is released or vented from the port 4, the compression spring (3) shifts the tube (2), to the right and results in a closed passage (1) - no flow. |

|

3/2 Way Coax Pneumatic Valves

Pneumatic equivalent of 3/2 solenoid type—externally piloted, fail‑safe open/closed, similar options in port types, orifice sizes, and pressures up to 64 bar

Technical information or buy 3/2 coaxial air pilot valves

3/2 way normally closed air piloted coaxial valve in the failsafe closed state.This 3 way normally closed air actuated coaxial valve is in the rest or fail position. These externally controlled pneumatic valve is in the rest or fail safe position, with the control tube (2) through which the medium (blue) flows being pushed by a compressed spring (3) against the seal of the valve seat (1). The valve is thus permanently closed from the input P to output A. From P to output R, the medium can be flow through the valve. |

|

3/2 way normally closed air pilot coaxial valve in the actuated open state. This 3 way normally closed air actuated coaxial valve is in the actuated position. By supplying the compressed control air at the port 4, the space in the cylinder is set under pressure, which pushes the control tube (2) in the axial direction away from the valves seat (1) and so releases the flow path passage from P to A. The opposite side of the control tube is at the same time pressed in the 3/2 Way valve seat (4) and so closes the passage from A to R. Due to this shift in the valve, the return spring (3) is compressed. When port 4 is exhausted to atmosphere, the compression spring (3) pushes the control tube (2) back to its initial position in the valve seat. The valve is then closed from P to A. Connection from P to R is thus open again. |

|

3/2 way normally open air piloted coaxial valve in the failsafe open state.This 3 way normally open air actuated coaxial valve is in the rest or fail position. These externally controlled pneumatic valve is in the rest or fail safe position, with the control tube (2) through which the medium (blue) flows being pushed by a compressed spring (3) against the seal of the valve seat (1). The valve is thus permanently closed from the input P to output A. From P to output R, the medium can be flow through the valve. When the Normally open valve is in the rest position, the control

tube (2) through which the medium (blue) flows, is pressed by a

compression spring (3), to the left away from valve seal (1) and results

in an open passage P to A and in turn pushes against 3/2 way seal $4)

thus closes the connection from P to R. |

|

3/2 way normally open air piloted coaxial valve in the actuated closed state.This 3 way normally open air actuated coaxial valve is in the actuated position. If the space in the cylinder is filled through the port 4 with the control air (green compressed air), the control tube (2) moves in the axial direction away from the 3/2-Way valve seat (4), and so opens the passage from P to R. The opposite side of the control tube is pressed at the same time into the valve seat (1) and thus closes the passage from P to A. Due to this tube shift in the valve, the return spring is compressed further. When venting port 4, the return spring (3) shifts the control tube (2) back to its initial position away from the 3/2 valve seat. The valve is then open again. |

|

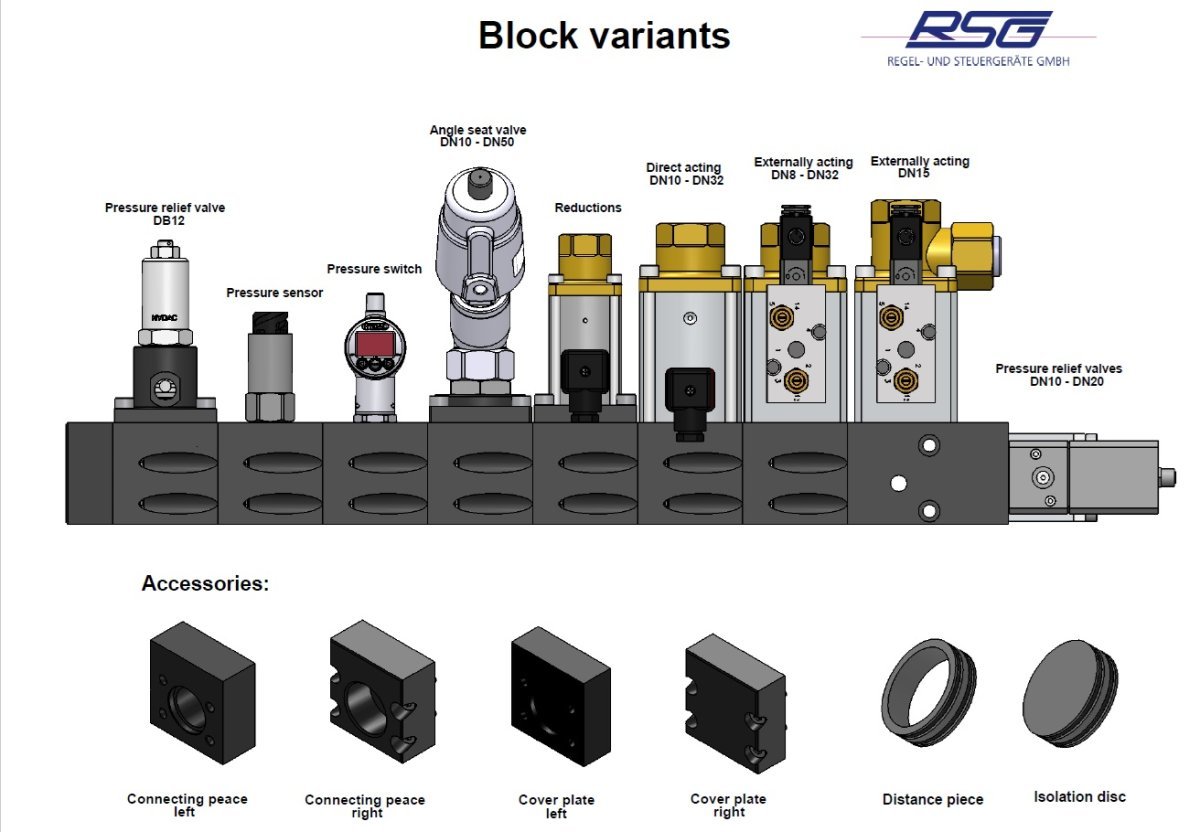

Modular Coax Valve Systems

Manifold or strip mounting groups multiple coax valves sharing a common inlet/outlet, saving space and piping

Configurations may mix 2/2 NO/NC and 3/2 valves with different orifices to fine‑tune flow to each port

Custom manifolds can be built, e.g., a 3D‑printed manifold delivered within ~30 days, validated by May 2023 and fully deployed by November 2023.

Read more about this special project.

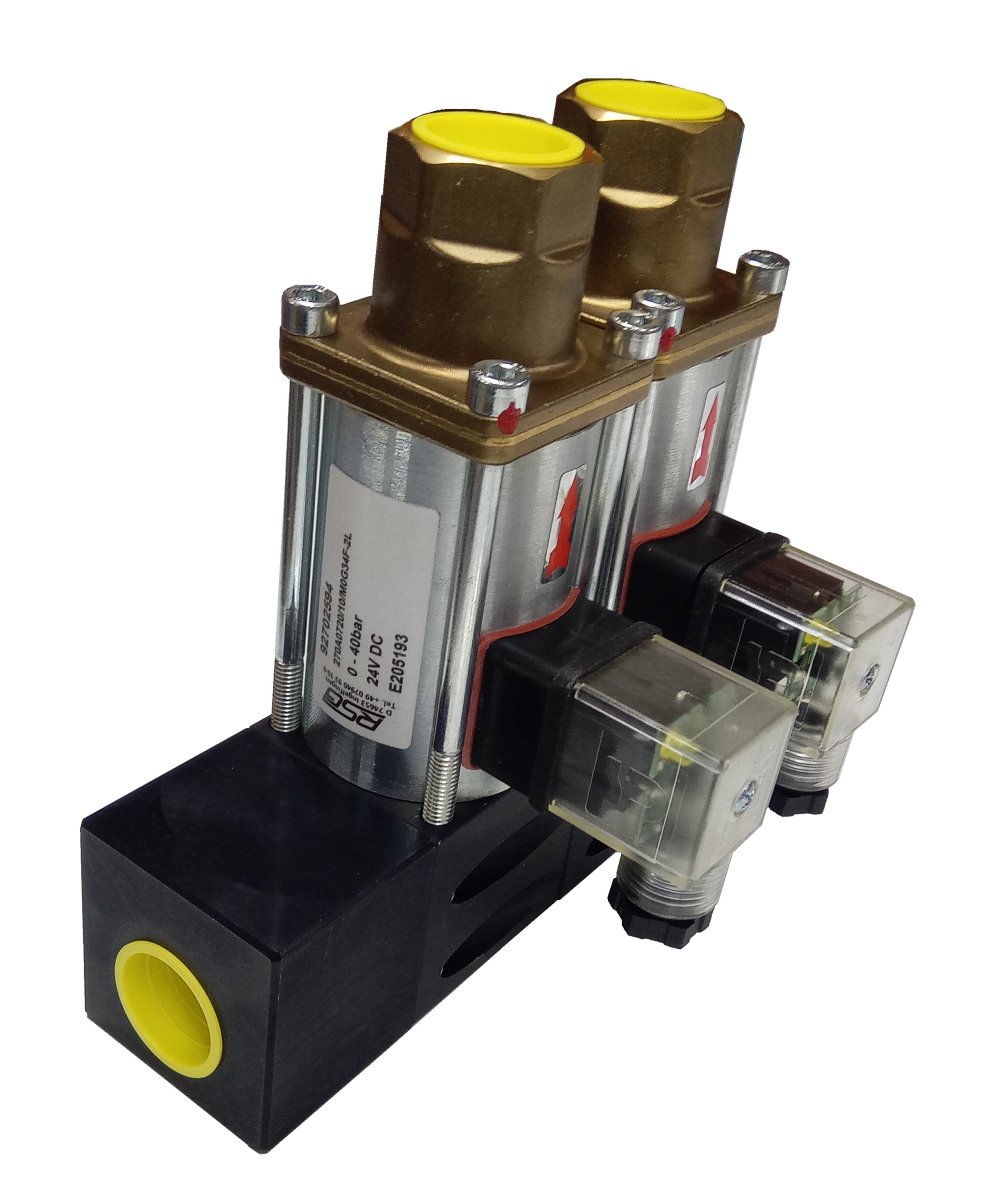

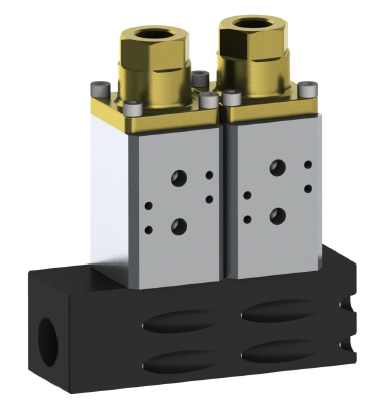

270X Standard Coaxial solenoid valve manifold system

270X 3D printed custom manifold system for low pressure test

Final production of custom made manifold system

Modular coaxial valve solutions and configurations coaxial valve modular systems sub base mounted to a single manifold are easily achievable on the same manifold.

The coaxial valve modular system has almost limitless potential with so many valve 2/2 and 3/2 way coax model options offering compact and high pressure control for even most most arduous media applications.

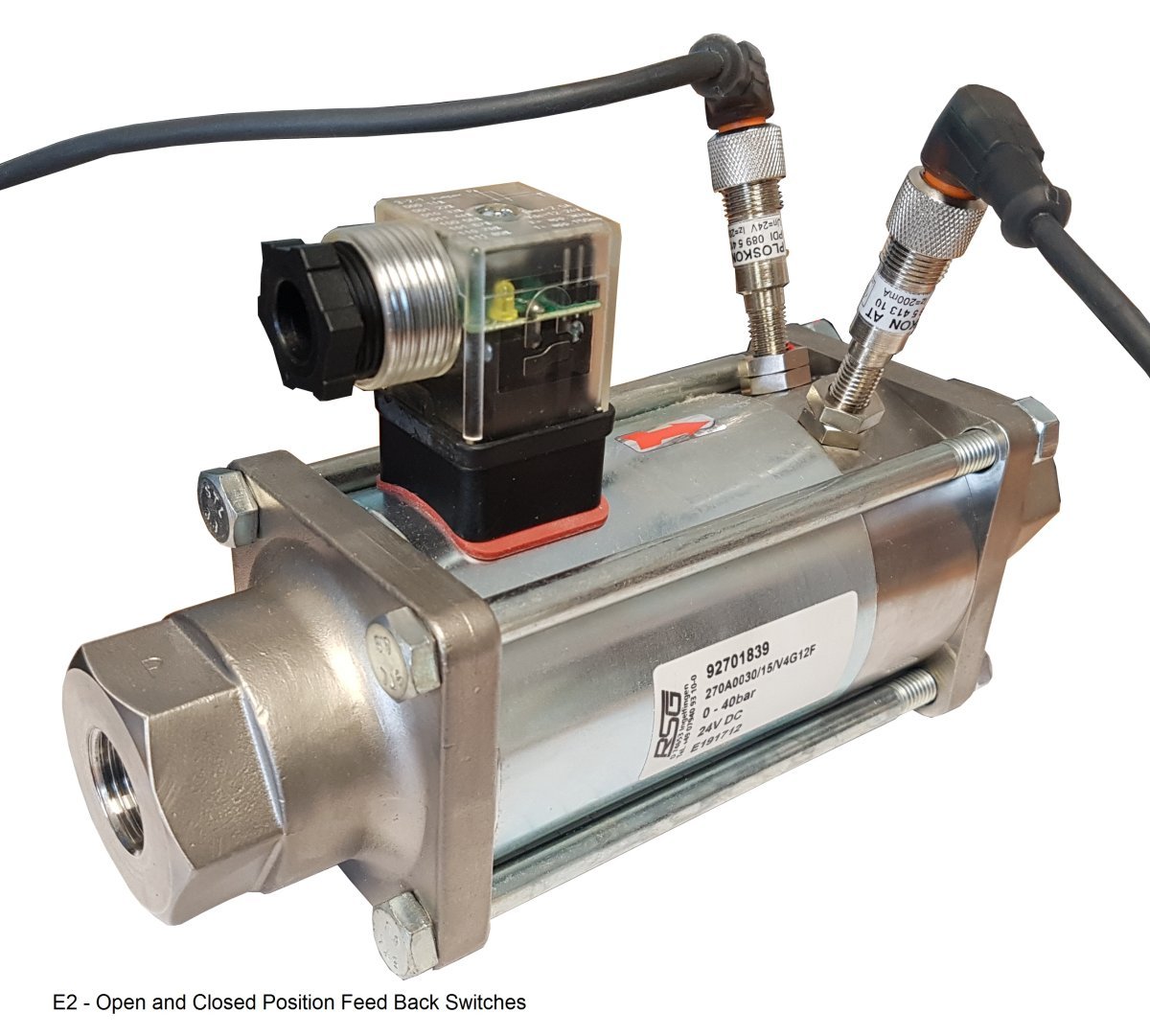

This is further enhanced when you consider that most coaxial valves either air operated or solenoid operated across the range of BSP/NPT or flanged end connections from 1/8 through to 2" can include open and close position feed back volt free switches, manual over ride facilities, various materials of construction from galvanised or nickel plated steel, nickel plated brass, brass, AISI316 stainless steel or AISI303 stainless steel, a wide choice of sealing materials such as NBR, EPDM, Viton or PTFE, a full range of orifice sizes from 1.0mm through to 50mm offering different flow characteristics, oil and grease free options, heavy duty aluminium terminal boxes to protect the solenoid coil electrical entry to name but a few.

Valve Terminology & Specifications

Seal types: VITON, NBR, EPDM, PTFE, Fluoroloy 21 for gases, UHMW Polyethylene for water (limescale removal), BAM approved VITON for oxygen service. Many others available with different chemical compatibility

Thread types: BSPP (Europe, UK) and NPT (North America); flange options PN16/40/100

Orifice and port sizes: 10–50 mm tubes matching threads from ¼″ to 2″; choose tube size to match flow needs without waste

Body materials: Brass, AISI 303/316 stainless steel, galvanised or nickel‑plated steel

Features & Benefits

Key Advantages

Pressure-balanced operation works at zero pressure differential and resists back pressure

Fast and reliable switching with cycle speeds as quick as ~25 ms

Low wear, maintenance-free, and tolerant of contaminated, viscous, or gelatinous media

Bi‑directional flow flexibility without performance loss

Industrial Applications

Used in hydraulics, vacuum systems, gas handling, dosing/dispensing, machine tools, marine, rail, lubricants, chemicals, ceramic paste and hydrogen tech

Technical Resources & Guidance

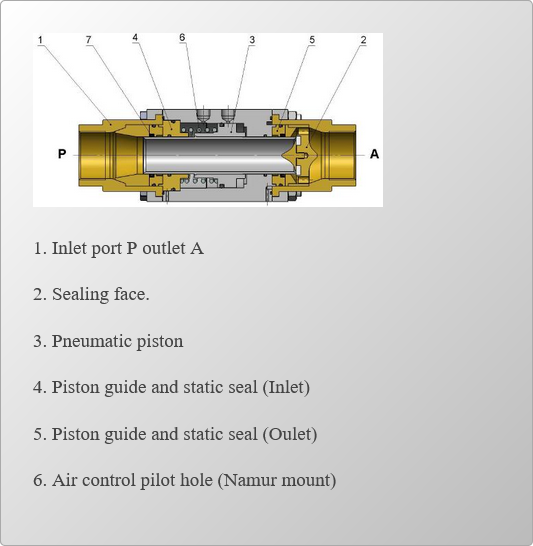

Data sheets available for model families (e.g., 269, 280, 290 series) include pressure ratings (up to 160 bar pneumatic), thread sizes, materials, orifice options

Specification assistance ensures correct valve selection based on pressure, flow, media, voltage, and thread standards.

| Orifice | 2/2 Way Kv (m³/h) | 3/2 Way Kv (m³/h) |

|---|---|---|

| 10 mm | 2.5 | 2.5 |

| 15 mm | 4.5 | 5.6 |

| 20 mm | 6.8 | 8.0 |

| 25 mm | 11.5 | 11.5 |

| 32 mm | 20.0 | 17.9 |

| 40 mm | 38.2 | 34.0 |

| 50 mm | 47.2 | 42.0 |

Choosing the Right Coaxial Valve

Selection Checklist

Flow requirements (orifice vs. ports).

Valve function (2/2 vs. 3/2, NO/NC, solenoid vs. pneumatic).

Pressure demands (inlet, outlet, back‑pressure).

Media compatibility (seals, materials).

Thread/flange standards (BSP/NPT/flange).

Actuation voltage or air supply specs.

Additional options: ATEX, vacuum version, overrides, position feedback.

Custom & Special Solutions

Custom manifold designs using standard valve modules to fit compact installations

Bespoke high‑pressure (100 bar) manifolds with integrated control and monitoring, delivered via modular systems and rapid manufacturing

Contact Information & Support

Address

Connexion Developments LtdUnit 3, Rainbow Court

Armstrong Way

Great Western Business Park

Yate

Bristol

BS37 5NG

United Kingdom

Conclusion

Download data sheets for each valve family to compare specs.

Use our selection tool or consult technical support to choose the correct valve.

Contact us today to discuss custom modular manifold systems for your specific application.