Latching Solenoid Valves: Energy-Efficient Control Solutions

Understanding Latching Solenoid Valves: The Game-Changer

How does your phone remember your photos when it's turned off? Latching solenoid valves use a similar "memory" concept to control the flow of liquids and gases. A standard solenoid valve needs a constant electric current to stay open or closed, much like an old light bulb that only works when power is flowing. A latching valve, however, only needs a short pulse of energy to change its state and will then hold that position indefinitely.

This ability comes from bi stable technology, meaning the valve has two stable positions (open and closed). Inside the valve is a permanent magnet. When a brief electrical pulse is sent to a coil, it creates a magnetic field that pushes or pulls the valve's plunger. Once the plunger moves, the permanent magnet holds it firmly in place with zero further power consumption. This eliminates the constant power draw, heat, and wasted energy of traditional valves, making them ideal for battery-powered equipment or remote installations.

The Magic of the Dual-Coil Design

The mechanism for this is often a clever dual-coil design. Think of it like a common light switch on your wall. You flip it one way to turn the light on, and it stays on without you holding the switch. Flip it the other way, and it turns off. The switch uses no power to stay in either position. Latching valves operate on the same principle:

- A quick pulse of power to the first coil moves the valve into the open position.

- Another quick pulse to the second coil returns it to the closed position.

By removing the need for a constant holding current, this design can cut energy consumption by over 95% in many setups. This incredible efficiency makes latching solenoid valves a popular choice for UK applications like water management and smart agriculture. As the country's water industry adopts more automated irrigation to meet environmental targets, the low power draw and reliability of these valves are crucial, a trend confirmed by recent market analysis.

They offer a more intelligent approach to fluid control in a world focused on energy conservation. You can explore a wide variety of these components in our selection of bistable valves for various applications. For engineers and system designers, this technology is a major step forward.

The Energy Revolution: Why Smart Engineers Choose Latching

What if you could run a massive agricultural irrigation system for an entire season using the same electricity it takes to brew a few pots of coffee? This is the reality that latching solenoid valves make possible. Unlike standard valves that need constant power to stay open or closed, latching valves only need a short pulse of energy to switch their state. This tiny power requirement changes everything about project economics and system design.

The move away from power-hungry, continuously energised valves is a key decision for any engineer focused on efficiency. For instance, one agricultural facility that upgraded its systems cut its valve-related electricity expenses by an incredible 95%. This isn't just a minor budget saving; it's a strategic shift that significantly lowers operational costs and frees up capital for other important investments.

The True Value: More Than Just Money

While the financial argument is strong, the advantages of using latching solenoid valves go much deeper. The initial cost is often recovered quickly, sometimes in less than a year. This fast return on investment is fueled by benefits that conventional valves simply can't offer, such as needing smaller power supplies and lighter wiring.

- Reduced Carbon Footprint: By practically eliminating energy use, the associated carbon emissions drop significantly. This is a direct contribution to meeting sustainability goals and environmental standards, which are increasingly important for modern businesses.

- Minimal Heat Generation: A standard valve gets hot because of the constant current flowing through it, which can damage sensitive fluids or create heat problems in enclosed spaces. Latching valves stay cool, protecting the media and making thermal management easier.

- Enhanced Reliability During Outages: Once a latching valve is set, it stays in that position even if the power fails completely. This built-in security is invaluable for critical processes like chemical dosing or emergency shutdown systems, where an unexpected valve change could be dangerous or costly.

- Ideal for Remote and Mobile Systems: Their low power consumption makes them a perfect fit for systems powered by batteries or solar panels. This opens up new automation possibilities in remote areas where mains power is expensive, unreliable, or simply not available.

The table below highlights the stark operational differences, making the choice clear.

Standard vs. Latching Valve Comparison

| Feature | Standard Solenoid Valve | Latching Solenoid Valve |

|---|---|---|

| Energy Use | Continuous power draw to hold state | Brief pulse to change state |

| Heat Output | Significant; can affect media | Negligible; runs cool |

| Power Outage | Reverts to default state (fail-safe) | Remains in the last state |

| Best For | High-frequency switching | Low-frequency, long-hold states |

These distinct operational benefits are fuelling their adoption across the UK. This trend is backed by market data; the UK control valve market, which includes latching solenoid valves, is expected to grow from USD 350 million in 2024 to USD 1,500 million by 2035. This growth highlights a clear industry shift towards efficiency and resilience. You can find more details in the complete UK control valve market report.

Ultimately, choosing latching technology is a forward-thinking move. It’s about building systems that are not just more affordable to operate, but also more sustainable, dependable, and ready for the future.

Real-World Success Stories: Where Latching Valves Shine

While the theory is interesting, the true test of latching solenoid valves is how they perform in the real world. Across the UK, these components are solving practical problems where standard valves simply can’t keep up. They are the unsung heroes in remote water systems and smart city buildings, providing dependable fluid control where constant power is a luxury, not a guarantee. Let's look at a few examples where this technology makes a real difference.

While the theory is interesting, the true test of latching solenoid valves is how they perform in the real world. Across the UK, these components are solving practical problems where standard valves simply can’t keep up. They are the unsung heroes in remote water systems and smart city buildings, providing dependable fluid control where constant power is a luxury, not a guarantee. Let's look at a few examples where this technology makes a real difference.

Water Management in Remote Locations

In places with unstable power grids or completely off-grid, latching valves are a game-changer. Picture a water pumping station in the Scottish Highlands. With a standard valve, even a brief power outage would cause it to fail-safe, shutting down the water supply and requiring a technician to travel for a manual reset. This is more than an inconvenience; it's a major operational headache.

By installing latching solenoid valves, the problem vanishes. These valves remember their last position—open or closed—even when the power goes out. This built-in memory maintains system stability, preventing service interruptions and expensive emergency call-outs. This application is part of a growing trend; it's estimated that up to 20% of new automated irrigation and water treatment installations in the UK now use latching solenoid valves, as detailed in a market analysis report on these components.

Smart Agriculture and HVAC Optimisation

In controlled environments like commercial greenhouses, latching valves deliver a one-two punch of efficiency. A grower can set up precise, automated irrigation schedules that run on battery or solar power, significantly cutting down on energy costs. And because the valves only draw power for a moment to switch, they produce almost no heat, protecting the sensitive temperature balance needed for healthy plant growth.

The same principle applies to modern HVAC systems. Building managers deploy latching valves for zone control, allowing them to send heated or chilled water only to occupied areas. The benefits are clear:

- Minimal Energy Use: The valves only consume power for the instant they switch states, contributing directly to a building’s energy efficiency.

- Simpler Installation: Lower power requirements mean smaller power supplies and less complicated wiring runs.

- Quiet Performance: With no constant electrical current, there is no "hum," making them perfect for offices, hospitals, and other noise-sensitive spaces.

For these general-purpose tasks, versatile brass-bodied valves often provide the ideal mix of performance and value.

Industrial Processes and Critical Safety Systems

In tougher industrial environments, the right material and function are non-negotiable. For chemical plants or manufacturing lines handling corrosive fluids, durable stainless steel latching valves are essential for long-term reliability. Their ability to hold their position during a power dip prevents serious accidents, like an uncontrolled mixing of chemicals or a failure in a vital cooling system.

This "fail-in-place" capability is also fundamental for emergency shutdown (ESD) systems. When an emergency stop is hit, a latching valve can be pulsed to a safe state—for instance, closed to cut off fuel flow—and it will remain in that state even if the entire facility loses power.

Furthermore, for any system that handles drinking water, from municipal networks to commercial buildings, using a WRAS-approved latching valve is vital for compliance. This approval certifies that the valve's materials are safe for potable water, while its latching function helps manage the supply network with greater safety and efficiency. This high degree of dependability is also why these valves are specified for aerospace systems and smart city infrastructure projects.

Choosing Your Perfect Latching Valve: A Practical Guide

After seeing the real-world problems latching solenoid valves can solve, the next logical step is to figure out how to choose the right one for your job. Selecting the best valve isn’t a guessing game; it’s about carefully matching the valve’s features to your system’s specific needs.

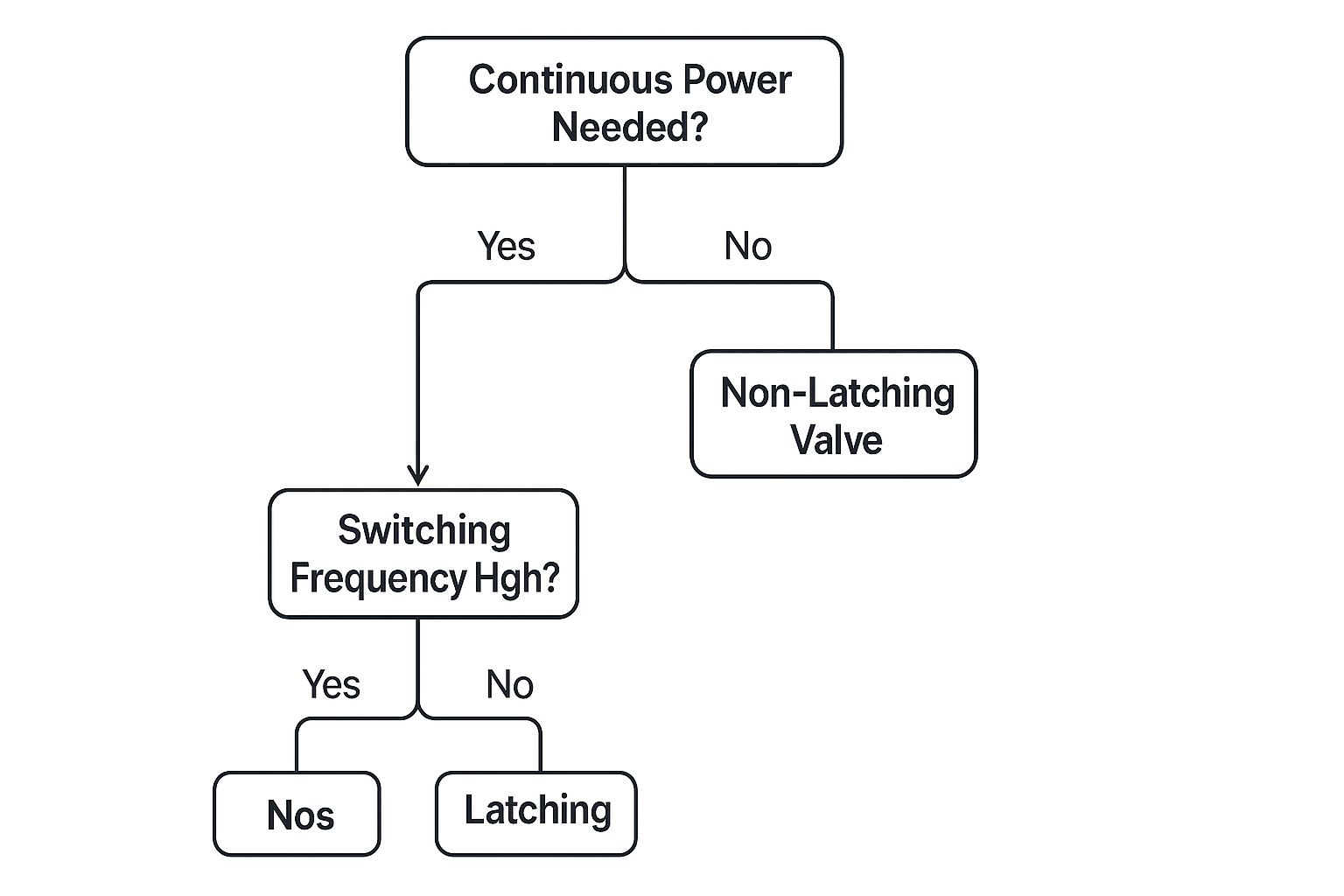

Before you start comparing materials and pressure ratings, it's a good idea to confirm that a latching valve is truly what you need. This decision tree helps you visualise the choice between latching and non-latching valves, based on your power source and how often the valve needs to switch.

The key takeaway here is that latching solenoid valves are the ideal solution when power is limited or needs to be conserved, and when the valve will stay in one position for long periods.

Key Decision Factors: Pressure, Media, and Environment

Once you're sure a latching valve is the way to go, your selection process begins with three fundamental questions about pressure, media, and environment. You need to know that the valve's pressure rating, measured in bar or psi, can safely handle your system's operational pressures.

Next, consider what will be flowing through it. Is it clean water, a potentially corrosive chemical, or a gas? The valve's materials must be compatible with the media to avoid premature failure. Finally, think about where the valve will operate. Will it face extreme heat, high humidity, or a corrosive atmosphere? The environment will dictate the best body and seal materials for long-term reliability.

Material Matters: Brass vs. Stainless Steel

The material of the valve body is a major decision that affects both cost and durability. For latching solenoid valves, the choice usually comes down to two primary options: brass and stainless steel, each with its own set of strengths.

For many common jobs, like automated irrigation or standard HVAC systems, a brass valve is a fantastic choice, offering a great mix of toughness and affordability. However, when your system handles aggressive fluids, food-grade products, or operates in a corrosive setting, stainless steel is the clear winner. It provides superior resistance to rust and chemical reactions, which easily justifies its higher price tag.

To help you decide, here’s a straightforward comparison of how these two materials stack up.

Latching Solenoid Valve Material Comparison

Comparison of popular valve body materials showing their suitability for different applications, pressure ratings, and fluid compatibility

| Material | Max Pressure | Temperature Range | Best Applications | Corrosion Resistance |

|---|---|---|---|---|

| Brass | Good | Wide | General purpose, air, water, neutral fluids | Fair to Good |

| Stainless Steel | Excellent | Very Wide | Corrosive media, food/beverage, chemicals | Excellent |

As the table shows, a brass valve like those in the LPU225 brass series is suitable for many tasks. For more demanding applications, a stainless steel model like an LSPU225 latching valve is the essential choice.

Critical Certifications and Connections

Beyond the core materials, you also need to think about certifications and the physical fit. For any application involving drinking water in the UK, using a WRAS (Water Regulations Advisory Scheme) approved valve is a legal requirement. This certification ensures no materials in the valve will leach into the water supply, making products like the LPU225D latching WRAS valves essential for potable water systems.

Don't forget the practical details of installation. Make sure the valve's port size (e.g., 1/2", 1") matches your existing pipework to prevent flow problems or the need for extra fittings. You also need to match the valve's coil voltage (e.g., 12V DC, 24V DC) to your control system's power supply. Getting these details right from the start saves a lot of headaches down the line.

Making the right choice means balancing these factors. While this guide focuses on latching types, having a good grasp of all valve designs is helpful. For a wider view, take a look at our general guide on the solenoid valve. By matching the valve's capabilities to your system's needs, you can ensure a reliable and effective setup.

Installation Mastery: Getting It Right From Day One

Choosing the right latching solenoid valve is a great start, but the job isn’t done until it’s installed correctly. A premium valve can easily fail if the installation is rushed or mishandled. These components have specific needs that can trip up technicians who are used to standard valves. Nailing the installation from the beginning is the secret to getting decades of reliable, low-energy service. It all starts with understanding the unique electrical and physical setup of bistable technology.

Choosing the right latching solenoid valve is a great start, but the job isn’t done until it’s installed correctly. A premium valve can easily fail if the installation is rushed or mishandled. These components have specific needs that can trip up technicians who are used to standard valves. Nailing the installation from the beginning is the secret to getting decades of reliable, low-energy service. It all starts with understanding the unique electrical and physical setup of bistable technology.

Electrical Nuances: Polarity and Pulses

The most frequent installation error with latching solenoid valves is wiring. Unlike standard AC valves where wire orientation doesn't matter, most latching models are DC-powered with a dual-coil design. This makes polarity absolutely critical. If you connect the positive and negative wires backward for the 'open' command, the valve might do nothing, or worse, it might activate the 'close' function instead. Reversed polarity is a common source of day-one headaches.

Beyond polarity, the control system must be set up to deliver a short electrical pulse—often lasting just a fraction of a second—not a continuous flow of power. Sending constant current to a latching coil is a surefire way to overheat and destroy it. Think of it like a quick knock on a door, not leaning on the doorbell. While these valves are energy savers in the long run, their electronics are sensitive. Protecting them with surge protectors and proper earthing is fundamental, just as with any industrial electrical equipment.

Physical Placement and Environmental Factors

How and where you mount the valve is just as crucial as how you wire it. Always consult the manufacturer's instructions for the best mounting position. Many latching solenoid valves work best when installed upright, which allows gravity to assist the internal plunger mechanism. It's also vital to anchor the valve body securely to counter system vibration. In industrial environments, constant shaking can subtly weaken the magnetic force that holds the valve in its latched position.

Protecting the valve from its environment is not optional. The coil and electrical parts must be shielded from moisture, particularly in outdoor settings or areas that get washed down. Selecting a valve with the appropriate IP (Ingress Protection) rating for the location is key. Extreme heat or cold can also hinder performance, so install the valve away from hot machinery or pipes prone to freezing. For a broader look at system-wide best practices, consider this Tank Installation Guide.

Commissioning: The Professional's Final Check

A professional job always ends with a careful commissioning process. This is more than just flipping a switch; it's a step-by-step confirmation that the valve is behaving exactly as it should. First, manually signal the control system to send an 'open' pulse. You should hear a distinct click as it latches. Next, send the 'close' pulse and confirm it fully returns to its resting state.

This simple two-step test validates that your polarity is correct and your control signal is working. It’s also the perfect time to ensure the signal is a pulse, not a continuous current. If things aren't working right, here are a few common snags:

- Valve fails to switch: The most common causes are reversed polarity or a control pulse that is too weak or missing entirely.

- Valve chatters or won't stay latched: This often points to low voltage, a pulse that isn't long enough, or excessive vibration from the system.

- Leaks after installation: This is a classic plumbing error. Check for the flow direction arrow marked on the valve body and make sure it matches the direction of flow in your pipes.

Leading Solutions: LSPU, LPU225, And LPU225D Explored

Once your system is properly installed, the long-term success of your project hinges on the valve itself. Not all latching solenoid valves are created equal; deciding between materials like brass or stainless steel, or selecting a model with specific certifications, is a crucial choice. To see this in action, let's look at three distinct product families: the LSPU for harsh environments, the LPU225 for general use, and the LPU225D for certified potable water systems.

LPU225: The Versatile Brass Workhorse

For a broad set of general-purpose tasks, the LPU225 latching brass valve is a dependable workhorse. Its brass construction offers excellent durability for controlling neutral media like air, water, and light oils, making it a reliable and budget-friendly option. Think of it as the trusty multi-tool in an engineer’s toolkit.

You’ll find these valves providing consistent performance in automated building ventilation, general irrigation, and various pneumatic control circuits where extreme corrosion isn't the main issue. Their great balance of performance and value makes them a popular starting point for many fluid control projects.

LSPU: The Stainless Steel Guardian

When the working environment gets tough or the media is aggressive, you need a valve built to handle the pressure. This is where the LSPU latching stainless steel range truly shines. Made from high-grade stainless steel, these valves provide superior resistance to corrosion, chemicals, and extreme temperatures.

They are the go-to choice for demanding industries like food and beverage processing, chemical dosing, and marine applications where brass would fail. This rugged build protects system integrity and prevents contamination, making the initial investment a wise decision for critical processes. For a full breakdown of this durable series, you can view our LSPU225 series guide.

LPU225D: The WRAS-Approved Choice for Potable Water

In the UK, any component that touches the public water supply must meet strict safety regulations. The LPU225D latching WRAS valves are specifically engineered to meet this standard. WRAS (Water Regulations Advisory Scheme) approval certifies that the valve’s materials are safe and will not leach harmful substances into drinking water.

This certification makes the LPU225D series the mandatory choice for municipal water distribution, commercial kitchen equipment, and smart water metering systems. Using a WRAS-approved valve isn't just good practice—it's a legal requirement that ensures public health and regulatory compliance.

To help you distinguish between these options, the table below provides a direct comparison of their key features and ideal applications.

| Product | Material | Pressure Rating | Certifications | Typical Applications | Key Benefits |

|---|---|---|---|---|---|

| LPU225 | Brass | Up to 10 Bar | CE | General-purpose air, inert gas, water, light oil control | Cost-effective and reliable for a wide range of tasks |

| LSPU | Stainless Steel | Up to 10 Bar | CE | Chemical dosing, food processing, marine, aggressive media | Maximum resistance to corrosion and high temperatures |

| LPU225D | WRAS-Approved Brass | Up to 10 Bar | WRAS, CE | Potable water, drinking water, public water supply | Certified safety and compliance for drinking water systems |

As the table shows, the primary differences lie in the material construction and the certifications, which directly influence where each valve can be safely and effectively used.

A wide variety of configurations are available across these product families to meet precise system needs. With different port sizes and functions, including 2/2-way (two ports, two positions) and 3/2-way options, there is a specific latching valve for almost any fluid control challenge you might face. This flexibility is key to designing an efficient and effective system.

Future-Proofing Your Investment: What's Next For Latching

As industrial systems become smarter and more connected, the demand for efficiency grows. This is where latching solenoid valves truly shine. Their extremely low energy use is no longer just a bonus feature—it's a core requirement for building the efficient, automated systems of the future. Their design principle of "set and forget" makes them a key component in the next generation of fluid control.

The Rise of Intelligent Fluid Control

The real advantage appears when you connect this low-power operation to intelligent systems. Because they sip energy, latching valves are perfect for devices that run on batteries, like remote sensors or monitors in an Internet of Things (IoT) network. Imagine a sprawling facility where every valve can communicate its status and health data without being wired to a constant power source. This unlocks a new level of control and insight:

- Predictive Maintenance: By analysing cycle counts and operational data, systems can alert you when a valve needs service before it fails, helping you avoid costly, unexpected downtime.

- AI-Driven Optimisation: Smart control systems can use artificial intelligence to review data from an entire site, automatically pulsing latching valves to fine-tune flow rates and achieve maximum efficiency.

- Enhanced Remote Management: Technicians can safely and reliably operate valves in hard-to-reach or hazardous areas from a central hub, confident that the valve will maintain its position without continuous power.

Sustainability and Smarter Infrastructure

Saving energy is no longer just good practice; in many places, it's becoming the law. Regulations worldwide are demanding greater efficiency, a factor that is reshaping the European solenoid valve market, including the UK. National goals for building smart cities and expanding renewable energy infrastructure depend on components that use as little power as possible.

Latching solenoid valves are critical for the real-time monitoring and ultra-low power systems these projects need. You can learn more about these market shifts in this detailed industry report. This means choosing energy-efficient parts is less of a choice and more of a requirement for modern design and compliance.

Investing in Tomorrow's Technology Today

When you select a high-quality latching valve, you are making a forward-thinking choice for your systems. The core benefits of energy efficiency and reliable state-holding are exactly what modern industry demands. As technology and materials improve, you can expect these components to become even more durable and capable.

By choosing proven solutions—like the tough LSPU stainless steel series, the versatile LPU225 brass models, or the LPU225D WRAS-approved valves for potable water—you’re doing more than just fixing a current fluid control issue. You are building a system that's prepared for smarter, more independent, and more sustainable work down the line. This approach ensures your investment pays off for years.

To get your system ready for the future, browse our wide selection of 2/2-way latching bistable valves and discover the right valve for your needs.