Solenoid Valve Mastery: Your Complete Engineering Guide

Making Sense of Solenoid Valves: The Hidden Champions

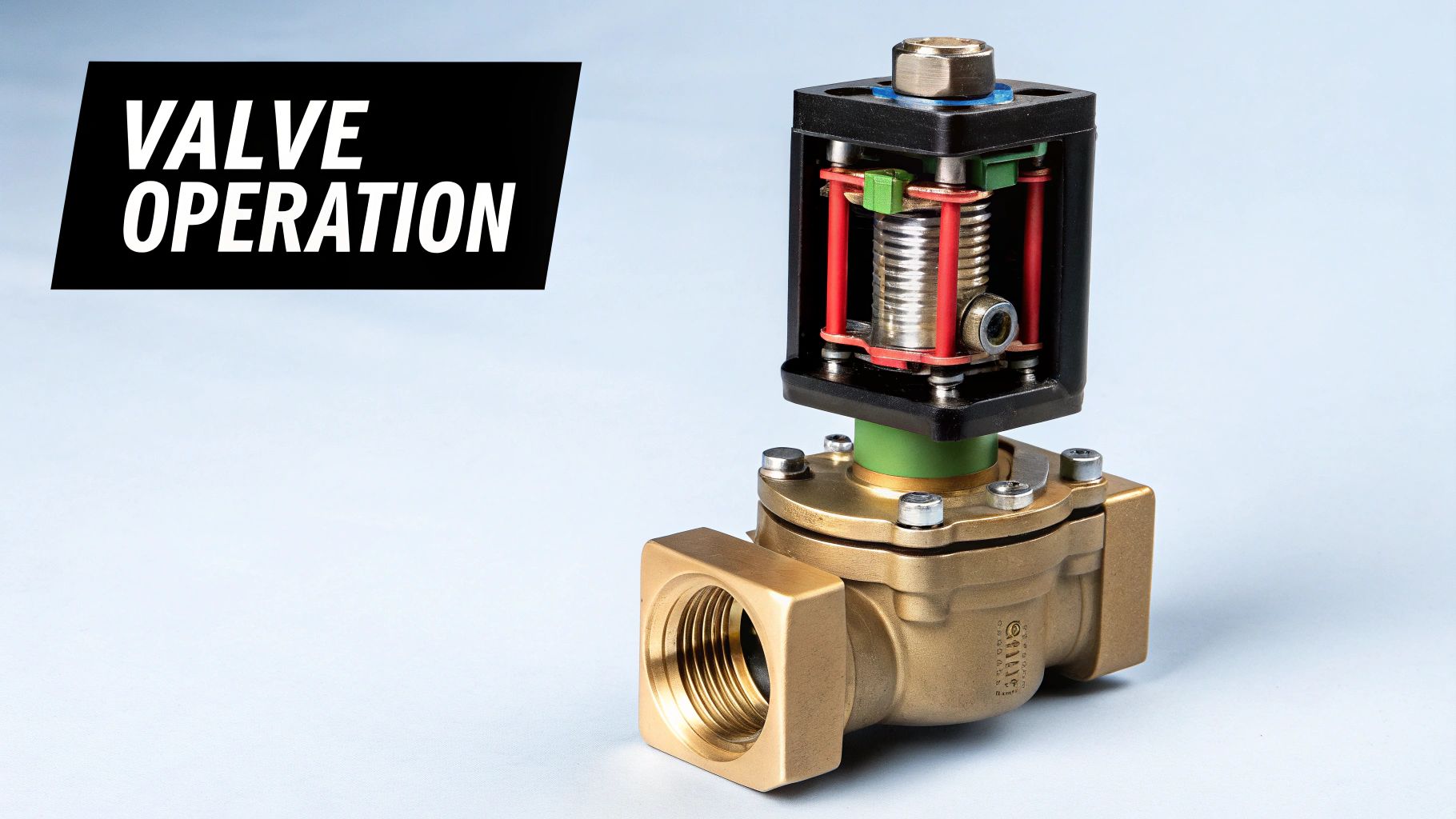

This image gives us a peek inside a direct-acting solenoid valve. Notice the electromagnetic coil and plunger. These are the key players, transforming an electrical signal into the mechanical motion that controls the flow of liquids or gases. These seemingly simple parts are the foundation for a surprisingly wide range of applications.

Imagine being able to stop water rushing through a massive industrial pipe with the flick of a switch, from miles away. That’s the power of solenoid valves. They're like remote controls for fluids, quietly working behind the scenes in countless everyday objects.

From the coffee maker in your kitchen to the engine in your car, these electromagnetic devices are essential, acting as precise gatekeepers for fluid control. Their real magic lies in the way they bridge the gap between the digital world of electrical signals and the physical world of fluid dynamics. Essentially, when a computer needs to manage liquid or gas flow, it talks to a solenoid valve using electricity.

Why Solenoid Valves Are Indispensable

Solenoid valves are everywhere because they offer a powerful combination of control, efficiency, and reliability. They react to electrical commands incredibly fast, sometimes in mere milliseconds, allowing for extremely precise control over fluid movement. This rapid response makes them perfect for automated systems that need to make quick adjustments.

Their sturdy construction also ensures dependable operation, even in tough conditions. And, just like regular maintenance keeps your heat pump running smoothly, regular maintenance can extend the lifespan of your solenoid valves.

Bridging the Digital and Physical Worlds

Solenoid valves act as critical intermediaries between electrical control systems and the physical processes they govern. This bridging capability is especially vital in today's automated systems.

For instance, in a process control system, a computer can fine-tune a solenoid valve to carefully regulate the flow of chemicals into a reactor. This level of precision helps guarantee product quality and safety.

Real-World Applications: A Glimpse into Their Versatility

The sheer variety of places where you find solenoid valves highlights just how adaptable they are. In irrigation systems, they direct water flow to different areas, ensuring efficient water use. In medical devices, they precisely control the delivery of fluids and gases, playing a vital role in patient care.

And in heavy-duty industrial machinery, they manage pneumatic and hydraulic systems, powering a vast array of automated processes. Their widespread use across so many different industries underscores their significant role in modern engineering and technology.

This guide will dive deep into the world of solenoid valves, giving you a thorough understanding of how they work, how to choose the right one, and how to keep them in top shape. We'll explore the scientific principles behind their operation and examine real-world examples, uncovering the secrets of these unsung heroes of fluid control.

The Science Made Simple: How Solenoid Valves Actually Work

This image gives us a peek inside a direct-acting solenoid valve. Notice the electromagnetic coil and plunger – these are the key players in transforming electrical signals into the mechanical movements that control fluid flow.

Ever wondered how a simple electrical signal can control the rush of liquids or gases under pressure? The answer lies in the fascinating world of electromagnetism. Imagine a solenoid valve as a miniature, yet powerful, electromagnet tucked inside a metal casing. This electromagnet works together with a spring-loaded gate, which acts as the valve, deciding whether the fluid can pass or not.

The Electromagnetic Dance: From Electricity to Motion

When electricity courses through the solenoid valve's coil, it creates a magnetic field. This field is strong enough to overcome the spring's resistance and push or pull the valve mechanism. This is where things get interesting – different types of solenoid valves achieve this movement in unique ways.

Some valves use direct magnetic force to open or close the valve. Think of it like pulling a door handle – the magnetic field directly acts on the valve. Others, however, use a pilot system. A small initial movement, triggered by the electromagnet, harnesses the fluid's own pressure to do the main work of opening or closing the valve. This is more like using a small lever to open a much larger gate, where the fluid pressure does the heavy lifting.

Understanding Direct-Acting Solenoid Valves

Direct-acting valves are the sprinters of the solenoid valve world, renowned for their rapid response times. The electric current directly activates the valve, offering near-instantaneous control. This makes them perfect for situations needing quick and precise adjustments. However, they are best suited for applications with lower pressure and flow rates.

Exploring Pilot-Operated Solenoid Valves

Pilot-operated solenoid valves, on the other hand, are the marathon runners. They might not be as quick off the mark as direct-acting valves, but they can handle significantly higher flow rates and pressures. They achieve this by cleverly using the system's fluid pressure to assist in opening and closing the valve. This design makes them perfect for heavy-duty industrial applications dealing with large volumes of fluid that still require precise control.

To help visualize the differences, let's take a look at this comparison:

Solenoid Valve Operating Principles Comparison: How different solenoid valve mechanisms compare in performance and applications

| Operating Type | Response Time | Power Usage | Best Applications |

|---|---|---|---|

| Direct-Acting | Very Fast | Lower | Systems with lower pressure and flow rates, requiring quick responses |

| Pilot-Operated | Slower | Higher | High-pressure, high-flow rate systems in industrial settings |

As you can see, the choice between direct-acting and pilot-operated valves depends heavily on the specific needs of the application.

The Timing of the Electromagnetic Dance

The timing of the electromagnetic action within a solenoid valve is vital for smooth operation. The speed at which the valve opens and closes depends on its design, the strength of the magnetic field, and the fluid pressure. For instance, faster response times are critical in applications like fuel injection systems, where precise timing directly impacts engine performance.

Different designs also handle varying pressure conditions differently. Direct-acting valves are better suited for low-pressure situations, while pilot-operated valves excel in high-pressure environments. This intricate dance between electrical input and mechanical output is what makes solenoid valves so reliable and precise across a huge range of applications. Understanding these core principles helps us appreciate why solenoid valves are such essential components in countless systems.

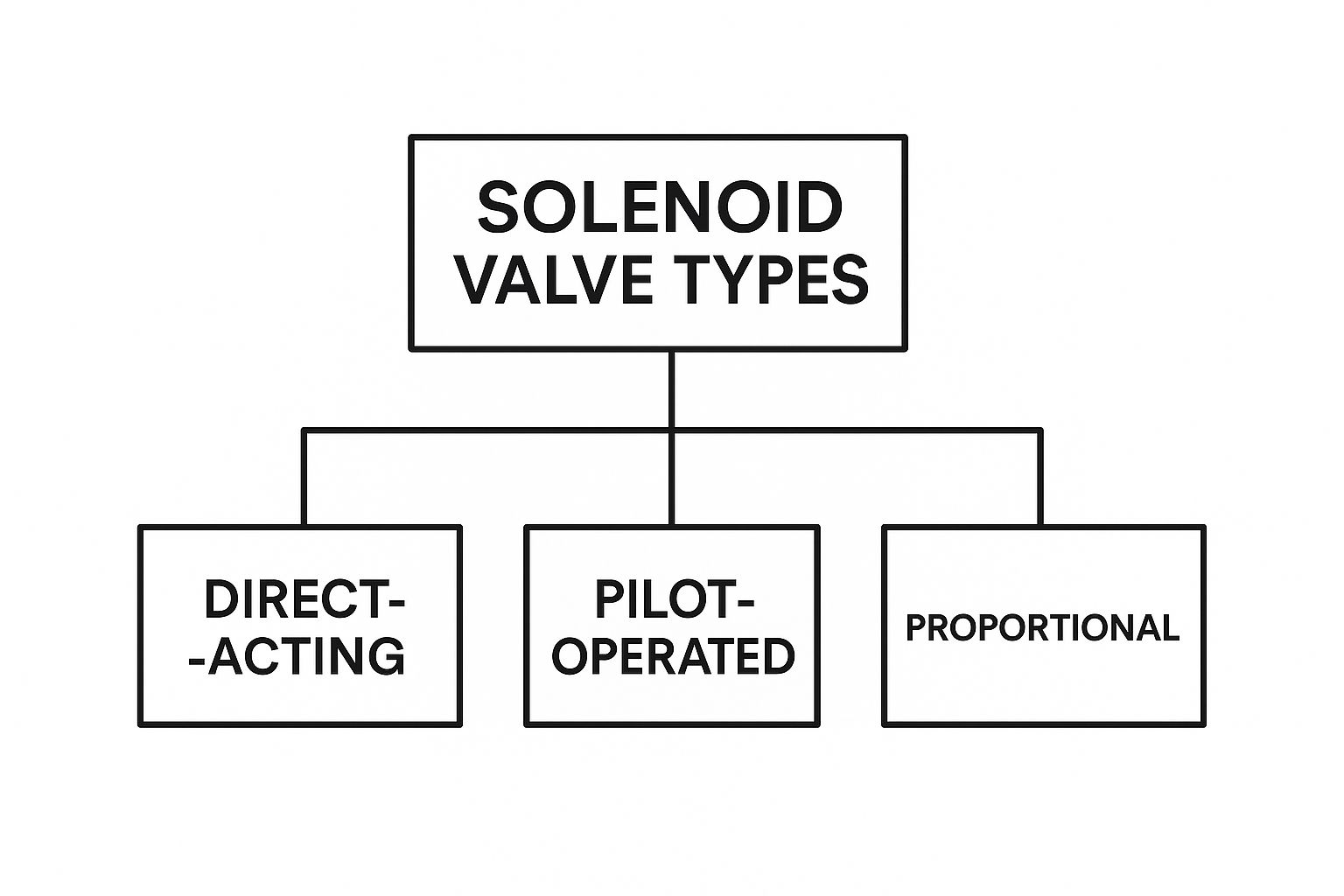

Navigating Solenoid Valve Types: Finding Your Perfect Match

The infographic above gives us a helpful overview of common solenoid valve types, splitting them into direct-acting, pilot-operated, and proportional. Think of it as a family tree of valves, showing how they're all related. Seeing these connections helps us grasp the core differences in how they work. This is key to picking the right valve for a specific job.

Direct-Acting Solenoid Valves: The Sprinters

Imagine direct-acting solenoid valves as the sprinters in a race. They're incredibly fast, boasting near-instantaneous response times. This speed makes them perfect when you need immediate action and precise control, such as in medical devices or lab equipment. The trade-off is that they generally handle lower flow volumes.

Pilot-Operated Solenoid Valves: The Powerlifters

If direct-acting valves are sprinters, pilot-operated valves are the powerlifters. They may not be as quick, but they can handle much higher flow rates. This makes them a good fit for industrial applications needing to control large volumes of fluids. The secret to their strength? They cleverly use the system's own fluid pressure to help operate the valve.

Two-Way, Three-Way, and Four-Way Valves: Managing Flow Paths

Now, let's talk about how these valves manage flow. Two-way valves are like a simple on/off switch for your fluids. They're great for basic start-stop control.

Three-way valves are more like a traffic director at a roundabout. They manage flow between different paths, making them ideal for diverting fluids or controlling things like pneumatic cylinders.

Finally, four-way valves are the most complex, like a busy intersection. They can completely reverse flow direction and handle intricate system operations, giving you maximum control.

To help you choose the best valve for your needs, let's look at a comparison table:

Solenoid Valve Type Selection Guide

Complete comparison of valve types with specifications and ideal applications

| Valve Type | Flow Capacity | Response Speed | Pressure Range | Typical Applications |

|---|---|---|---|---|

| Direct-Acting | Low to Medium | Very Fast | Low to Medium | Medical Equipment, Analytical Instruments |

| Pilot-Operated | High | Medium | Medium to High | Industrial Automation, Large-Scale Fluid Control |

| Two-Way | Varies | Varies | Varies | Simple On/Off Control, Appliances |

| Three-Way | Varies | Varies | Varies | Diverting Flow, Pneumatic Cylinders |

| Four-Way | Varies | Varies | Varies | Complex Flow Control, Hydraulic Systems |

This table summaries the key differences between the valve types, making it easier to see which one might be the best fit for a specific application. Remember that "Varies" indicates that these specifications depend on the individual valve design and manufacturer.

Matching Valves to Applications: Practical Examples

Picking the right valve is all about understanding its strengths and weaknesses. Need a fast response in a low-flow system? A direct-acting valve is likely the way to go. High-flow application? A pilot-operated valve is the better choice, even if it’s a bit slower.

Think about a washing machine. A two-way valve might control the water coming in, while a three-way valve could direct that water to different wash cycles. In a factory, a four-way valve might control the movement of a pneumatic cylinder. If you're in the UK and looking for suppliers, Solenoid Valve World provides a good starting point.

These everyday examples show how the right valve choice makes a real difference in how well a system works. By carefully considering your needs, you can confidently choose the solenoid valve that fits the job perfectly.

Smart Selection: Choosing Solenoid Valves That Actually Work

Picking the right solenoid valve is a bit like choosing the right shoes. The wrong pair can lead to blisters, sore feet, and a generally unpleasant experience. Similarly, the wrong solenoid valve can result in costly system failures, frustrated customers, and hours of troubleshooting. You need to start by understanding what your valve will be working with. What kind of fluid is it? Is it corrosive? What temperature and pressure extremes will it face? How quickly does your system need to react?

Many people get tripped up by focusing solely on the technical specs, like focusing only on shoe size and ignoring whether you need running shoes or hiking boots. A solenoid valve that performs flawlessly in a lab might completely fall apart when exposed to fluctuating temperatures, vibrations, or electrical interference out in the real world.

Considering Real-World Factors

We'll walk you through a practical, step-by-step approach that considers not only the basic requirements but also those subtle, often overlooked factors that differentiate a successful installation from a costly headache. Think about the valve's working environment. Will it be exposed to extreme temperatures, humidity, or harsh chemicals? These conditions can drastically impact its lifespan and reliability.

Imagine a solenoid valve controlling a sprinkler system in the UK. It needs to withstand freezing winter temperatures. Choosing a valve made of a durable material like brass or stainless steel is essential for survival. Similarly, a valve in a chemical plant might need to resist corrosive substances, making a specialised material like PTFE-coated stainless steel the best choice.

A Systematic Approach to Selection

Choosing the right valve boils down to carefully evaluating a handful of key factors. First, what media will be flowing through the valve? Different fluids require different valve materials and internal designs. Water, air, oil, and gas all have unique characteristics that influence valve selection. Think of it like choosing the right pipe for the job – you wouldn’t use a garden hose for a high-pressure water jet.

Next, consider the flow rate and pressure in your system. Solenoid valves are designed for specific operating ranges. Choosing a valve that aligns with your system's pressure is critical for optimal performance. It’s like making sure your water pump is powerful enough for your sprinkler system.

You also need to consider voltage and power requirements. Solenoid valves come in various voltage ratings. Make sure the valve you choose is compatible with your electrical system – like making sure you have the right power adapter for your electronics. Finally, are there any required certifications? For applications like drinking water or hazardous environments, certifications such as WRAS or ATEX are mandatory in the UK. Think of these as safety guarantees.

Practical Selection Scenarios

Let’s look at some real-world examples. For an automated garden watering system, a plastic solenoid valve might be perfectly adequate for controlling water flow to different zones. But in a chemical processing plant, a stainless steel solenoid valve with a PTFE coating would be necessary to handle corrosive chemicals. It’s all about choosing the right tool for the job.

For more helpful guidance, take a look at this resource: Choosing a Solenoid Valve.

Ensuring Long-Term Reliability

By carefully considering these factors and following a structured selection process, you can choose a solenoid valve that will reliably perform for years to come. Remember, investing in a high-quality solenoid valve is a wise decision that saves you time and money in the long run by preventing costly failures and system downtime. This proactive approach helps ensure your systems operate smoothly and efficiently, minimising disruptions and maximising productivity. Choosing the correct valve isn’t just about ticking off boxes on a spec sheet; it's about understanding the specific demands of your application and selecting a valve that will thrive in its intended environment.

Solenoid Valves in Action: Where Engineering Meets Reality

This image shows solenoid valves at work in an industrial setting. Their small size hides their important role: controlling the flow of fluids to keep processes running smoothly. This is where theory meets practical application.

Solenoid valves quietly manage important processes in our daily lives. Take water treatment plants, for example. These valves manage the complex filtration process, controlling the chemicals added and the system cleaning. Precise timing, controlled by electrical signals, makes sure clean water comes out of our taps. These valves turn digital commands into physical actions.

In factories, solenoid valves control pneumatic systems, coolant flow, and process gases. This precise control is key for safe and efficient production. Think of a car assembly line. Solenoid valves help robotic arms, welding equipment, and paint sprayers work smoothly, keeping the production line moving.

This leads us to the automotive industry, where solenoid valves are essential parts of vehicle systems. Your car likely has a dozen or more, controlling everything from fuel injection to transmission. A valve failure here isn't just a minor issue—it’s a safety risk. These valves are vital for safe driving.

Real-World Problem Solvers: Case Studies

Let's look at how solenoid valves solve real problems. In pharmaceutical manufacturing, precision is everything. Contamination can be disastrous, so these valves ensure sterile fluid handling. They control ingredient flow, cleaning cycles, and product integrity, protecting public health.

But the needs are different on an offshore oil rig. Harsh conditions and limited access make reliability paramount. Maintenance is incredibly expensive, so valves must endure extreme environments and work reliably for long periods. They control the flow of oil, gas, and drilling fluids, keeping operations running smoothly in tough conditions. These examples show how adaptable solenoid valves are to different industries. The UK solenoid valve industry is expected to grow steadily, with a CAGR of 4.3% from 2025 to 2035, thanks to the nation's focus on sustainability and better water quality. Discover more insights.

Pushing the Limits of Technology

Different industries have pushed solenoid valve technology in interesting ways. The need for precise control in medical devices has led to tiny, high-precision valves that deliver small amounts of fluid accurately. When choosing solenoid valves, think about how AI might help. Check out this guide on how to Build an AI Chatbot. Likewise, aerospace engineering demands specialised valves that can handle extreme temperatures, pressures, and vibrations. These examples demonstrate the continuous innovation happening in solenoid valve design.

Maintenance That Actually Prevents Problems

Let's talk maintenance. It's often a case of too much or too little. A well-maintained solenoid valve can hum along happily for years, but neglect it, and it'll likely quit at the worst possible moment. Think cascading failures, costly downtime, and maybe even hazardous situations. Understanding how things break down is the first step to preventing it. Dirt build-up, coil burnout, seal wear, and plain old mechanical wear all leave their own clues. Just like a doctor diagnosing a patient, you need to learn how to "read" your valves. Interactive videos can be a really helpful way to learn these diagnostic skills. Check out this article on interactive video for training.

Remember, different applications mean different failure patterns. A valve handling clean water will have different issues than one wrestling with abrasive slurries or harsh chemicals. It's like comparing a city car to an off-road truck - the wear and tear happens in different places.

Practical Maintenance Strategies: Balancing Thoroughness and Efficiency

Maintenance is all about finding that sweet spot: thorough enough to catch problems early, but efficient enough not to waste resources on unnecessary tasks. Imagine you're a detective – you want to find the clues before the crime happens, but you don't want to waste time chasing red herrings. Learning to recognise the subtle signs of trouble, like unusual noises or sluggish response times, is key. This allows you to make informed decisions: clean, replace a part, or retire a valve before it causes a major headache.

For example, a valve in a high-vibration environment, like a factory floor, might need its mounting and connections checked more often than one in a quiet control room. And a valve controlling corrosive chemicals might need regular seal replacements, while one handling clean water could go much longer between cleanings. It's all about tailoring your approach. For further reading on this, check out Solenoid Valve Installations and Maintenance Instructions.

Interpreting the Signs: Understanding What Your Valve Is Telling You

Let's talk symptoms. Unusual operating sounds, like humming, buzzing, or clicking, could signal electrical problems with the solenoid coil. Think of it like a car engine – a new knock often means trouble. Slow response times might suggest a weakening coil, sticky internal parts, or low system pressure. Imagine a tired athlete – they're just not as quick off the mark. External leaks usually point to worn seals or loose connections – a bit like a leaky faucet. All of these are your valve's way of saying, "Hey, pay attention to me!"

Developing a Proactive Maintenance Schedule

A smart maintenance schedule blends preventative measures with responses to specific problems. Regular visual inspections are your first line of defense. Think of it like a routine health checkup – it can catch small issues before they become big ones. Checking for leaks, loose wiring, and corrosion should be part of every routine check. And periodic testing of the valve's operation is like a stress test – it helps ensure everything is working as it should.

Knowing When to Replace: Extending Valve Lifespan

Even with the best care, parts wear out. Knowing when to replace components is key to getting the most out of your solenoid valves. Worn seals are easy to replace and can prevent more serious leaks – it's like changing the tires on your car before they blow out. A burnt-out solenoid coil can often be replaced too, bringing the valve back to life. This proactive approach saves money and keeps your system running smoothly.

Preventing Downtime: The Ultimate Goal of Maintenance

The ultimate goal of maintenance is to prevent those expensive and disruptive downtime events. By regularly inspecting, testing, and replacing parts as needed, you significantly boost the reliability and lifespan of your solenoid valves. This means fewer emergency repairs, less time troubleshooting, and a more efficient operation overall. By understanding the specific needs of your application and creating a tailored maintenance plan, you can ensure your solenoid valves perform reliably for years to come, keeping your systems running at peak performance. Just like a well-maintained car, it’s all about preventative care for the long haul.

Explore a wide range of solenoid valves and other fluid control components at Solenoid Valve World. We offer a variety of solutions for all your fluid control needs.