Non Return Check Valve Guide: Mastering Flow Control Systems

Understanding Non-Return Check Valves: The Silent Guardians

Imagine your home's plumbing. Water flows in one direction, right? You wouldn't want your shower water flowing back into your drinking water supply. That's where a non-return check valve comes into play. Like a one-way street for fluids, it ensures everything moves in the right direction, preventing backflow.

These often-overlooked components are crucial for protecting systems and preventing costly damage. Picture a factory's pump system: Backflow could ruin the pump, leading to thousands of pounds in repairs and lost production. Non-return check valves act as silent guardians against such scenarios, working tirelessly in the background.

From complex lab setups to the water mains supplying your home, these valves are everywhere. Think of the vast water network crisscrossing the UK – non-return check valves are a key part of its smooth operation. They are essential in various sectors, including manufacturing, water treatment, and even in your household appliances.

Why Understanding Non-Return Check Valves Matters

Their importance often becomes clear only when something goes wrong. Imagine contaminated water flowing back into a treatment plant. The consequences for public health and the cost of cleanup could be disastrous.

Understanding how these valves work is crucial for preventative maintenance and efficient system design. It’s like knowing how your car’s engine works – it helps you spot potential problems before they become major headaches. Learn more about non-return check valves.

While pinning down exact UK-specific market data can be tricky, we know these valves are widely used across crucial industries. The European non-return valve market, encompassing the UK, reportedly represents 25-30% of the overall European control valve market, valued at over USD 4 billion annually. Discover more market insights. Within the UK, these valves are particularly prevalent in the water and wastewater sector, with over 80% of water utilities relying on them. This underscores the importance of understanding these essential components, especially within critical UK industries. This knowledge enables facility managers to make smart choices about installation, maintenance, and replacement, contributing to long-term reliability and cost-effectiveness. By preventing backflow and its associated problems, non-return check valves become essential components in any fluid system.

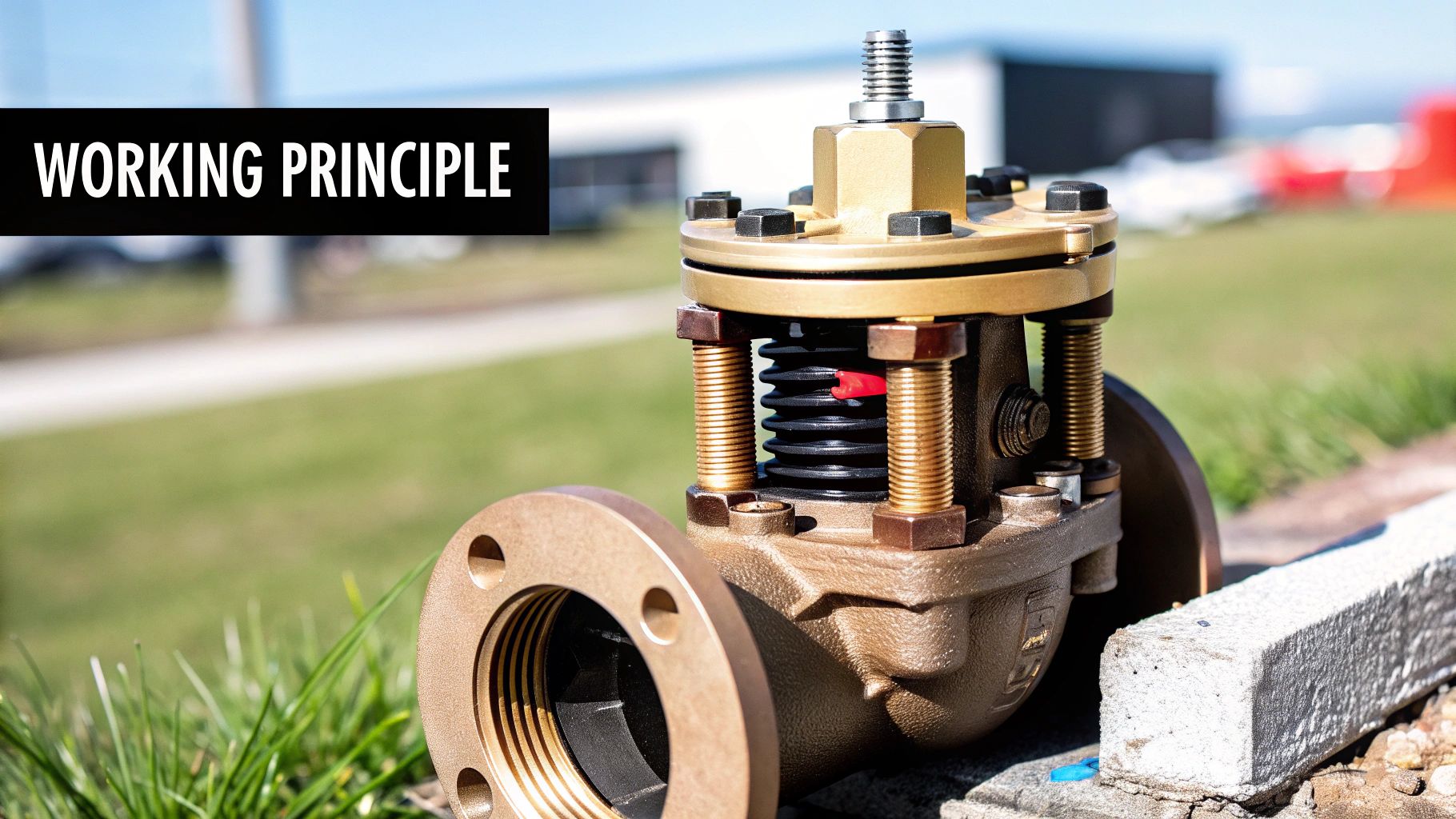

How Non-Return Check Valves Actually Work: The Mechanics

Ever wondered how such a simple device can be so smart about flow direction? Think of a non-return check valve like a one-way turnstile in a busy London Underground station. It smoothly manages the flow of people, only allowing them to pass in one direction. These valves do the same for fluids in piping systems. Let's explore how these essential components work.

Cracking Pressure and Response Time: Understanding Valve Behavior

Just like a turnstile needs a little push to rotate, a non-return check valve needs a minimum upstream pressure to open. This is called the cracking pressure. It's the pressure needed to overcome the force holding the valve closed, allowing the fluid to flow.

How quickly the valve reacts to flow changes is also important. This is the response time. A fast response stops damaging backflow surges, much like a quickly closing turnstile prevents platform overcrowding. Cracking pressure and response time are key to understanding how well a valve performs.

Inside the Mechanism: Exploring Different Types

Different non-return check valves use various internal mechanisms. The spring-loaded disc check valve, for instance, uses a spring to hold a disc against a seat, effectively sealing the valve. Fluid pressure overcomes the spring force, opening the disc and allowing flow. When the flow stops or reverses, the spring pushes the disc back onto the seat, preventing backflow. Think of it like a door closer, always ensuring the door returns to its closed position.

Then there’s the swing check valve, which uses a hinged disc or flap. Forward flow swings the disc open, while reverse flow slams it shut. It's a bit like a saloon door, easy to push open in one direction but firmly blocked in the other. Understanding these internal workings highlights the clever design of different valve types.

Preventing Valve Chatter: Ensuring Smooth Operation

Imagine the irritating clatter of a poorly maintained turnstile. Similarly, valve chatter is the rapid opening and closing of the valve due to pressure or flow fluctuations. This creates noise and can lead to wear and tear.

Choosing the right valve and designing the system properly are key to avoiding chatter. Just as a well-lubricated turnstile operates smoothly, a properly selected and installed non-return check valve will perform reliably and quietly for years. This knowledge helps engineers and facility managers make informed choices and prevent potential issues. From managing flow in sensitive lab equipment to ensuring the safe operation of industrial pipelines across Britain, understanding how non-return check valves work is vital for efficient and reliable fluid control.

Choosing The Right Non Return Check Valve Type

Picking the right non-return check valve is like choosing the right wrench – the wrong one can lead to frustration and even damage. This guide walks you through the different types, helping you find the perfect fit for your needs.

Exploring the Variety of Non Return Check Valves

There's a whole family of non-return check valves, each with its own personality. Swing check valves, for instance, are like the trusty old hammer in your toolbox – simple, robust, and great for basic jobs like managing water flow in large mains. Their hinged disc swings open with the flow and slams shut when it reverses, preventing backflow. They're inexpensive and easy to maintain, but they aren’t the best for systems with frequent flow changes.

When space is tight, spring-loaded check valves are your go-to solution. Think of them as a precision screwdriver – compact and responsive. The spring pushes the valve closed quickly, minimizing backflow. This makes them perfect for applications where space is at a premium and rapid flow control is essential. The downside is that, like a spring in any tool, it can wear out and need replacing.

Tilting disc check valves offer a compromise between swing and spring-loaded types. They’re more efficient than swing valves and quieter than spring-loaded ones – imagine a well-oiled ratchet, smooth and precise. This makes them a good choice for noise-sensitive environments.

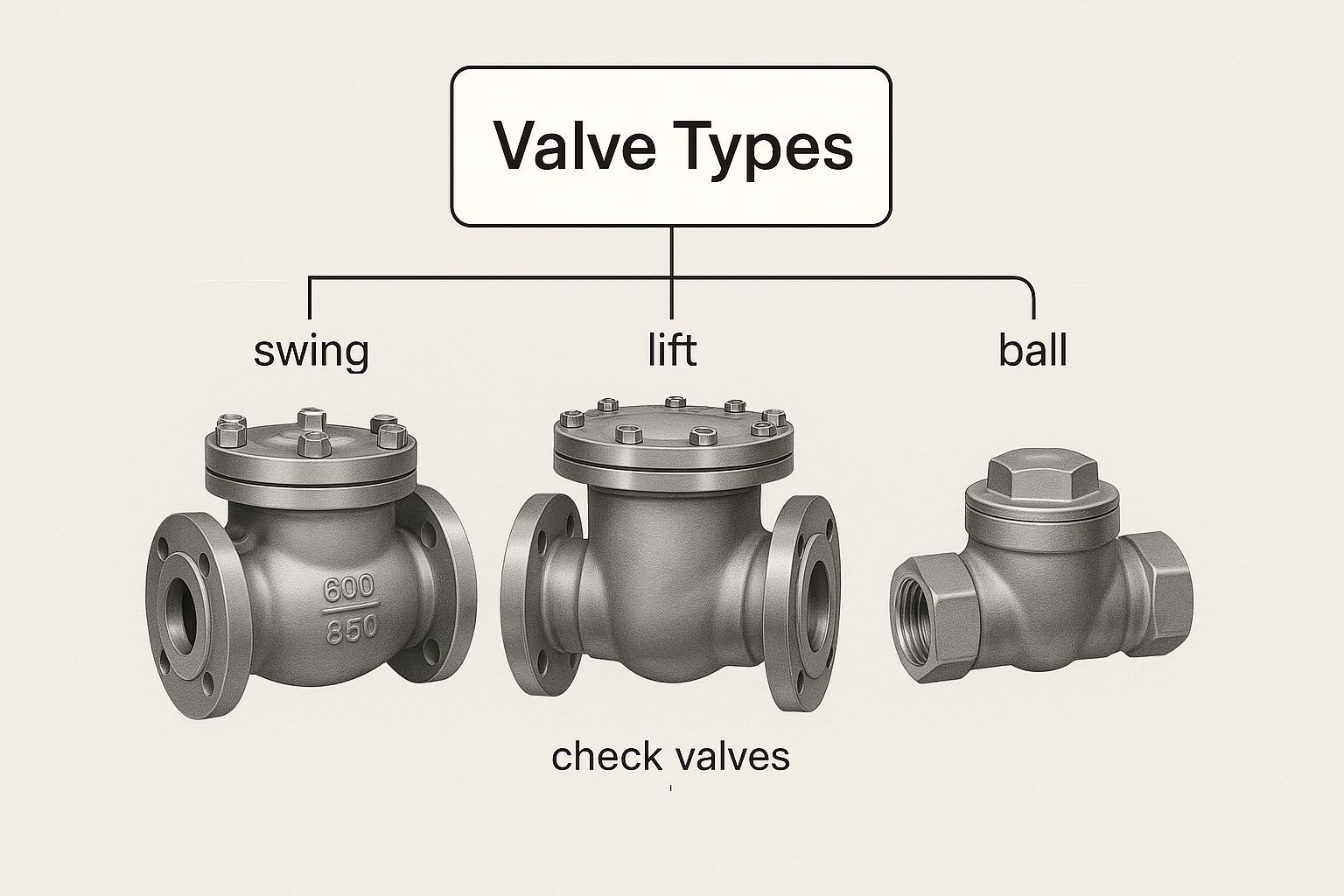

This infographic gives you a visual comparison of swing, lift, and ball check valves. It's like looking at an exploded diagram of each tool, showing you how the internal mechanisms differ. Each type has its own set of pros and cons depending on the task at hand.

We also have ball check valves, where a ball acts as the stopper against backflow, and diaphragm check valves, perfect for handling messy fluids like slurries or corrosive chemicals. Finally, wafer-style check valves are the space-saving champions, designed for snug installation between pipe flanges, making them ideal for retrofitting existing systems. For more detailed information, explore our guide on non-return valves.

Matching Valve Type to Application

Choosing the right non-return check valve isn't a guessing game. It depends on several factors, including the fluid type, pressure, temperature, and flow rate. Think about it – you wouldn't use a wrench designed for plumbing on an electrical panel. Similarly, a valve handling harsh chemicals needs different characteristics than one managing clean water in a home.

Swing check valves thrive in large diameter pipes with fairly consistent flow, often found in large-scale water systems across the UK. Their sturdy build can handle high flow rates. On the other hand, spring-loaded check valves are best suited for smaller systems with fluctuating flow, like those in appliances or precise process control systems.

To help you choose the perfect valve, let's take a closer look at a comparison of common types:

Non Return Check Valve Types Comparison

This table provides a quick overview of different check valve types, their ideal uses, pressure ranges, and common material options.

| Valve Type | Best Applications | Pressure Range | Key Advantages | Typical Materials |

|---|---|---|---|---|

| Swing Check Valve | Large diameter water and wastewater systems | Medium to High | Simple, robust, inexpensive | Cast iron, ductile iron, bronze |

| Spring-Loaded Check Valve | Smaller systems, appliances, process control | Low to Medium | Compact, responsive, quick closing | Brass, stainless steel |

| Tilting Disc Check Valve | Noise-sensitive environments, moderate flow rates | Low to Medium | Efficient, quiet operation | Cast iron, stainless steel |

| Ball Check Valve | Compact systems, low pressure applications | Low | Simple, low cost | Plastic, brass, stainless steel |

| Diaphragm Check Valve | Corrosive or slurry fluids | Low to Medium | Handles challenging media | Various elastomers and body materials |

| Wafer Check Valve | Space-restricted installations, retrofitting | Low to Medium | Compact, easy installation | Stainless steel, cast iron |

As you can see, each valve type has its own strengths. Picking the right one ensures your system runs smoothly and efficiently.

Choosing the right non-return check valve is a crucial step in building a reliable fluid system. Understanding the unique traits of each type empowers you to make an informed decision, preventing costly repairs and ensuring long-term performance. A well-chosen valve is an investment in efficiency and peace of mind.

Smart Selection Criteria That Actually Matter

Let's be honest, picking the right valve can feel more complicated than it needs to be. Datasheets often boast impressive specs, but do they translate to real-world performance? We'll skip the jargon and focus on what truly matters for your specific needs. Think of it like choosing the right tires for your car – a powerful engine is great, but useless if you can't get traction on a muddy road.

Balancing Cost and Reliability: Avoiding Expensive Mistakes

Talk to any experienced facility manager, and they'll tell you: the cheapest option upfront often leads to bigger expenses down the line. It's the same with tools – a cheap wrench might work for a while, but it'll probably break sooner, needing constant replacements and ultimately costing more. The key is finding the sweet spot between initial cost and long-term reliability.

This means thinking beyond the sticker price and considering the potential cost of maintenance, repairs, and the downtime they cause. A slightly pricier valve made of durable materials and designed for your specific operating conditions could save you a bundle over its lifespan.

Matching Valve Characteristics to Operating Conditions

Choosing a non-return check valve is all about finding the right fit for your system. This involves understanding the pressure and temperature your system operates under. A valve designed for a low-pressure home plumbing system won’t last in a high-pressure industrial environment, just like a compact car won’t handle an off-road rally.

The fluid type is another critical factor. Some fluids are corrosive, while others contain particles that can damage certain valve types. Selecting a valve compatible with your fluid ensures smooth and reliable operation. For example, resilient hinge check valves have become essential in the UK water industry, significantly cutting operational costs. Simple weight and lever swing check valves are already common in the UK water sector, serving millions of people. However, resilient hinge check valves have reportedly saved the UK water industry millions of pounds by reducing maintenance, replacements, and water loss from leaks. Discover more insights into these cost savings.

Avoiding Common Selection Mistakes: Keeping Maintenance Teams Happy

The wrong non-return check valve can be a constant source of headaches for your maintenance team. Think of a dripping faucet – a minor annoyance that turns into a major frustration. Similarly, a poorly chosen valve can cause anything from irritating noise to complete system failure.

Common mistakes include ignoring the cracking pressure, choosing the wrong valve type for the fluid, and underestimating the importance of proper installation. These oversights can lead to increased wear and tear, early valve failure, and expensive downtime. Understanding these potential problems helps you make informed decisions that keep your maintenance team happy and your systems running smoothly.

Practical Frameworks for Confident Decisions

Making the right choice doesn't have to be overwhelming. Start by clearly defining your operating conditions and the characteristics of the fluid you're working with. Next, consider the total cost of ownership, not just the upfront price. Finally, talk to experienced professionals who can offer practical advice based on their real-world knowledge. This approach gives you a solid framework for making confident decisions, ensuring you select the perfect non-return check valve for your specific needs. It’s like talking to a mechanic before buying a car – their expertise helps you make a smart investment that fits your individual needs.

Real Applications Where Non-Return Check Valves Shine

From your morning shower to massive infrastructure projects like the Thames Barrier, non-return check valves are quietly working behind the scenes. These often-overlooked components play a crucial role in systems we rely on every day. Let's explore some real-world examples where these valves truly make a difference.

Protecting Critical Equipment in Manufacturing

Imagine a bustling factory with a complex network of pipes and pumps. A sudden pressure drop could cause backflow, like a river changing direction, potentially damaging expensive pumps. Non-return check valves act like a one-way gate, preventing this reverse flow and ensuring smooth, continuous operation. This is especially important in industries like chemical processing, where even a small backflow incident could lead to costly shutdowns and extensive cleaning.

Ensuring Purity in Food and Beverage Processing

Hygiene is paramount in food and beverage production. Non-return check valves are essential for preventing cross-contamination by ensuring fluids only flow in one direction. Picture a dairy processing plant: these valves prevent milk from flowing back into the pasteurization system, protecting product quality and consumer safety.

Maintaining Comfort and Efficiency in Heating Systems

These valves play a vital role even in simple home heating systems. They maintain efficient circulation by preventing hot water from flowing back into the boiler, ensuring consistent warmth throughout the house. This not only improves comfort but also extends the lifespan of the boiler and reduces energy consumption.

Essential Components in Offshore Oil and Gas Platforms

The challenging conditions of the North Sea demand robust equipment. On offshore oil platforms, non-return check valves are crucial for maintaining flow direction in complex piping systems. They protect expensive extraction equipment and prevent potentially dangerous backflow situations that could compromise operations.

Emerging Applications in Renewable Energy and Smart Water Networks

As the UK invests in renewable energy and smart water networks, the role of non-return check valves is expanding. In solar thermal systems, they prevent heat loss, much like insulation in a house. In smart water grids, they help manage flow and prevent contamination, optimizing resource use and minimizing waste. You might be interested in: check valves for more information on various applications.

The Growing UK Market for Non-Return Check Valves

The increasing importance of non-return check valves is reflected in the growth of the UK market. While often categorized under control valves, the non-return check valve segment holds significant value within the industrial, water treatment, and energy sectors. UK market analysis projects substantial growth in the control valve market (including non-return check valves), from £277 million in 2024 to approximately £1.2 billion by 2035, a 13% compound annual growth rate (CAGR). Find out more about market growth. This demonstrates the growing recognition of these valves’ vital contribution across various industries.

From preventing expensive equipment damage to ensuring safe and efficient operations, non-return check valves are integral to many sectors across the UK. Their widespread use highlights their critical role in modern industrial applications. As technologies and infrastructure continue to develop, the importance of these essential components will only continue to grow.

Installation Strategies That Prevent Future Headaches

Even the highest quality non-return check valve can cause maintenance issues down the line if not installed correctly. It's a bit like setting up a new faucet in your kitchen – even the most expensive model will leak if the plumbing isn't done right. This section offers practical advice for ensuring your non-return check valve operates smoothly and reliably for years to come.

Critical Details for Long-Term Success

Small details often have a significant impact on a non-return check valve's performance. Pipe alignment, for instance, is crucial. A misaligned pipe stresses the valve body, similar to how a crooked shelf strains its brackets. This can lead to leaks and wear out the valve prematurely.

Support spacing is another key factor. Imagine a long, unsupported pipe – it'll sag and bend, stressing the joints. A non-return check valve requires proper support to prevent similar strain and ensure smooth operation.

The valve's orientation is also important. Some valves are designed for vertical setups, while others are best installed horizontally. Installing a valve in the wrong orientation is like using a Phillips head screwdriver on a flathead screw – it might work temporarily, but it's not efficient or safe.

Installation Considerations for Different Environments

Different environments pose unique installation challenges. In buried water mains, soil movement can put pressure on the pipework. The valve installation needs to account for this, incorporating flexible connectors and sufficient support to prevent damage.

In high-temperature industrial settings, thermal expansion is a major factor. Pipes expand and contract with temperature fluctuations, just like metal bridges on a hot summer day. The installation must accommodate this movement to avoid stressing the non-return check valve.

Let's dive into some specific installation requirements for various applications:

Before we move on, let's look at a table summarizing the installation requirements we've discussed for different applications. This table provides a handy reference guide for ensuring proper installation in various environments.

| Application Type | Orientation Requirements | Support Spacing | Clearance Needed | Special Considerations |

|---|---|---|---|---|

| Underground Water Mains | Typically horizontal, but depends on specific valve | Close support spacing to account for soil movement | Sufficient clearance for maintenance and potential pipe movement | Flexible connectors to accommodate soil shifting |

| High-Temperature Industrial | Dependent on valve design; may be vertical or horizontal | Supports designed to account for thermal expansion | Ample clearance for maintenance and thermal expansion | Expansion loops or joints to absorb pipe movement |

| Residential Water Supply | Typically vertical or horizontal based on pipe configuration | Standard support spacing as per local plumbing codes | Enough clearance for maintenance access | Isolation valves for easy maintenance and replacement |

| HVAC Systems | Dependent on system layout, often horizontal | Support based on pipe size and weight | Clearance for airflow and maintenance | Vibration dampeners to minimize stress on the valve |

Remember, consulting the manufacturer's specifications for your specific non-return check valve is always essential for detailed guidance and optimal performance. This table provides a general overview, but specific requirements might vary.

Practical Guidance and Common Mistakes

Here are some practical tips for successful installation:

Clearance Requirements: Ensure adequate space around the valve for maintenance access. Like leaving space around your furnace, you need room to work if something goes wrong.

Proper Support Techniques: Use appropriate supports to prevent stress on the valve body. A well-supported bookshelf holds more weight, and a properly supported valve better withstands pressure fluctuations, extending its lifespan.

Common Mistakes to Avoid: Avoid overtightening connections, installing the valve backward, and neglecting proper pipe alignment. These common errors can cause leaks, premature failure, and expensive repairs.

These recommendations are based on real-world experience. Following these guidelines ensures your non-return check valve operates reliably and efficiently for many years.

Maintenance Approaches That Actually Work

The best maintenance plan for your non-return check valves isn’t some complex, over-engineered system. It’s the one your team can stick to, day in and day out. Just like keeping up with your car’s maintenance, regular checks and simple preventative steps can save you from major problems later on. Let’s talk about some practical, effective approaches based on what we’ve heard from UK maintenance professionals.

Recognizing the Early Warning Signs

Catching valve trouble early is like noticing a strange noise in your car engine – it's a sign to investigate before things get worse. Small changes in your system pressure can be a clue that something's up with your non-return check valve. Odd noises, like clicking or banging, can also point to internal wear or damage. And remember, accurate installation from the start is key. Referring to detailed Construction Drawings when installing your non-return valves can prevent a lot of headaches down the line.

It ensures proper setup and minimizes the risk of future issues.

Prioritizing Maintenance Tasks for Maximum Impact

Not all maintenance tasks are equally important. Some offer a much better payoff for your time. Regularly checking for leaks on the outside of the valve is a quick and easy way to catch issues early. During planned downtime, take a look at the valve's internal components, such as the disc or ball. Addressing wear and tear proactively prevents bigger failures.

Think of predictive monitoring systems as your high-tech maintenance assistant. These systems use sensors to constantly track valve performance, giving you a heads-up about potential issues before they become critical. It's like having a mechanic continuously monitoring your car's engine, providing early warnings of potential problems. The move to more durable materials, like resilient polymers and stronger metals, has also made a huge difference. Valve lifespan has increased significantly, and failure rates have dropped by as much as 50% compared to older models. This translates to real cost savings. Some UK utilities have reported saving up to £5 million per year by upgrading their non-return valve designs. Explore further details about these advancements.

Realistic Inspection and Testing Strategies

Create an inspection schedule that’s practical for your team. How often you inspect depends on several factors: how crucial the valve is, the conditions it operates in, and the type of fluid it handles. A non-return check valve in a high-pressure system will need more frequent attention than one in a low-pressure application.

Simple tests, like pressure testing and visual checks, can uncover hidden problems. Just like a doctor uses diagnostic tests to identify health issues, these tests can pinpoint potential valve problems. Regular testing keeps your valves running smoothly and avoids unexpected downtime.

Extending Valve Life Without Breaking the Bank

Small preventative measures can go a long way in extending the life of your non-return check valves. Regular cleaning keeps debris from building up, ensuring the valve operates smoothly. Proper lubrication reduces friction and wear on the internal components, just like regular oil changes for your car. By putting these practical strategies into action, you can get the most out of your valves without overspending. For more ideas on maximizing valve life, check out these proactive maintenance strategies. They offer comprehensive plans similar to what we've discussed here, ensuring the longevity and optimal performance of your non-return check valves.

Key Takeaways For Non-Return Check Valve Success

Selecting, installing, and maintaining non-return check valves effectively boils down to understanding a few key principles. This section offers practical advice drawn from real-world experience, providing a roadmap for success whether you're designing a new system or improving an existing one.

Smart Selection: Matching the Valve to the Job

Choosing the right non-return check valve is a lot like choosing the right wrench for a bolt – the best fit depends on the job. Consider these factors:

Fluid Characteristics: Think about the fluid itself. Is it corrosive, like battery acid? Does it contain solids, like sand in a well? The fluid's properties will determine the necessary valve material and design.

Operating Conditions: What kind of pressures and temperatures will the valve experience? These operating conditions are crucial for selecting the correct pressure rating and ensuring material compatibility.

System Requirements: Is space tight? Does the system see a lot of flow changes? These practical considerations influence the valve type and size you'll need.

Installation Best Practices: Preventing Future Headaches

Proper installation is just as important as choosing the right valve in the first place. Skipping seemingly small details can cause major issues later on. Keep these key points in mind:

Precise Alignment: Make sure your pipes are properly aligned to avoid putting stress on the valve body. A misaligned valve is like a tilted picture frame – it might work for a while, but it's not ideal and won't last.

Adequate Support: Just like a bridge needs strong supports, your valve and surrounding pipes need proper support to prevent sagging and stress. This ensures they can handle the pressure and weight of the fluid.

Correct Orientation: Pay close attention to the manufacturer's instructions for installation orientation. Installing a valve backward is like trying to put on your shoes the wrong way – it simply won't function correctly.

Effective Maintenance: Maximizing Valve Life

Even the highest-quality non-return check valves require regular maintenance to ensure they operate smoothly over the long haul. Think of it like regular car maintenance—a little preventative care goes a long way. For some in-depth guidance, check out these proactive maintenance strategies. Here are a few key maintenance strategies:

Regular Inspections: Schedule routine inspections to catch potential problems early. It’s like a regular checkup with your doctor – preventative care can stop small issues from turning into big problems.

Targeted Testing: Perform the appropriate tests to verify the valve is working as expected and identify any hidden issues. These tests are like diagnostic tools, giving you a detailed look at the health of your valves.

Preventative Measures: Don't underestimate the power of simple steps like cleaning and lubrication. These small actions can significantly extend the lifespan of your valves, similar to how regular oil changes keep your car running smoothly.

By focusing on these key takeaways, you can ensure your non-return check valves perform reliably and efficiently, contributing to the smooth operation of your entire fluid system. For a wide range of high-quality valves and expert advice, visit Solenoid Valve World. We offer solutions for a variety of applications, from simple residential plumbing to complex industrial systems.