Non-Return Valves: Expert Guide to Types & Installation

Understanding Non-Return Valves: The Unsung Heroes of Flow Control

Think of your home's plumbing like a network of one-way streets. Non-return valves are the traffic cops, making sure everything flows in the right direction. These essential, yet often overlooked, components prevent backflow – a plumbing problem that can contaminate your water or damage your appliances.

This guide explores why these valves are so important, not just in your house, but in complex industrial systems as well. We'll delve into the different types and how choosing the right valve and placement is just as critical as selecting the correct pipe size. By the end, you'll have a new appreciation for flow control and the long-term value of quality non-return valves.

This image shows us a variety of non-return valves, giving us a peek inside at how they work. Notice the different designs – each one achieves the same goal of preventing backflow, but in a slightly different way.

The image highlights the wide range of valve designs, each optimized for specific uses and pressure requirements. This underscores the importance of selecting the right valve for your system. It's like choosing the right tool for a job – you wouldn't use a hammer to tighten a screw. Likewise, a swing check valve meant for a large pipe won't work well in a small, high-pressure system.

Why Backflow Prevention Matters

Non-return valves aren't just about convenience; they're crucial for safety and protecting your entire system. In industrial settings, backflow can contaminate products, damage equipment, or even create dangerous situations. Imagine a chemical plant where backflow mixes incompatible substances – the results could be disastrous. Even in a home, backflow can contaminate your drinking water with wastewater, creating serious health risks. These valves are essential safeguards against such problems.

Real-World Impact

Engineers have plenty of stories about both valve failures and successes. One engineer told a story about a near disaster at a power plant where a faulty non-return valve almost shut down the entire system. On the other hand, another engineer described how properly installed non-return valves protected a water treatment plant during a flood, preventing widespread contamination. These real-world examples show the critical role these unsung heroes play in ensuring system reliability and safety. They're the silent guardians of our infrastructure, working behind the scenes to keep essential processes running smoothly.

How These Ingenious Devices Actually Work

Let's explore the inner workings of non-return valves. Imagine a door that only opens one way – that’s the basic idea. Instead of hinges and handles, these valves use the force of flowing fluids and some clever engineering to ensure a one-way street for liquids or gases.

The Dance of Pressure and Mechanics

Non-return valves operate on the fundamental principle of pressure differentials. When fluid flows in the desired direction, the pressure pushes open a blocking element within the valve. This element might be a swinging disc, a lifting poppet, a flexible diaphragm, or a spring-loaded ball. Like our one-way door, pressure pushes it open, but any backward force closes it tight.

This sealing action is essential for preventing backflow. If the flow stops or reverses, the pressure difference flips. The blocking element is no longer pushed open and either falls back into its closed position (thanks to gravity or a spring) or is pushed shut by the reversed pressure. This quick closure prevents unwanted flow in the wrong direction.

This diagram showcases various types of non-return valves, highlighting their internal components and how they manage flow. Notice the different designs, from the straightforward swing check valve to the more intricate lift check valve.

The image clearly illustrates the different mechanisms within each valve type. This underscores the fact that while the core principle of preventing backflow is consistent, the specific design determines how each valve accomplishes this. This variety allows for tailoring and optimization in diverse applications, emphasizing the importance of choosing the right valve for your system's needs.

Cracking Pressure and Flow

Two important concepts govern a non-return valve’s performance: cracking pressure and flow coefficient. Cracking pressure is the minimum upstream pressure needed to open the valve. It’s like the initial push required to open that one-way door. A lower cracking pressure means easier opening, but it also means the valve might be more vulnerable to backflow if the pressure difference isn’t substantial.

The flow coefficient (Cv) measures how efficiently the valve allows fluid to pass through when fully open. A higher Cv signifies less resistance and better flow, crucial for minimizing pressure drops in your system.

Backpressure: The Silent Enemy

Another critical factor is backpressure tolerance. This refers to the valve's ability to withstand pressure from the downstream side without leaking. High backpressure can force the blocking element open slightly, allowing reverse flow. This can harm equipment and compromise the entire system. Selecting a valve with adequate backpressure tolerance is essential, especially in systems with fluctuating or potentially high downstream pressures. This ensures the valve remains a reliable protector against backflow, even in tough conditions.

Exploring The 4 Main Types: Finding Your Perfect Match

Not all non-return valves are the same. Each type has its own strengths, weaknesses, and ideal working conditions. This guide explores the four main types, helping you choose the right one for your specific needs. It's like choosing the right tool for a job – you wouldn't use a hammer to tighten a screw, just as you wouldn't use a swing check valve designed for a large pipe in a small, high-pressure system.

Swing Check Valves: The Dependable Workhorses

Swing check valves are common in large pipe systems. They have a hinged disc that swings open with forward flow and closes with back pressure, much like a saloon door. This simple design makes them reliable and cost-effective. However, their swinging action can be slow, making them less suitable for systems with quick flow changes.

Lift Check Valves: Precision Under Pressure

Lift check valves are the go-to for high-pressure applications. These valves use a guided poppet that lifts vertically to allow flow. This precise action makes them ideal for high-pressure, high-velocity situations, but they may require more maintenance than swing check valves. The guided movement minimizes wear and tear, extending their lifespan in demanding environments.

Diaphragm Valves: Gentle Protection For Sensitive Systems

Diaphragm valves are perfect for handling sensitive fluids or systems needing minimal pressure drop. A flexible diaphragm acts as the blocking element, responding smoothly to pressure changes. This gentle action is ideal for delicate systems, minimizing damage to sensitive components or fluids.

Spring-Loaded Check Valves: Quick Response For Dynamic Flows

Spring-loaded check valves shine in systems with fluctuating flows. A spring helps the valve close quickly, minimizing backflow and pressure surges. This rapid response is crucial in dynamic systems, ensuring precise control and protection against damaging pressure fluctuations.

To understand the differences between valve types better, let's look at the following comparison table. It summarizes the operating mechanisms, ideal uses, advantages, and limitations of each type.

Non-Return Valve Types Comparison A detailed comparison of the four main types of non-return valves, showing their operating mechanisms, typical applications, advantages, and limitations

| Valve Type | Operating Mechanism | Best Applications | Key Advantages | Limitations |

|---|---|---|---|---|

| Swing Check | Hinged disc swings open and closed | Large diameter, low-pressure systems | Simple, reliable, cost-effective | Slow closing, prone to slamming in pulsating flow |

| Lift Check | Guided poppet lifts vertically | High-pressure, high-velocity systems | Precise control, good for high pressure | Can be more complex, requires more maintenance |

| Diaphragm | Flexible diaphragm acts as a barrier | Sensitive fluids, low pressure drop required | Gentle action, protects sensitive systems | Limited pressure and temperature range |

| Spring-Loaded | Spring assists in quick closing | Pulsating or fluctuating flow systems | Fast response, minimizes backflow and surges | Can be more expensive than other types |

As the table highlights, each valve type has specific strengths and weaknesses. Choosing the correct valve depends on your system's unique requirements.

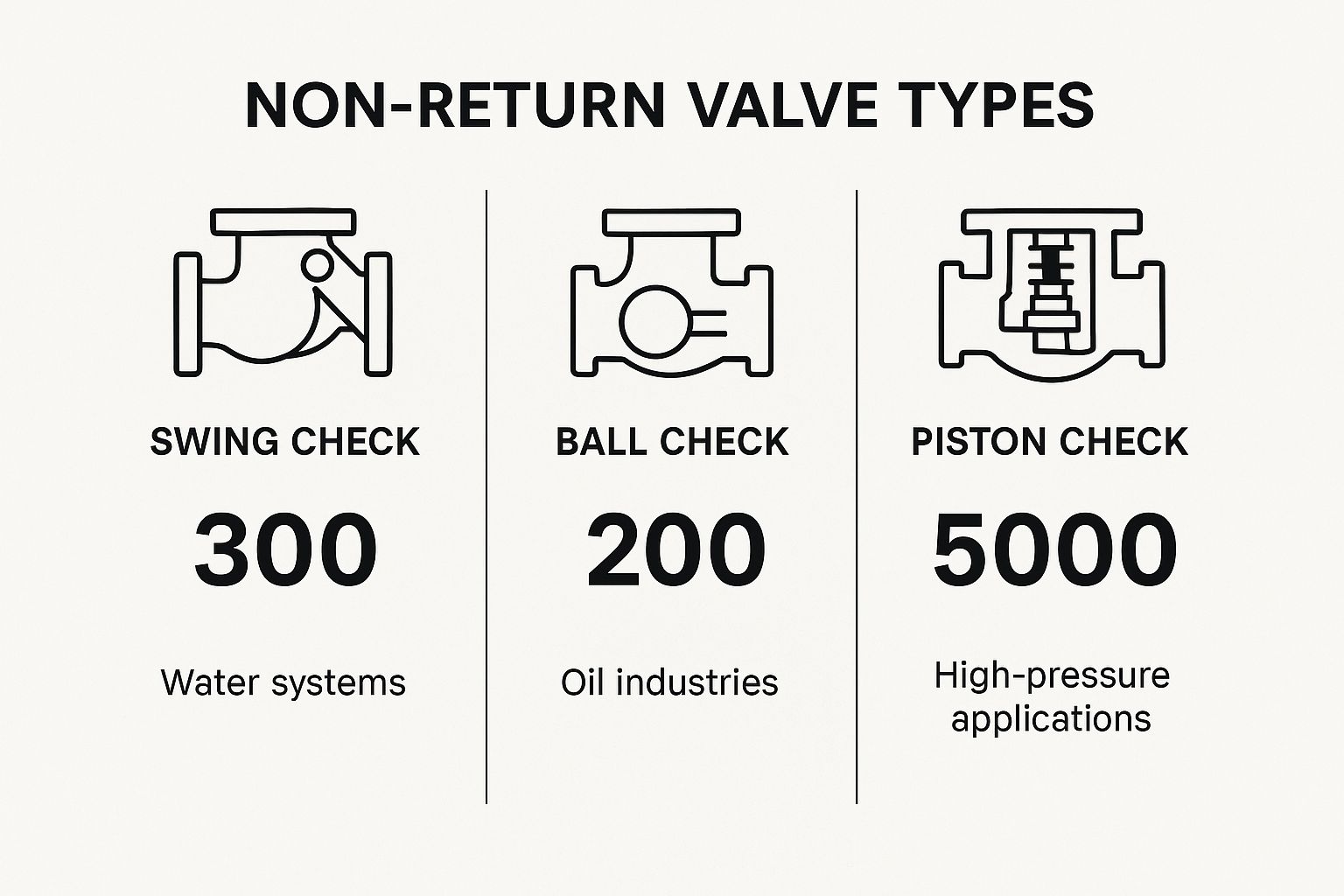

The infographic above visually represents the differences in design and common uses for several types of non-return valves. As you can see, picking the wrong type can cause problems—imagine a delicate diaphragm valve in a high-pressure hydraulic system!

For more detailed information, check out these resources:

Materials And Pressure Ratings: Building For The Long Haul

Choosing the right materials for your non-return valves is a bit like choosing the right materials to build a house. You wouldn't build a seaside cottage out of cardboard, right? It's not just about the initial cost—it's about making sure your valves can handle the wear and tear of your system for years to come.

Material Selection: Matching The Valve To The Task

Different materials react differently to various factors like pressure, temperature changes, and the chemicals in the fluids passing through them. Brass, for instance, is a good, cost-effective choice for standard plumbing, but it won't hold up against harsh chemicals or high temperatures. Stainless steel, however, is much more versatile and resists corrosion, making it a reliable option in many industrial settings.

For really tough applications, you might need something even stronger. Superalloys like Inconel or Hastelloy can handle extreme temperatures and corrosive environments. Then there are advanced polymer composites, which are particularly useful in chemical processing and water treatment because they offer excellent resistance to specific chemicals. These high-end materials might cost more upfront, but their durability and lower maintenance needs often make them a smarter investment in the long run.

Interestingly, the UK’s tap and valve industry, which includes non-return valves, is seeing steady growth. In 2024, UK production hit about 127,000 tons, a 1.9% jump from the year before. Forecasts predict the market will reach 226,000 tons by 2035, showing a rising demand for reliable flow control solutions. Discover more insights into the UK tap and valve market.

Decoding Pressure And Temperature Ratings

Understanding pressure ratings and temperature limits is essential. These ratings tell you the safe operating zone for your valve. Going beyond these limits can cause early wear, leaks, or even a complete failure. Think of it like a pressure cooker—if the pressure gets too high, things can go wrong quickly! Similarly, a non-return valve pushed past its pressure rating can fail and cause serious damage and downtime.

Manufacturers usually provide information on the maximum allowable pressure (MAP) and maximum operating temperature (MOT). Never exceed these values. Some manufacturers also provide performance curves, which show how the valve performs under different pressure and temperature conditions. These curves are incredibly useful for choosing the right valve for systems where conditions change frequently.

The Long-Term Enemies: Corrosion, Erosion, And Thermal Cycling

Besides pressure and temperature, other factors like corrosion, erosion, and thermal cycling can significantly shorten a valve's lifespan. Corrosion is the chemical breakdown of a material, which can weaken the valve body and its internal parts. Erosion, the physical wear from the flow of fluids, can damage the sealing surfaces and affect performance. Thermal cycling—the repeated expansion and contraction of materials due to temperature changes—can lead to fatigue and cracks.

This image shows a variety of valves, highlighting the different materials and construction methods used. Note the robust designs and attention to detail – these are vital for long-term reliability.

To help you choose the best material for your needs, take a look at the table below:

Material Selection Guide For Non-Return Valves: This table provides a comprehensive guide to different valve materials, their properties, common uses, and temperature/pressure limitations.

| Material | Temperature Range | Pressure Rating | Chemical Resistance | Typical Applications | Cost Factor |

|---|---|---|---|---|---|

| Brass | Moderate | Moderate | Fair | Residential plumbing, low-pressure systems | Low |

| Stainless Steel | Wide | High | Excellent | Industrial applications, chemical processing, water treatment | Medium |

| Cast Iron | High | High | Good | Wastewater, fire protection systems | Medium |

| PVC | Moderate | Low | Excellent (to specific chemicals) | Water treatment, irrigation | Low |

| Inconel | Very High | Very High | Excellent | Extreme temperature and pressure applications, aerospace | High |

Key takeaways from the table: Material selection involves balancing cost, performance requirements, and the specific demands of your application. While brass is cost-effective for less demanding situations, stainless steel offers a broader range of applications. For truly extreme conditions, specialized materials like Inconel are necessary, despite their higher cost.

By carefully considering these factors – material properties, pressure and temperature limits, and potential long-term wear – you can select materials that will withstand these challenges and ensure your non-return valves operate reliably for years to come. Choosing the right material is an investment in the long-term health and efficiency of your entire system.

Selection Criteria: Making The Right Choice Every Time

Choosing the right non-return valve is critical, whether for a simple home plumbing system or a complex industrial process. It's a bit like choosing the right footwear: you wouldn't wear running shoes to climb a mountain, would you? Similarly, the wrong non-return valve can lead to inefficiency, damage, and expensive repairs down the line.

Understanding Your System's Needs

The first step is understanding what your system actually needs. Think about the type of fluid involved, the operating pressure and temperature, and the expected flow rate. These factors are crucial in determining the right valve type and material. For instance, a system with corrosive chemicals needs a chemically resistant valve, perhaps stainless steel. A high-pressure system demands a valve built to withstand that pressure.

Installation space and orientation also matter. Some valves need specific positions to work best. And don't forget about future maintenance! A valve crammed into a tight spot might seem space-saving now, but it could be a real headache later.

For a deeper dive into selecting the right valve, check out our guide on non-return valves.

Balancing Cost and Lifecycle Considerations

While the initial price tag is important, don't let it be your only guide. Think about the total cost over the valve's lifespan. This includes installation, maintenance, and potential replacements. A more expensive, high-quality valve might actually save you money in the long run by needing less maintenance and lasting longer. Sometimes, saving a little upfront can lead to bigger expenses later.

Interestingly, the UK's non-return valve market benefits from its location in Europe, a central hub for industrial automation and energy efficiency. This emphasis on reliable flow control solutions drives the demand for high-quality non-return valves. Learn more about the non-return valve market.

Interpreting Manufacturer Specifications

Manufacturer specifications are packed with valuable information. Pay close attention to pressure ratings, temperature limits, and material compatibility charts. These tell you the valve's operating limits and suitability for your application. Watch out for potential problems, like a pressure rating lower than your system requires or materials that aren't compatible with the fluids you're using. Understanding these specs is key to making a good decision.

Asking the Right Questions

Don't be afraid to reach out to the manufacturer or a qualified supplier if you have questions. They can offer expert advice and help you pick the perfect valve. Asking about the recommended maintenance schedule or how the valve performs under pressure fluctuations can uncover valuable information that isn't always obvious in the specs.

By following these guidelines, you can choose a non-return valve that not only meets your current needs but also delivers reliable performance for years to come, preventing costly mistakes and ensuring smooth operation.

Installation Best Practices: Getting It Right From The Start

Even the best non-return valve can fail if it's not installed correctly. We've seen top-notch valves ruined by simple installation mistakes that could have easily been avoided with a bit of planning. This guide walks you through the key installation steps that separate smooth-running projects from expensive headaches. We'll start with prepping your system and end with those all-important commissioning checks, making sure your valves work perfectly from the get-go.

System Preparation and Valve Orientation

Before you install your non-return valve, make sure the piping system is clean and free of any debris. Think of it like painting a wall – you wouldn't start on a dirty surface, right? Any foreign material can mess with the valve's operation, potentially causing leaks or wearing it out prematurely. Give the system a good flush to remove any loose particles or gunk.

Next up, check the valve's orientation. Most valves have an arrow on the body showing the direction of flow. Installing it backwards stops it from working and might even damage it. Imagine a one-way street sign facing the wrong way – total chaos! The same principle applies to non-return valves.

Support and Spacing: Preventing Stress and Ensuring Maintainability

Proper support is crucial, especially for larger, heavier valves. An unsupported valve can strain the piping, leading to leaks or even pipe breaks. It's like building a bridge – you need strong supports for stability. Use the right supports to prevent strain and ensure the valve stays put for the long haul.

Thinking ahead to maintenance is also key. Leave enough room around the valve so you can easily access it for inspections and repairs. Cramming it into a tight spot might seem like a good idea at first, but it will be a real pain if you ever need to replace it.

As a side note, the UK's tap and valve manufacturing industry, which includes non-return valves, has faced some tough times. Over a five-year period ending in 2019, the industry's revenue declined at a rate of -7.5% each year. However, recent production increases hint at a potential comeback in related sectors, including non-return valves. Learn more about the UK tap and valve industry.

Common Installation Pitfalls and How To Avoid Them

Even seasoned pros can fall into these common installation traps:

- Not Enough Clearance: As mentioned earlier, insufficient space around the valve makes future maintenance a difficult and costly affair.

- Poor Pipe Support: Without the right support, stress can build up in the piping, potentially causing leaks or even breaks.

- Wrong Orientation: Installing the valve backwards stops it from working properly and could cause damage.

This image showcases correctly installed non-return valves, demonstrating good practices for support, spacing, and orientation. Notice how the valves are easily accessible and well-supported, making maintenance a breeze.

Post-Installation Checks: Commissioning and Initial Testing

After installation, don't just assume everything is fine. Run some thorough commissioning tests to make sure the valve is working as it should. These tests usually involve checking for leaks, verifying the flow direction, and making sure the valve opens and closes correctly under different pressures. Think of it as the final quality check before a product launch.

Initial Testing Best Practices

Initial testing includes these important steps:

- Visual Inspection: Look for any visible signs of damage or misalignment.

- Leak Testing: Pressurize the system and check for leaks around the valve and its connections.

- Operational Test: Simulate typical operating conditions to confirm the valve opens and closes as expected.

By following these installation best practices and carrying out thorough post-installation checks, you’ll ensure your non-return valves perform reliably, protecting your system and preventing expensive problems down the road. This proactive approach is a smart investment in long-term reliability and efficiency.

Maintenance and Troubleshooting: Keeping Your Valves Happy

Think of your piping system as a well-oiled machine. A properly maintained non-return valve is like a crucial cog, keeping everything running smoothly. Conversely, a neglected valve can throw a wrench in the works, leading to costly downtime and repairs. This section covers some proven maintenance strategies and troubleshooting techniques used by facilities that have achieved long-term valve reliability.

Recognizing The Early Warning Signs

Just like a doctor diagnosing a patient, learning to spot the subtle signs of valve trouble is crucial. A slight change in system pressure, unusual noises like chattering, or a decrease in flow rate can all be indicators of a developing problem. Addressing these early warnings is like catching a cold before it turns into pneumonia – a little preventative care can save a lot of trouble down the line. For example, a slightly higher than usual pressure drop across your non-return valve might indicate a partial blockage. Left unchecked, this could lead to complete valve failure.

When installing non-return valves, consider incorporating shut-off valves for maintenance and safety. For expert guidance on installation, check out these tips on installing a Marine Fuel Shut Off Valve.

Troubleshooting Common Non-Return Valve Problems

Non-return valves, like any piece of equipment, can experience a few common issues. Chattering, a rapid opening and closing of the valve, is often caused by pressure fluctuations or an incorrectly sized valve. Internal leakage, where fluid seeps through the closed valve, can result from worn seals or debris stuck in the valve. Flow restriction usually points to a blockage or a valve that's simply too small for its job. Diagnosing these problems often involves simple checks: listening for unusual sounds, measuring pressure differentials, or visually inspecting the valve for any obvious damage.

For a deeper dive into the world of non-return valves, check out our comprehensive guide on non-return/check valves.

Maintenance Schedules and Inspection Techniques

Just like your car needs regular tune-ups, establishing a consistent maintenance schedule is essential for keeping your non-return valves in peak condition. This should include periodic inspections, cleaning, and testing. How often you perform maintenance depends on a few factors: the valve type, the system's operating conditions, and how critical the application is. A non-return valve in a critical process line, for instance, will likely require more frequent inspections than one in a less demanding role.

Effective inspection techniques are your best defense against unexpected problems. Visual inspections can reveal external damage or wear, while functional testing, which simulates real-world operating conditions, can identify internal issues like leakage or restricted flow. Regular maintenance and thorough inspections are proactive measures that minimize downtime and extend the life of your valves.

Record-Keeping and Predictive Maintenance

Imagine having a logbook for your valves. Keeping detailed records of inspections, repairs, and replacements is invaluable for optimizing your maintenance strategies. These records can reveal patterns and trends, helping you predict potential failures and schedule maintenance proactively. For example, if your records show a particular type of valve tends to fail after a specific number of operating cycles, you can schedule preventative maintenance before a failure occurs.

Mastering predictive maintenance is like having a crystal ball for your piping system. By analyzing historical data, monitoring valve performance, and using this information to anticipate future problems, you can minimize those dreaded emergency repairs, optimize valve performance, reduce downtime, and keep maintenance costs under control.

Ready to take control of your fluid systems? Visit Solenoid Valve World for a wide selection of high-quality non-return valves and expert advice. We offer a comprehensive range of valves, along with the technical support you need to choose the right one for your specific application. Benefit from free next-day UK delivery and expert guidance from our UK-based team.