Your Guide to Pneumatic Actuated Valve Systems

A pneumatic actuated valve is a clever device that uses compressed air to open or close a valve automatically. It's like having a powerful, air-powered assistant for your industrial pipelines, giving you rapid and incredibly reliable control over the flow of liquids or gases. Their simple but robust mechanics make them a true workhorse in countless automated systems.

How Do Pneumatic Actuated Valves Actually Work?

At its heart, a pneumatic actuated valve is a beautifully simple machine. It’s all about converting the potential energy from compressed air into physical, mechanical motion.

Imagine you had to turn a massive, stiff valve wheel on an industrial pipe by hand. It would take a lot of muscle and quite a bit of time. A pneumatic actuator does the same job in a flash, all with a simple pulse of air. This swift action removes the need for someone to be there in person, delivering a level of speed and precision that’s non-negotiable in modern industry. The whole operation hinges on a few key components working together in perfect sync.

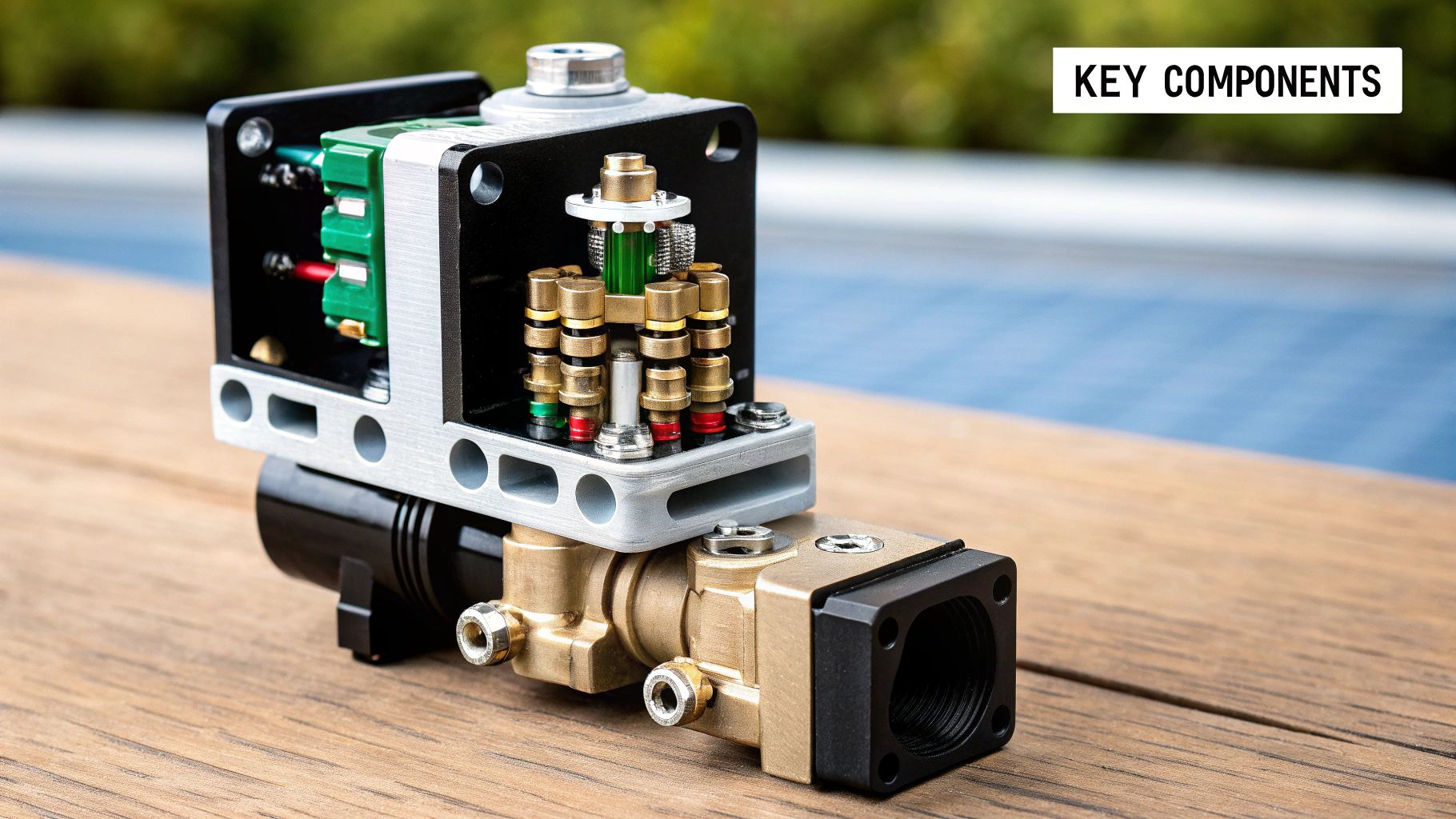

The Three Core Components

To really get a grip on how these valves work, let’s break the system down into its three essential parts. Each one plays a distinct and vital role.

First, let's summarise the core components and their roles in a simple table.

Core Components and Their Roles

| Component | Function | Simple Analogy |

|---|---|---|

| The Actuator | The 'engine' of the system. It houses a piston or diaphragm that moves when air pressure is applied. | The muscle |

| The Valve | The part that directly controls the flow of media (e.g., a ball or butterfly valve). | The gatekeeper |

| Compressed Air | The fuel. Clean, pressurised air is delivered from a compressor to the actuator on demand. | The power source |

In short, the actuator is the brains and the brawn, the valve is the gate, and the compressed air is the energy that makes everything happen. It’s a beautifully efficient system.

Key Takeaway: The entire principle is about turning air pressure into force. By controlling the air sent to the actuator, you can precisely control the valve’s position—whether that’s fully open, fully closed, or somewhere in between.

This technology is a real cornerstone of industrial automation across the United Kingdom. In sectors like oil and gas, chemical processing, and water treatment, pneumatic actuated valves are indispensable. A major reason for this is safety; because they operate without electricity right at the point of actuation, they don’t create sparks. This makes them essential for safe fluid control in the potentially hazardous environments often found in the UK’s energy and processing plants. You can find more details on this industrial trend by exploring the latest pneumatic market research.

A Simple Operational Walkthrough

Let's walk through the process step-by-step using one of the most common types: a "fail-close" spring-return model.

- Resting State: To start, there’s no air pressure. A powerful internal spring holds the valve firmly in the closed position, blocking any flow through the pipe.

- Actuation Signal: A control system sends a signal, usually to a small solenoid valve, which opens and lets compressed air rush into the actuator’s chamber.

- Movement: This sudden influx of air pressure pushes against a piston or diaphragm, easily overpowering the force of the spring.

- Valve Opening: As the piston moves, it turns a stem connected to the valve. This rotates the valve (like a ball or butterfly disc) into the open position, allowing the fluid or gas to flow freely.

- Closing: To shut the valve, the air supply is cut off and the air inside the actuator is vented out. The spring's stored energy instantly takes over, pushing the piston back to its original spot and snapping the valve closed.

This entire cycle can happen almost instantly. This gives you the rapid response needed for everything from routine process adjustments to critical emergency shutdowns. For a deeper dive into the components that make up these systems, you might be interested in our guide to the basics of pneumatic systems.

The Two Main Types of Pneumatic Actuators

While every pneumatic actuator runs on compressed air, the way they turn that air into action isn't one-size-fits-all. The movement they produce falls into two camps, and this is the first big choice you'll make when picking a pneumatic actuated valve. Your actuator’s motion must match how the valve it’s controlling is designed to operate.

So, what are our options? We're talking about rotary and linear actuators.

Each one is built for a specific job, translating air pressure into a very different kind of force. Getting this right is absolutely fundamental to making sure your valve works correctly, efficiently, and safely. Let’s break down how they work and which valves they're made for.

Rotary Actuators: For a Quick Turn

Rotary actuators do exactly what their name suggests: they produce a turning or twisting motion. Most often, this is a 90-degree arc. Think about turning a doorknob or flicking a lever—that’s the kind of quarter-turn action these devices deliver. This makes them a perfect partner for any valve that opens and closes with a simple rotation.

You'll almost always find rotary actuators paired with ball valves and butterfly valves. There are two common ways they create this turning force:

- Rack and Pinion: This is the most popular design. It uses a piston with gear teeth (the "rack") that meshes with a circular gear (the "pinion"). When air pushes the piston forward, its straight-line movement is cleverly converted into a smooth rotational force on the pinion, which turns the valve stem.

- Scotch Yoke: This mechanism is a bit different. A pin on the piston slides inside a slotted arm, called a "yoke". As the piston moves, the pin forces the yoke to pivot, creating the rotation. Scotch yoke designs are real powerhouses, known for producing higher torque right at the beginning and end of the stroke—perfect for cracking open or tightly seating large valves.

The big win for rotary actuators is their compact design and how efficiently they convert a simple push into powerful torque. They deliver the high turning force needed to operate quarter-turn valves quickly and reliably.

This style of pneumatic actuated valve is a common sight across process industries, especially for straightforward on/off flow control in pipelines.

Linear Actuators: Straight-Line Power

In contrast to their rotary cousins, linear actuators provide motion in a straight line. It's a simple, direct push or pull action. Picture a powerful rod moving back and forth—that's the essence of it. This kind of force is exactly what's needed for valves that open by lifting a gate or a plug clean out of the flow path.

This makes them the go-to choice for gate valves, globe valves, and other multi-turn valve types. Again, there are two primary designs you’ll come across:

- Piston Actuators: These work a lot like a piston in a car engine. Air pressure is fed to one side of a sealed piston, forcing it to travel down the length of a cylinder. This creates a powerful, direct thrust that’s transferred to the valve stem, lifting or lowering it.

- Diaphragm Actuators: Instead of a solid piston, this type uses a flexible, pressure-sensitive diaphragm. When air fills the chamber, it pushes on the diaphragm, which is connected to the valve stem. Diaphragm actuators are often chosen for their sensitivity, which allows for very precise, modulating control—a huge advantage for globe valves.

The choice between a piston and a diaphragm often boils down to force versus finesse. Piston designs typically generate more raw power, making them ideal for high-pressure systems or bigger valves. Diaphragm actuators, however, offer much finer control, making them a staple in processes where you need to carefully throttle the flow, not just switch it on or off.

Choosing Between Single and Double-Acting Actuators

Once you've figured out if you need rotary or linear motion, the next big decision is all about how the actuator uses compressed air. This boils down to choosing between a single-acting and a double-acting design. It’s a decision that directly shapes your system’s safety, running costs, and overall efficiency, as each type has its own strengths for different jobs.

At its heart, the difference is straightforward. A single-acting actuator uses air for one-way movement and a mechanical spring to get back. A double-acting actuator, on the other hand, uses air pressure for both the opening and closing strokes, giving you a different level of control.

Single-Acting for Fail-Safe Certainty

Think of a single-acting actuator as your system’s built-in safety net. Often called a spring-return actuator, it’s built with a powerful internal spring that forces the valve into a default position—either fully open or fully closed—the moment air supply is cut off.

Compressed air works against this spring to move the valve into its operating position. If that air pressure disappears—maybe a compressor fails or an air line is severed—the spring’s stored energy instantly takes over. It snaps the valve back to its pre-set "fail-safe" state.

This fail-safe capability isn't just a nice-to-have; it's non-negotiable in critical applications. For any system handling hazardous chemicals or flammable gases, you need a valve that shuts down automatically to prevent a disaster. That's precisely the job of a single-acting pneumatic actuated valve.

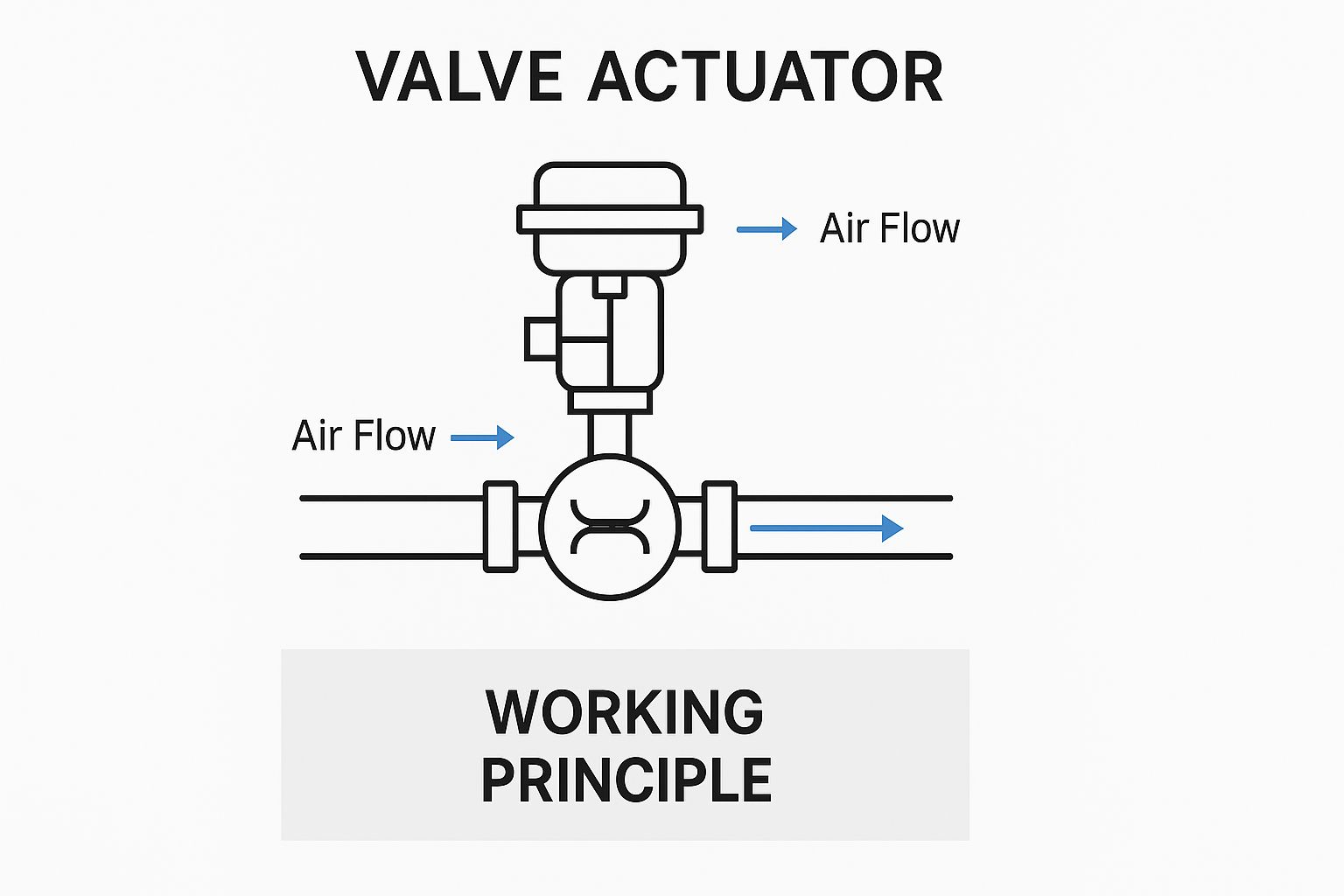

This image clearly shows how the pressurised air drives the actuator's mechanism within a pipeline.

You can see how the controlled airflow translates directly into the mechanical force needed to operate the valve.

Double-Acting for Total Control

When you need precision and raw power, a double-acting actuator is the way to go. It has two air ports and relies on compressed air to drive the piston in both directions—one port to push it open, the other to pull it shut. Since there's no spring fighting back, all the air pressure gets converted directly into output torque.

This design gives you some key advantages. It delivers more consistent and higher torque throughout the entire stroke, which is perfect for bigger valves or systems with high-pressure media. It also allows for much finer control, as you can stop and hold the valve at any point in its travel just by balancing the air pressure on both sides of the piston. To learn more, you can explore the different types of pneumatic actuators for valves and their control methods.

Head-to-Head Comparison

Making the right choice means weighing the trade-offs between safety, cost, and what you need the valve to do day-to-day. The table below lays it all out to help you see which model is the best fit for your application.

Comparing Single-Acting vs. Double-Acting Actuators

Here’s a feature-by-feature comparison to help you decide which operating principle fits your needs.

| Feature | Single-Acting (Spring-Return) | Double-Acting |

|---|---|---|

| Operating Principle | Air pressure moves the valve one way; a spring handles the return journey. | Air pressure drives the valve in both directions (opening and closing). |

| Fail-Safe Function | Excellent. Automatically returns to a safe position when air is lost. | None. The valve stays put in its last position if air pressure fails. |

| Air Consumption | Lower, since air is only needed for one stroke. | Higher, as air is used for both the opening and closing strokes. |

| Torque Output | Lower for its size because it has to overcome the internal spring. | Higher for its size, with more consistent torque through the full stroke. |

| Initial Cost | Generally higher due to the internal spring mechanism. | Typically lower in cost and simpler in construction. |

| Best For | Safety-critical systems, emergency shutdown (ESD) valves, and simple on/off control. | Larger valves, high-pressure applications, and precise modulating control. |

Ultimately, single-acting actuators are the go-to for safety, while double-acting actuators offer superior power and control for more demanding or nuanced operations.

Why Choose a Pneumatic Actuated Valve?

When you’re specifying equipment for a process, the decision often boils down to the practical pros and cons of one technology over another. A pneumatic actuated valve isn’t just another component on a P&ID diagram; it's a strategic choice with real, tangible benefits for both your operations and your budget. Their widespread use across so many critical industries is no accident—it comes down to a powerful combination of safety, durability, and cost-efficiency.

So, what makes simple compressed air such a compelling choice over electric or hydraulic alternatives? The answer lies in four key areas where these devices consistently outperform, giving engineers and plant managers real peace of mind and long-term value.

Unmatched Safety in Hazardous Environments

The single biggest advantage of a pneumatic actuated valve is its inherent safety. It runs on compressed air, which means there is no risk of sparks at the point of actuation. This isn't just a small perk; it’s a non-negotiable requirement for any site classified as a hazardous area. In these places, even a tiny electrical spark could ignite flammable gases, vapours, or dust, leading to a catastrophic failure.

Think about environments like:

- Oil and gas refineries

- Chemical processing plants

- Paint and solvent manufacturing facilities

- Grain storage silos

In these settings, using electrical equipment means adding costly and complex explosion-proof enclosures. A pneumatic actuator elegantly sidesteps this entire problem, offering a simple, mechanically safe solution that’s intrinsically suited for volatile atmospheres.

Exceptional Reliability and Longevity

In the world of industrial machinery, complexity is often the enemy of reliability. Pneumatic actuators are loved for their simple, robust design. They have far fewer moving parts than their electric counterparts—no motors, gears, or delicate electronic control boards to burn out or fail.

This simplicity translates directly into a longer service life and less downtime. The basic mechanics of a piston or diaphragm driven by air are incredibly durable and can handle millions of cycles with only minimal maintenance. As long as you feed them clean, dry air, these workhorses can operate for years on end, even in harsh, high-vibration environments that would quickly destroy more sensitive electronic systems.

Key Insight: The simple design of a pneumatic actuated valve is its greatest strength. Fewer moving parts and no complex electronics mean fewer things can go wrong, leading to a much lower total cost of ownership over the valve's lifespan.

Impressive Speed and Power

When you need a valve to react right now, pneumatics are tough to beat. The rapid release of compressed air creates an almost instant force, allowing for incredibly fast actuation speeds. This is vital for applications that need quick cycling or, more critically, for emergency shutdown (ESD) systems.

In a crisis, a valve might need to slam shut in a fraction of a second to isolate a process or stop a dangerous overflow. The direct-acting force of pneumatics, especially when paired with a spring-return mechanism, delivers this rapid, reliable response without a moment's hesitation.

And don’t let their size fool you—these actuators pack a serious punch. They can generate huge linear or rotary force from a relatively compact and lightweight unit. This makes them perfectly capable of operating large, high-pressure valves that would otherwise need much bulkier and more expensive electric actuators.

Overall Cost-Effectiveness

Finally, a pneumatic actuated valve often proves to be the more economical choice, both when you buy it and over its entire operational life. The initial purchase price is frequently lower than that of an electric actuator with a similar torque output.

But the savings don't stop there. Their straightforward design means maintenance is simpler and less frequent, which cuts down on labour costs and the need for specialised technicians. Air consumption is also very efficient, particularly in single-acting models. And since compressed air is a standard utility in most industrial facilities, it’s already a cost-effective power source.

How to Select the Right Pneumatic Actuated Valve

Choosing the right pneumatic actuated valve is much more than just matching pipe sizes. It's a critical decision that dictates how safely and efficiently your system will run. Get it right, and you’ve got a reliable component that needs minimal attention. Get it wrong, and you could be facing poor performance, premature failure, or even a hazardous situation.

Think of it as a methodical process. By working through a few key factors one by one, you can confidently specify a valve and actuator combo that's perfectly suited for the job. Let's walk through what you need to consider, from the forces inside the pipe to the world outside it.

Calculating Required Torque

First things first: you need to figure out how much muscle is needed to turn the valve. This rotational force is known as torque. It’s what the actuator needs to produce to shift the valve between its open and closed positions.

Several factors influence how much torque is required:

- Valve Size: It’s simple physics. Bigger valves need more force to operate.

- Media Pressure: High pressure in the pipeline pushes hard against the valve's internal parts (like a ball or disc), creating resistance the actuator must overcome.

- Media Type: What’s flowing through the pipe matters. Clean water is one thing, but a sticky slurry or an abrasive fluid can dramatically increase the force needed to get things moving.

Your actuator manufacturer will have detailed torque charts. You need to work out the valve's "break torque"—the initial grunt needed to unseat it—and then select an actuator that can deliver more than that. A safety margin of 25-30% is a good rule of thumb here.

Assessing the Operating Environment

A valve and actuator don't live in a bubble. The surrounding environment can have a huge impact on their lifespan and performance, so you have to take a hard look at where the unit will be installed.

Ask yourself these questions about the location:

- Temperature: Is the valve going to bake in extreme heat or face freezing conditions? The materials for seals and even lubricants need to be chosen carefully to stop them from going brittle or failing.

- Corrosion: Will the valve be exposed to a damp, salty, or chemically aggressive atmosphere? The housing materials—for instance, choosing stainless steel over aluminium—must be able to stand up to corrosion.

- Hazardous Areas: Is the valve operating where flammable gases or dust could be present? In that case, it absolutely must have the correct ATEX rating for explosive atmospheres. This is a common and non-negotiable requirement in the UK’s oil and gas, chemical, and processing industries.

Ignoring the environment is a classic mistake that can lead to a valve failing much sooner than expected. A unit specified for a clean, dry factory floor simply won't last in a marine or chemical plant setting.

Evaluating Air Supply and Fail-Safe Needs

The compressed air system is the lifeblood of your pneumatic actuator. You have to make sure the actuator you pick is a good match for the air pressure your facility can reliably supply.

Key Consideration: The available air pressure directly dictates how much torque an actuator can generate. If your plant runs on lower pressure (say, 4 bar), you’ll need a larger actuator to produce the same force as a smaller one operating at a higher pressure (like 8 bar).

Finally, you need to decide on the valve’s safety function. This brings us back to the choice between single and double-acting actuators. Just ask one simple question: what needs to happen if the compressed air supply fails?

- Fail-Close: If the valve must shut to prevent a spill or halt a process, a single-acting, spring-return actuator is the only choice. The spring forces it closed when the air is gone.

- Fail-Open: If the valve needs to open to relieve pressure or allow coolant to flow, you’ll want a fail-open configuration.

- Fail-in-Place: If the valve's position isn't critical during a power loss and it can just stay put, a double-acting actuator might be a more straightforward and cost-effective option.

By systematically working through torque, environment, air supply, and the fail-safe action, you build a solid specification. This structured approach ensures the pneumatic actuated valve you choose will be a reliable, long-lasting, and safe part of your system.

Common Applications Across UK Industries

It's one thing to talk about technical specs, but where the real value of a pneumatic actuated valve shines is out in the field. These devices are the quiet workhorses humming away behind the scenes in some of the UK’s most critical industries. They’re not just components; they are essential for everything from keeping our drinking water pure to preventing disasters on oil rigs.

By looking at where they are used, we can see a clear line between their design features—like fail-safe action and spark-free operation—and the real-world problems they solve every day. Let’s explore where these valves are making a genuine impact.

Water and Wastewater Treatment

In the UK's vast water treatment network, you simply can't compromise on precision or reliability. Pneumatic actuated valves are a cornerstone of these facilities, handling everything from raw water intake to the precise dosing of treatment chemicals. Their ability to cycle on and off rapidly is perfect for controlling flow through filters and membranes.

What’s more, their non-electric nature makes them the ideal, low-maintenance choice for damp or corrosive environments. It’s no surprise they’re so common across the country. In fact, trends show that over 70% of new valve installations in UK wastewater treatment plants since 2022 have used pneumatic actuators. This is largely driven by their speed and the fact they eliminate spark risk in areas where flammable gases can be released from biological sludge processes. You can learn more about the global market trends behind this move by exploring the full research on pneumatic valve actuators.

This reliance on air-powered control is a fundamental part of modern utility management. For a solid grounding in the principles at play, take a look at our guide on pneumatic system basics.

Oil and Gas Production

Nowhere is the safety benefit of a pneumatic actuated valve more critical than in the oil and gas industry. On offshore platforms in the North Sea and at onshore processing facilities, the air is often thick with flammable hydrocarbons. In these hazardous zones, a single spark could be catastrophic.

This is where the intrinsically safe design of pneumatic actuators really proves its worth. They form the backbone of vital safety systems, especially:

- Emergency Shutdown (ESD) Systems: These valves must slam shut in seconds to isolate a pipeline or piece of equipment in an emergency. Single-acting, spring-return actuators provide that guaranteed fail-safe action every time.

- Process Control: They expertly manage the flow of crude oil, natural gas, and refined products without introducing any ignition source into the environment.

In such a high-stakes environment, the choice is simple. The robust, non-electric, and fail-safe operation of a pneumatic actuated valve isn’t just a preference—it’s an absolutely essential layer of protection for workers and multi-billion-pound assets.

Food, Beverage and Pharmaceuticals

In sectors where hygiene and precision are everything, pneumatic actuated valves are once again the preferred choice, but for a different set of reasons. Here, the game is all about cleanliness, batch consistency, and avoiding contamination at all costs.

Walk through a modern food production line or a pharmaceutical plant, and you'll find these valves controlling the flow of ingredients with incredible accuracy. Stainless steel valves paired with pneumatic actuators give a smooth, crevice-free surface that is easy to clean and sterilise, leaving no place for bacteria to hide. They are commonly used for:

- Batching and Mixing: Adding the perfect amount of each ingredient to a mixture, every single time.

- Clean-in-Place (CIP) Systems: Diverting powerful cleaning fluids and steam through the pipework to maintain sterile conditions.

- Filling and Packaging: Handling the fast, repetitive cycles required for bottling or packaging lines without fail.

From dairies and breweries to pharmaceutical manufacturing, the clean, reliable, and precise control offered by a pneumatic actuated valve makes it an indispensable tool for delivering safe, high-quality products.

Frequently Asked Questions

Even when you've got the basics down, a few practical questions always pop up when it comes time to specify, install, or look after a pneumatic actuated valve. Let's tackle some of the most common queries with clear, straightforward answers to help you get the most out of these essential components.

What Maintenance Does a Pneumatic Actuated Valve Require?

The good news is that maintenance is generally minimal, but what little is required is absolutely vital for long-term reliability. The single most important thing you can do is look after your compressed air supply.

Making sure the air is clean and dry is non-negotiable; it's the best way to prevent internal corrosion and stop seals from getting damaged. Beyond that, a simple, regular inspection schedule is usually all it takes. You'll want to check seals and O-rings for any signs of wear or brittleness and lubricate the moving parts based on what the manufacturer recommends. It's also a great idea to cycle the valve every now and then, especially if it sits in one position for long periods, just to keep everything moving smoothly.

Can I Control the Speed of a Pneumatic Actuator?

Yes, absolutely. Controlling the speed of a pneumatic actuator is a very common requirement, and thankfully, it’s quite simple to do. The standard way to achieve this is by fitting flow control valves, which are often just called speed controllers, onto the air lines that feed the actuator.

These small but effective regulators let you precisely meter the amount of air going into or, more commonly, coming out of the actuator. A quick adjustment allows you to fine-tune the opening and closing speed to perfectly match your process needs. This is critical for preventing issues like "water hammer" in liquid lines or for any task that needs a more gentle, controlled motion.

Practical Tip: For the smoothest action, you'll want to slow down the valve's movement by restricting the air as it exhausts from the actuator, not as it enters. This creates a cushion of back pressure, giving you much more controlled and less jerky movement.

What Is the Difference Between Fail Open and Fail Close?

This is all about safety. The terms describe what the valve does by default if the power or air pressure is suddenly lost, a key feature of single-acting, spring-return actuators. Deciding between them comes down to one simple question: what is the safest state for the system during a failure?

Fail-Close (FC): When the air supply cuts out, the valve automatically shuts and stops the flow. This is the most common setup and is essential for any application where you need to contain a hazardous material or prevent a tank from overflowing. Think of it as the default "safe-off" position.

Fail-Open (FO): In this case, the valve automatically moves to the open position when there's a failure. This is crucial for systems where you need to prevent a dangerous pressure build-up, like in pressure relief lines, or for certain cooling systems where a continuous flow must be maintained at all costs to ensure safety.

At Solenoid Valve World, we offer an extensive range of pneumatic actuated valve solutions to meet the demanding requirements of any industry. Explore our catalogue to find the perfect components for your application.