Pneumatic Actuators for Valves: Your Complete Control Guide

How Pneumatic Actuators Transform Valve Control

Picture a busy factory. Conveyors hum, machines whir, and amidst it all, valves carefully control the flow of liquids and gases. These valves aren't controlled manually anymore. Instead, pneumatic actuators automate them, acting as the silent force behind modern industrial control. They harness the power of compressed air to open and close valves with impressive speed and accuracy.

This is a huge leap from the old days of manual valve operation. Back then, workers had to physically crank valves open and closed, a slow, labour-intensive, and error-prone process.

Pneumatic actuators offer a simple but powerful solution. They convert compressed air energy into mechanical motion, like the "muscle" that operates the valve. Think of compressed air as the fuel, and the actuator as the engine converting that fuel into useful work.

This work can range from precisely regulating chemicals in a processing plant to quickly shutting off a valve in an emergency.

The Impact on UK Industries

This change in valve control has significantly affected UK industries. The UK industrial sector has seen increased adoption of pneumatic actuators, fuelled by automation and renewable energy investments. This shift also stems from the UK's focus on smart factories and automated manufacturing. This has led to integrating pneumatic actuators into systems like robotic equipment, conveyor belts, and packaging machinery across various sectors. These sectors include food processing, pharmaceuticals, and Automobile manufacturing. Discover more insights on this trend. This widespread use highlights their importance in modern operations.

Understanding the Power of Air: From Pressure to Motion

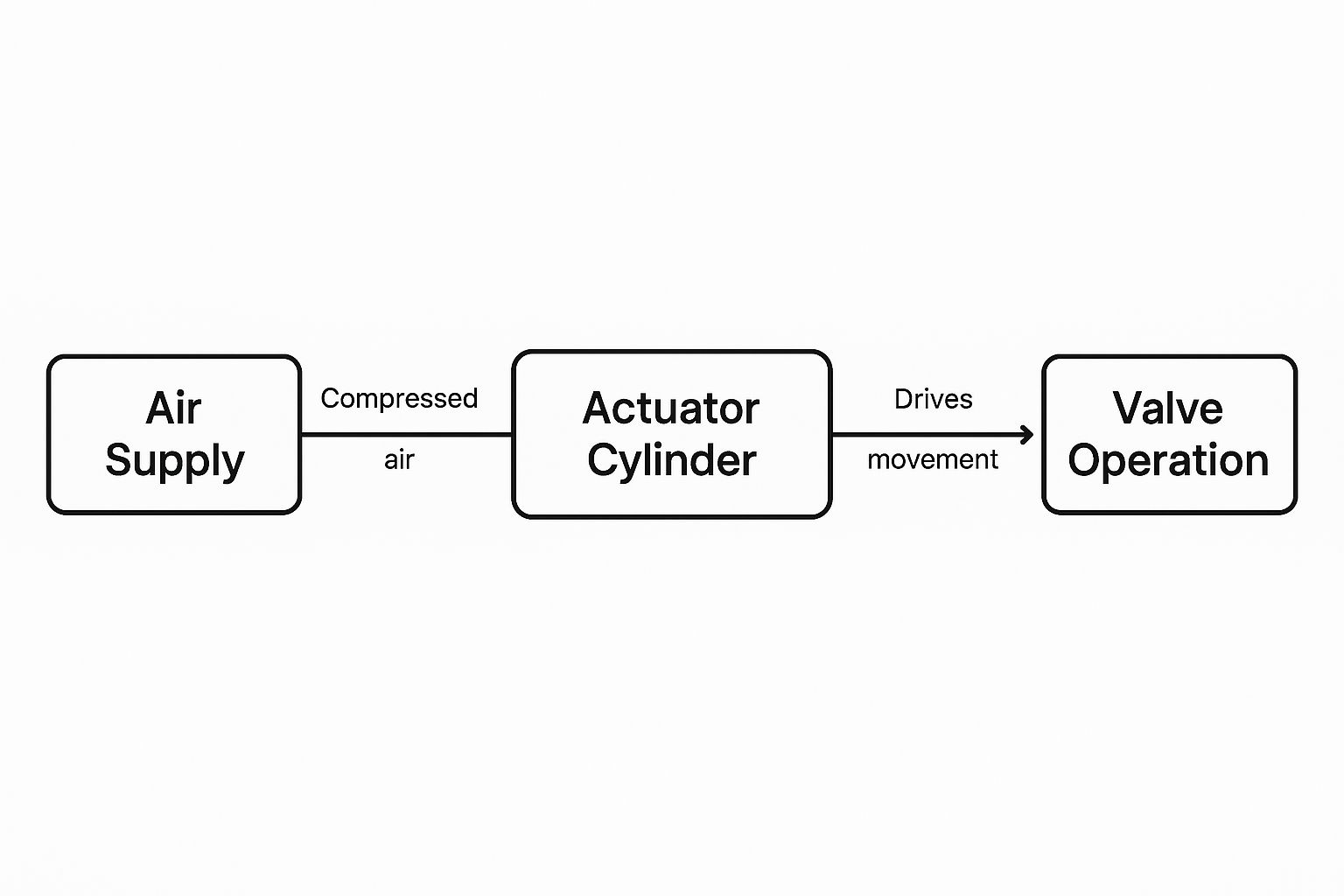

So, how do these systems work? At the heart of a pneumatic actuator is a piston inside a cylinder. Compressed air enters the cylinder, pushing the piston and creating linear motion. This linear motion then converts into the rotary or linear motion needed to operate the valve.

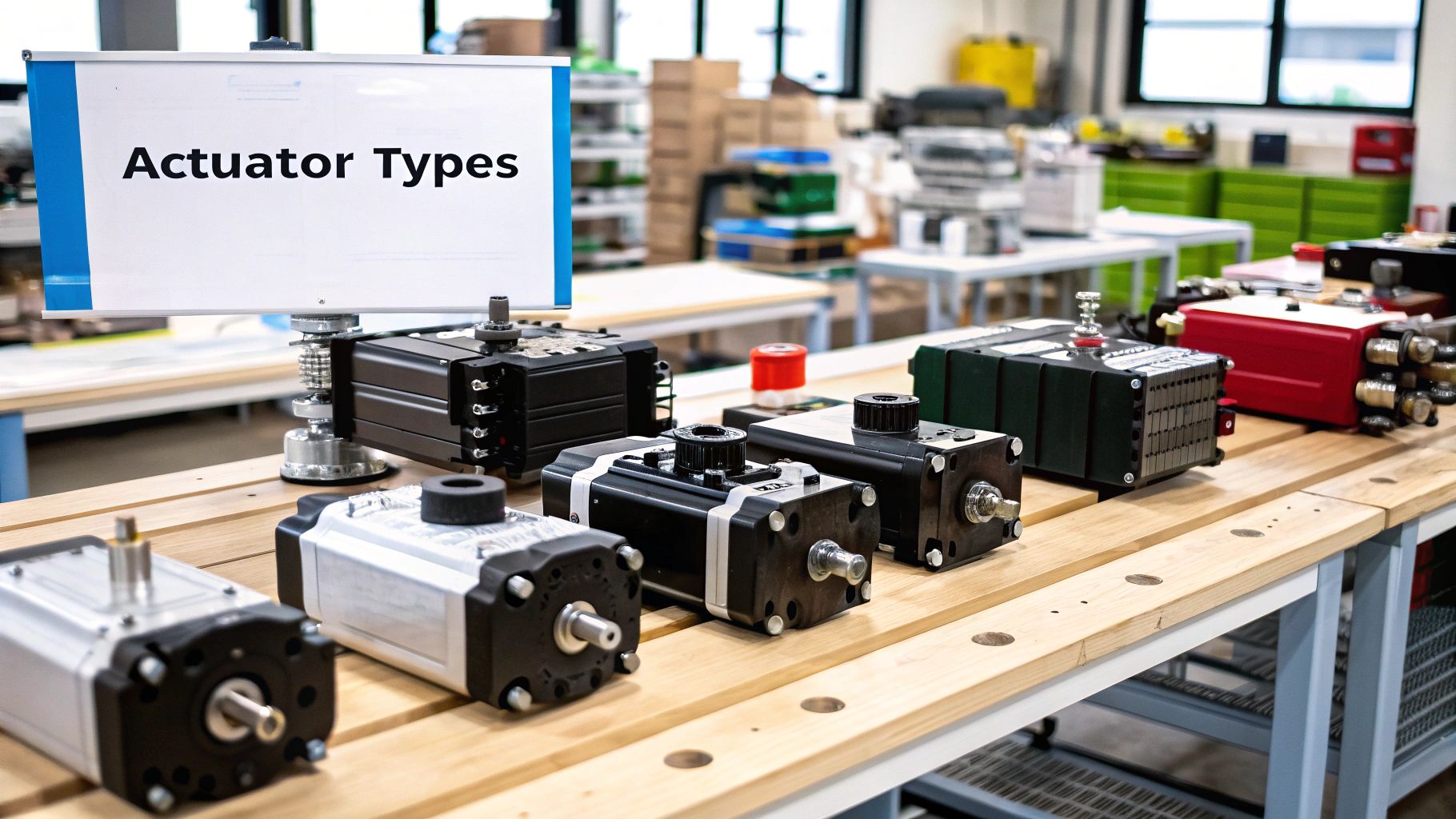

Different pneumatic actuator types, such as rack-and-pinion or scotch yoke designs, use different mechanisms for this conversion. Each design suits specific valve types and applications. You might be interested in: exploring the basics of pneumatic systems.

Why Choose Pneumatic? Reliability, Simplicity, and Safety

Pneumatic actuators have several advantages over other actuation technologies. Their simplicity leads to robust performance and minimal maintenance. They're inherently safe – unlike electrical systems, there's no spark risk in hazardous environments. Plus, their speed is unmatched, making them perfect for applications needing rapid response, such as emergency shutdowns.

These benefits explain why pneumatic actuators have become the go-to choice in so many industries, from oil and gas to pharmaceuticals and food processing. Their ability to provide precise control, reliable operation, and increased safety makes them vital in today's intricate industrial processes.

Choosing the Right Actuator for Your Application

Picking the right pneumatic actuator for your valve is a bit like choosing the right tool for a job. You wouldn’t use a hammer to tighten a screw, right? The same principle applies here: understanding the different types of pneumatic actuators is key to getting the best performance and avoiding costly mistakes. It all starts with grasping the basic relationship between air pressure and mechanical force. More air pressure equals more force to move the valve – simple as that.

This infographic shows how it works: compressed air enters the actuator cylinder and creates the force needed to control the valve. It highlights the direct connection between your air supply, the actuator's movement, and how you ultimately control the valve.

Spring-Return vs. Double-Acting Actuators

One of the first decisions you'll face is choosing between spring-return and double-acting actuators. Spring-return actuators have a built-in spring that returns the valve to its default position (usually closed) if the air pressure drops. Think of it as a safety net. This is crucial in safety-critical systems. Imagine a chemical plant during a power outage – spring-return actuators would automatically shut off valves, preventing potentially dangerous leaks.

Double-acting actuators, on the other hand, use air pressure for both opening and closing the valve. This gives you precise control in both directions, perfect for applications like regulating flow rates in a water treatment facility.

Linear vs. Rotary Actuators: Matching Motion to Valve Type

The type of valve you're working with determines whether you need a linear or rotary actuator. Linear actuators produce a straight-line push or pull, ideal for sliding-stem valves often found in process control systems. Rotary actuators create a turning motion, perfect for quarter-turn valves like ball and butterfly valves common in pipelines and industrial settings. The actuator's movement has to match the valve's design to work properly.

Rack-and-Pinion, Scotch Yoke, and Vane Actuators: Decoding Performance Characteristics

Rotary actuators can be further broken down into different types. Rack-and-pinion actuators are known for their consistent torque, making them reliable in demanding applications. Scotch-yoke actuators, however, deliver higher torque at the beginning and end of their rotation, useful for valves that need extra force to start and finish their movement. Finally, compact vane actuators are the space-savers, perfect for tight installations where larger actuators just won't fit.

To help you visualize the differences, let’s look at a comparison table:

| Actuator Type | Motion Type | Best Valve Applications | Key Advantages | Typical Torque Range |

|---|---|---|---|---|

| Rack-and-Pinion | Rotary | General purpose, high cycle applications | Reliable, consistent torque | Wide range available, from low to high |

| Scotch Yoke | Rotary | On-off applications requiring high starting and ending torque | High breakaway and seating torque | Medium to high |

| Vane | Rotary | Compact installations, limited space | Small size, lightweight | Low to medium |

| Linear (Diaphragm) | Linear | Sliding-stem valves | Simple, cost-effective | Low to medium |

| Linear (Piston) | Linear | Sliding-stem valves requiring high force | High thrust force | Medium to high |

This table summarizes the key features of each actuator type, making it easier to choose the right one for your needs. Remember, selecting the right actuator isn’t just a technical detail – it directly impacts your system's performance.

Choosing the right actuator isn't simply a matter of picking one from a catalog; it has tangible real-world consequences. A poorly matched actuator can lead to unreliable system performance, increased maintenance costs, and even safety hazards. For example, an undersized actuator might struggle to operate a large valve, while an oversized one could damage it. Factors like the valve’s torque requirements, the operating environment, required speed, and any fail-safe needs all play a role in the decision-making process. For more information on selecting the right valve, you can Check out our guide on: solenoid valves. In the end, choosing wisely means your pneumatic actuators will provide the precise control your systems require, leading to better efficiency, improved safety, and a boost in overall performance.

Why Engineers Choose Pneumatic Over Everything Else

What makes pneumatic actuators the top pick for so many control engineers in the UK when it comes to valves? It boils down to a powerful trio of advantages: speed, simplicity, and inherent safety. Let's explore why these qualities are so important.

The Need for Speed: Rapid Response in Critical Situations

Picture a chemical leak that demands an immediate valve shutdown. Seconds matter. Pneumatic systems shine in these high-pressure scenarios, reacting with lightning-fast speed. Their rapid response can be the difference between a near miss and a catastrophe.

This speed makes them perfect for emergency shutdowns, critical process control, and any application where quick action is essential.

Simplicity Equals Reliability: Fewer Moving Parts, Less to Go Wrong

Pneumatic actuators for valves have a beautifully simple mechanical design. With fewer moving parts, there are fewer opportunities for things to break down. This leads to lower maintenance costs, less downtime, and a more reliable system overall. This inherent simplicity builds robustness, keeping plants running smoothly and predictably.

Safety First: Inherently Safe in Hazardous Environments

In industries like oil and gas or chemical processing, explosion risks are a constant concern. Pneumatic systems offer a key advantage: they're inherently explosion-proof. Unlike electrical systems that can create sparks, pneumatic systems use compressed air, eliminating that ignition hazard.

This makes them the natural choice for hazardous environments where safety is paramount. The reliance on compressed air also gives pneumatic systems built-in overload protection. If a valve gets stuck, the pneumatic actuator simply stalls instead of breaking, preventing damage and ensuring a controlled response.

This self-protecting feature minimizes the risk of equipment failure and keeps operations flowing smoothly.

Performance in Extreme Conditions: Unfazed by Temperature Fluctuations

From the cold North Sea to the intense heat of industrial furnaces, UK facilities operate across a wide range of temperatures. Pneumatic systems maintain consistent performance even in these extreme environments. Unlike electric actuators, which can be affected by temperature swings, pneumatic actuators remain reliable regardless of the ambient conditions.

This makes them a versatile option for challenging locations. You might also find pneumatic solenoid valves interesting for more specialised uses.

The increasing use of automation across various sectors is driving the growth of pneumatic actuators in the UK. The global pneumatic actuators market, including the UK, was valued at roughly USD 51.71 billion in 2023 and is expected to grow at a CAGR of 5.2% from 2024 to 2030. Discover more insights.

These combined advantages make pneumatic actuators the preferred solution for engineers in demanding industries across the UK. Their reliability, speed, safety, and resilience are crucial for maintaining smooth operations, minimising downtime, and ensuring safe and efficient processes.

Sizing and Selection That Actually Works

Picking the right pneumatic actuator for your valve isn't about grabbing the biggest, most expensive one on the shelf. It's more like finding the right shoes for a hike – you need something that fits the terrain and the demands of your journey. In the case of valves, it's about precisely matching the actuator's capabilities to the valve's specific needs.

Understanding Valve Torque Requirements

The first step in sizing a pneumatic actuator is figuring out how much force is needed to turn the valve. This rotational force is called valve torque, and you'll usually find it listed in the valve manufacturer’s data sheet. Think of it like loosening a nut – a larger, tighter nut requires more force than a smaller one.

Adding Safety Factors: Planning for the Unexpected

Once you know the valve torque, you need to add a safety factor. This extra cushion accounts for things like wear and tear, fluctuations in air pressure, and potential blockages. A typical safety factor is between 1.5 and 2, meaning the actuator should be able to generate 1.5 to 2 times the required valve torque. This is like building a bridge to hold more weight than it's expected to carry – it's that extra bit of security.

Environmental Impacts on Performance

Just like you wouldn't wear sandals in a blizzard, you need to consider the impact of the environment on your actuator's performance. Extreme temperatures can affect the actuator’s seals and lubricants, impacting its effectiveness and lifespan. For challenging environments, specialised actuators designed for extreme temperatures or corrosive atmospheres might be necessary.

Sizing Calculations: Air Pressure, Actuator Area, and Output Force

The magic of sizing calculations lies in understanding how air pressure, actuator area, and output force all work together. The force the actuator produces is directly related to the air pressure and the area of the actuator's piston. Higher air pressure or a larger piston area equals more force. Imagine pushing a button: a larger button requires less pressure to activate.

Decoding Manufacturer Data Sheets: Understanding Performance Curves

Manufacturer data sheets are like a treasure map to understanding actuator performance. They contain valuable information, including performance curves that show the relationship between air pressure and output force or torque. These curves tell you how the actuator will behave under real-world conditions, which is essential for choosing the right one.

Insider Tips for Reliable Performance

Here are a few practical tips to ensure your pneumatic actuator provides reliable performance for years to come:

Over-sizing vs. Under-sizing: Avoid both extremes. Over-sizing wastes energy and money, while under-sizing risks the actuator not being powerful enough to operate the valve reliably. It's about finding the "Connexion" actuator – just the right size for the job.

Maintenance and Lubrication: Regular maintenance, including checking for leaks, cleaning filters, and lubrication, keeps your actuator running smoothly and extends its lifespan. Just like a car needs regular oil changes, your actuator needs some TLC.

Material Compatibility: Make sure the actuator's materials are compatible with the fluids it will be handling. If your valve controls corrosive chemicals, your actuator needs to be made of something that can withstand those chemicals.

To help you navigate the selection process, we've compiled a handy table summarising the key considerations:

Actuator Selection Criteria Matrix

Essential factors to consider when selecting pneumatic actuators, including valve requirements, environmental conditions, and performance specifications

| Selection Factor | Key Considerations | Impact on Performance | Typical Values/Ranges |

|---|---|---|---|

| Valve Torque | Required rotational force to operate the valve | Determines the minimum actuator output torque | Valve manufacturer's data sheet |

| Safety Factor | Accounts for variations in operating conditions | Ensures reliable operation under less-than-ideal conditions | 1.5 - 2 |

| Air Pressure | Available air supply pressure | Affects actuator output force | Manufacturer's specifications |

| Actuator Area | Effective area of the actuator piston | Influences actuator output force | Manufacturer's specifications |

| Environmental Conditions | Temperature, humidity, corrosive atmosphere | Impacts actuator performance and lifespan | Consider specialised actuators for extreme environments |

| Performance Curves | Relationship between air pressure and output force/torque | Provides real-world performance data | Manufacturer's data sheets |

This table provides a framework for selecting the right actuator for your application. By considering these factors, you can ensure reliable and efficient valve operation.

By taking a systematic approach and considering these factors, you can select pneumatic actuators that provide dependable and efficient performance over their lifespan. This not only minimises downtime and maintenance costs but also ensures safe and optimal operation of your entire valve control system.

Installation Secrets From the Pros

Even the top-of-the-line pneumatic actuators won't perform if installed incorrectly. This section delves into the tricks of the trade that seasoned professionals use to ensure a smooth setup and years of reliable service. Proper lifting equipment is essential during installation. If you need resources on this, check out Lifting Equipment Hire. Now, let's dive into the core elements of actuator installation.

Mounting Strategies: Preventing Stress and Premature Failures

Think of mounting an actuator like building a house: a solid foundation is paramount. Incorrect mounting can concentrate stress on certain points, weakening the actuator over time and leading to early failure. Just as a house with a shaky foundation will develop cracks, a poorly mounted actuator will eventually give way under operational stress.

Experts use specific mounting techniques, such as correctly sized brackets and precise bolt tightening torques, to distribute stress evenly and avoid these problems.

Air Line Routing: Maintaining Signal Integrity

The air lines supplying compressed air to your actuators are like the nervous system of your control system. Proper routing is vital to maintain signal integrity, ensuring the air pressure reaches the actuator quickly and consistently. Imagine a kinked garden hose restricting water flow. Similarly, poorly routed air lines can impede airflow, causing slow actuator response and diminished performance.

Professionals avoid sharp bends and select appropriate tubing materials to minimise pressure drops and keep actuators responsive.

Connection Techniques: Withstanding the Test of Time

The connections between your actuators and valves must endure the harsh realities of industrial environments: temperature swings, vibrations, and constant cycling. Cutting corners here is a recipe for disaster. Think of loose wiring in your house – it’s a fire hazard. Similarly, loose or incorrect connections in your pneumatic system can cause leaks, poor performance, and even safety issues.

Experts use specialised fittings and correct tightening techniques to create robust, leak-free connections built to last.

Actuator Orientation and Bracket Design: The Fine Details That Matter

Even seemingly small details like actuator orientation can significantly impact performance and lifespan. Mounting an actuator in the wrong position can place unnecessary stress on internal components, leading to premature wear and tear.

Likewise, well-designed brackets are crucial for proper alignment between the actuator and the valve. Misalignment can cause binding, increased friction, and a shortened actuator life. Think of a misaligned door – it’s difficult to operate.

Pros pay close attention to these nuances, ensuring the actuator is orientated correctly and the brackets maintain perfect alignment. They recognise that these small details have a big impact in the long run. By focusing on these seemingly minor points and following best practices, you can ensure your pneumatic actuator installation is professionally done, maximising its lifespan and ensuring reliable operation.

Real-World Success Stories Across Industries

Pneumatic valve actuators are the quiet workhorses of countless industries throughout the UK. They're not just theoretical devices; they're actively ensuring safety and efficiency in places you might not even think about, from the harsh conditions of offshore oil platforms to the precise needs of pharmaceutical manufacturing. These tough pieces of equipment truly show their value where reliability is absolutely essential.

Ensuring Safety and Efficiency in Demanding Environments

Imagine a water treatment facility facing a contamination event. Quick action is crucial. Pneumatic actuators, with their rapid response, jump into action, isolating the contaminated area to protect public health and minimise environmental damage.

Likewise, in chemical processing plants, safety is paramount. The intrinsically safe operation of pneumatic actuators, driven by compressed air rather than electricity, eliminates the risk of sparks in volatile environments, protecting workers and preventing potential disasters.

Power generation is another area where precision is key. Here, pneumatic actuators control steam flow, and their accuracy directly impacts both efficiency and safety margins. Proper installation and maintenance are crucial, often involving surface preparation. Depending on the actuator type, this might involve understanding how to strip paint from metal. This resource offers helpful advice on different methods and best practices for proper surface preparation.

Hygienic Design and Automation in Food Production

Even in the food industry, hygiene is paramount. Pneumatic actuators, designed with sanitation in mind, can withstand frequent wash-downs without impacting performance. This ensures food safety and compliance with strict regulations, making them a perfect fit for this demanding sector.

And speaking of demanding, the UK automotive actuators market, including pneumatic versions, reached USD 2.8 billion in 2024. It's expected to grow to a whopping USD 5.26 billion by 2031. You can find more details on this growth here. This highlights the increasing automation and technological advancements in the automotive industry, where pneumatic actuators play a key role in reliable and efficient manufacturing.

From Routine Tasks to Mission-Critical Operations

The versatility of pneumatic valve control is truly impressive. They handle everything from routine but important jobs like managing flow rates in pipelines to critical operations like emergency shutdowns in hazardous environments.

Learning From Industry Experts and Real-World Examples

By exploring real-world case studies and listening to experienced professionals, we can truly appreciate how pneumatic actuators solve unique challenges in various industries. These stories demonstrate the remarkable adaptability and dependability of this robust technology. They highlight the value and effectiveness of pneumatic valve control in diverse settings, showcasing their adaptability and long-term advantages. From everyday applications to complex, mission-critical installations, pneumatic actuators consistently deliver the precise control and reliability required in today's challenging industrial landscapes.

Your Next Steps to Pneumatic Success

So, you’ve got a good grasp on pneumatic valve actuators. Now, let's talk about putting that knowledge to work, whether you're updating older systems, designing brand new automated setups, or troubleshooting existing problems.

Building Productive Supplier Relationships

Finding the right supplier is like finding a reliable mechanic – you want someone who does more than just sell you parts. Look for a partner who understands your specific needs and can offer expert advice. A good supplier becomes an extension of your team, supporting you from the initial design phase all the way through to ongoing maintenance. This collaboration ensures you select the correct pneumatic actuators and have access to dependable support when you need it.

Navigating Technical Specifications

Technical specs can seem daunting, like reading a foreign language. But don't worry! Once you understand key parameters like valve torque, actuator size, and air pressure requirements, you can confidently evaluate your options and make informed decisions. Think of it like choosing the right engine for a car - you need to understand horsepower and torque to make the best choice. Your supplier can act as your translator, clarifying any confusing information and guiding you towards the best fit for your application.

Implementation Strategies That Minimise Disruption

Upgrading to pneumatic valve actuators doesn't have to be a major overhaul. Think of it like remodelling a kitchen – you can do it in phases to minimise disruption to your daily life. By carefully planning your implementation with your supplier, you can minimise downtime and transition smoothly to automated control. A phased approach lets you upgrade systems incrementally, keeping your processes running without a hitch.

Addressing Cost Concerns and Demonstrating ROI

Investing in pneumatic actuators might seem like a significant upfront cost, but the long-term benefits are like compound interest - they add up over time. Automation reduces labor costs, improves efficiency, and enhances safety, leading to a demonstrable return on investment (ROI). To convince stakeholders, build a business case that highlights these benefits, much like presenting a compelling investment opportunity.

Focus on tangible advantages:

- Reduced downtime

- Increased production output

- Improved quality control

Quantify these benefits whenever possible to showcase the clear financial return of choosing pneumatic solutions. For example, calculate how much money you'll save by reducing downtime by a certain percentage.

By following these practical steps, you can confidently implement pneumatic actuators for valves, achieving substantial improvements in efficiency, reliability, and safety within your operations. Your journey toward optimised valve control starts with knowledge and ends with successful application.

Ready to dive deeper into the world of pneumatic control? Visit Solenoid Valve World for a comprehensive selection of solenoid valves, pneumatic actuators, and expert technical advice tailored to your needs.