Pneumatic Angle Seat Piston Valves: Complete Guide

Understanding What Makes These Valves Special

In the world of industrial fluid control, not all valves are the same. Think of pneumatic angle seat piston valves as the high-performance sprinters of automation—built for speed, precision, and relentless endurance. While many traditional valves create obstacles for the media they control, forcing it through restrictive, winding paths, these specialised designs work in harmony with the flow. This fundamental difference is what sets them apart, delivering a level of efficiency and reliability that is essential in demanding environments.

Their unique construction allows them to handle conditions that would cause more conventional valve types, like standard ball or globe valves, to falter or fail completely. They are engineered to perform where others can't.

The Ingenuity of the Angled Design

The secret to their superior performance lies in the name itself: the angle seat. Unlike a traditional globe valve where the fluid must make two sharp turns, creating significant turbulence and pressure drop, the pneumatic angle seat piston valve features a streamlined, Y-shaped body. This geometry creates a much smoother, almost straight-through flow path when the valve is open.

Imagine a busy motorway. A standard valve is like a junction with multiple tight, 90-degree turns and stop signs, causing traffic to slow down, bunch up, and waste fuel. An angle seat valve, in contrast, is like a gentle, sweeping slip road that allows traffic to merge seamlessly at high speed. This design distinction is critical; it means:

Higher Flow Rates: The unrestricted path allows for a flow capacity that is often up to 30% greater than comparable globe valves.

Minimal Pressure Loss: Less turbulence means less energy is wasted, preserving pressure within the system.

Reduced Water Hammer: The smooth closing action, guided by the piston, helps to prevent the damaging hydraulic shock waves known as water hammer.

To better understand these differences, let's compare the design features of an angle seat valve directly against a traditional globe valve.

Design Comparison: Angle Seat vs Traditional Globe Valves

A detailed comparison showing key design differences and their impact on performance characteristics

| Feature | Angle Seat Design | Traditional Globe | Performance Impact |

|---|---|---|---|

| Body Shape | Y-shaped or angled body. | S-shaped or Z-shaped body. | The Y-shape provides a much straighter, less restrictive flow path. |

| Flow Path | Fluid makes a gentle turn (approx. 45°). | Fluid makes two sharp 90° turns. | Drastically reduces turbulence and pressure loss in angle seat valves. |

| Actuation Speed | Piston actuator provides very fast opening/closing (milliseconds). | Often slower; may use diaphragms or multi-turn handwheels. | Angle seat valves are ideal for high-cycle, time-critical applications. |

| Flow Capacity (Cv) | High; up to 30% more flow than a globe valve of the same size. | Lower due to the tortuous flow path. | Allows for smaller, more cost-effective valves for the same flow requirement. |

| Water Hammer | Inherently resistant due to controlled closing against the flow. | More susceptible to water hammer on fast closure. | Protects pipework and other system components from hydraulic shock. |

| Slurry/Viscous Media | Handles fluids with suspended solids well due to open path. | Prone to clogging and erosion in the complex flow path. | More versatile for challenging media like slurries, viscous liquids, or steam. |

This table shows that the angle seat valve's design isn't just a minor variation; it's a complete re-thinking of flow dynamics that leads to tangible performance gains in demanding industrial settings.

The Power of the Piston Actuator

The other key component is the pneumatic piston actuator. This is the engine that drives the valve's rapid response. When compressed air is supplied to the actuator, it forces a piston to move linearly, swiftly lifting the valve seal off its angled seat. This direct, powerful motion allows the valve to open or close in milliseconds, a speed essential for high-cycle applications like bottling plants or textile dyeing machinery where precise timing is everything.

The pneumatic angle seat piston valve has been a trusted component in UK and European industrial markets for over 50 years. This long history speaks to the effectiveness of its robust design, which centres on a piston actuator operating with a fast, precise linear stroke. The distinctive angle seat configuration optimises for high flow rates and remarkable durability, making these valves exceptionally well-suited for the most demanding operational environments. To find out more about their long-standing role, you can explore detailed information on actuated angle seat valves at Valves Online.

How These Valves Actually Work In The Real World

Beyond the technical drawings, the real-world performance of pneumatic angle seat piston valves is a story of speed and precision. Picture a large-scale brewery's bottling line. Thousands of bottles need filling with perfect accuracy every hour. A valve controls each fill, stop, and release cycle. A slow or faulty valve here doesn't just mean a minor hiccup; it leads to wasted product, under-filled bottles, and costly production delays. This high-stakes environment is exactly where the angle seat valve excels.

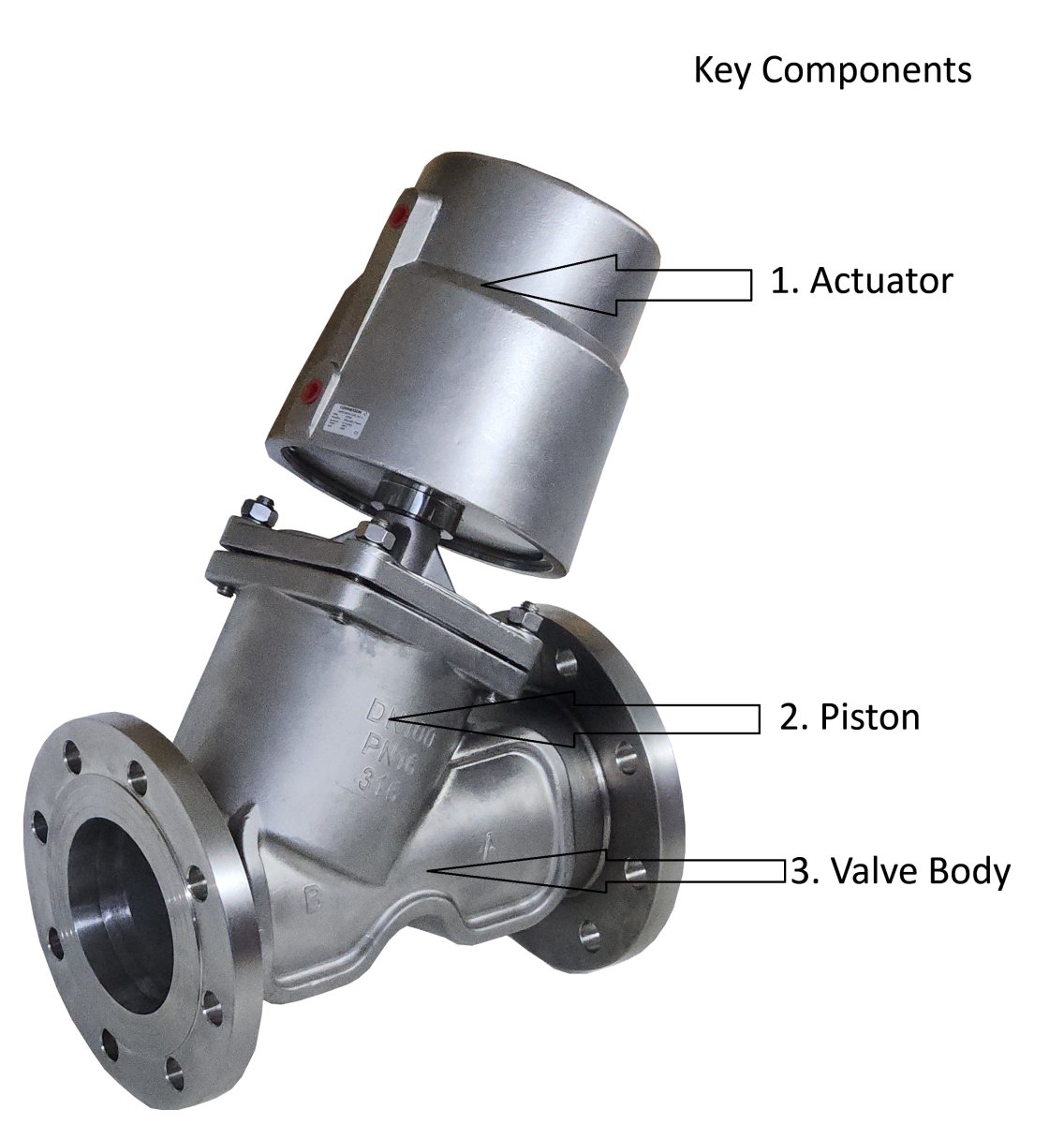

The infographic below shows the key components that make this level of performance possible.

This close-up view highlights how the powerful actuator, strong body, and carefully designed seat combine into a single, highly effective unit.

The Complete Operating Sequence

The operation is a masterpiece of mechanical efficiency, set in motion by a simple pulse of compressed air. This sequence happens in milliseconds, which is why these valves can achieve life spans exceeding 10 million cycles in some cases.

It all starts when a control signal is sent to an external pilot valve. Once activated, the pilot valve funnels compressed air into the port of the large piston actuator that sits on top of the valve body. If you're interested in the specifics of pilot valves, our guide on pneumatic solenoid valves provides more detail.

This burst of pressurised air acts on the piston, forcing it to move. The piston is attached to a stem, which holds the valve's seal. As the piston shifts, it rapidly pulls the stem and seal away from the angled valve seat. This action creates a clear, almost unobstructed pathway for the fluid or gas to flow through. The entire opening motion is incredibly quick and forceful.

To close the valve, the compressed air supply is vented away from the actuator. A powerful return spring inside the actuator then takes charge, slamming the piston and stem back into place. This drives the seal firmly against the angled seat, cutting off the flow cleanly and creating a tight seal. This spring-return design also serves as a critical fail-safe mechanism. If the compressed air is lost, the spring automatically pushes the valve into its default state (usually closed), preventing any uncontrolled flow and protecting the entire system.

Thriving Under Pressure

This rapid, robust cycle is what makes pneumatic angle seat piston valves essential in industries where any downtime is a major problem. For example, in a chemical processing plant, they might dose precise amounts of aggressive chemicals into a reactor. A standard valve could fail quickly due to corrosion or constant use, but the angle seat valve’s durable materials and simple mechanics ensure it operates reliably for years.

The table below gives an idea of their performance across different industrial settings.

Operating Characteristics Across Different Applications

Performance data showing response times, cycle rates, and reliability metrics for various industrial applications

| Application | Typical Cycle Time | Expected Life Cycles | Maintenance Interval |

|---|---|---|---|

| Food & Beverage (Bottling) | 50-100 milliseconds | 5-10 Million+ | 12-24 Months |

| Chemical Dosing | 100-200 milliseconds | 3-7 Million | 6-18 Months |

| Steam Control (Industrial Laundry) | 150-300 milliseconds | 2-5 Million | 18-36 Months |

| Water Treatment | 200-500 milliseconds | 4-8 Million | 24-48 Months |

As shown, these valves maintain impressive cycle times and lifespans even in demanding conditions, with maintenance needs varying based on the intensity of the application.

In large-scale water treatment plants, these valves are trusted to manage the flow of various chemicals. Their consistent operation and fail-safe design are vital for protecting public health. Their ability to handle high temperatures also makes them a prime choice for controlling steam in industrial laundries or for high-temperature sterilisation in the food and pharmaceutical sectors. Their simple yet powerful operation is their greatest asset.

Materials That Make Or Break Performance

The long-term success of any pneumatic angle seat piston valve installation comes down to a choice made long before the first pipe is connected: the material. Selecting the right materials for the valve body and its seals isn't just a small detail; it's the difference between a valve that runs smoothly for years and one that causes constant maintenance issues. This choice is a careful balance between the fluid being controlled, the operating temperature, and industry-specific regulations.

Body Materials: The First Line of Defence

The valve body is the main shield against the process media, making its material makeup critically important. For most general uses involving water, air, or neutral fluids, 304 stainless steel provides a dependable and budget-friendly option. However, when the working environment gets tougher, an upgrade is necessary.

For applications with corrosive chemicals, salt water, or certain food and pharmaceutical products, 316L stainless steel is the clear winner. The addition of molybdenum in the 316L grade gives it much better resistance to chlorides and acids, stopping the pitting and corrosion that would ruin a standard 304 body. For a plant engineer, choosing 316L for a chemical dosing line isn’t an extra cost; it’s a smart move to prevent system failure and maintain product purity. The "L" stands for low carbon, which improves corrosion resistance after welding—a key factor during system assembly.

Seal Materials: The Unsung Heroes of Reliability

While the body provides the structure, the internal seals are what guarantee a tight shut-off, time after time. The choice of seal material is entirely guided by the application.

PTFE (Polytetrafluoroethylene): Often the standard choice, PTFE performs exceptionally well in many situations. It has excellent chemical resistance and can cope with very high temperatures, making it perfect for steam and harsh fluids. Its low-friction surface also helps it last for many cycles. However, PTFE is quite hard and can struggle with dirty media, where small particles might prevent a perfect seal.

EPDM (Ethylene Propylene Diene Monomer): When working with water or steam applications that don't involve oils or fats, EPDM is a great, and often cheaper, alternative to PTFE. It creates a fantastic seal, especially at lower pressures, but it doesn't hold up well against petroleum-based fluids.

FKM (Fluoroelastomer): For jobs involving oils, fuels, and many chemicals at high temperatures, FKM (Viton) is the material you need. It offers strong performance where EPDM or other rubbers would quickly break down.

Navigating the Certification Maze

In many sectors, following the rules is essential. Certifications aren't just pieces of paper; they are proof that a valve is safe and fit for its intended environment. For pneumatic angle seat piston valves used in the UK and Europe, key certifications include:

CE Marking: This shows the product meets EU safety, health, and environmental protection standards.

ATEX Certification: This is vital for valves used in potentially explosive areas, like those found in the gas industry or chemical plants.

FDA Compliance: This is required for materials that touch food, drinks, or medicines, ensuring they are non-toxic and won't release harmful substances.

Real Applications Where These Valves Excel

The true measure of any industrial component isn't found in a catalogue, but in the demanding reality of a busy production facility. Pneumatic angle seat piston valves are the dependable workhorses in a surprising range of industries, from sterile pharmaceutical labs to the steam-filled environments of large-scale laundries. Their unique blend of speed, durability, and high flow makes them vital where process control is critical and failure is simply not an option.

Let's explore the specific fields where these valves truly shine.

Food and Beverage Production

In the food and beverage industry, hygiene and efficiency are the top priorities. Picture a large bottling plant where thousands of containers are filled every hour. Each filling cycle demands a valve that can open and close with split-second precision to pour the exact amount of liquid, preventing waste and contamination. The fast-acting nature of a pneumatic angle seat piston valve is a perfect fit for these high-cycle applications.

These facilities also rely on high-temperature sterilisation processes between batches. The valves excel here, effortlessly managing steam and hot cleaning fluids that would cause other valve types to fail. Their stainless steel construction and food-grade seal options ensure product purity is never compromised.

Key applications include:

Filling and Bottling Machinery: Providing precise control for drinks, sauces, and other liquids.

Clean-in-Place (CIP) Systems: Reliably managing the flow of hot water, steam, and cleaning agents.

Dairy Processing: Handling milk and other viscous products in pasteurisation and frothing equipment.

Chemical Processing and Pharmaceuticals

Chemical plants often present some of the harshest conditions for any equipment. Here, valves must control the flow of aggressive substances, often at extreme temperatures and pressures. A standard valve might corrode or fail, leading to dangerous leaks and expensive downtime. The robust design of angle seat control valves makes them a great choice. With bodies made from corrosion-resistant 316L stainless steel and seals from materials like PTFE, they can safely handle a wide variety of acids, alkalis, and solvents.

In the pharmaceutical world, precision and sterility are non-negotiable. These valves are used to accurately measure ingredients for drug manufacturing and to control the flow of purified water and steam for sterilising equipment. Their reliability ensures that production batches are consistent and meet strict regulatory standards. Within the UK, these valves are used widely in fine chemical manufacturing and water treatment where dependable control is essential. You can read more about the industrial reliance on this technology from Valves Online.

Water Treatment and General Industry

From municipal water treatment plants to industrial laundries and textile dyeing facilities, controlling the flow of water and steam is a daily challenge. Water treatment plants use these valves for dosing chemicals and managing filtration processes. Their ability to handle media with some suspended solids without clogging gives them an edge over more delicate valve designs. If you want a deeper look at their construction, you can check out our guide on angle seat piston valves for a full overview.

In industrial textile and laundry operations, they are the go-to solution for managing steam, ensuring dyeing processes are consistent and equipment runs smoothly. Crucially, their design helps to minimise water hammer, protecting the entire piping system from damaging hydraulic shocks.

Market Growth Driving Innovation Forward

The market for pneumatic angle seat piston valves is not just growing; it's being actively redefined by the push towards Industry 4.0 and greater automation worldwide. This expansion creates significant opportunities for facilities that can adopt these advanced valve technologies. The demand is no longer for simple components that open and close. Instead, industries need parts that integrate into digital systems, providing data and responding with incredible precision.

The Forces Behind Market Expansion

The main driver of this growth is the constant move towards automation across all industrial sectors. As manufacturing becomes more complex and production lines get faster, the need for components that can keep up is critical. Pneumatic angle seat piston valves, known for their fast cycle times and high reliability, are perfectly suited for this new environment. They have evolved from standalone mechanical devices into key players in "smart" manufacturing. This shift fuels the demand for valves fitted with position sensors and control heads that feed real-time performance data directly into central control systems like a PLC or DCS.

At the same time, new markets and applications are creating fresh demand. For instance:

Renewable Energy: Biogas production facilities require precise control over gas flow, often in difficult operating conditions.

Advanced Manufacturing: Industries using sophisticated processes, from textiles to electronics, depend on the split-second response times these valves offer.

Water Scarcity Solutions: Modern water and wastewater treatment plants rely on durable, automated valves to manage complex purification cycles efficiently.

This upward trend is backed by solid market projections. The global angle seat piston valve market was valued at roughly USD 1.02 billion in 2023 and is expected to reach around USD 1.39 billion by 2030. This growth is heavily influenced by the increasing need for automated solutions in UK industries like pharmaceuticals, chemical processing, and water treatment. Global forecasts point to a compound annual growth rate (CAGR) of about 4.3% between 2025 and 2033, showing a period of sustained expansion. You can discover more insights about these market projections from Valuates Reports.

This data highlights an important point for plant managers and engineers: investing in quality pneumatic angle seat piston valve technology is more than a simple maintenance decision. It's a strategic move that aligns a facility with the future of industrial efficiency, ensuring it stays competitive and ready for the next wave of automation.

Smart Selection And Sizing Strategies

Choosing the right **pneumatic angle seat piston valve** isn’t like picking a standard part off a shelf; it's about matching a specialised tool to a specific job. Making the correct choice can streamline your operation, but a mismatch can lead to costly failures and ongoing frustration. The decision boils down to a few key factors: flow needs, pressure conditions, and how the valve connects to your system. Getting these right is the key to a valve that performs reliably for years.

The selection process starts with a solid understanding of your system's demands. This information will guide the sizing of both the valve itself and the actuator that drives it.

Calculating Valve Size For Optimal Flow

A common mistake engineers make is to oversize a valve, believing that "bigger is always better." This is a costly misconception. An oversized valve often operates at a fraction of its capacity, causing it to chatter and leading to poor control and rapid wear on the seal and seat. On the other hand, an undersized valve acts as a bottleneck, restricting flow and causing a significant pressure drop that can starve your system.

The secret to proper sizing lies in the flow coefficient (Cv), a value indicating how much fluid can pass through the valve. To find the correct Cv, you need to know three things:

The required flow rate (for example, in litres per minute)

The inlet pressure (pressure going into the valve)

The outlet pressure (pressure coming out of the valve)

With these numbers, you can use a standard Cv formula to calculate the ideal valve size. This ensures the valve operates within its best control range, typically between 20% and 80% open, which delivers stable and efficient performance.

Sizing The Actuator And Choosing Connections

Once the valve body is correctly sized, you need to match it with an actuator—the pneumatic "engine" that powers it. The right actuator size depends on:

Process Media Pressure: The higher the fluid pressure in your system, the more force the actuator needs to open the valve against it.

Available Air Supply Pressure: The pressure of your compressed air system dictates how much force the actuator can generate. A system with lower air pressure might require a larger actuator to do the same job.

Fail-Safe Requirements: A normally closed (NC) valve relies on a spring to shut. The actuator must be powerful enough to overcome both this spring force and the media pressure to open. For applications needing very specific pressure control downstream, you might need to consider other components. You can learn more about pressure reducing valves for air and water in our detailed article.

Finally, think about the end connections. Threaded options like BSP or NPT are common, affordable, and easy to fit. However, for high-pressure systems or in set ups where the valve needs to be removed often for cleaning, flanged connections provide a stronger, more secure seal. This robust connection prevents leaks and makes servicing much simpler in the long run.

Installation and Maintenance Secrets From the Pros

Even the toughest pneumatic angle seat piston valves need proper care during installation and throughout their service life. The real secret to getting the most out of them isn't a complex formula but rather a thoughtful setup and a proactive maintenance plan. This approach is what separates a reliable, long-lasting system from one that suffers from frequent downtime and costly repairs.

Putting in a little effort at the start ensures your valve works as designed from day one, giving you the high flow rates and quick cycling you expect.

Piping and Air Supply Best Practices

One of the most common installation mistakes involves the pipework. To get the best performance and avoid turbulence that can wear out the valve, you should always have a straight section of pipe before and after it. A good rule of thumb is to allow for a straight run that is at least 3 to 5 times the pipe's diameter both upstream and downstream of the valve. Also, double-check the flow direction arrow on the valve body—installing it backwards can cause serious water hammer and control problems.

The quality of the compressed air that powers the actuator is just as critical. Contaminated, wet, or unregulated air is the leading cause of early actuator failure. A dedicated FRL (Filter-Regulator-Lubricator) unit isn't an optional extra; it's a necessity.

Filtration: Clears out damaging particles and moisture from the air supply.

Regulation: Keeps the air pressure going to the actuator steady and within the manufacturer's specified range.

Lubrication: Adds a fine oil mist to lubricate the actuator's internal seals, which helps it run smoothly and last much longer.

Proactive Maintenance and Troubleshooting

It’s always better to catch problems early rather than reacting to a failure. Technicians should conduct regular visual checks, looking for any leaks around the stem packing or connections. Listen for strange noises when the valve operates, as this could signal internal wear or trapped debris. You should also keep an eye on the actuator's cycle speed; if it starts to slow down, it often points to an issue with the air supply or worn-out internal seals.

Just as these valves need consistent attention, other important industrial systems, like HVAC units, also rely on diligent upkeep. To get an idea of what a thorough plan looks like, you can find a comprehensive HVAC maintenance checklist that shows how detailed schedules ensure top performance for different mechanical systems.

When a problem does pop up, a logical troubleshooting process saves time. If a valve won't operate, the first things to check are the pilot solenoid and the air supply. If the valve is leaking when closed, the likely culprit is a worn seal, a damaged seat, or debris stuck inside. By understanding these key principles, you can extend the life of your valves and ensure your facility runs on the consistent, reliable performance they provide.

Key Takeaways For Valve Success

Getting the most out of your pneumatic angle seat piston valves comes down to a few key ideas that tie everything together. It's about looking past the data sheet and using what you know in your specific industrial setting. Think of these points as a practical guide to achieving dependable, efficient fluid control, which will protect your investment and reduce operational headaches.

Master the Fundamentals

The starting point for any successful setup is getting the basics right. This means respecting the valve's core design and its operational requirements.

Flow is King: The Y-shaped body is built for high flow rates with very little pressure drop. To get this benefit, you must size the valve correctly. This involves an accurate Cv calculation based on your system's actual pressure and flow rate. A common mistake is over sizing, which causes poor control and wears out the valve sooner.

Clean Air is Non-Negotiable: Think of the piston actuator as the engine of your valve. Its performance depends entirely on a supply of clean, dry, and regulated compressed air. A properly installed Filter-Regulator-Lubricator (FRL) unit isn't just an extra; it's vital for a long service life and preventing actuator problems.

Respect the Installation: Look for the flow direction arrow on the valve body and pay close attention to it. Installing the valve backwards can lead to serious water hammer and issues with control. Also, make sure there are adequate straight pipe runs before and after the valve to encourage a smooth, even flow.

A Proactive Approach to Longevity

Long-term success isn't down to luck; it's the result of proactive maintenance. By shifting from a reactive "fix it when it breaks" approach to a preventive one, you can avoid expensive, unplanned downtime and make your components last much longer.

This means setting up a schedule for regular inspections:

Listen and Look: During operation, listen for any strange noises and check for leaks around the stem packing.

Monitor Performance: Keep an eye on how long the valve takes to open and close. If it becomes sluggish, this often points to a problem with the air supply or the internal seals.

Plan for Seal Replacement: Seals are parts that wear out over time. Based on the fluid, temperature, and how often the valve operates, you should plan to replace the seal kits before a major failure happens.

By putting these practical tips into practice, you can ensure your pneumatic angle seat piston valves perform as consistently and effectively as they were designed to.

Ready to apply these strategies with high-quality parts? Explore our wide range of valves and pneumatic equipment at Solenoid Valve World and receive the expert support you need for your next project.