Your Guide to Pressure Release Valve Systems

Ever heard a kettle whistle? That's probably the simplest and most familiar pressure release valve you'll ever come across. It’s a basic but brilliant bit of engineering, safely letting off steam before the pressure builds to dangerous levels and causes the whole thing to fail.

A pressure release valve is, at its core, your system's automatic safety guard.

Why a Pressure Release Valve Is Your System's First Defence

In any system that works under pressure – whether it's a simple boiler in a factory or a complex chemical reactor – the risk of over-pressure is a constant and serious threat. If that pressure isn’t controlled, it can lead to catastrophic equipment failure. We’re talking about costly downtime, environmental damage, and, worst of all, serious injuries.

This is exactly where a pressure release valve becomes a non-negotiable line of defence.

It’s a purely mechanical device, engineered to automatically pop open and vent gas or liquid the moment the system pressure climbs past a pre-set limit. Its job is straightforward but absolutely critical: to protect a vessel or pipeline from ever exceeding its maximum allowable working pressure.

A pressure release valve isn't just another component; it's a completely autonomous safety system. It requires no human input and no external power to do its job, which is what makes it one of the most reliable safety mechanisms you can have in any industrial setting.

This vital function is why these valves are found in almost every sector. Their widespread demand highlights just how important they are for maintaining operational safety and meeting regulatory standards. In the UK, for example, consistent demand across key industries shows a steady market, and you can explore more data on the European pressure relief valve market to see just how significant these devices are.

To give you a clearer picture, here’s a quick summary of what these essential devices do.

Pressure Release Valve Characteristics at a Glance

| Characteristic | Description |

|---|---|

| Primary Function | Automatically releases excess pressure from a system. |

| Operating Principle | Purely mechanical; opens when a pre-set pressure is exceeded. |

| Key Types | Includes direct-acting, pilot-operated, and balanced bellows designs. |

| Core Importance | Prevents catastrophic equipment failure, downtime, and safety hazards. |

In short, these valves are fundamental to safe and compliant operations.

The Consequences of Neglect

So, what happens if you ignore the importance of a properly functioning pressure release valve? Frankly, the consequences can be dire. A system suffering from an over-pressure event without this safeguard is effectively a ticking time bomb.

The potential outcomes are not pretty:

- Ruptured Vessels: Tanks and pipes can burst violently, spewing out whatever hazardous materials they contain.

- Destructive Chain Reactions: The failure of just one part of the system can easily trigger a domino effect, leading to widespread damage.

- Regulatory Penalties: If you’re found to be non-compliant with safety standards, you can face hefty fines and serious legal trouble.

Understanding these risks is precisely why good engineers and facility managers put so much emphasis on choosing and maintaining the right valves. For a more detailed look into their core features and common uses, our comprehensive overview of the pressure relief valve offers all the essential information you’ll need.

How a Pressure Release Valve Actually Works

At its core, a pressure release valve works on a beautifully simple principle: balance. Picture a set of scales. On one side, you have the pressure inside your system. On the other, you have a counteracting force, which is usually a powerful, precisely calibrated spring. As long as the system pressure behaves and stays below a certain limit, the spring wins the tug-of-war, keeping the valve shut tight.

That pre-determined limit is what we call the set pressure. It’s the exact point where the valve is designed to crack open. When a sudden surge or an unexpected process hiccup causes the pressure to climb and push against the valve's internal disc, it begins to overpower the spring's resistance.

Once the system pressure nudges past this set pressure, the valve springs into action. The disc lifts away from its seat, creating a path for the excess pressure—be it gas or liquid—to safely escape through a designated outlet.

The Operational Cycle Explained

The valve's job isn't just about opening; it’s a full, controlled cycle designed to get things back to normal quickly and safely. A couple of key terms define this process:

- Overpressure: This is how much extra pressure above the set point is needed to push the valve fully open. For a typical valve, a 10% overpressure might be required to reach its maximum discharge capacity.

- Blowdown: This is the difference between the set pressure and the pressure at which the valve closes again. A valve can't just slam shut the instant the pressure dips back to the set point; it needs to stay open just long enough to stabilise the system. A typical blowdown is around 7% below the set pressure.

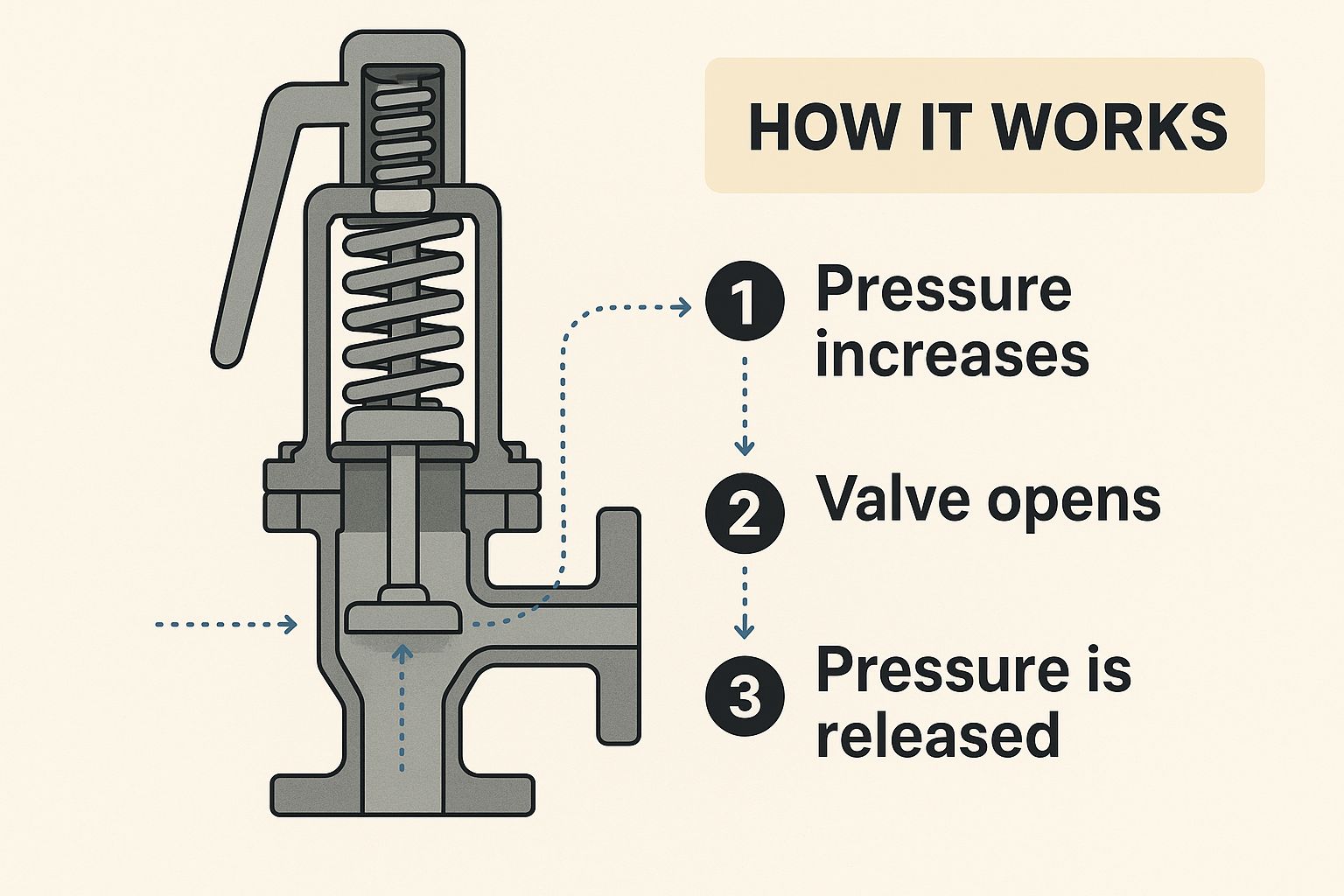

This diagram gives you a simplified look at the mechanics in action.

As you can see, the spring compresses under the increased force, allowing the disc to lift and vent the overpressure. Once the danger has passed, the spring's force takes over again, resealing the valve.

Designs for Different Demands

The most common design you’ll come across is the spring-loaded valve, which uses a simple helical spring to provide the closing force. For more demanding or sensitive applications, however, you might see a pilot-operated valve. This is a more advanced design that cleverly uses the system's own pressure to help keep the valve sealed, allowing it to operate much closer to its set pressure without any pesky leaks.

This sort of engineering is crucial for UK industries, but the manufacturing side of things faces its own pressures. The UK's tap and valve manufacturing sector has shrunk by a compound annual rate of 7.5% between 2019 and 2024. This is mostly down to stiff competition from global suppliers, which has squeezed domestic production even though these safety devices are always in demand. For a closer look at the economic forces at play, you can explore this analysis of UK tap and valve market trends.

Ultimately, a pressure release valve is an autonomous guardian. Its entire purpose is to wait for a specific condition and then act instantly, reliably, and without any external command to protect people, equipment, and the environment.

Choosing the Right Valve for Your Application

Not all pressure release valves are created equal. Choosing the wrong one can be just as dangerous as having no valve at all. It's a bit like picking tyres for a vehicle; you wouldn't put standard road tyres on a tractor that's about to plough through a muddy field. The same logic applies here—the valve has to be perfectly matched to its operating environment and the job at hand.

Your decision will hinge on your system's unique quirks, especially the presence of back pressure. This is the pressure at the valve's outlet, and if it's not accounted for, it can stop the valve from opening when it’s most needed.

To make the right choice, it helps to understand the main players on the field.

Conventional Spring-Loaded Valves

The conventional spring-loaded valve is the most common and straightforward design you'll find. It's a simple, robust workhorse. However, its opening pressure is directly affected by any back pressure in the system.

This design is a great fit for simple applications where back pressure is either non-existent or constant. For instance, if the valve just vents straight into the atmosphere, there's no back pressure to worry about. In that scenario, a conventional valve is a reliable and cost-effective choice. But if that back pressure is unpredictable, it can stop the valve from opening at its set point, creating a major safety risk.

Balanced-Bellows Valves

For systems grappling with variable or high back pressure, the balanced-bellows pressure release valve is a far better option. This clever design uses a flexible metal bellows to shield the valve's disc from whatever is happening downstream.

Essentially, the bellows "balances out" the back pressure. This ensures the valve opens precisely at its set pressure, no matter the conditions on the outlet side. This feature is vital in applications where several valves discharge into a shared header pipe, which can create wildly unpredictable back pressure. As a bonus, the bellows also shields the spring and other internal parts from corrosive process fluids.

A balanced-bellows valve is a significant reliability upgrade for complex systems. Think of it as an insurance policy against unpredictable back pressure, ensuring your primary safety device isn't compromised by downstream fluctuations.

Pilot-Operated Valves

When you need a perfect seal or are dealing with extremely high operating pressures, the pilot-operated valve is the gold standard. This is a more advanced design that uses a small pilot valve to control a much larger main valve.

It uses the system's own pressure to hold the main valve shut with incredible force. This allows the system to run much closer to its set pressure—often up to 98%—without a hint of a leak. Once the set pressure is hit, the small pilot actuates, which in turn triggers the main valve to pop open fully and instantly.

If you're interested in other ways to manage system pressure, our guide on understanding pressure reducing valves offers some excellent complementary insights.

Key Factors for Valve Selection and Sizing

When it comes to selecting and sizing a pressure release valve, you’re dealing with a mission-critical engineering task where precision is everything. A mistake here doesn’t just cause a minor hiccup; it can compromise your entire safety system. To get it right, you need to dig deep into the valve's operating environment and understand every variable at play.

This is much more than just finding a valve that fits your pipework. It's about developing a detailed picture of your system's behaviour, the fluid it handles, and the absolute worst-case scenarios it might face. If you overlook even one of these factors, you could end up with a valve that chatters, leaks, or—even worse—fails to open when you need it most.

Defining Your Operational Parameters

Before you even glance at a product catalogue, the first job is to nail down the operational data. This information is the bedrock of your entire selection process.

- Set Pressure: This is the big one. At what precise pressure does the valve need to start opening? This number is dictated by the Maximum Allowable Working Pressure (MAWP) of the vessel or system the valve is there to protect.

- Required Flow Capacity: When things go wrong, how much fluid (be it gas or liquid) does the valve need to vent to get the system pressure back to a safe level? You'll need to calculate this based on the worst-case overpressure event, like a blocked outlet or an external fire.

- Operating and Maximum Temperature: The valve's materials must be up to the job of handling the full temperature range they'll encounter. That includes normal operating conditions right through to the intense heat generated during a release. Extreme temperatures can seriously degrade a valve's performance and material integrity.

One of the most common pitfalls we see is setting the system's operating pressure too close to the valve's set pressure. Best practice, outlined in standards like API 520, calls for a buffer of at least 10% between the normal operating pressure and the set pressure. This prevents ‘simmering’ or premature opening.

Matching Materials to the Medium

With your core parameters defined, the next challenge is choosing the right materials. What's flowing through your system? The answer to that question will determine which materials will last and which will fail. A valve designed for clean steam has completely different needs to one that’s managing corrosive chemicals.

Material selection always involves striking a balance between performance and cost, with the main goal being to prevent corrosion, erosion, and chemical attack.

- Stainless Steel: This is a go-to choice for a huge range of applications thanks to its superb corrosion resistance. It’s perfect for water, steam, and milder chemicals. For anything involving chlorides, you’ll often see 316 stainless steel specified for its extra resilience.

- Carbon Steel: A solid, cost-effective option for non-corrosive services like air or hydrocarbon gases. However, it's a poor choice for aggressive media unless it has protective coatings.

- Special Alloys: When you're dealing with highly corrosive substances or extreme temperatures, you have to bring in the exotic materials. Alloys like Monel, Hastelloy, or Inconel are built to handle things like acids, seawater, or high-temperature gases that would make short work of standard metals.

Picking the right material for your pressure release valve isn’t just about making it last longer. It's a fundamental safety requirement that guarantees the device will be ready to do its job reliably throughout its service life.

Installation and Maintenance Best Practices

Choosing the perfect pressure release valve is a great start, but it’s only half the story. The real test of its worth as a safety device comes down to two things: a flawless installation and a disciplined maintenance schedule. A top-of-the-line valve can quickly become a weak link if it's not fitted correctly or is left to degrade over time.

Think of it this way: getting the fundamentals right from day one is your best defence against future headaches. It's what ensures the valve will do its job when you need it most—during an overpressure event.

Critical Installation Steps

Setting up a pressure release valve is about more than just tightening a few connections. It’s about creating the perfect environment for it to operate without a hitch. For a more detailed walkthrough, you can check out our guide on how to install a pressure relief valve, but these are the absolute must-dos:

- Get the Orientation Right: Most spring-loaded valves are designed to be installed vertically, with the spring housing pointing straight up. Mounting it sideways or upside down can stop it from opening cleanly or reseating properly.

- Avoid Pipe Stress: Make sure the inlet and outlet pipes are supported independently. The weight and strain from unsupported pipework can physically distort the valve body, leading to leaks or preventing the disc from creating a tight seal.

- Plan Your Discharge Piping: The outlet pipe needs to be at least the same diameter as the valve's outlet. Keep it as short and straight as you can, and make sure it slopes away from the valve. This allows for proper drainage and prevents any back pressure from building up.

Proactive Maintenance and Inspection

Once your valve is in place, it’s not a "fit and forget" component. It needs a structured maintenance programme to ensure it remains reliable, in line with UK standards like the Pressure Systems Safety Regulations (PSSR 2000). A proactive mindset here is non-negotiable.

A valve that fails an inspection isn't a failure—it's a success for your maintenance plan. It means you've spotted a potential disaster before it had a chance to happen.

Regular visual checks and formal testing are the cornerstones of good practice. Keep an eye out for these tell-tale signs:

- Corrosion or Rust: Any visible signs of decay on the valve body or its connections are a major red flag.

- Leaks or Drips: Even a small amount of moisture suggests a seal has been compromised.

- Odd Noises: Hissing or chattering sounds can be a symptom of an oversized valve or system pressure that’s hovering too close to the set point.

This kind of vigilance is vital across countless industries. For instance, the UK's pressure relief devices market, which was valued at around $55.9 million in 2023, largely serves the healthcare sector by providing therapeutic surfaces to prevent pressure ulcers in patients. It’s a powerful reminder that whether it’s for patient well-being or industrial safety, proper pressure management saves lives and assets.

For anyone managing systems where these valves are critical, it's worth exploring these preventive maintenance tips for commercial refrigeration systems. Ultimately, a robust maintenance framework is your best insurance policy for both safety and reliability.

Answering Your Pressure Release Valve Questions

Even with a solid grasp of how these valves work, questions always pop up in the field. This is where theory meets reality. We’ve put together answers to the most common queries we hear, giving you direct, clear advice for real-world situations.

Think of this as your go-to guide when you're on-site and need a quick, reliable answer.

What Is the Difference Between a Relief Valve and a Safety Valve?

You’ll often hear these terms used as if they mean the same thing, but in the world of engineering and safety standards, the difference is crucial. It all comes down to how the valve acts under pressure, which in turn determines how it protects your system.

Getting this right is fundamental to choosing the correct device.

- A pressure relief valve is your typical go-to for liquid service. It opens proportionally – as system pressure creeps up past the set point, the valve opens just enough to bleed off the excess. Imagine gently turning a tap to ease the pressure, not flinging it wide open.

- A pressure safety valve is built for the challenges of compressible fluids like gas or steam. It doesn't do "gradual". When it hits its set pressure, it 'pops' open, fully and almost instantly. This rapid, high-volume venting is essential for getting large amounts of gas out of the system, fast.

Some clever devices, known as safety relief valves, are certified to perform either function, offering a bit of versatility. But the core decision is always about the physics: do you need the gentle, proportional control for a liquid, or the immediate, full-bore opening for a gas?

The key takeaway is this: the choice between 'relief' and 'safety' isn't just about names. It’s about matching the valve’s opening action to the physical properties of the fluid it’s handling.

How Often Should a Pressure Release Valve Be Tested?

There’s no single, one-size-fits-all answer here. The testing frequency is dictated by UK regulations like the Pressure Systems Safety Regulations 2000 (PSSR) and is always based on the valve's specific job and environment. This schedule is formally laid out by a 'competent person' in a document called a Written Scheme of Examination.

Still, we can look at some general rules of thumb:

- For clean, non-corrosive services – think compressed air, steam, or clean water – testing is often required every 12 to 24 months.

- For corrosive, fouling, or dirty services, the schedule gets a lot tighter. Testing might be needed as often as every 6 months, or even more frequently if conditions are particularly harsh.

Ultimately, the testing interval is a risk-based decision. It’s tailored to the application to make sure the valve remains a dependable safeguard for its entire service life.

What Causes a Pressure Release Valve to Leak or Chatter?

Leaks and chattering are the two classic signs that something isn't right with your valve or the wider system. A healthy valve should sit quietly and stay perfectly sealed until it's needed. If it’s making noise, it’s trying to tell you something.

Leaking or 'Simmering'

This is when the valve doesn't fully reseat after opening, or weeps slightly under normal operating pressure. You might hear a gentle hissing. The most common culprit is setting the system's normal operating pressure too close to the valve's set pressure. You need a bit of a buffer – a 10% gap is a good rule of thumb.

Other causes include:

- A tiny bit of grit or debris trapped between the disc and the seat.

- Corrosion or physical damage to the sealing surfaces.

- The valve not being installed perfectly straight.

Chattering

Chatter is a much more violent and serious problem. It’s a rapid, destructive opening and closing of the valve that can cause severe mechanical damage in no time at all.

The number one cause of chatter is an oversized valve. The valve pops open, releases a tiny bit of pressure, and the system pressure immediately drops so fast that the valve slams shut again. This creates a destructive, high-frequency cycle that hammers the valve to pieces.

Can I Adjust the Set Pressure of a Valve Myself?

In a word: no. Adjusting the set pressure on a pressure release valve is a job strictly for trained and certified technicians. These are precision safety instruments, not just any old flow control valve.

For that reason, the adjustment mechanism is deliberately sealed – often with a wire and lead seal – to show that it hasn't been tampered with. Breaking that seal instantly invalidates the valve's certification.

To be put back into service, the valve has to be removed, professionally re-calibrated on a test bench, and then re-certified to verify its new set pressure and ensure it seals correctly. Trying to tweak it yourself in the field is a massive safety risk; you could render the one device designed to protect your system completely useless in an emergency.

At Solenoid Valve World, we understand the critical role these devices play in keeping your operations safe and compliant. We offer a comprehensive selection of pressure control equipment and provide UK-based technical support to help you select the right components for your system. Explore our full range of valves and fittings today at https://solenoid-valve.world.