Proportional Control Valve: Guide to Types & Applications

Think of a proportional control valve as a sophisticated dimmer switch for fluids. It goes far beyond the simple on/off function of a standard valve. Instead of just being fully open or fully closed, it can precisely adjust its position to deliver the exact amount of flow or pressure needed at any given moment. This ability to modulate is all thanks to a variable electronic signal, making it a true cornerstone of modern, automated industrial processes.

From Simple Taps to Smart Control

Imagine trying to fill a glass of water with a tap that only has two settings: full blast or completely off. You'd almost certainly make a mess and find it impossible to fill the glass just right. This is exactly the limitation of conventional on-off valves in any complex system. They offer purely binary control – it's all or nothing.

A proportional control valve elegantly solves this problem by introducing nuance. It takes a variable electronic command, usually a voltage signal (like 0-10V) or a current signal (like 4-20mA), and translates it into a specific physical position. A 2V signal might open the valve 20%, a 5V signal 50%, and a 10V signal 100%. This gives you an incredible degree of fine adjustment.

This level of control is indispensable in today's industrial world. It isn't just a matter of convenience; it’s about driving efficiency, ensuring safety, and boosting product quality. By delivering the precise flow or pressure needed, these valves get rid of the waste and instability caused by abrupt starts, stops, and overshoot.

Key Benefits of Proportional Control

Bringing proportional control into your operations offers real, tangible advantages that have a direct impact on your bottom line and overall process excellence.

- Superior Process Accuracy: By matching flow or pressure exactly to the system's demands, product quality becomes far more consistent. This could mean getting the mix of chemicals perfect or smoothly managing the speed of a hydraulic motor.

- Significant Energy Savings: Instead of running a pump at full power and then choking the flow with a restrictive valve, a proportional system modulates the flow directly. This simple change can drastically cut down on wasted energy.

- Improved Equipment Longevity: The smooth, gradual changes in pressure and flow prevent the mechanical shock and jarring movements that punish equipment. This reduces wear and tear on pumps, actuators, and other critical components.

This move toward smarter components is clearly reflected in market trends. The UK proportional control valve market is a key growth area within the broader control valve industry, valued at around USD 350 million recently and projected to hit USD 1,500 million by 2035. This growth is being fuelled by the relentless push for automation and greater efficiency, especially when components like these can reduce energy consumption by up to 20% in fluid systems. For a deeper dive, you can explore the market dynamics and future growth projections for the UK proportional valve market.

The Core Difference: An on-off valve asks, "Should I be open or closed?" A proportional control valve asks, "How open should I be?" This fundamental shift from a binary question to a variable one is what unlocks a whole new level of system intelligence.

To help clarify the distinction, let's break down the key differences between these two valve types.

Proportional vs On-Off Valves at a Glance

This quick comparison table highlights the fundamental differences between basic on-off control and the advanced regulation that proportional valves bring to the table.

| Feature | On-Off Valve (Conventional) | Proportional Control Valve (Advanced) |

|---|---|---|

| Functionality | Fully open or fully closed | Variable opening (e.g., 0% to 100%) |

| Control Type | Binary (All or nothing) | Analogue (Fine-tuned adjustment) |

| Input Signal | Simple on/off electrical signal | Variable signal (e.g., 4-20mA or 0-10V) |

| Precision | Low; not suitable for regulation | High; ideal for precise process control |

| Energy Efficiency | Lower; can lead to wasted energy | Higher; matches output to demand, saving power |

| System Impact | Can cause pressure spikes and shock | Smooth operation, reducing wear on components |

| Best For | Simple open/close tasks, isolation | Regulating flow, pressure, speed, temperature |

As you can see, while both have their place, proportional valves offer a level of sophisticated control that is essential for modern, high-performance systems. Understanding how a proportional control valve works is the first step toward realising these benefits in your own applications.

How Proportional Control Valves Work

At its heart, a proportional control valve is a master of translation. It takes a subtle electrical signal and converts it into a precise, powerful mechanical movement. This isn't just a simple on/off switch; it’s a sophisticated piece of engineering where several key components work in perfect concert.

To really get a feel for how they operate, it helps to follow the journey from the initial electrical command right through to the final, finely-tuned flow of fluid. This process is what sets these valves apart, allowing for incredible degrees of control. It all comes down to three main parts working together.

The Core Components

Every proportional control valve relies on a trio of essential parts. Each has its own job, but they are completely dependent on one another. If one part isn't performing, the precision of the entire system is compromised.

- The Valve Body: This is the rugged outer casing that houses everything and directs the fluid. Inside, you'll find the channels, ports, and the crucial moving part—usually a spool or a plug—that physically blocks or allows fluid to pass.

- The Proportional Solenoid: Think of this as the brains and the brawn of the unit. It’s a specialised electromagnet that takes a variable electrical signal from a controller (like a PLC) and turns it into physical force.

- The Actuator: This is the mechanism, driven directly by the solenoid, that physically shifts the spool or plug inside the valve body, adjusting the size of the opening.

Together, this team translates an abstract electrical instruction into a tangible, real-world result.

From Signal to Mechanical Action

The entire process kicks off when an electronic controller dispatches a variable input signal to the proportional solenoid. This signal is typically a current ranging from 4-20mA or a voltage between 0-10V.

The magic of the solenoid is its ability to create a magnetic force that is directly proportional to the strength of that incoming signal. A low signal generates a weak magnetic force; a high signal generates a strong one.

This varying force pushes against a spring-loaded actuator, moving the internal spool to a very specific position inside the valve. For example, a 4mA signal might keep the valve completely shut, an 8mA signal could slide it 25% open, while the full 20mA signal would open it all the way.

An Analogy: Picture yourself pushing a toy car against a spring. A light touch only moves it a little bit. A hard shove sends it much further. The proportional solenoid operates on this same principle, but it uses magnetic force instead of your hand to precisely position the valve's inner workings against a calibrated spring.

This direct, repeatable relationship between the input signal and the valve's opening is what gives us such nuanced control over flow rate and pressure.

The Critical Role of Feedback Loops

Of course, just sending a command isn't always enough for guaranteed accuracy in the real world. Things like fluctuations in fluid pressure, friction, or even temperature changes can slightly alter the valve's actual position. For applications demanding the highest precision, advanced proportional valves incorporate a feedback loop.

Many modern valves have an integrated position sensor, such as an LVDT (Linear Variable Differential Transformer). This sensor's only job is to constantly measure the exact position of the spool and report that information back to the controller.

The controller then compares the actual position to the desired position from its original command. If there’s even a tiny discrepancy, it instantly adjusts the electrical signal to the solenoid, correcting the spool's position in real-time. This "closed-loop" system ensures the valve doesn't just hit its target but stays there, actively fighting against external disruptions to deliver rock-solid, reliable performance.

Exploring the Main Types of Proportional Valves

A proportional control valve isn't a one-size-fits-all device. Just as a mechanic needs different spanners for different jobs, an engineer needs to select the right kind of valve for a specific task. The variations are broadly categorised by their construction and what they’re designed to do.

Getting these differences right is crucial for building an efficient and reliable system. The two main structural types are direct-acting and pilot-operated valves, each with its own strengths in performance, power, and suitability for different system pressures.

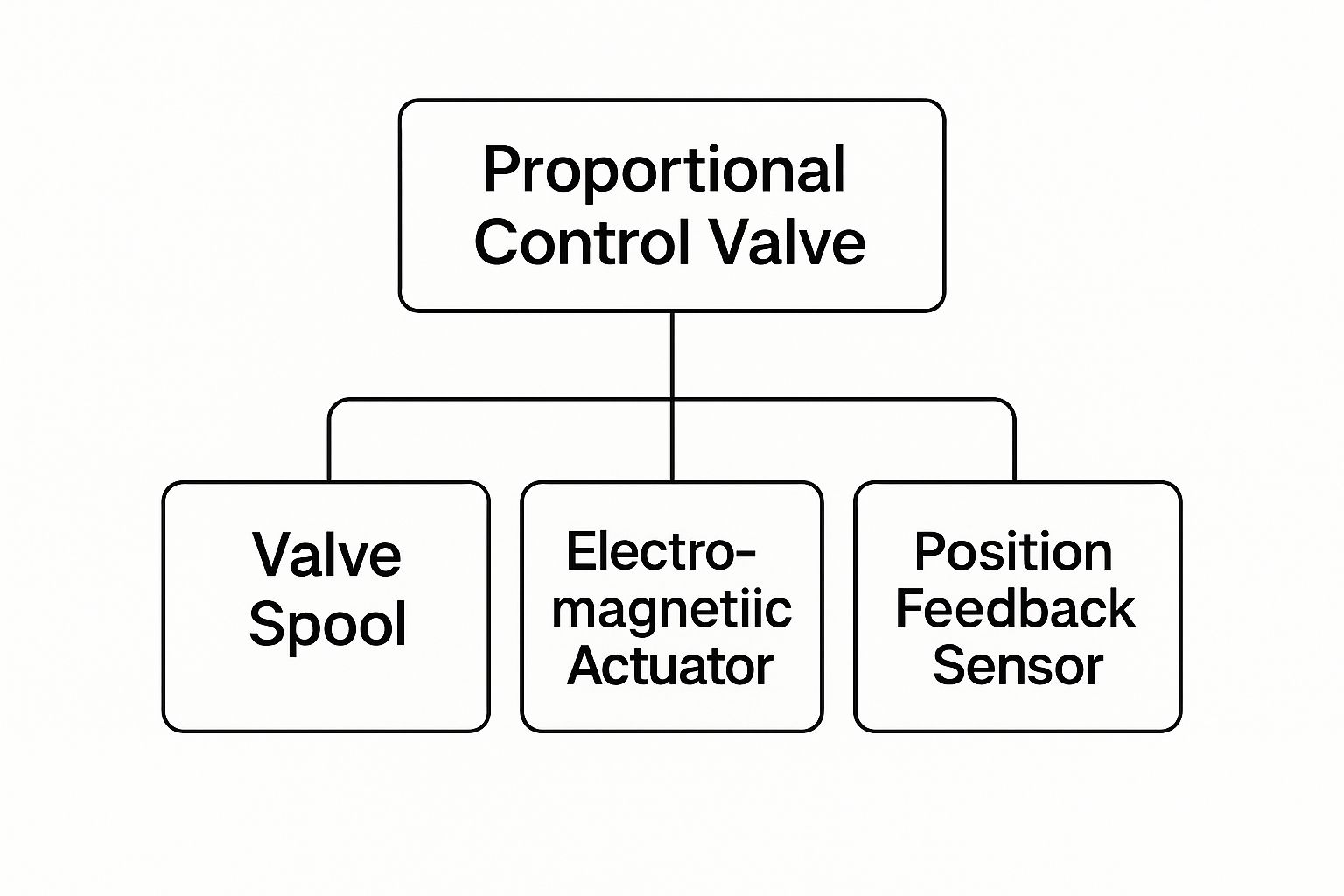

This diagram shows the fundamental building blocks you’ll find in most proportional control valves.

As you can see, the electromagnetic actuator, valve spool, and position sensor are the core trio that makes precise control possible. The actuator translates the electrical signal into physical force, the spool makes the mechanical move to control flow, and the sensor provides the vital feedback needed for accuracy.

Direct-Acting Proportional Valves

A direct-acting proportional valve is the most straightforward design. In this setup, the proportional solenoid acts directly on the main spool or poppet that controls the fluid flow. Think of it like a dimmer switch wired straight to a light bulb—the force from the solenoid is solely responsible for moving the valve and overcoming any system pressures.

This direct connection means you get very fast response times, making these valves perfect for jobs where quick adjustments are critical. However, because the solenoid has to do all the heavy lifting, they are generally limited to lower-flow and lower-pressure systems. Pushing against high pressure requires a huge, power-hungry solenoid, which just isn’t practical for bigger jobs.

Pilot-Operated Proportional Valves

For high-pressure or high-flow applications, a pilot-operated valve is the go-to choice. This design uses a clever two-stage approach to manage powerful forces with very little electrical input. It’s a bit like using a small lever to operate a much larger hydraulic machine.

Here's how it works: a small, direct-acting proportional valve (the 'pilot') controls a tiny amount of fluid pressure. This pilot pressure is then used to move the main, much larger spool. The solenoid only needs enough force to control the small pilot stage, while the system's own pressure does the real work of shifting the main stage. This clever setup allows a small, energy-efficient solenoid to control massive flow rates and pressures.

Key Takeaway: The choice between direct-acting and pilot-operated is a trade-off. Direct-acting offers speed and simplicity for smaller systems, while pilot-operated provides the power and efficiency needed to control large-scale industrial flows.

To help clarify the differences, this table breaks down the key characteristics of each type.

Comparison of Proportional Valve Actuation Types

| Characteristic | Direct-Acting Valve | Pilot-Operated Valve |

|---|---|---|

| Response Time | Very fast; ideal for rapid adjustments. | Slower due to the two-stage process. |

| Power Consumption | Higher, as the solenoid must overcome all system forces directly. | Lower, as the solenoid only controls the small pilot stage. |

| Ideal Application | Low-flow and low-pressure systems. | High-flow and high-pressure systems. |

| Complexity | Simpler design with fewer components. | More complex, involving a pilot and main stage. |

| Size | Can become large and bulky for even moderate flows. | More compact and efficient for controlling large flows. |

Ultimately, understanding this comparison helps you match the valve's capabilities to the demands of your hydraulic or pneumatic circuit.

Functional Types and Their Jobs

Beyond their internal construction, proportional valves are also classified by their specific job within a system. Think of them as specialised tools, each designed to manage a distinct aspect of fluid power.

Here are the most common functional types you’ll encounter:

- Proportional Flow Control Valves: These are the speed controllers. Their primary job is to regulate the volume of fluid passing through, which directly controls the speed of an actuator like a hydraulic cylinder or motor. On a factory conveyor belt, for instance, this valve ensures products move at a consistent, precise speed.

- Proportional Pressure Relief Valves: These act as intelligent safety guards. They constantly monitor system pressure. If it exceeds a set level, they open just enough to bleed off the excess, maintaining a stable and safe operating pressure. Unlike a simple relief valve that just pops fully open, a proportional one can adjust to hold pressure at an exact setpoint.

- Proportional Directional Control Valves: These valves are the masters of motion, managing both the direction and the amount of flow. They can smoothly start, stop, and reverse an actuator while also controlling its speed. They are essential in sophisticated machinery like mobile cranes, where operators need to lift heavy loads with finesse and precision.

By understanding both the construction (direct vs. pilot) and the function (flow, pressure, or directional), you can pinpoint the exact type of proportional control valve needed to bring precision and efficiency to your application.

How to Select the Right Proportional Control Valve

Choosing the right proportional control valve is about more than just matching pipe sizes. Get it right, and the valve becomes an invisible, efficient part of your system. Get it wrong, and you’re in for a world of constant headaches, poor performance, and maybe even damaged equipment.

Think of it like picking the right engine for a vehicle. You wouldn’t drop a hatchback engine into a massive lorry and expect it to haul a heavy load. In the same way, a proportional control valve has to be carefully matched to the job it's being asked to do.

Start with the Fluid and System Parameters

First things first, you need to know exactly what the valve will be dealing with. The fluid—or media—is your starting point, as its properties will dictate the materials we need for the valve body and its seals.

From there, you need to pin down the core operational numbers for your system. These figures are the foundation of a good selection, ensuring the valve is neither overworked nor so oversized it can't do its job properly.

Key parameters to define include:

- Media Type: Are you working with something neutral like water or compressed air, or something more aggressive like a chemical? This directly influences your choice of materials, whether that’s brass, stainless steel, or specialised plastics.

- Operating Temperature: You need to know the absolute minimum and maximum temperatures the valve will see. Every component, especially the seals and electronics, has a strict operating range that can't be pushed.

- Pressure Range: What are the minimum and maximum pressures at the inlet and outlet? Running a valve above its pressure rating isn't just bad practice—it's a serious safety risk. For systems with extreme pressure demands, you'll need to look at specialised components. You can learn more about components designed for extreme environments by reading our guide on high-pressure solenoid valves.

Crucial Tip: Always design for the worst-case scenario. A system designed only for normal operating conditions is a system waiting to fail when an unexpected pressure or temperature spike hits.

Understanding Flow Rate and Valve Sizing

This might be the most critical part of the puzzle. We’re talking about the flow coefficient, known as Cv (or Kv in metric systems). This isn't about the pipe diameter; it’s a measure of the valve's true capacity to pass fluid at a given pressure drop.

Getting the Cv value right is absolutely essential.

- Undersizing (Cv too low): The valve becomes a bottleneck. It will starve your system of flow, forcing pumps and compressors to work overtime just to keep up.

- Oversizing (Cv too high): This is a surprisingly common and costly mistake. A valve that’s too big for the job becomes incredibly twitchy. The tiniest control adjustment will cause a massive change in flow, making any kind of fine control almost impossible. You'll have bought a precision instrument and turned it into a clumsy on/off switch.

To get the right Cv, you’ll need your desired flow rate and the pressure drop across the valve. Manufacturers provide formulas and charts to help with this calculation for both liquid and gas applications.

Matching Control Signals and Response Time

Finally, you need to make sure the valve can actually talk to your control system and act fast enough for your process. This means checking its electrical inputs and its physical reaction speed.

Consider these final technical points:

- Control Signal: Does your PLC or controller send a 4-20mA current signal or a 0-10V voltage signal? The valve must be built to understand the same language your controller is speaking.

- Response Time: How quickly does the valve need to open or close? For a process that demands rapid changes, like controlling pressure in a fast-moving robotic arm, a valve with a snappy response time is a must.

- Hysteresis and Repeatability: Hysteresis is the small difference in the valve’s position depending on whether it’s opening or closing to hit a setpoint. For high-precision jobs, you need a valve with low hysteresis and high repeatability, ensuring it does the exact same thing, every single time.

By working through these criteria—from the fluid itself to flow rates and control signals—you build a complete picture of the perfect valve for your needs. This methodical approach takes the guesswork out of the equation and sets you up to choose a proportional control valve that will deliver reliable, top-tier performance for years to come.

Real-World Applications and Industry Impact

It’s one thing to talk about theory, but seeing a proportional control valve in action is where you truly appreciate its value. This is where the concepts of precision flow and pressure management become real, tangible results, driving efficiency and innovation across major UK industries. From sprawling manufacturing plants to critical public utilities, these valves are the unsung heroes making operations safer, more productive, and much more economical.

And this isn't just a gut feeling; the numbers back it up. Proportional control valves have played a huge part in the UK's industrial efficiency gains over the last few decades. In fact, studies from industrial bodies show that swapping older on/off systems for these components in automated fluid power setups can lead to a 25% reduction in energy use. For demanding sectors like automotive and aerospace, that precision slashes cycle times by holding exact pressures, boosting productivity by around 15%. You can discover more about these market efficiency findings and their wider impact.

Precision Speed Control in Manufacturing

Picture a conveyor belt in a bottling plant. If it jerks or runs at an inconsistent speed, bottles will topple. That means spills, waste, and expensive downtime. A classic on/off system just can't provide the smooth handling needed.

This is a textbook case for a proportional flow control valve. By carefully modulating the hydraulic fluid flowing to the conveyor's motor, the valve ensures the belt accelerates smoothly, holds a perfectly steady speed, and then slows down gently.

- Benefit: This simple change stops product damage and waste in its tracks.

- Impact: It lets the plant run at higher speeds with far greater reliability, giving a direct boost to output and profitability.

Accurate Chemical Dosing in Water Treatment

For municipal water treatment facilities, getting water quality right isn't just a goal—it's a public health obligation. The job involves adding tiny, precise amounts of chemicals like chlorine or flocculants. Get it wrong, and the consequences can be serious.

A proportional control valve delivers the pinpoint accuracy this critical task demands. It's linked to sensors that monitor water quality in real time, allowing the valve to make minute adjustments to the flow of treatment chemicals on the fly.

Key Insight: This setup creates a responsive, closed-loop system that reacts instantly to changes in water conditions, making sure the chemical dose is always perfect. It turns what was a manual, error-prone task into a highly reliable, automated process.

This level of precision doesn't just guarantee safety; it also stops the costly waste of expensive chemicals, leading to big operational savings for local authorities.

Load-Sensing Hydraulics in Heavy Machinery

Think about a massive crane lifting a delicate, multi-tonne load on a construction site in London or Manchester. The operator needs complete control—the ability to lift, lower, and position that load with millimetre precision, no matter how heavy it is. This is all made possible by load-sensing hydraulic systems, which are built around proportional directional control valves.

These aren't simple open-and-shut valves. They intelligently direct flow and pressure exactly where needed, and only when needed. When the operator nudges a joystick, the proportional valve translates that tiny input into a smooth, controlled movement of the crane's boom. The system automatically senses the load's weight and provides just enough power to move it safely and efficiently, without wasting a drop of energy. For similar applications that use gases instead of liquids, you might want to read our guide on how pneumatic solenoid valves work.

Across all these different sectors, the story is the same. The proportional control valve brings the finesse and intelligence that modern industry relies on, turning brute force into precise, efficient, and safe mechanical work.

Installation and Maintenance Best Practices

A high-performance proportional control valve is only as good as its installation. To get the precision and reliability you're paying for, a meticulous approach to both the setup and ongoing care isn't just a good idea—it's essential. Proper installation is what stops a valve from failing early and ensures it operates exactly as intended from day one.

Think of it like laying the foundations for a house; any shortcuts you take here will create headaches later on. A correctly installed and maintained valve protects your investment, minimises expensive downtime, and delivers flawless performance for years. This whole process starts before you even reach for a spanner.

Pre-Installation Checks and Setup

Before you even think about connecting the valve, the system it’s about to join needs to be spotless. Contamination is the number one enemy of any proportional control valve. The internal tolerances are incredibly tight, meaning even microscopic bits of debris can cause sticking, erratic behaviour, or a complete shutdown.

It's absolutely critical to thoroughly flush the entire system to get rid of any stray metal shavings, dirt, or sealant residue from previous work. After that, installing an upstream filter isn't just a recommendation—it's your valve's best friend and its single greatest line of defence.

Once the system is clean, you can focus on the physical and electrical setup.

- Correct Mounting Orientation: Always mount the valve according to the manufacturer's specifications. Getting this wrong can mess with the internal mechanics, trap air where it shouldn't be, or stop the solenoid from working properly.

- Secure Electrical Connections: Make sure all wiring is secure, correctly shielded, and protected from moisture or vibration. A loose connection can introduce signal noise, leading to inconsistent and unpredictable valve performance.

- Verify System Parameters: Double-check that the system's real-world operating pressure and flow rates are well within the valve's specified limits. Over-pressurising a valve is a recipe for disaster.

A proactive approach is everything. It's far easier to prevent contaminants from ever reaching the valve with good filtration than it is to fix a valve that's already been damaged by debris.

Creating a Proactive Maintenance Schedule

Maintaining a proportional control valve isn't about waiting for something to break. It’s about setting up a proactive schedule to spot the early signs of wear and keep the whole system running at peak efficiency. This schedule should be a living document that you adjust based on how hard the valve works and the environment it’s in.

Start with a simple, regular checklist for visual inspections. Look for any signs of hydraulic or pneumatic leaks around the valve body and its fittings. A tiny leak is often the first warning sign of a failing seal or a connection that’s worked itself loose.

Beyond just looking, you need to listen to what the valve is telling you through your control system. Pay close attention to any diagnostic alerts and performance data. Keep an eye out for trends like slower response times, difficulty holding a setpoint, or an increase in electrical current draw—these are classic signs of internal wear or rising friction. Understanding how other safety components work is also useful; you can read our guide on how pressure relief valves protect your system for more on that.

Finally, don't ignore strange noises. Any hissing, buzzing, or chattering sounds that weren't there before often point to internal problems, like contamination or air trapped in a hydraulic system. Catching these early signs will help you avoid a sudden, catastrophic failure and keep your operations running smoothly.

Frequently Asked Questions

As you get to grips with proportional control valves, a few common questions tend to pop up, especially when you're comparing them to other valve types or digging into the technical jargon. Let's clear up some of the most frequent queries.

Answering these helps build a solid foundation, making you more confident when it comes to choosing, installing, or troubleshooting these crucial components.

What Is the Difference Between a Proportional Valve and a Servo Valve?

While both valves give you variable control, the real difference is a trade-off between ultimate performance and everyday durability.

Think of a servo valve as a high-performance racing car. It’s incredibly fast and precise, but it's also more expensive and extremely sensitive to any dirt or contaminants in the system. You'd choose a servo for the most demanding, high-speed jobs where pinpoint accuracy is everything.

A proportional control valve, on the other hand, is more like a trusty workhorse. It’s tough, far more forgiving of the typical contaminants you find in industrial fluid systems, and much more cost-effective. For the majority of industrial tasks that need great control without the absolute precision (and cost) of a servo, a proportional valve is the smarter, more robust choice.

The Bottom Line: Servo valves deliver peak performance but demand a higher price and pristine operating conditions. Proportional valves offer excellent, reliable control that’s built for real-world industrial environments.

What Does Hysteresis Mean for a Proportional Valve?

In simple terms, hysteresis is a small difference in the valve's actual position when it approaches a setpoint from different directions.

Imagine telling the valve to open to 50%. Its final position might be a fraction different if it was moving from a 25% open position compared to if it was moving from a 75% open position. This tiny bit of "lag" or "memory" is its hysteresis.

A valve with low hysteresis is more repeatable. It hits the same target position more consistently, no matter what its last command was. For high-precision jobs like maintaining a specific pressure or speed, choosing a proportional control valve with low hysteresis is key to ensuring your system performs reliably day in and day out.

Can I Replace an On-Off Valve with a Proportional Valve?

Yes, absolutely. However, it's a significant system upgrade, not just a simple swap. The biggest change is on the control side. Your system will need a controller, like a PLC with an analogue output card, that can send a variable electrical signal (like 4-20mA or 0-10V). An on-off valve just needs a basic power-on or power-off signal.

While the upgrade requires new control hardware, the benefits can be massive. Shifting from a simple on-off function to nuanced proportional control can drastically improve your system's efficiency, precision, and overall capability—especially if you need to accurately manage speed, force, or position.

For expert guidance and a comprehensive selection of valves to suit any application, explore the full range at Solenoid Valve World. Find the perfect proportional control valve for your system today by visiting https://solenoid-valve.world.