Your Guide to Quick Disconnect Fittings

Ever tried to connect a high-pressure hydraulic line? It used to be a time-consuming, tool-heavy job. Now, imagine clicking that same line into place as easily as you would a garden hose. That’s the magic behind quick disconnect fittings.

These ingenious devices create secure, tool-free connections for fluid and gas lines in an instant, massively boosting efficiency and safety on site. For any job where speed and a reliable connection are non-negotiable, they are absolutely essential.

So, What Are They Really?

At its simplest, think of a quick disconnect fitting as a tough, industrial-strength version of the connector on your air compressor or garden hose. Its whole purpose is to let you connect and disconnect pressurised fluid or gas lines immediately and safely, without reaching for a single spanner or wrench.

This simple push-to-connect action shaves a huge amount of time off tasks that would otherwise involve threaded fittings, which need to be painstakingly tightened and double-checked for leaks.

Every quick disconnect is built around two core parts: a male plug (often called the nipple) and a female coupler (the socket). When you push the plug into the coupler, a clever internal locking mechanism—usually a set of ball bearings or pins—clicks everything securely into place. At that very same moment, internal valves in both halves swing open, letting the fluid or gas flow.

When it's time to disconnect, those same valves instantly snap shut. This action stops the flow dead in its tracks, preventing messy spills, keeping workers safe from hazardous materials, and saving costly media from being wasted. It's this self-sealing design that makes them so invaluable.

To help you get a clearer picture of these essential components, we've put together a quick summary.

Key Features of Quick Disconnect Fittings at a Glance

| Feature | Description & Benefit |

|---|---|

| Tool-Free Operation | Connections are made by hand, eliminating the need for tools. This dramatically speeds up changeovers and maintenance tasks. |

| Instant Sealing | Internal valves automatically close upon disconnection, preventing leaks and spills. This enhances safety and reduces media loss. |

| Locking Mechanism | A secure physical lock (e.g., ball bearings) prevents accidental disconnection under pressure, ensuring a reliable connection. |

| Versatility | Available in a wide range of sizes, materials, and designs to suit various fluids, gases, pressures, and temperatures. |

| Increased Efficiency | Drastically reduces connection and disconnection time compared to traditional threaded or flanged fittings. |

This table shows just how much thought goes into making a seemingly simple connection both fast and incredibly secure.

The Anatomy of a Secure Connection

To really get to grips with how these fittings create a perfect, leak-proof seal under serious pressure, let's break down the parts doing all the hard work:

- Male Plug (Nipple): This is the 'male' end of the fitting. It’s designed with a very specific, precisely machined shape that slides into the female coupler, engaging the locking system and opening the valve.

- Female Coupler (Socket): This is the 'female' side, which houses the locking mechanism (like those ball bearings) and a retractable sleeve. Pulling back this sleeve is what releases the plug, allowing for a quick disconnection.

- Internal Valves: Most high-quality designs will have valves in both the plug and the coupler. These can be different styles, like poppet or flat-face, but the principle is the same: they are pushed open when connected and are spring-loaded to slam shut the second they’re disconnected.

- Seals: These are the unsung heroes. O-rings and other seals, usually made from robust materials like Nitrile (Buna-N) or Viton, are squeezed tight during connection. This compression creates an impassable, leak-proof barrier that holds up against the system’s working pressure.

The real genius of a quick disconnect fitting is how it merges three critical jobs into one smooth action: it physically locks the two halves together, it opens a clear path for flow, and it creates a perfect seal. This all-in-one functionality is what makes them a cornerstone of modern industry.

The Evolution of Industrial Connections

To really get a feel for why modern quick disconnect fittings are so important, it’s worth taking a quick look back at where they came from. Long before they became the slick, high-tech components we use today, they were born out of a very real, practical need on the factory floor, especially during the UK's manufacturing boom in the mid-20th century.

Picture a busy production line where every second is vital. In that kind of setting, changing pneumatic or hydraulic tools with old-school threaded connections was a slow, awkward, and often messy job. Every single changeover meant downtime, the risk of a leak, and a hit to productivity. The need for a faster, more reliable way to swap out fluid and gas lines was obvious.

From Simple Problem-Solvers to High-Tech Solutions

The very first quick disconnect fittings were designed to fix that exact problem. They gave workers the ability to connect and disconnect pressurised lines in just a few seconds, with no tools needed. It was a simple idea, but it had a massive impact, immediately boosting efficiency in Britain's core manufacturing industries.

Of course, as industrial processes became more advanced, the fittings had to keep up. Those early designs were great, but they needed to evolve to handle new challenges:

- Higher Pressures: Hydraulic systems started running at immense pressures, which meant the fittings needed much stronger locking mechanisms and more robust seals to cope.

- Extreme Temperatures: The rise of new industrial applications demanded fittings that could perform just as reliably in freezing conditions as they could in high-heat environments.

- Wider Media Compatibility: Fittings had to be able to handle an ever-growing list of substances—from inert gases and water to aggressive chemicals and thick fluids—without corroding or failing.

This was a critical period of innovation. It forced designers to experiment with tougher materials like stainless steel and advanced sealing compounds, which really laid the foundation for the versatile fittings we rely on today.

The core idea of a quick connection never changed, but the technology certainly did. The journey of the quick disconnect fitting is really a story of constant adaptation, driven by the ever-increasing demands of industrial automation and safety.

This evolution kicked into high gear as British sectors like automotive and aerospace adopted more sophisticated manufacturing methods. For example, the move to just-in-time assembly lines in the UK's automotive sector—one of the largest in Europe—made rapid, leak-proof connections an absolute must-have.

The history of these fittings shows a clear progression from simply speeding up tool changes to becoming a true cornerstone of modern industrial infrastructure. This journey is reflected in market analysis, which shows how their use has expanded from heavy industry into critical applications in healthcare and energy. You can explore further research on the quick disconnect fittings market to see just how deeply they've been integrated. Today, their development continues to be shaped by strict safety regulations and the constant drive for even greater efficiency, ensuring they have a secure place in the future of industry.

Choosing the Right Type of Fitting

Not all quick disconnect fittings are created equal. Walk into any well-stocked workshop, and you'll find a dizzying array of options. Picking the perfect match for your specific application can feel overwhelming, but it really just boils down to understanding a few key categories. Get this choice right, and you're set up for efficiency, safety, and a long life for your equipment.

Think of it like choosing the right tyres for a vehicle. You wouldn't put skinny road tyres on a farm tractor, nor would you fit chunky off-road tyres on a Formula 1 car. In the same way, a fitting designed for a low-pressure pneumatic air tool is going to fail, and fail spectacularly, if you try to use it in a high-pressure hydraulic system on a piece of heavy construction machinery.

You'll mainly come across three families of fittings: hydraulic, pneumatic, and fluid transfer couplings. Each one is engineered with specific materials, valve designs, and pressure ratings to thrive in its intended environment. A mismatch won't just lead to poor performance; it can cause dangerous leaks or even a catastrophic failure.

Matching the Fitting to the Job

The best way to cut through the noise is to start with the demands of your system. This first step acts like a compass, pointing you towards a specific design style that offers the best performance and safety for what you need to do.

A few common design styles you'll see are:

- Poppet-Style Couplings: These are the real workhorses, perfect for general-purpose jobs like pneumatic air lines or simple water connections. They’re robust and don’t cost the earth, but be aware they can allow for a tiny bit of spillage when you disconnect them.

- Flat-Face (Dry-Break) Couplings: These are absolutely essential for hydraulic systems or when you're handling sensitive or hazardous fluids. Their clever design ensures a minimal-spill, or "dry-break," disconnection, protecting both the environment and your team from nasty leaks.

- Ball-Lock or Pin-Lock Fittings: You’ll often find these in the food and beverage industry, particularly in homebrewing setups. They provide a rock-solid and simple connection that's a breeze to clean and keep hygienic.

It's also crucial to remember that a system is only as strong as its weakest link. For instance, when setting up a fuelling system, selecting a proper fuel tank adapter is every bit as important as choosing the right quick disconnect to ensure everything is compatible and operates safely.

Why the Right Choice Matters

Getting the fitting right is about so much more than just making a connection. The right quick disconnect is a massive upgrade over old-school threaded connections, delivering huge improvements in speed, safety, and long-term costs.

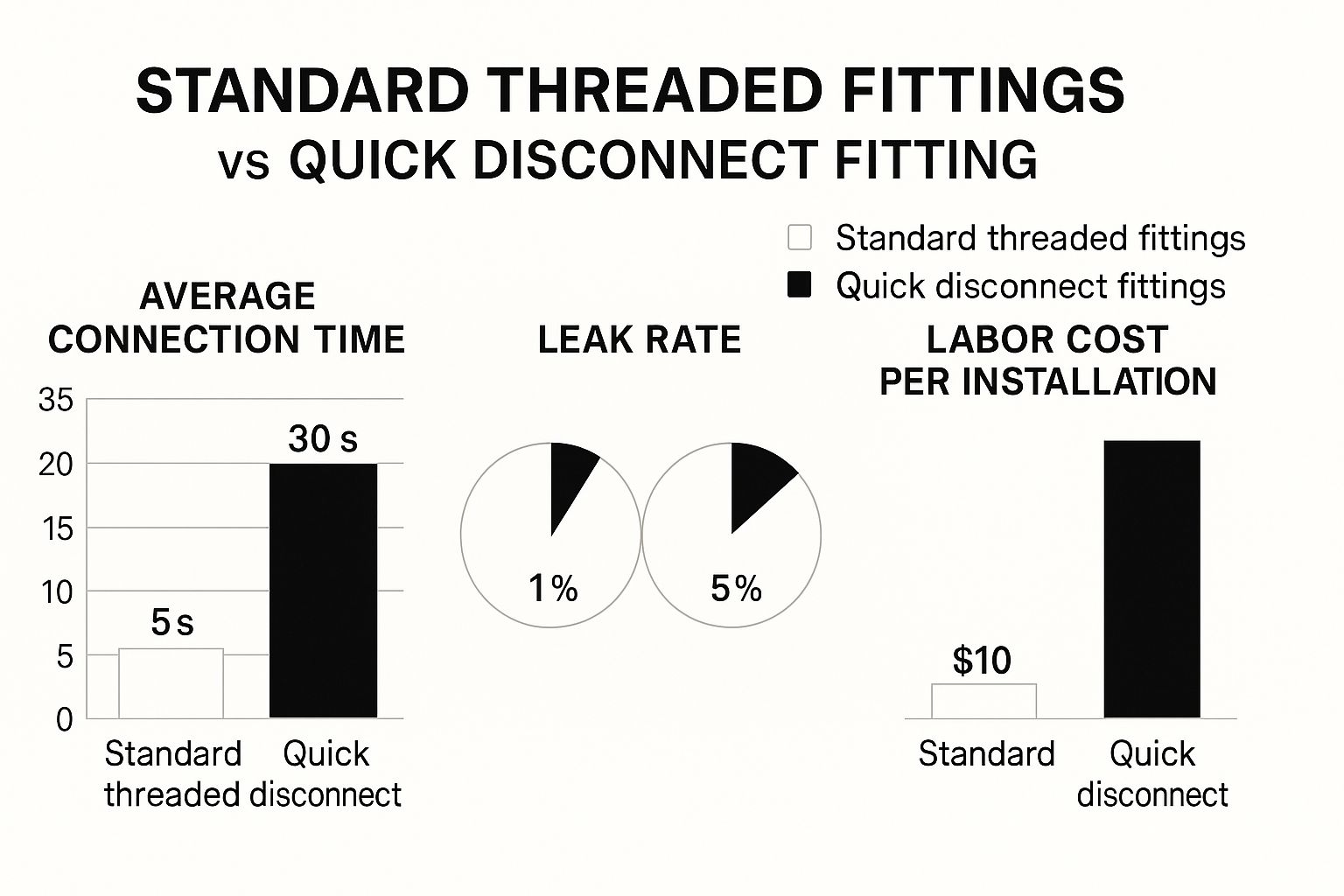

Take a look at how quick disconnects stack up against standard threaded fittings. The operational advantages are crystal clear.

The numbers don't lie. Quick disconnects slash connection time and labour costs while making a significant dent in leak prevention.

By investing just a few moments to select the appropriate style—whether it's a simple poppet valve for your workshop air line or a high-performance flat-face fitting for critical hydraulics—you are making a strategic decision. This choice directly impacts operational uptime, workplace safety, and your bottom line.

Matching Your Fitting to the Right Material

Choosing the right quick disconnect fitting goes far beyond simply matching the size and type. The material the fitting is made from is one of the most critical factors for guaranteeing safety, performance, and a long operational life.

Think of it like choosing cookware for a kitchen. You wouldn't use a delicate plastic bowl on a hot hob, and you certainly wouldn't store acidic lemon juice in a cast iron skillet. The same logic applies here. A fitting's material must be perfectly suited to the media it will handle, the pressure it will endure, and the environment it will live in.

Get this wrong, and you're looking at rapid corrosion, chemical breakdown, or even catastrophic failure. That can lead to costly downtime, damaged equipment, and serious safety risks for your team. A thoughtful decision upfront is the best way to prevent these problems down the line.

Common Materials And Their Uses

Different materials bring distinct advantages to the table, making them better suited for certain jobs. Understanding these properties is the key to making the right call for your system.

Brass: A fantastic all-rounder, brass is widely used for pneumatic air lines and general-purpose water connections. It offers good corrosion resistance and is relatively cost-effective, making it a reliable workhorse for less demanding applications where chemical compatibility isn't a major concern.

Stainless Steel: When you need serious strength and superior corrosion resistance, stainless steel is the go-to option. It’s ideal for high-pressure hydraulic systems, food processing environments, and applications involving aggressive chemicals or saltwater exposure. For an idea of how tough these can be, just look at the robust properties of stainless steel bulkhead tank fittings.

Specialty Plastics (e.g., Polypropylene): In medical, pharmaceutical, and food-grade applications, specialty plastics are often the top choice. They are lightweight, boast excellent chemical resistance against a huge range of substances, and prevent media contamination, which is absolutely essential for sterile environments.

Don't Forget The Seals

The body material is only half the story. The internal seal material is just as important, as it’s what forms the leak-proof barrier. A perfect stainless steel body will fail instantly if its internal seal is incompatible with the fluid passing through it.

Choosing a quick disconnect fitting is a two-part decision. You must match both the body material to the environment and the seal material to the media. Overlooking the seal is one of the most common and costly mistakes we see.

Common seal materials include Nitrile (Buna-N), which is great for petroleum-based fluids and air, and Viton (FKM), which excels with high temperatures and aggressive chemicals. Selecting the correct one is vital. The principles are very similar to those for solenoid valves, and you can learn more by exploring our detailed guide on solenoid valve seal materials.

Getting Installation and Maintenance Right

Let's be honest, a quick disconnect fitting is only as good as its installation and the care you give it. You can have the best component in the world, but if it’s not installed and maintained correctly, it’s bound to fail. That means leaks, safety risks, and expensive downtime nobody wants.

Following a few straightforward best practices from day one will ensure you get maximum performance and a long service life from your fittings.

When installing, it all starts with the threads. Always use the right thread sealant or tape for a leak-proof seal, but here’s a pro tip: keep it off the first two threads. This simple step prevents sealant from getting pushed into your system where it can cause blockages. Also, avoid over-tightening. It’s a common mistake, but cranking down too hard can damage the threads or even crack the fitting, creating a weak spot that’s guaranteed to fail under pressure.

Proactive Upkeep for Lasting Performance

Once your fittings are installed, routine maintenance is your best line of defence against surprise failures. A quick, regular inspection can catch a small issue before it snowballs into a major headache, saving you a world of time and money. Think of it as a quick health check-up for your entire fluid or gas system.

A consistent maintenance schedule is just as crucial for these fittings as it is for more complex parts. Preventative care is everything. Many of the same principles apply across different system components, and you can find some great guidance for building a solid maintenance plan in our article on solenoid valve installation and maintenance instructions.

Here’s a simple checklist to run through during your inspections:

- Check for Leaks: Use your eyes and ears. Look for any fluid drips or listen for the distinct hiss of escaping air around the connection points.

- Inspect for Wear and Corrosion: Give the fitting body, sleeve, and locking mechanism a good look. Are there any signs of rust, pitting, or other physical damage?

- Examine Seals and O-rings: When the fitting is disconnected, check the seals. If they look cracked, feel brittle, or are misshapen, they need replacing immediately.

- Use Dust Caps: This one is so simple but so effective. If fittings will be disconnected for a while, always pop on the protective dust caps to keep dirt and other contaminants out of the line.

Remember, regular maintenance isn't just about fixing problems—it's about stopping them before they start. A few minutes spent on a visual check can prevent hours of downtime and create a much safer working environment for everyone. Being proactive is the secret to getting the most out of your quick disconnect fittings.

Modern Applications and Critical Industry Roles

While quick disconnect fittings are absolute champions on the factory floor, their influence reaches far beyond traditional manufacturing. They play a crucial part in sectors where speed and reliability can literally be a matter of life and death. When you look at these high-stakes roles, you really start to appreciate just how vital this technology has become.

From busy workshops to quiet hospital rooms, these fittings are the unsung heroes of modern systems. In consumer gear, for example, they make setting up specialised tools a breeze. This massively improves the user experience with products like the best foam guns for garden hoses, which depend on a fast, leak-free connection to work properly.

Life-Saving Medical Connections

Nowhere is the need for rapid, secure connections more critical than in healthcare. Medical-grade quick disconnect fittings are essential parts of life-saving equipment like hospital ventilators and oxygen delivery systems. In these environments, there is simply zero room for error.

A sterile, secure, and instant connection can make all the difference in a critical care situation. The fittings used here are specifically designed to be non-spill and are made from materials that prevent any contamination, ensuring patient safety is always the top priority. Their simple push-to-connect design lets medical staff swap gas lines or fluid bags in seconds—a crucial advantage during an emergency.

The COVID-19 pandemic threw this critical role into the global spotlight. In the UK, the sudden, massive demand for ventilators and respiratory support devices led to a surge in the use of these fittings. This event alone is estimated to have accelerated their adoption in medical and industrial automation by a significant 15-20% between 2020 and 2023. You can see more on these trends and their impact on the quick connect fitting industry.

Powering the Digital and Agricultural Worlds

Beyond healthcare, you'll find quick disconnect fittings in industries that might seem completely unrelated but share a common need for efficiency and precision.

- Data Centre Cooling: The servers that power our digital lives generate an immense amount of heat. Advanced liquid cooling systems rely on non-spill quick disconnect fittings, which allow technicians to "hot-swap" server components without shutting everything down or risking a catastrophic coolant leak.

- Food and Beverage: In processing plants, hygiene is everything. Stainless steel, food-grade fittings make rapid cleaning and equipment changeovers possible, which minimises downtime and prevents cross-contamination between different product batches.

- Advanced Agriculture: Modern farm machinery is packed with complex hydraulic and pneumatic systems for everything from steering to operating heavy implements. Quick disconnect fittings allow farmers to swiftly change tools and attachments right there in the field, maximising productivity during tight planting and harvesting windows.

These fittings often work alongside other components, and it's helpful to see how they fit into the bigger picture. For anyone interested, our guide on pneumatic solenoid valves offers more context on related control technologies.

Common Questions About Quick Disconnect Fittings

Even when you feel you’ve got a handle on the basics, real-world questions always pop up when you're working with quick disconnect fittings. Getting these questions answered properly is the key to keeping your system safe, avoiding expensive mistakes, and getting the performance you expect.

Let's walk through some of the most common queries we hear from technicians and engineers out in the field.

Can You Mix and Match Brands?

This is probably the most frequent mistake we see people make—trying to connect a plug from one brand to a coupler from another. So, can you do it?

The short answer is no. We strongly advise against mixing components from different manufacturers, even if they look like they fit together. Tiny, almost invisible differences in dimensions, valve designs, or locking mechanisms can cause poor performance, nagging leaks, or worse—a dangerous connection failure under pressure. For guaranteed safety and reliability, always use a matched pair from the same manufacturer.

Sticking to this simple rule will save you a world of trouble.

Understanding Shut-Off Mechanisms

Another point that often causes confusion is the difference between shut-off types. What really separates a single shut-off from a double shut-off coupling?

A single shut-off coupling has a valve only in the coupler (the female half). When you disconnect it, flow from the supply line stops. Simple enough. However, the male plug and whatever hose is attached to it will drain any fluid left inside.

A double shut-off coupling, on the other hand, has valves in both the plug and the coupler. The moment you disconnect, it stops the flow from both sides of the connection. This design is absolutely essential for hydraulic systems or any job where spilling fluid would be a major safety or environmental hazard.

How to Choose the Right Fitting Size

Finally, how do you pick the right size for your system? It's about more than just matching your hose diameter; the real goal is to support your system's required flow rate.

Think of it this way: a fitting that's too small for the flow you need (measured in LPM or GPM) acts like a bottleneck in a pipe. This restriction chokes your system's efficiency, creates unwanted heat, and can starve downstream components of the pressure they need. Conversely, a fitting that's way too big is often just an unnecessary expense.

To get it right, always check the manufacturer’s specifications and flow rate charts. This allows you to select a size that precisely matches what your system demands to operate correctly.

For all your fluid and gas control needs, from specialised valves to essential pneumatic components, Solenoid Valve World offers expert support and a comprehensive product selection. Find the perfect solution for your system at https://solenoid-valve.world.