Solenoid Valve Normally Closed: Complete UK Selection Guide

Understanding Normally Closed Solenoid Valve Fundamentals

At the heart of many critical systems across the UK, you'll find the normally closed solenoid valve. These components play a crucial role in ensuring both safety and efficiency in various applications, from complex industrial processes to everyday household appliances. This section explores the core principles behind these valves, explaining their operation and highlighting their importance in safety-conscious designs.

How Normally Closed Solenoid Valves Work

A normally closed (NC) solenoid valve, in its default state, blocks the flow of media. This means when power is off, the valve remains closed. This inherent characteristic is key to its fail-safe operation. A spring-loaded plunger keeps the valve seat tightly sealed, ensuring no flow.

This closed position, importantly, doesn't require continuous power. This is a major advantage for energy efficiency, a growing concern in the UK. For instance, in a gas safety shut-off system, a normally closed valve automatically stops gas flow during a power outage.

Key Components and Their Function

Several key components work together to ensure the reliable operation of a normally closed solenoid valve:

- Solenoid Coil: This electromagnetic coil, typically made of copper wire, is the heart of the valve's operation. It generates the magnetic field needed to actuate the valve. When an electric current flows through the coil, it creates a magnetic force.

- Plunger/Armature: The plunger, made of a ferromagnetic material, reacts to the magnetic field generated by the solenoid coil. When energized, the coil attracts the plunger, overcoming the spring force and opening the valve.

- Spring: The spring plays a vital role, maintaining the valve's closed position when power is off. It also pushes the plunger back to its closed position when the coil is de-energized.

- Valve Seat and Seal: These components work in tandem to create a tight seal when the valve is closed, preventing any leaks. Precision in their design and manufacture is critical for long-term reliability.

- Valve Body and Ports: The valve body houses all the internal components. The ports provide the entry and exit points for the controlled media.

The Importance of Fail-Safe Operation

The normally closed configuration provides inherent safety advantages. This is especially critical in applications where uncontrolled media flow could present a hazard. The UK's increasing focus on sustainability and energy efficiency also contributes to the rising demand for these valves. The UK solenoid valve market is expected to see a Compound Annual Growth Rate (CAGR) of 4.3% between 2025 and 2035, driven partly by this national focus. You can learn more about the solenoid valve market here.

These operating principles and inherent fail-safe characteristics make normally closed solenoid valves vital components across diverse UK industrial and commercial settings. Understanding these basics is crucial for selecting the right valve for your specific application. This ensures optimal performance, safety, and efficiency. In the following sections, we'll delve into various applications and technical specifications.

Critical Applications Across UK Industries

Normally closed solenoid valves are essential components in various UK industries. Their fail-safe design makes them ideal for safety-critical applications, ensuring controlled operation and minimizing potential risks. Let's explore some key sectors where these valves are vital.

Water Treatment Facilities

In UK water treatment plants, normally closed solenoid valves precisely regulate water flow and chemical dosing. They ensure accurate control during different treatment phases, including filtration, disinfection, and pH balancing. For instance, a normally closed solenoid valve can quickly shut off the water supply if a leak occurs, preventing flooding and damage.

This level of control is essential for maintaining water quality and meeting UK regulatory standards. Furthermore, automating processes with these valves improves efficiency and reduces human error.

HVAC Systems in the UK

Heating, ventilation, and air conditioning (HVAC) systems throughout the UK depend on normally closed solenoid valves for safe and efficient performance. These valves manage the flow of refrigerants, water, and other media within the systems.

Consider a standard air conditioning unit. A normally closed solenoid valve controls the refrigerant flow to the compressor. The valve opens when cooling is needed, allowing refrigerant to flow. It closes when the target temperature is reached, conserving energy. This on-demand operation optimizes energy use in UK buildings.

Safety in Gas Distribution Networks

Normally closed solenoid valves are crucial for gas distribution networks across the UK. Their fail-safe design offers a vital safety net in emergencies, such as gas leaks. This is especially important in densely populated areas.

The valves automatically shut off the gas supply in these situations, preventing potentially disastrous incidents. This inherent safety feature is crucial for public safety and compliance with UK gas safety regulations.

Essential for Chemical and Pharmaceutical Processing

Chemical and pharmaceutical plants in the UK rely on the precision and safety of normally closed solenoid valves. These valves have diverse applications, including controlling reactive chemical flow, managing ingredient mixing, and ensuring accurate dosing.

In pharmaceutical production, for example, precise control over ingredient flow is crucial for producing high-quality medications. The fail-safe nature of normally closed valves helps prevent cross-contamination and ensures a safe manufacturing process.

Applications in the Automotive and Energy Sectors

Normally closed solenoid valves play a critical role in industries ranging from automotive to oil and gas. In automotive manufacturing, these valves contribute to automated processes like paint spraying and welding. They're also used in safety systems for pipelines and refineries in the oil and gas sector.

Renewable energy systems, such as solar thermal, utilize normally closed valves to control heat transfer fluids. Across these sectors, these valves ensure compliance with British safety standards and contribute to efficient operations. Their fail-safe design safeguards both equipment and personnel, making them essential for UK industries.

Technical Specifications That Drive Performance

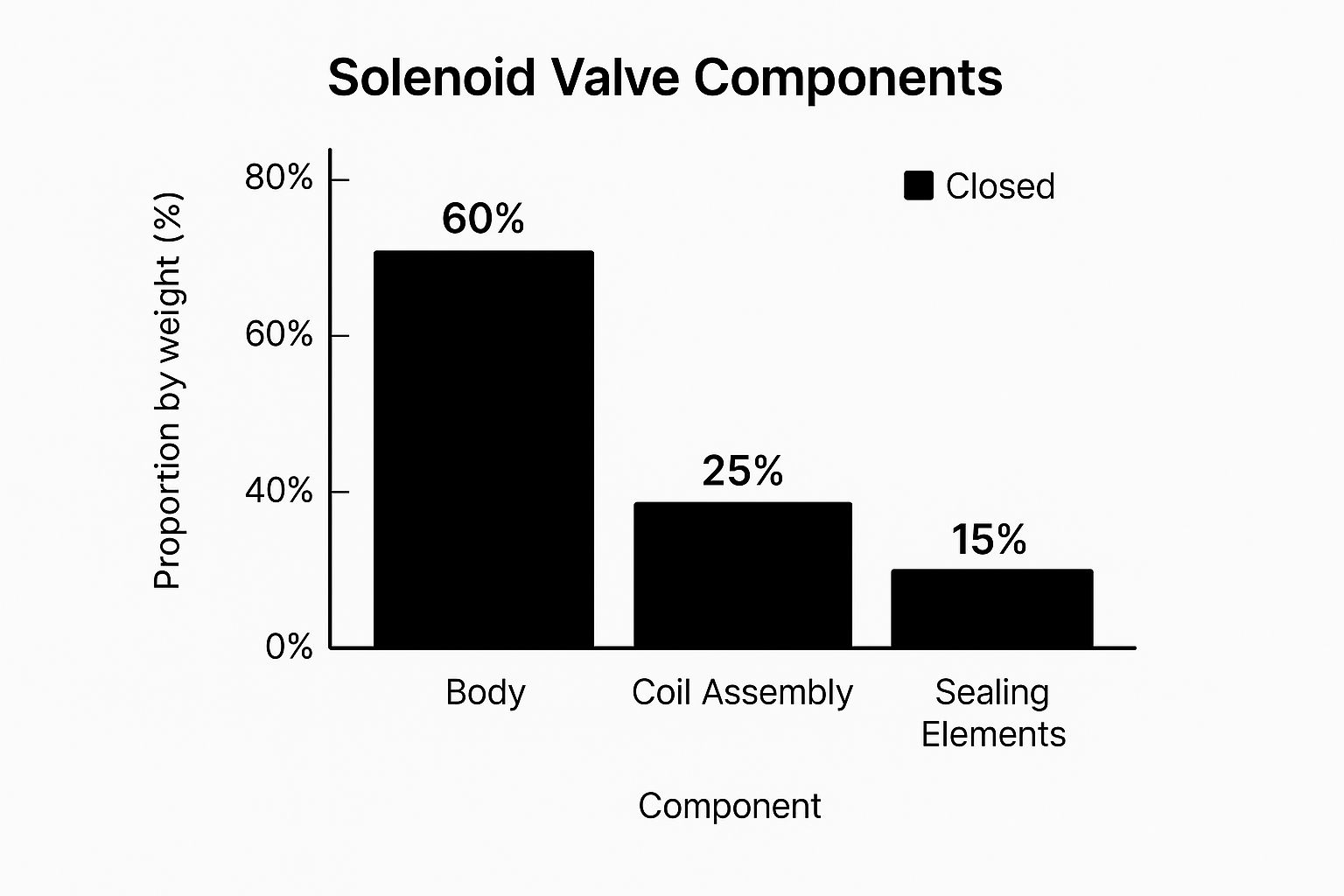

This infographic illustrates the composition of a typical normally closed solenoid valve, broken down by weight. The largest component is the body, providing a robust foundation. Next is the coil assembly, responsible for the valve's actuation. Finally, the precision-engineered sealing elements, though smaller in proportion, play a vital role in preventing leaks.

Understanding the technical specifications of these valves is essential for selecting the correct component for your application. Datasheets provide detailed information on a valve’s capabilities and limitations, which is crucial for engineers optimizing system performance and ensuring long-term reliability.

Decoding the Datasheet: Key Parameters

Datasheets can be complex, but focusing on the key parameters makes them easier to navigate. Here are some of the most critical specifications to consider when selecting a normally closed solenoid valve.

Pressure Ratings: This defines the safe operating pressure range, crucial for both low-pressure and high-pressure applications. A valve for a domestic water system will have a significantly lower pressure rating than one used in industrial hydraulics.

Flow Coefficients (Cv): The Cv value indicates the valve's flow capacity. A higher Cv means greater flow, directly impacting system efficiency and operational costs.

Temperature Range: This specifies the temperature limits for effective valve operation. Selecting the correct temperature range ensures reliability in diverse environments, from freezing outdoor conditions to high-temperature industrial processes.

Response Time, Duty Cycle, and Longevity

Beyond the basics, other specifications offer deeper insights into performance and lifespan.

Response Time: This measures how quickly the valve opens or closes. Fast response times are essential in applications demanding precise control, like safety shut-off systems.

Duty Cycle: This indicates how long the valve can remain energized without overheating. A higher duty cycle is beneficial for continuous operation.

Material Compatibility and Environmental Ratings: Compatibility between valve materials and the working media prevents corrosion and ensures long-term reliability. Environmental ratings (like IP ratings) protect against dust and moisture.

Sizing Calculations and Selection Criteria

Accurate valve sizing is crucial for optimal system performance. Sizing calculations consider factors like flow rate, pressure drop, and pipe diameter. Choosing the right valve ensures efficient operation and prevents undue stress on the system. Other selection criteria include reliability, cost, and compliance with relevant industry standards.

Normally Closed Solenoid Valve Specifications Comparison

The following table compares specifications across different valve sizes and pressure ratings. This information is essential for selecting the right valve for your specific application.

| Port Size | Pressure Rating | Flow Rate | Power Consumption | Response Time |

|---|---|---|---|---|

| 1/4" | 0-10 bar | 0.5 Cv | 10W | 20 ms |

| 1/2" | 0-15 bar | 1.2 Cv | 15W | 30 ms |

| 3/4" | 0-20 bar | 2.0 Cv | 20W | 40 ms |

| 1" | 0-25 bar | 3.5 Cv | 25W | 50 ms |

As you can see, larger port sizes generally correlate with higher pressure ratings, flow rates, and power consumption, while response times tend to increase slightly. Choosing the optimal balance of these specifications depends on the specific needs of your system.

Proven Selection Strategies For UK Applications

Selecting the right normally closed solenoid valve is critical for the safety and efficiency of your applications. This requires a systematic approach, considering factors ranging from media compatibility to adherence to UK standards. This section outlines proven strategies employed by experienced British engineers to ensure informed valve choices.

Media Compatibility and Environmental Conditions

The initial step involves determining media compatibility. The valve's internal components must be resistant to the controlled media, whether it's water, air, gas, or other fluids. The valve also needs to be suitable for the application's specific environmental conditions. Factors such as temperature, humidity, and potential exposure to corrosive substances must be considered.

For instance, a valve destined for outdoor use in the UK will require different protection than one used indoors. Careful consideration of these factors is vital for long-term reliability.

Performance Requirements and Pressure Drop Calculations

Next, define the necessary performance characteristics, including factors like flow rate, pressure rating, and response time. Accurate pressure drop calculations are also essential. These calculations determine the pressure loss across the valve, ensuring sufficient system pressure.

This is particularly crucial in applications with demanding performance needs. Precise calculations can prevent system inefficiencies and potential failures.

Energy Efficiency and British Standards Compliance

Energy efficiency is a primary concern in the UK. Choosing an energy-efficient solenoid valve can significantly reduce operating expenses. It's also vital to ensure compliance with all relevant British standards, including ATEX and CE marking requirements.

This confirms that the valve meets the necessary safety and performance benchmarks for UK applications. For a more detailed guide, check out How to master solenoid valve selection. British engineering firms using structured valve selection procedures report significant returns. They cite 43% fewer field failures and 67% lower maintenance costs compared to those using traditional methods. Properly specified normally closed valves achieve 89% reliability rates over five years. Further insights can be found in this study on UK valve selection statistics.

Cost-Benefit Analysis and Supplier Evaluation

Perform a thorough cost-benefit analysis to assess the long-term costs of different valve options. Consider not only the initial purchase price but also factors like maintenance expenses and expected lifespan.

Selecting a reputable supplier is equally crucial. Evaluate suppliers based on their experience, product quality, and technical support capabilities. This ensures access to reliable products and assistance when needed.

Reliability Factors and Long-Term Performance

Finally, prioritize reliability factors for sustained performance. Features like robust construction, high-quality sealing materials, and proven track records in similar applications contribute to long-term durability.

This is especially important in demanding industrial environments where downtime can be costly. You may find this resource helpful: How to choose a solenoid valve. By adhering to these proven selection strategies, UK engineers can confidently select the right normally closed solenoid valve for their specific requirements. This ensures optimal performance, safety, compliance with UK standards, and a strong return on investment.

Installation Excellence And Safety Best Practices

Getting the best performance and longest life from your normally closed solenoid valve depends on proper installation. This guide offers best practices used by top UK industrial contractors to help you achieve reliable and safe installations.

Mounting Procedures and Pipeline Preparation

Before you install the valve, make sure the pipeline is ready. This means thoroughly cleaning the pipes to remove any debris or contaminants that could affect the valve. Correct mounting procedures are essential for preventing leaks and ensuring long-term stability. Securely mount the valve following the manufacturer’s instructions, using the right brackets and supports.

Pay close attention to valve orientation. Many normally closed solenoid valves have specific flow directions, usually marked by arrows on the valve body. Installing the valve in the wrong direction can reduce performance and even cause damage.

Electrical Connections and Safety Protocols

All electrical connections should be made by a qualified electrician, following UK electrical codes and regulations. Use correctly sized wiring and ensure proper grounding to avoid electrical hazards. Electrical safety protocols are critical. Always disconnect the power before working on any electrical connections to prevent shock.

Double-check all wiring connections are tight and properly insulated. This helps prevent short circuits and ensures reliable operation. These careful steps reduce the risk of electrical faults and help maintain a safe working environment.

Commissioning and Validation Testing

After installation, commissioning procedures are essential. This involves testing the valve to ensure it’s working correctly. Validation testing protocols confirm the valve performs as expected under real-world conditions, including pressure and temperature changes.

Keep detailed records of the installation process, including wiring diagrams and test results. This documentation will be valuable for future maintenance and troubleshooting.

Safety Considerations for Pressurized Systems

Working with pressurized systems requires extra care. Always depressurize the system before working on any components, including the normally closed solenoid valve. Wear the appropriate safety gear, such as eye protection and gloves.

Understand the specific safety requirements for the materials you’re working with. For example, if you’re handling flammable gases, ensure adequate ventilation and eliminate any ignition sources. You might be interested in: How to master solenoid valve installations.

Avoiding Costly Installation Mistakes

Many common installation errors can affect performance and safety. Overtightening fittings can damage the valve body, and inadequate pipe support can lead to leaks and vibrations. Using the wrong sealing materials can also cause leaks and premature valve failure.

By following these best practices and the manufacturer’s instructions, you can avoid expensive mistakes and ensure a reliable, long-lasting installation. Careful planning and execution are key to a successful installation. This approach minimizes problems and ensures the normally closed solenoid valve provides optimal performance and safety throughout its life. A properly installed valve is essential for the reliable and safe operation of your entire system.

Troubleshooting Common Issues And Maintenance Excellence

Maintaining your normally closed solenoid valves is essential for ensuring reliable operation and a longer service life in demanding UK industrial environments. This section offers practical guidance, developed by experienced UK maintenance professionals, for troubleshooting common issues and implementing effective preventative maintenance.

Diagnosing Common Problems

Even with correct installation and component selection, solenoid valves can sometimes malfunction. Quickly identifying the root cause is crucial to minimize downtime. Here’s a structured approach to diagnose and resolve common issues:

No Flow: If the valve doesn't open when energized, the problem might be electrical. Check for a faulty coil, a blown fuse, or incorrect wiring. A mechanical issue, such as a jammed plunger, could also be the cause.

Valve Doesn't Close: If the valve stays open even when de-energized, suspect a damaged spring, debris lodged in the valve, or worn seals. This can lead to continuous flow and wasted energy.

Slow Response: A sluggish valve response might indicate a weak coil, low voltage, or excessive friction in the mechanical parts. This can affect the precision of controlled processes.

External Leaks: Leaks around the valve body often indicate damaged seals or loose fittings. Tightening connections or replacing worn seals usually rectifies this.

You might find this helpful: How to master troubleshooting solenoid valves.

Step-by-Step Diagnostic Procedures

To systematically address these problems, follow these steps:

Isolate the Valve: Before any maintenance, isolate the valve from the system. Shut off the media supply and disconnect the power.

Visual Inspection: Examine the valve for any visible signs of damage, like cracks, leaks, or loose wiring.

Electrical Testing: Use a multimeter to check the coil's resistance and ensure the correct voltage is supplied to the valve.

Mechanical Inspection: Disassemble the valve carefully (following the manufacturer's instructions). Inspect the plunger, spring, and seals for wear or damage.

Preventive Maintenance Schedules

A proactive maintenance approach prevents problems before they escalate. Establish a regular schedule based on operating conditions and the manufacturer’s recommendations:

Regular Inspections: Conduct visual inspections monthly to identify leaks or physical damage.

Cleaning: Clean the valve internals annually to remove debris. Use a suitable cleaning solvent and follow safety guidelines.

Coil Testing: Test coil resistance every six months to detect early signs of coil burnout.

Seal Replacement: Replace seals proactively based on the manufacturer's recommendations or at the first sign of wear. This prevents unexpected leaks.

The following table provides a quick guide to common solenoid valve issues, probable causes, solutions, and preventive measures.

Common Solenoid Valve Problems and Solutions

| Symptom | Probable Cause | Solution | Prevention Method |

|---|---|---|---|

| No Flow | Faulty Coil/Wiring | Replace Coil/Check Wiring | Regular Coil Testing |

| Valve Doesn't Close | Damaged Spring/Debris | Replace Spring/Clean Valve | Scheduled Cleaning |

| Slow Response | Weak Coil/Low Voltage | Replace Coil/Check Voltage | Voltage Monitoring |

| External Leaks | Damaged Seals/Fittings | Replace Seals/Tighten Fittings | Regular Inspection/Seal Care |

This table summarizes common problems, making it easier to diagnose and prevent future issues. Regular maintenance is key to extending the life of your solenoid valves.

Extending Valve Service Life

Maximizing the lifespan of your solenoid valves involves several key strategies:

Use Genuine Replacement Parts: Genuine parts ensure proper fit and performance, contributing to long-term reliability.

Proper Storage: Store spare valves in a clean, dry environment to prevent corrosion and damage.

Follow Manufacturer Guidelines: Adhering to the manufacturer's instructions for maintenance and troubleshooting ensures optimal performance.

By following these troubleshooting and maintenance guidelines, your normally closed solenoid valves will operate reliably and efficiently, supporting critical processes across diverse UK industries. Explore Solenoid Valve World's extensive product range and expert resources for all your solenoid valve needs here.