Swing Check Valves Guide: Types, Installation & Tips

At its most basic, a swing check valve is a simple, automatic one-way gate for pipelines. It’s designed to do one job and do it well: let fluid or gas flow in a specific direction while reliably stopping it from flowing backwards. This critical function, known as backflow prevention, is a cornerstone of system safety and efficiency.

Understanding the Role of Swing Check Valves

Think of it as a one-way street for the fluids in your system. That’s the core idea behind how swing check valves protect your pipework. They are the unsung heroes in countless industrial and municipal applications, working silently in the background to prevent failures that could be catastrophic.

Without them, a sudden reversal of flow could wreak havoc, causing severe damage to expensive equipment like pumps and compressors, or even contaminating processed fluids.

The mechanism is wonderfully straightforward. Inside the valve, a disc (often called a 'flapper') hangs on a hinge. When fluid moves in the right direction, its pressure simply pushes the disc open, clearing the path. But if the flow stops or tries to reverse, gravity and the back-pressure instantly swing the disc shut against its seat. This creates a tight seal, stopping the reverse flow dead in its tracks.

To give you a clearer picture, let's break down the main features and benefits.

Swing Check Valve Key Features at a Glance

This table summarises the fundamental characteristics that make swing check valves so widely used.

| Feature | Description | Primary Benefit |

|---|---|---|

| Automatic Operation | Opens and closes based on flow and pressure dynamics, with no need for external power or manual control. | Reliability. It acts as a passive, fail-safe device that is always ready to work. |

| Simple Mechanism | Consists of a body, a hinged disc (flapper), and a seat. | Low Maintenance. Fewer moving parts mean less can go wrong, reducing downtime. |

| Low Pressure Drop | The disc swings fully out of the flow path, creating minimal obstruction. | Energy Efficiency. Less energy is needed to pump fluid through the system. |

| Versatile Design | Available in various designs (e.g., tilting disc, wafer) and materials to suit different applications. | Adaptability. Can be specified for almost any fluid, pressure, or temperature. |

| Backflow Prevention | The primary function is to seal against reverse flow, protecting upstream equipment. | Equipment Protection. Shields pumps and compressors from damage caused by backflow. |

These simple yet effective benefits are why they're a go-to choice in so many industries.

Key Takeaway: The main purpose of a swing check valve isn't about regulating flow or pressure. It's about being a fail-safe that automatically prevents backflow without needing any external control or power.

The importance of this function is reflected in its market size. The global swing check valves market was valued at approximately USD 1.2 billion and is projected to climb to about USD 1.8 billion by 2033. This growth is fuelled by ongoing industrial development and infrastructure projects, particularly in regions like the United Kingdom where strict safety and environmental standards demand robust backflow prevention.

Their simplicity, reliability, and low pressure drop make them a default choice in many scenarios. From municipal waterworks preventing used water from re-entering the main supply to oil and gas pipelines ensuring product only flows towards its destination, the swing check valve is a truly fundamental component in modern fluid handling.

How a Swing Check Valve Works

To really get your head around how a swing check valve works, it helps to think of it as a simple, automatic gatekeeper inside a pipe. Its entire job relies on basic physics, with no need for outside controls or power. The process is brilliantly simple, depending on just four key parts working together.

The main components are the valve body (the outer casing), the disc (or flapper, which is the gate), the hinge pin that the disc pivots on, and the seat, which is the surface the disc presses against to stop the flow. When fluid starts moving in the right direction, its own force is enough to push the disc open, letting it flow through with very little getting in the way.

This initial push needs a specific amount of pressure, a concept known as cracking pressure.

Understanding Cracking Pressure

Cracking pressure is simply the minimum upstream pressure required to lift the disc off its seat, overcoming gravity and the disc's own weight. For a standard swing check valve, this pressure is incredibly low – often less than 0.5 PSI. This means they open with very little effort, so they don't create a significant blockage or pressure drop in the system, which is a huge plus for energy efficiency.

Once that cracking pressure is met, the disc swings open. As the flow gets stronger, the disc moves further out of the way until it’s sitting almost parallel to the flow, creating a wide-open path. This clever design is exactly why swing check valves are known for their low head loss compared to other valve types.

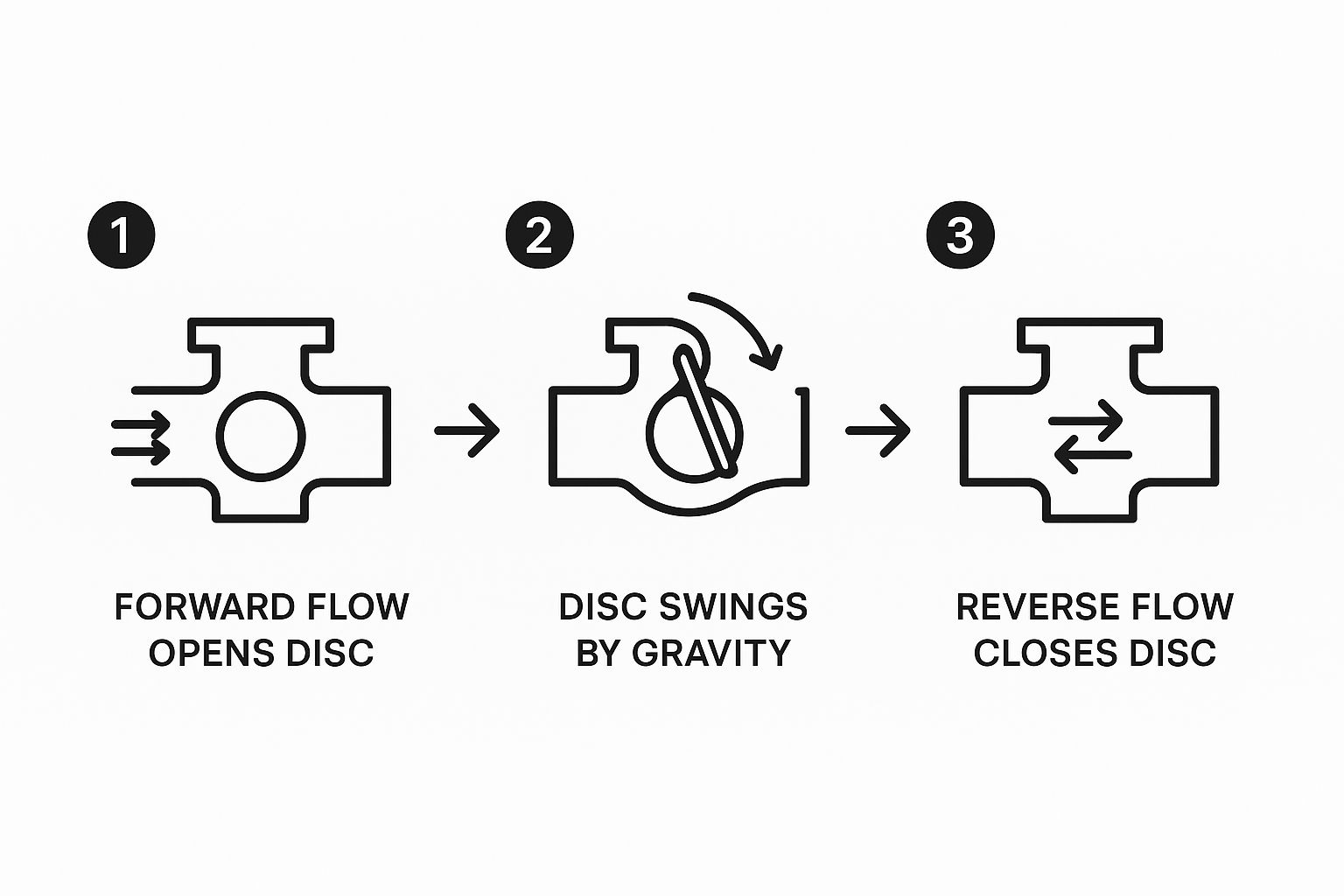

The diagram below shows you exactly how the valve responds as the flow changes.

This visual breaks down the three distinct phases of operation, from opening up with forward flow to closing securely when the flow stops or tries to reverse.

The Closing Mechanism: Sealing Against Backflow

The real magic happens when the forward flow slows down or stops altogether. At that point, gravity takes over, and the disc starts to swing back towards its closed position. If any flow starts moving backwards—a problem called backflow—the pressure from this reversal slams the disc shut against its seat, creating a tight seal.

This automatic closing action is what protects vulnerable equipment upstream, like pumps, from the damaging effects of backflow. How quickly and firmly this happens is absolutely critical.

A proper seal is the most important job of any check valve. Even a tiny leak can compromise the integrity of the whole system, leading to equipment damage or contamination. How well it seals all comes down to the condition of the disc and the seat surfaces.

For this reason, choosing the right materials for these parts is vital, as is making sure they stay clear of any debris that could get in the way of a tight shut-off. While the basic idea is straightforward, there are many variations out there designed for specific jobs. If you're looking at different options, you can find a great overview of various check valves to compare their unique features.

The entire operational cycle of a swing check valve is passive and purely mechanical, which is a massive reason for its widespread use and reliability. It just reacts to what the fluid is doing inside the pipe.

- Forward Flow: Pushes the disc open.

- No Flow: Gravity begins to close the disc.

- Reverse Flow: Back-pressure forces the disc shut, creating a seal.

This simple, repeating cycle happens millions of times over a valve’s lifespan, quietly keeping fluid systems safe and efficient across countless industries.

Exploring Different Types of Swing Check Valves

While the core idea of a swing check valve is straightforward, they aren't a one-size-fits-all solution. Different system demands have pushed engineers to develop several design variations, each with its own set of strengths. Picking the right one isn't just about making a choice; it's about protecting your equipment effectively rather than accidentally creating new headaches.

You'll generally come across three main designs: the conventional swing check, the tilting disc, and the wafer-style. Each offers a unique balance of performance, price, and how easily it fits into your pipework.

The Conventional Swing Check Valve

This is the classic, the design most people picture when they hear the term. It has a full-sized disc hinged right at the top of the valve body. When flow starts, the disc swings completely up and out of the way.

This wide-open path is its biggest advantage, creating an almost unobstructed passage for the fluid and resulting in a very low pressure drop. Its simple, tough construction makes it a reliable and budget-friendly workhorse for many general-purpose jobs, especially where the flow is steady and predictable.

However, its size and simple hinge can be a liability in systems with pulsating flow or sudden stops. The large disc is slow to react and close.

When the forward flow suddenly stops or reverses, that slow-closing disc gets slammed shut by the full force of the backflow. This creates a violent pressure surge known as water hammer or valve slam – a shockwave powerful enough to damage pipes, fittings, and even upstream equipment.

This potential for valve slam is the main drawback of the conventional design and the very reason engineers went back to the drawing board.

The Tilting Disc Swing Check Valve

To get around the destructive problem of valve slam, the tilting disc check valve was developed. It’s a major step up for systems that deal with fluctuating or high-speed flows. Instead of hanging from a simple hinge at the top, the disc pivots on a point much closer to its centre.

This clever bit of engineering delivers two huge benefits:

- Faster Closing: The disc has a much shorter path to travel to seal the valve. This allows it to snap shut much more quickly the moment the flow stops, often sealing the pipe before any significant reverse flow can even start.

- Softer Closing: Because it closes so fast—before the backflow can build up momentum—the impact is much gentler. This dramatically reduces or completely eliminates the damaging effects of water hammer.

The result is a far more stable and quieter operation in tough conditions. You might pay a bit more upfront, and there's a slightly higher pressure drop compared to the conventional type, but the long-term protection it provides for the entire system is often well worth it. While this is a specific type of swing check, it shares its core purpose with a wider family of non-return check valves all designed to safeguard your system.

The Wafer-Style Swing Check Valve

Finally, we have the wafer-style swing check valve, a design born out of a different necessity: a lack of space. Just as the name implies, this valve is incredibly compact and light. It's essentially a thin body that gets 'sandwiched' between two pipe flanges, held securely in place by the flange bolts.

Wafer valves are the go-to choice when space and weight are at a premium, like on ships, in mobile equipment, or inside tightly packed plant rooms. They often use a dual-disc (or dual-plate) design where two D-shaped plates are hinged in the centre, folding together like butterfly wings to open.

This dual-disc setup is almost always spring-loaded. The springs provide a very fast, non-slam closing action, making these valves not only space-efficient but also fantastic at preventing water hammer. They are a hugely popular and versatile option, particularly in HVAC systems and clean water services.

Choosing the Right Materials for Your Application

Selecting the right material for a swing check valve is where its performance is truly decided. It’s the difference between a valve that lasts for decades and one that fails within months. Matching the material to the fluid, temperature, and pressure isn't just a technical detail; it is the most critical step in ensuring system safety, reliability, and long-term value.

Making the wrong choice can lead to rapid corrosion, seat leakage, or even catastrophic failure. This guide breaks down the most common materials for the valve body and its internal components, known as the 'trim', connecting them to real-world UK applications.

Common Body Materials and Their Uses

The valve body is the main pressure-containing structure, so its material must be robust enough to handle the system's operating conditions. Think of it as the valve's skeleton – it has to be tough.

- Ductile Iron: This is a very popular and cost-effective choice for general-purpose applications. It offers excellent strength and durability, making it ideal for water, wastewater, neutral liquids, and air services at moderate temperatures and pressures.

- Stainless Steel (304 & 316): When you need superior corrosion resistance, stainless steel is the standard. Grade 316, with its added molybdenum, is particularly effective against chlorides and is widely used in chemical processing, food and beverage production, and marine environments.

- Bronze & Brass: These copper alloys are excellent for resisting corrosion in water applications, especially saltwater. They are frequently specified for marine systems, fire protection services, and plumbing, though they have temperature and pressure limitations compared to steel.

- Specialised Alloys (e.g., Duplex, Monel): For the most demanding environments involving highly corrosive chemicals, high temperatures, or extreme pressures, specialised alloys are required. These are common in offshore oil and gas platforms, aggressive chemical plants, and desalination facilities.

The choice of material is directly linked to the industry. The UK’s industrial valve market is a prime example of this connection. Recent analyses show that around 30-35% of check valve sales in the UK were for the oil and gas sector, with another 25-30% going to water and wastewater management. The remainder is split between chemical processing, power generation, and food production, all of which demand specific material properties for their swing check valves. You can explore more data about the UK's diverse check valve market here.

Trim Materials: The Heart of the Seal

The term 'trim' refers to the internal working parts of the valve that are in direct contact with the fluid—specifically the disc, seat, and hinge pin. The material selection for these parts is just as important as for the body, as they are responsible for creating the seal.

At the core of this decision is a simple choice: a soft, resilient seat or a hard, metal-to-metal one.

Key Insight: A valve's ability to provide a tight shut-off, often referred to as its 'sealing class', is almost entirely dependent on the seat material. A resilient seat offers a superior, bubble-tight seal, while a metal seat provides durability in harsh conditions.

Resilient Seated Valves

These valves have a soft material, like rubber or plastic, embedded in the valve seat or on the disc face. When the valve closes, the metal disc presses into this soft material, creating an exceptionally tight, leak-free seal.

- EPDM (Ethylene Propylene Diene Monomer): Excellent for water, steam, and alcohols. It is a go-to for drinking water systems and general industrial use but is not suitable for oils or solvents.

- NBR (Nitrile or Buna-N): The best choice for oils, fuels, and petroleum-based hydraulic fluids. It's a workhorse in the oil and gas and automotive industries.

- Viton® (FKM): Offers broad chemical resistance and can handle higher temperatures than EPDM or NBR. It is often specified for aggressive chemical services.

Metal-to-Metal Seated Valves

In these designs, a metal disc closes directly onto a metal seat. This construction is essential for applications where soft seats would quickly degrade.

This type of seating is the only option for high-temperature services (e.g., steam over 120°C) or in pipelines carrying abrasive fluids like slurries or sand-laden water. While they are incredibly durable, they may not provide the same bubble-tight shut-off as a resilient seat and typically have a higher allowable leakage rate.

Choosing between a resilient and metal seat is a classic trade-off between tight sealing and raw durability. Below is a quick guide to help match the right body and trim materials to your specific needs.

Swing Check Valve Material Selection Guide

| Material | Key Properties | Typical UK Applications |

|---|---|---|

| Ductile Iron | Strong, cost-effective, good general-purpose choice. | Water treatment plants, municipal water distribution, HVAC systems, general industrial services. |

| Stainless Steel (316) | Excellent corrosion resistance, especially to chlorides. Hygienic. | Chemical processing, food & beverage production, pharmaceutical manufacturing, marine environments. |

| Bronze / Brass | Good corrosion resistance in water, particularly saltwater. | Marine piping, fire protection sprinkler systems, domestic and commercial plumbing. |

| EPDM (Resilient Seat) | Excellent for water and steam. WRAS approved grades available. | Potable water networks, food processing (non-oily), heating and cooling systems. |

| NBR (Resilient Seat) | Superior resistance to oils, fuels, and hydrocarbons. | Oil & gas pipelines, hydraulic systems, fuel handling facilities, automotive manufacturing. |

| Metal Seat (e.g., Stellite) | High durability, abrasion resistance, and high-temperature capability. | High-pressure steam lines in power plants, abrasive slurry transport, high-temperature chemical reactors. |

This table provides a starting point, but always remember to cross-reference your selection with the specific chemical compatibility, pressure, and temperature ratings of your system. Getting this right from the start saves a lot of headaches later on.

Installation and Maintenance Best Practices

Even the most perfectly chosen swing check valve is only as good as its installation. You can't afford to get this wrong—proper fitting and proactive maintenance are non-negotiable for keeping your system safe and running smoothly. Get these steps right, and you'll sidestep premature failure, expensive leaks, and frustrating downtime.

Think of this as your go-to field guide. It’s packed with hands-on advice for technicians and engineers, covering everything from the first turn of the wrench to building a solid preventative maintenance plan. Following these best practices will get the most life out of your valves and help you spot small problems before they become major headaches.

Critical Installation Steps

Positioning is everything for a swing check valve. Unlike some other valve types, this one relies on gravity to do its job. If you install it incorrectly, it simply won't work. Always defer to the manufacturer's instructions, but there are a few universal rules to live by.

Most standard swing check valves are built for horizontal pipes. In this orientation, the hinge pin absolutely must be level and at the top of the valve. This lets gravity pull the disc shut when the flow stops. If you install it sideways or upside-down, the disc will never seat correctly, and you’ll have zero backflow protection.

Vertical pipelines are a different story.

- Vertical Flow Upwards: You can use a standard swing check valve here, but only if the flow is moving up. The upward pressure lifts the disc open, and gravity helps it slam shut when the flow reverses or stops.

- Vertical Flow Downwards: Never, ever install a standard swing check valve in a downward flow line. Gravity will just hold the disc open all the time, making it completely useless. You'll need a spring-assisted valve for this specific job.

Key Takeaway: See that flow direction arrow on the valve body? It’s your most important guide. Always make sure the system flow matches that arrow. Ignoring it is the single most common—and most critical—installation mistake you can make.

Beyond orientation, think about the pipework around the valve. Turbulent flow, often caused by nearby pumps, elbows, or other fittings, can make the valve disc "chatter" or flutter. This vibration quickly wears out the hinge pin and seat. To avoid this, give the valve some breathing room with a straight run of pipe upstream and downstream—a good rule of thumb is 5 to 10 times the pipe's diameter.

A Proactive Maintenance Schedule

The beauty of a swing check valve’s simple design is that maintenance is more about smart inspection than constant repairs. A preventative schedule is your best tool. You'll need to tailor it to your specific conditions; systems with abrasive fluids or high-cycle rates will naturally need more frequent check-ups.

Here's what a typical routine should look like.

- External Visual Inspection (Quarterly): Walk the line and look for the obvious. Check for leaks around gaskets or flanges. Scan the valve body and bolts for any signs of corrosion. Give the fasteners a check to make sure they're still tight.

- Internal Inspection (Annually or during shutdown): This is where you get the real story. You'll need to isolate the valve, remove it from the line, and give its internals a thorough examination.

When you have it on the bench, focus on the components that take the most abuse:

- Hinge Pin and Disc: Check the hinge for any excessive play or wobbling. A loose hinge is a classic sign of wear and a primary cause of misalignment, which leads directly to leaks.

- Disc and Seat Surfaces: Look closely at the sealing surfaces. You're searching for any scoring, pitting, or bits of debris that might have gotten embedded. If it’s a resilient-seated valve, inspect the elastomer seal for cracking, hardening, or swelling.

- Leakage Test: Once it's all back together, don't just assume it's working. Perform a seat leakage test by pressurising the downstream side and ensuring you have a tight seal.

By taking this disciplined approach, you ensure your swing check valves do exactly what you paid for them to do. It’s not just about protecting the valve itself—it’s about providing reliable protection for the far more valuable equipment up and down the line.

Troubleshooting Common Swing Check Valve Problems

Even the most dependable swing check valves can cause headaches, especially in high-demand systems. When a problem pops up, figuring it out quickly is the key to minimising downtime and preventing a small issue from turning into a major system failure. Let's walk through a practical, problem-solution approach to the most common challenges you're likely to encounter.

Most issues with swing check valves boil down to three things: disruptive noise, frustrating leaks, and parts wearing out far too soon. Getting to the root cause of each is the first, most critical step toward a reliable fix.

Diagnosing and Curing Water Hammer

Water hammer, often called valve slam, is probably the most destructive problem you'll face. It's that jarring, loud bang you hear when a valve shuts. That noise is actually a violent pressure surge—a shockwave—tearing through your pipeline. This single event can be powerful enough to damage pipe supports, fittings, and other equipment upstream.

This issue is almost always caused by high-velocity reverse flow slamming the disc shut before it can close gently on its own. The conventional swing check valve design, unfortunately, is particularly prone to this.

Common Causes & Solutions:

- Improper Valve Type: The valve just can't close fast enough for the system's needs. In systems with high flow rates or frequent pump stops, a standard swing check is often too slow for the job.

- Solution: The best move is to replace it with a faster-acting valve. A tilting disc check valve or, even better, a spring-assisted, non-slam wafer valve is built specifically to close rapidly before that reverse flow can gain any real momentum. This effectively stops the slam before it can start.

- Incorrect Orientation: A valve designed for a horizontal pipe run might be installed in a vertical line without enough upward flow to cushion its closing.

- Solution: Double-check the installation against the manufacturer's specifications. If the valve is in a vertical pipe with upward flow, you need to be certain the flow velocity is high enough to properly manage the disc.

Solving Reverse Flow Leakage

A check valve that doesn't check is basically useless. When fluid leaks past the disc and flows backwards, it defeats the entire purpose of the valve. This can lead to serious problems like pump damage or product contamination.

A leaking check valve is a silent failure just waiting to happen. It might not make a sound, but it can cause pumps to spin backwards or allow contaminated fluids to mix with clean ones, leading to some very costly consequences.

The cause is almost always physical and relates to the integrity of the seal.

- Debris Trapped in the Seat: It doesn't take much. Small stones, scale from inside the pipe, or other solids can get lodged between the disc and the seat, preventing a tight seal. This is a very common issue in raw water or slurry applications.

- Solution: Isolate the valve, remove it from the line, and give it a thorough clean. It's also a good idea to flush the line before reinstalling it to prevent it from happening again straight away.

- Worn or Damaged Sealing Surfaces: Over time, the disc and seat can get scored, pitted, or eroded, especially in abrasive service. If you have a resilient-seated valve, the elastomer seal can harden, crack, or get physically damaged.

- Solution: You'll need to inspect the internal components. A metal seat might need to be re-lapped or machined back to a smooth finish, while a damaged resilient seal is a straightforward replacement job.

Stopping Annoying Valve Chatter

Valve chatter is a high-frequency, rapid fluttering of the disc. Not only does it create an incredible amount of noise, but it also causes extreme wear on the hinge pin and the disc itself, leading to a swift failure. Chatter happens when the flow isn't stable or strong enough to hold the disc fully open against its stop.

The disc essentially gets caught in a loop, partially opening and closing and hammering against its seat or stop.

- Low or Unstable Flow Velocity: This is the number one cause. The valve might be oversized for the actual flow rate, even if it matches the pipe diameter perfectly.

- Solution: The right fix is to size the valve based on the system's flow velocity (Cv), not just the pipe size. If the flow is consistently too low for the installed valve, you may need to fit a smaller one. Alternatively, a tilting disc or a spring-loaded valve will provide much better stability in these tricky low-flow conditions.

Frequently Asked Questions About Swing Check Valves

Even after you've got the basics down, you'll find that real-world applications throw up their own set of questions. When you're out in the field, it's the practical details that make all the difference. This section is all about tackling those common queries that engineers and operators run into every day.

We'll cut through the jargon and give you the straightforward answers you need to get the job done right, filling in any gaps that the technical manuals might have missed.

Can a Swing Check Valve Be Installed Vertically?

Yes, but there's a crucial catch: only in pipes with upward vertical flow. When installed this way, the forward flow has enough force to push the disc open, working against gravity. Once the flow stops or tries to reverse, gravity gives the disc a helpful nudge, ensuring it closes quickly and seals tight.

Whatever you do, never fit a standard swing check valve in a line with downward flow. Gravity will just pull the disc open and keep it there, making the valve completely useless at preventing backflow. For a downward flow scenario, you'd need to look at a spring-assisted valve instead.

What Is the Real Difference Between a Swing Check and a Lift Check Valve?

The easiest way to understand the difference is to picture how the disc moves. In a swing check valve, the disc is mounted on a hinge and swings open and shut just like a door. A lift check valve, on the other hand, has a disc or piston that moves straight up and down, guided by a central post.

This simple design difference creates two very different performance profiles:

- Swing Check: Because the disc swings right out of the way, it creates less of an obstruction and therefore a lower pressure drop. This makes it a great choice for horizontal pipelines and larger pipe diameters.

- Lift Check: This design has a higher pressure drop but closes much faster. It's generally a better fit for smaller pipes and is perfect for high-pressure gas or steam systems where you need a rapid, decisive shut-off.

The core distinction is the disc's path. A swing check's disc follows an arc, while a lift check's disc follows a straight, linear path. This seemingly small difference significantly impacts their ideal applications and performance.

How Do I Correctly Size a Swing Check Valve?

Sizing a swing check valve based on pipe diameter alone is one of the most common and costly mistakes we see. The right way to do it is to size the valve according to your system's flow velocity.

If the valve is too big for your actual flow rate, the fluid won't be moving fast enough to push the disc fully open and hold it steady. Instead, the disc will flutter and flap in the flow stream. This "valve chatter" is a killer for check valves, causing rapid wear and tear that will quickly destroy the hinge pin and seat.

To get it right, you need to calculate the fluid velocity under your normal operating conditions. With that number, you can pick a valve where the flow is strong enough to keep the disc held firmly open. Always refer to the manufacturer's flow performance (Cv) charts to make sure you're making the right choice.

At Solenoid Valve World, we provide the technical support you need to select the right valve for any application. Browse our extensive range of valves and control components online or contact our UK-based team for expert advice. Find the perfect solution for your fluid control system at https://solenoid-valve.world.