Coaxial Valves: High-Performance Fluid Control Solutions

What Are Coaxial Valves?

Coaxial valves are advanced electro mechanical devices designed to control the flow of fluids and gases with precision. Unlike traditional valves, they feature a coaxial design that allows for unobstructed flow paths, making them ideal for handling highly viscous, contaminated, or abrasive media.

Key Features of Coaxial Valves

High Flow Rates with Minimal Pressure Loss

The unique coaxial design enables high flow rates and low-pressure drops, making these valves suitable for applications requiring efficient fluid control.

Rapid Response Time

Coaxial valves offer fast actuation times, typically under 200 milliseconds, ensuring quick response in dynamic systems.

Wide Pressure and Temperature Range

These valves can operate under pressures up to 300 bar and temperatures up to 200°C, accommodating a broad spectrum of industrial applications.

Versatile Media Compatibility

Coaxial solenoid valves are compatible with various media, including oils, coolants, syrups, thick hydrocarbons, vacuum, gases', contaminated media, emulsions, and lubricants, provided the correct sealing materials are used.

Applications for Coaxial Valves

Industrial Automation

Ideal for systems requiring rapid and reliable switching of fluids and gases, such as lubrication systems in mechanical and plant engineering.

Vacuum and Gas Technology

Suitable for applications in vacuum systems and gas technologies, where precise control of media flow is essential.

Food and Beverage Processing

Coaxial valves are used in the food industry to control the flow of viscous substances like oils, creams, and syrups.

Chemical Processing

These valves handle aggressive and corrosive media, including acids and alkalis, in chemical processing applications.

Valve Types and Configurations

2/2 Way Coaxial Solenoid

These valves have two ports and two positions, allowing for simple on/off control of media flow.

3/2 Way Coaxial Solenoid

Featuring three ports and two positions, 3/2 way valves can divert or exhaust media flow, offering more complex control.

Externally Controlled Valves

2/2 way and 3/2 way Coaxial valves can be externally piloted via a NAMUR interface, providing flexibility in control methods.

Materials and Sealing Options

Coaxial valves are constructed from materials such as brass, steel, aluminium, and stainless steel (304 or 316). They offer a range of sealing materials, including Viton, EPDM, NBR, UHMW Polyethylene, and PTFE, to suit various applications.

Why Choose Coaxial Valves?

Compact Design: Their space-saving design allows for installation in tight spaces.

Low Maintenance: With fewer moving parts, these valves require less maintenance and have a longer service life.

High Reliability: Coaxial valves offer consistent performance, even under challenging conditions.

Energy Efficiency: They consume less power or air, contributing to overall system efficiency.

Frequently Asked Questions (FAQs)

What is the maximum pressure a coaxial valve can handle?

Coaxial solenoid valves can operate under pressures up to 300 bar, depending on the specific model and materials used.

Can coaxial valves handle viscous fluids?

Yes, the unobstructed flow path design allows coaxial valves to handle highly viscous fluids effectively.

Are coaxial valves suitable for food processing applications?

Absolutely, with appropriate sealing materials like PTFE, coaxial valves are ideal for controlling viscous substances in the food industry.

Explore Our Range of Coaxial Valves

Discover our extensive selection of coaxial solenoid valves, designed to meet the diverse needs of various industries. Whether you require valves for high-pressure systems, food processing, or chemical applications, we have the right solution for you.

Do you need a Coaxial Valve for your application?

System requires high flow rates with minimal pressure loss?

Media being controlled is more than 50 centistokes (Thick), contaminated or abrasive?

System has a high back pressure?

System flow in both directions?

System requires extremely fast acting valves?

You have a vacuum system?

Very low or zero pressure differential? (inlet and outlet pressures can equalise)

For oxygen service up to 20 or 40 Bar +60C Max, with special sealing and oxygen cleaning?

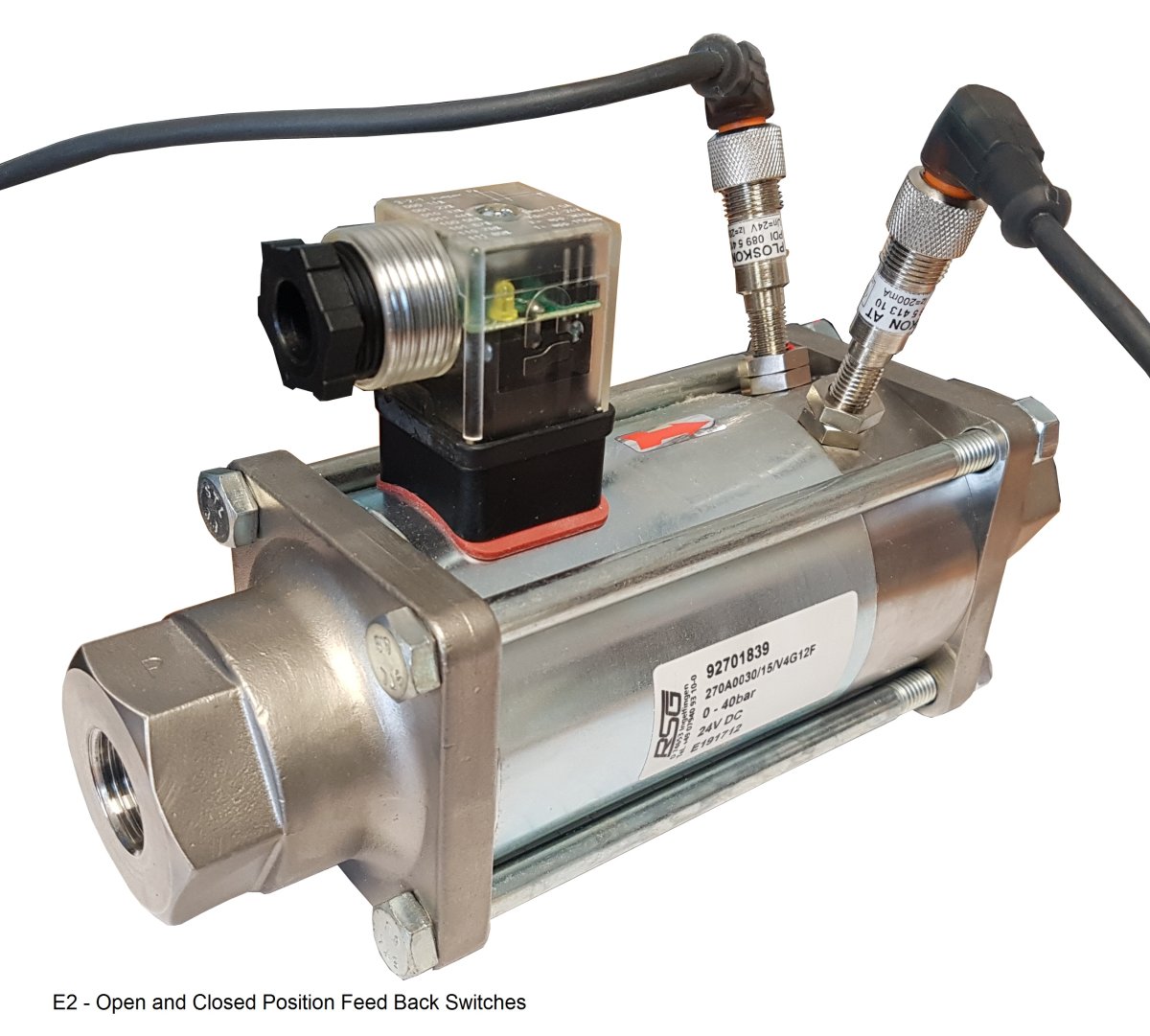

Require position feed back for open and or closed position?

Require a manual override facility?

Require mounting brackets?

Require a robust maintenance free valve with high cycle life for:

Ceramic pastes

Oils, corn oil, olive oil, castor oil, coconut oil, sesame seed oil, palm oil, linseed oil, etc

Creams, sour cream, ice cream, skin cream

Butter, peanut butter, almond butter, hazelnut butter, margarine etc.

Liquid Fats

Syrup or honey

Ink

Molten chocolate

Sauce

Thick hydrocarbons

If you require any or all of the above, you can view and buy a full range of coaxial valves here.

Coaxial Valve Orifice and Flow Rates.

There are a range of internal tube diameter sizes available for coaxial valves (both solenoid and pneumatically operated) typically 10mm internal diameter to 50mm. The tube internal diameter typically determines the flow rate (excepting that the port size is of equal size or more) offering a specific flow coefficient according to tube diameter. For example in the case of a 2-way coaxial valve typical Kv flow coefficients in litres per minute would be:

Tube Diameter (mm) |

Flow (Litres per minute) |

10 |

51 |

15 |

91 |

20 |

145 |

25 |

205 |

32 |

333 |

40 |

637 |

50 |

787 |

In practical terms Kv flow coefficient is the amount of water at 20°C that would flow with a pressure drop of 1 kilogram per centimetre across the valve. i.e. the pressure difference between inlet and out let pressure.

2/2 Way Coaxial Solenoid Valves.

2/2 Way Coaxial Pneumatic Valves

3/2 Way Coaxial Solenoid Valves

3/2 Way Coaxial Pneumatic Valves

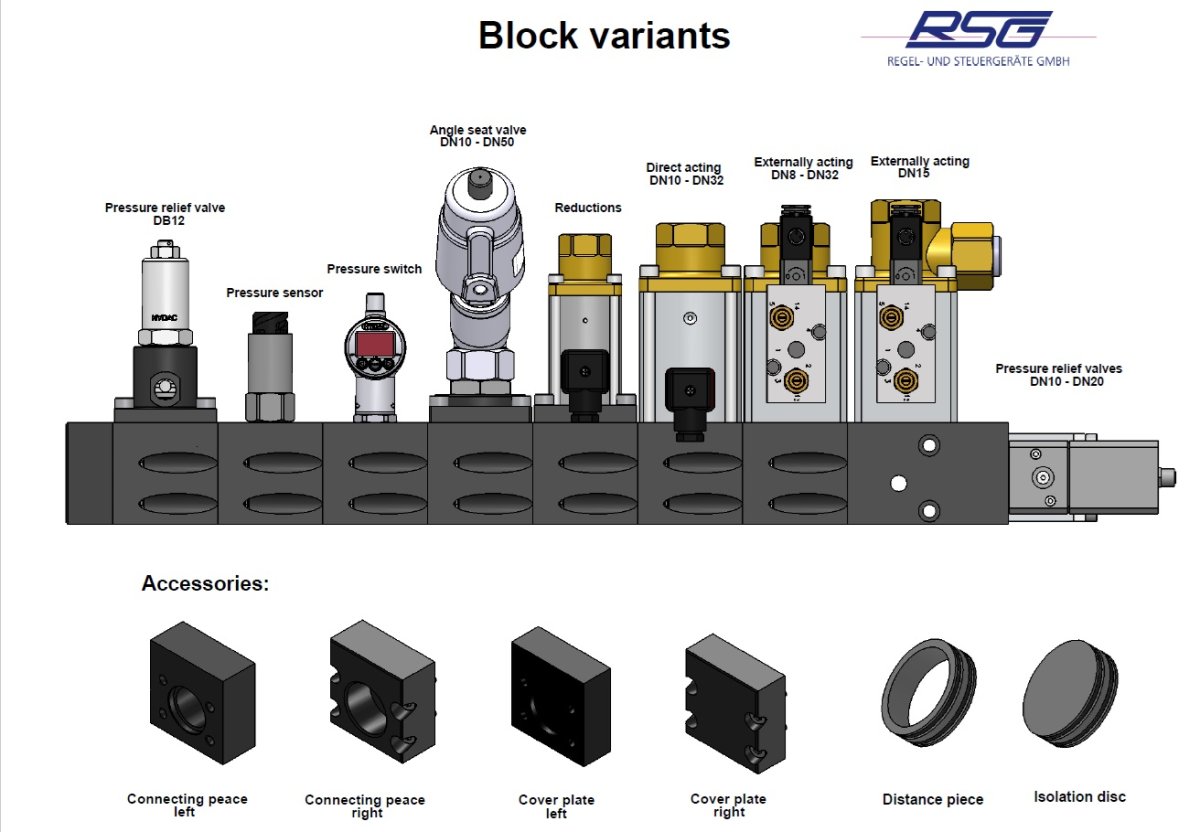

Coaxial Modular Systems

Coaxial Valve Technology.

Leading the way forward. Connexion Developments Ltd, in collaboration with RSG Regel - und Steuergerate GmbH, is pleased to announce a significant achievement in the realm of custom manifold design, specifically in the coaxial valve domain.

Initially employing standard 2/2 way coaxial valves for the construction of high-pressure 40 Bar fluid control systems, our client sought a more tailored solution for their manifold system.

Recognising the limitations of the existing approach, we introduced the RSG 270X modular system, which proved to be an optimal choice.

This modular system offers versatility through a range of combinations and full customisation capabilities, accommodating pressure control valves and monitoring devices. The seamless integration of the RSG 270X modular system paved the way for the development of a fully customised 3D-printed plastic valve manifold system tailored to the client's specifications. This bespoke solution, meticulously crafted to meet both dimensional and functional requirements, was delivered within a commendable 30-day timeframe in September 2022.

Following rigorous functional tests and evaluations, the successful validation in May 2023 led to the awarding of an 18-month contract. In July, a minor, non-critical modification to the valve's exterior was seamlessly incorporated into the design.

Despite this modification, the delivery timeline only experienced a minimal extension of three weeks. Consequently, the complete delivery was expedited, and the project was successfully concluded in early November 2023.