Breathing Air & Spray Booth Filter Sets — Independent Test Pass (Aug 2025)

Ultra-Clean Air for Garages, Spray Booths & Food Processing

Connexion Developments’ 3-stage Breathing-Air Filter Regulator Sets deliver technically clean, oil-free, odour-free air for demanding applications: automotive paint spray booths, breathing-air lines, and hygiene-critical production. Every set is factory assembled, silicone-free, pressure-tested to 15 bar, and supplied from UK stock with free next-day delivery (order cut-off 16:00).

Latest Test Results — EN 12021 Compliance Confirmed

In August 2025, our UFR-UMF-UMFB configuration was independently tested and passed a breathing-air quality check. Highlights included:

O₂ 20.65 %, Pressure 6.8 bar, CO = 0, Oil Content: Pass

Dewpoint −8 °C; CO₂ 361 (ppm)

Certificate reference: PM10145/002, completed 29/08/2025, Griffin Air Systems Ltd.

What it means: your spray-booth and breathing-air lines can meet the purity targets expected by EN 12021-style assessments when installed and maintained correctly.

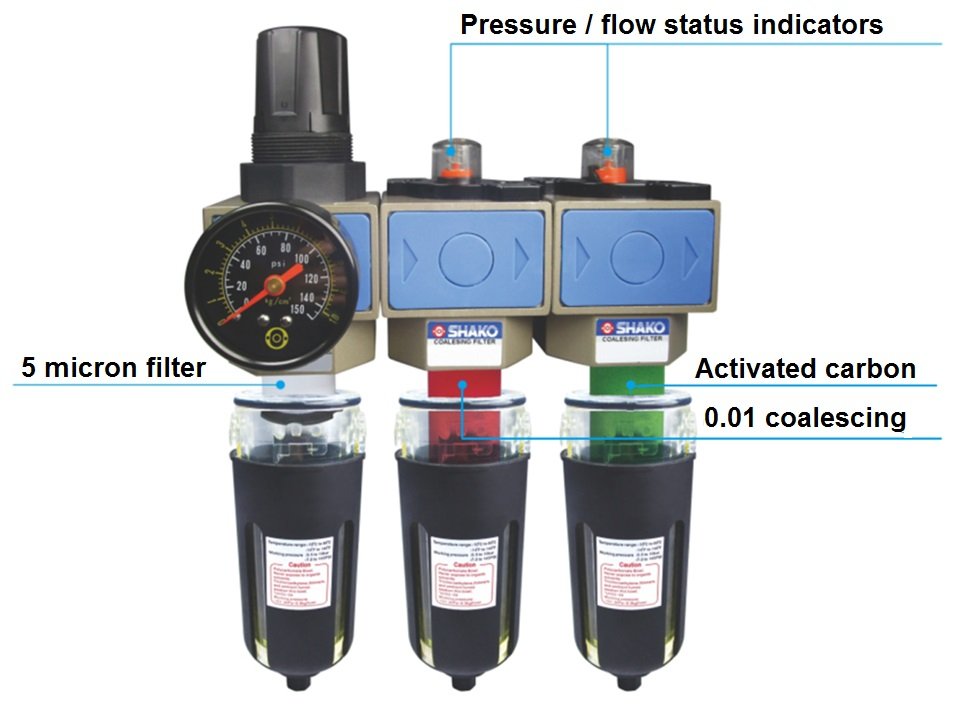

How the 3 Stage Filtration System Works

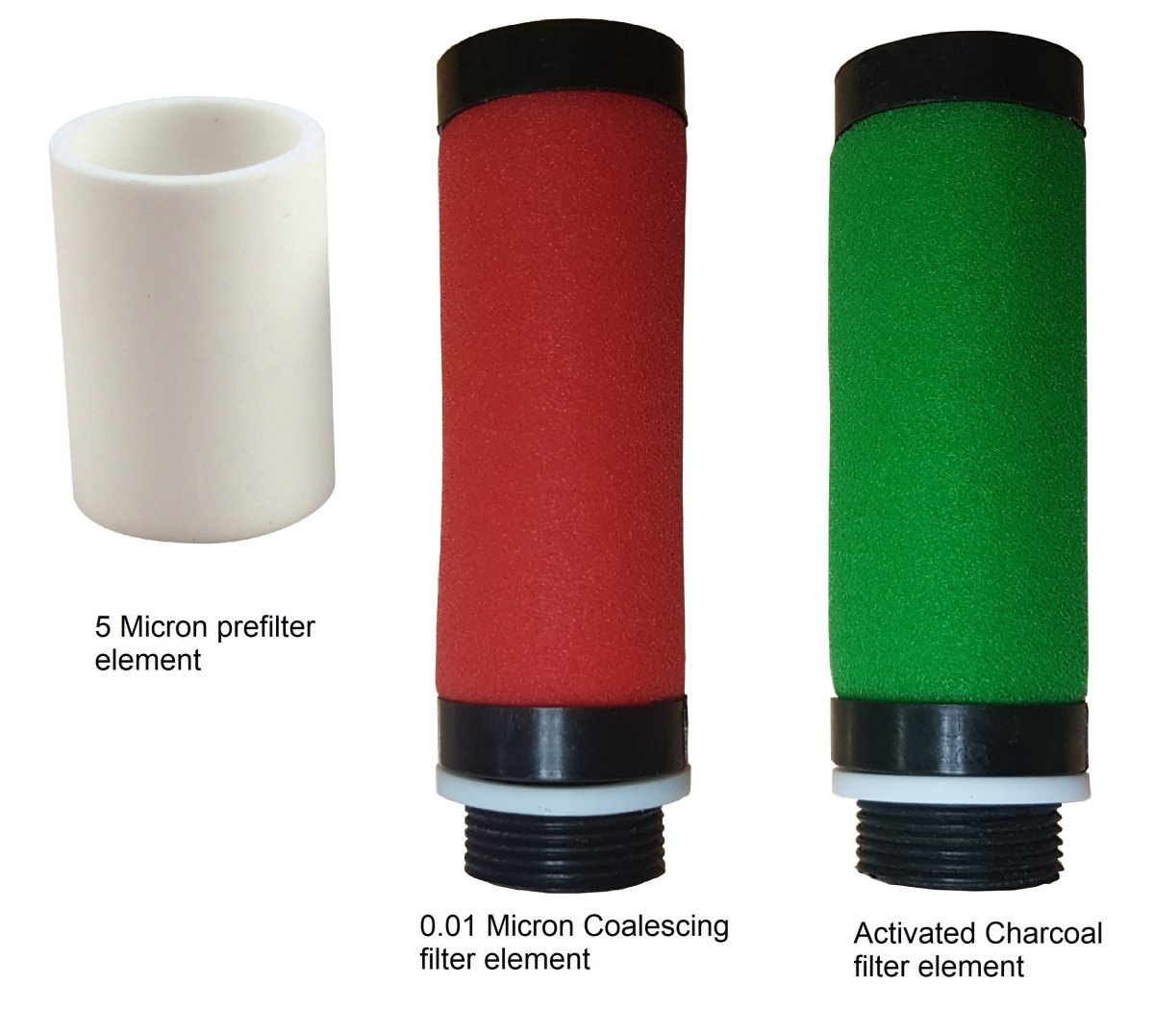

1) Pre-Filter (5 µm)

Removes bulk water and larger particulates to protect downstream elements.

2) Red Coalescing Filter (0.01 µm)

Captures oil mist and ultra-fine aerosols to achieve oil-free air.

3) Green Activated-Carbon Final Stage (to ~0.003 ppm)

Polishes residual vapours and odours for technically clean air suited to breathing-air use and paint finishing.

Why Body Shops & Food Plants Choose Connexion Developments

High Purity, Real-World Proof

Independently verified pass in Aug-2025 under typical working pressure.

Maintenance Made Easy

Visual filter-status gauges show when elements need attention — cut downtime and guesswork.

Compact but Capable

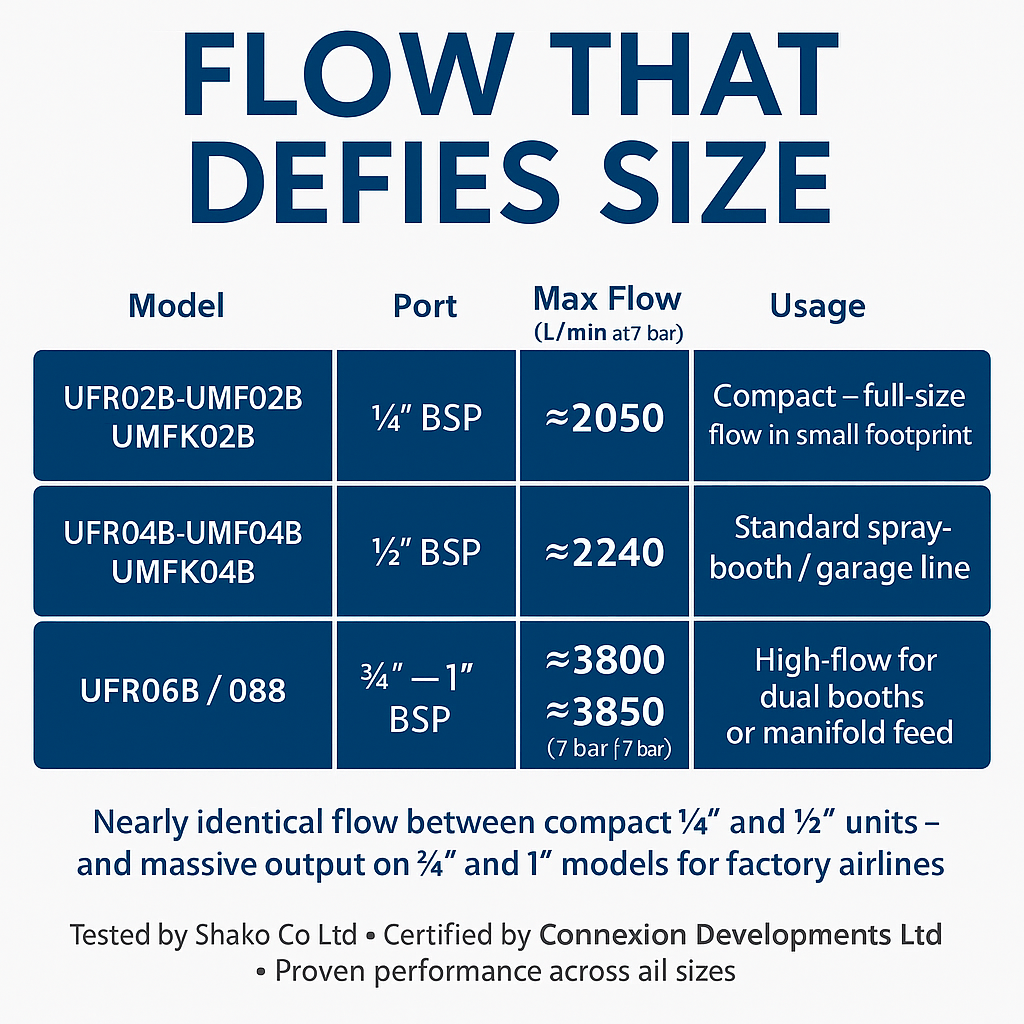

¼″, ⅜″ and ½″ units deliver near-identical, high usable flow for single booths and workstations; ¾″ and 1″ sizes provide higher flow for multi-booth or manifolded lines.

Built for Paint & Hygiene

Silicone-free assembly, pressure-tested to 15 bar, and supplied with genuine, affordable replacement elements from UK stock.

Typical Uses

Automotive paint spray booths (HVLP, refinishing, prep bays)

Breathing-air visor/hood lines and maintenance stations

Food & beverage processing lines requiring odour-free, oil-free air

General compressed air filtration before critical processes

What’s in the Box

Complete 3-stage assembly: regulator + pre-filter + coalescing + activated-carbon

Pressure gauge, mounting brackets & fixings, blanking plug

Quick-start instructions for right-first-time installation

Selecting the Right Size (Quick Guide)

Single Booth / Workstation

Choose ¼″–½″ BSP: compact, high-flow performance with minimal footprint.

Multi-Booth / Manifolded Lines

Choose ¾″ or 1″ BSP: higher flow capacity for plant-wide supply.

Need help sizing? Call us — we’ll recommend the correct set for your compressor pressure, line size and target flow.

Care & Compliance Tips

Change elements on time: use the filter-status gauge as your visual trigger.

Log periodic tests: keep EN 12021-style checks on file for audits; our Aug-2025 pass demonstrates the capability when maintained correctly.

Protect upstream: install water separators and drains where needed to extend element life.

FAQs

Are these filter sets suitable for breathing-air applications?

Yes — when installed and maintained correctly. Our configuration passed an independent breathing-air test in Aug-2025 at ~6.8 bar line pressure.

Do you stock replacement elements?

Yes — full element sets and individual 5 µm / 0.01 µm / activated-carbon cartridges are in stock and priced for regular maintenance.

Do smaller port sizes restrict flow?

The ¼″–½″ models offer very similar high flow for single-booth work; step up to ¾″–1″ for multi-booth or manifold supply.

Order Online

Popular configuration (product page):

Replacement elements: 1/4, 3/8 & 1/2 models

Replacement elements: 3/4 & 1" models

Free UK next-day delivery on stocked items. ISO 9001 & ISO 14001 systems.

Connexion Developments Ltd — Attention to Detail since 1998.