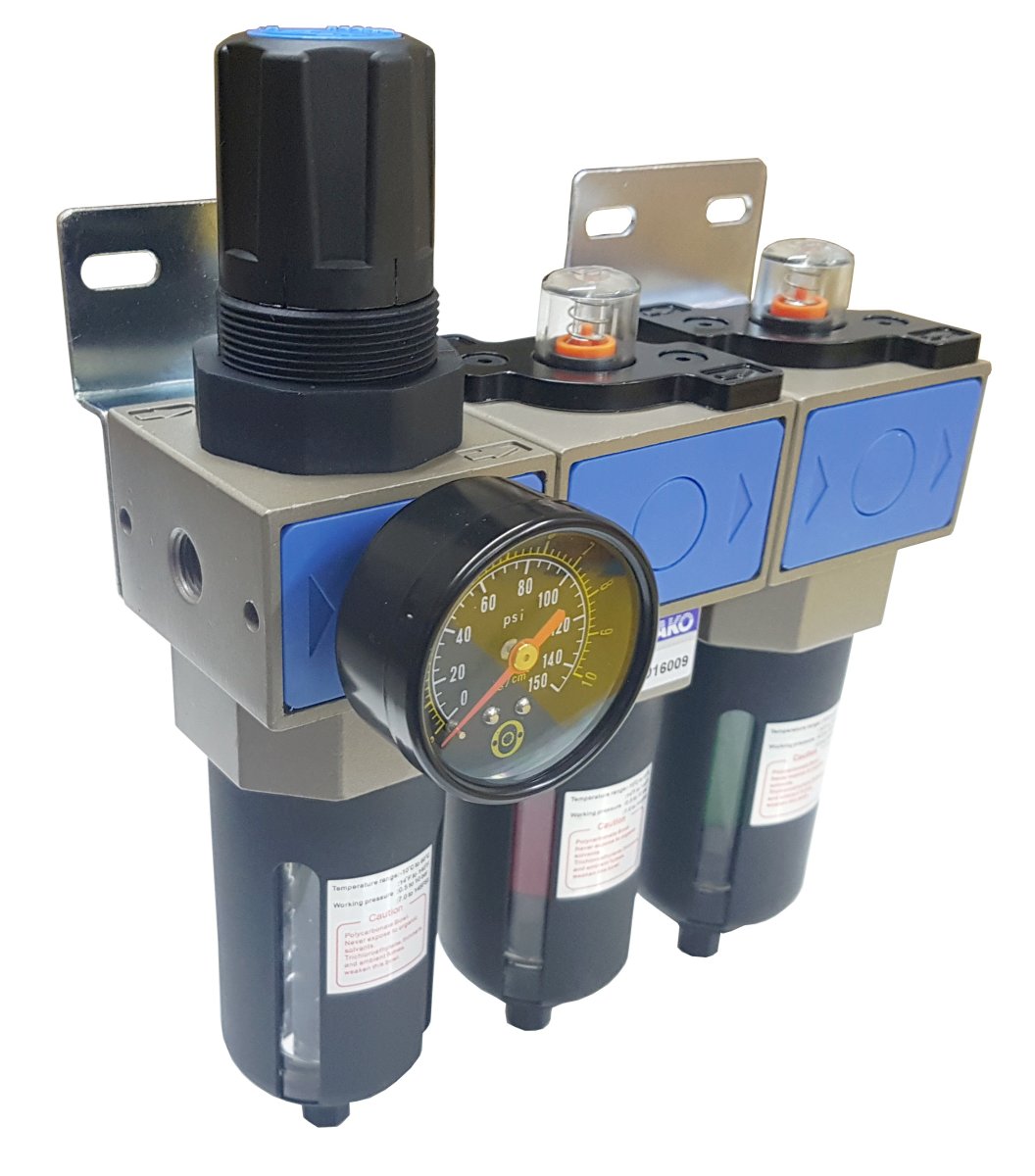

3-Stage Breathing Air Filter Regulator Set – UFR-UMFB-UMFKB

Ultra-clean, reliable breathing air — tested and trusted.

The best water separator for air compressor for painting

Our three-stage kit delivers dry, oil-free, odour free air for spray booths, hood/visor lines and maintenance stations, backed by real test reports and our trademark attention to detail.

Why Choose This 3-Stage Filter Regulator Set?

Enhanced Air Quality: Removes contaminants, moisture, and odours for superior air purity & filtration down to 0.003ppm for the highest demanding air applications.

Silicone Free: No Silicone used during production and assembled in Silicone free environment, a must have for paint spraying.

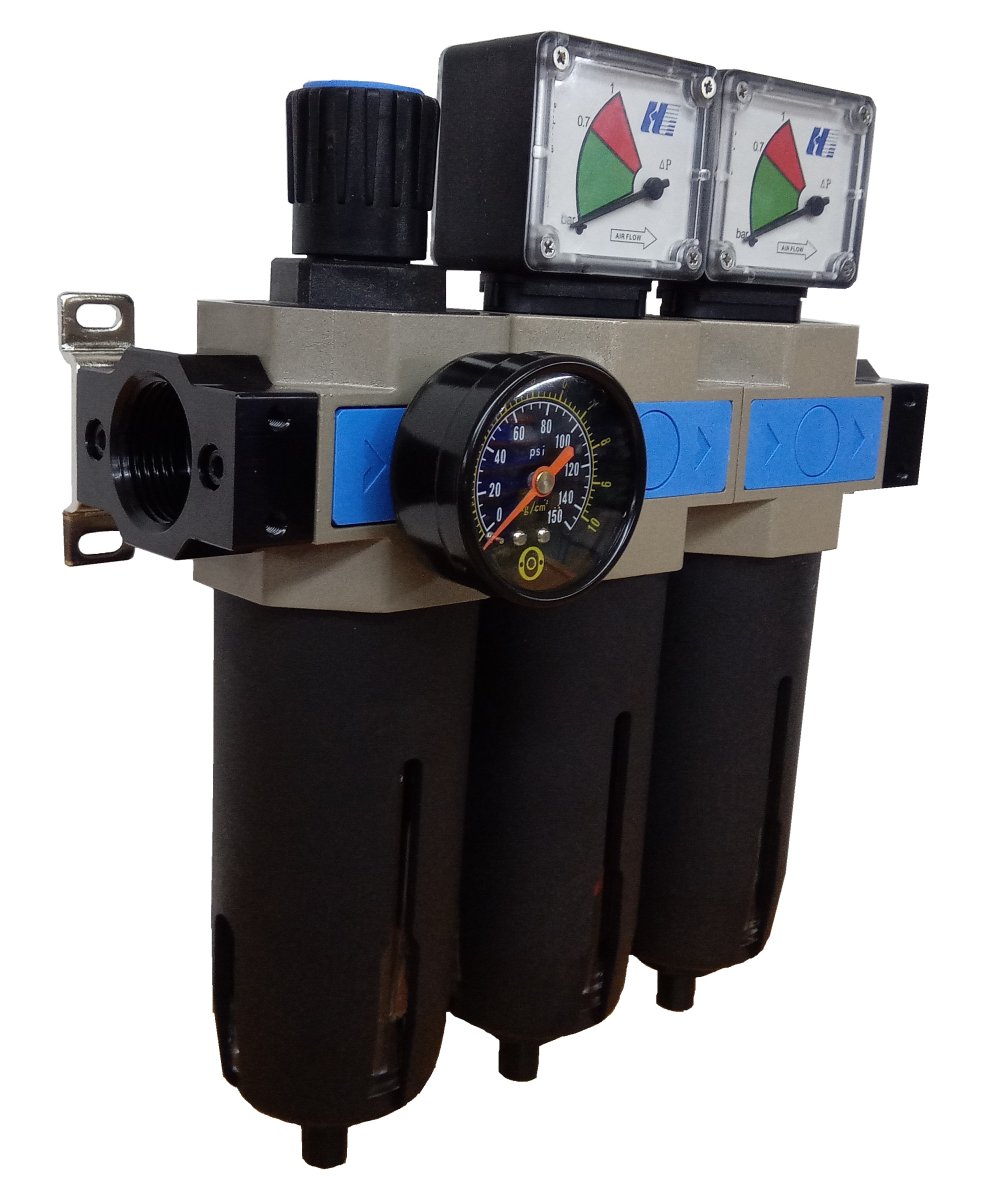

Filter Status Gauge: Visual filter flow gauges for coalescing and carbon filters - know in advance when filters need changing.

Built for the job: Fast-mount bowls with guards; optional acid/alkali-resistant or aluminium bowls for harsh environments.

Always in stock: Complete units, elements and spares on the shelf. Order by 16:00 for FREE UK next day delivery

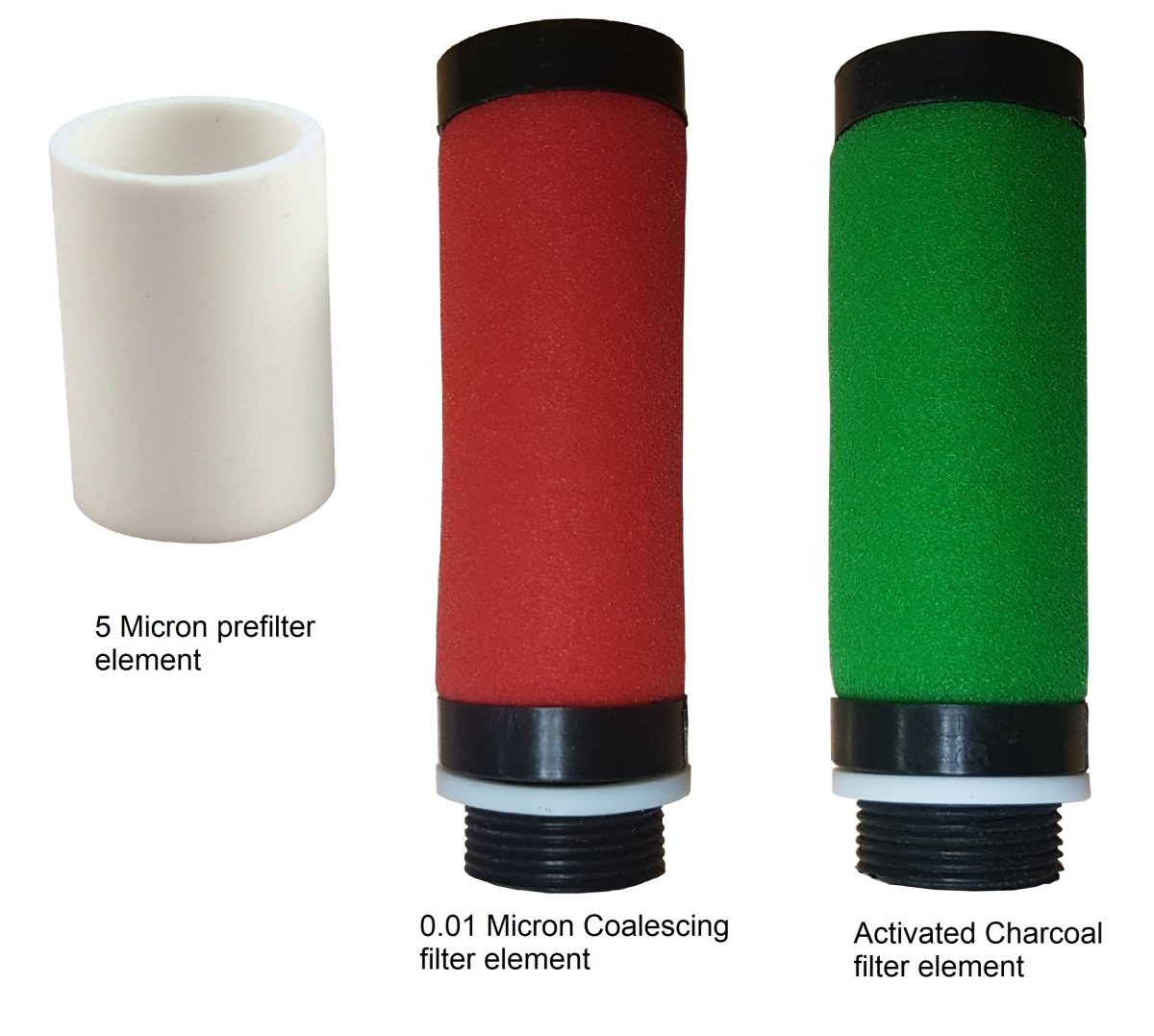

Three stages that work together: 5 µm particulate → 0.01 µm coalescing (RED) → activated carbon (GREEN).

Versatility: Suitable for various industrial applications, including spray-painting and breathing air supply.

Stable pressure control: Lockable regulator 0.5–10 bar; assembled & pressure tested to 15 bar.

Equipment Protection: Prevents damage to tools and ensures optimal performance.

Proven results: Independently tested, silicone free & reports available on request.

Compliance: EN12021 Air Quality Test for Breathing Air Certified.

ISO 9001 & ISO 14001 certified supplier

Technical support from a UK team

5μ pre-filter

Removes particles larger than 0.01mm and 90% of any water, and a 0.5 to 10 Bar pressure regulator.

0.01μ Red coalescing filter

Traps remaining oil, water and particles larger than 0.00001mm

Green activated carbon filter

Traps any biological particles and any remaining oil vapour and odours.

Giving technically absolutely clean air to give filtration down to 0.003ppm for the highest demanding air applications and provides safe, breathable air for the spray booth.

Typical applications

Body shops and paint spray booths

Manufacturing and assembly breathing lines

Inspection, cleaning and light maintenance areas

Any station where operators need clean, odour-free compressed air

What’s included

Pressure regulator (lockable) + gauge

Smooth, accurate set-point control for consistent breathing conditions.

Stage 1 – Particulate pre-filter (5 µm)

Traps rust, dust and condensate to protect downstream elements.

Stage 2 – Coalescing filter (0.01 µm, RED)

Removes fine aerosols and oil mist to very low carry-over.

Stage 3 – Activated carbon filter (GREEN)

Adsorbs oil vapour and odours to deliver fresh, neutral-smelling air.

Mounting brackets , screws, pressure gauge, blanking plug, bowl guards + Instructions (All Included).

Sizes & connections

Ports: 1/4″, 3/8″, 1/2″, 3/4" and 1" BSP as standard (NPT on request).

Temperature: 0 to +60 °C ambient.

Drain: Semi-automatic as standard (manual drain available).

Materials: Polycarbonate safety bowls with guards; optional chemical-resistant or aluminium bowls where solvents/vapours are present.

Performance & compliance notes

This assembly is designed to help users achieve breathing air quality consistent with recognised guidance (e.g., low CO/CO₂, very low oil mist, and a pressure dew point sufficiently below ambient to prevent condensation). Final compliance always depends on your compressor, intake environment and maintenance; verify with regular testing and keep records.

Testing frequency: We recommend testing at least every 3 months, or sooner if risks change (new processes, seasonality, filter changes, etc.).

Maintenance (simple and predictable)

Pre-filter (5 µm): Inspect monthly; replace 6–12 months or when ΔP rises.

Coalescing (RED): Replace 6–12 months depending on oil load and hours.

Carbon (GREEN): Replace 3–6 months or immediately if odour returns/solvent exposure increases.

Regulator & gauges: Function check during each element change.

Bowls: Inspect for crazing; use chemical-resistant/aluminium bowls in solvent areas.

Pro tip: keep a spare full set of elements on the shelf. We offer element bundles to save time and cost.

Installation guidance

Install upright with airflow following the stage order (Regulator 5 µm → RED → GREEN).

Fit as close as practical to the point-of-use.

Use clean pipework and purge lines before first use.

Add a downstream test point for periodic air-quality sampling.

Avoid locating polycarbonate bowls where solvent vapours may concentrate; choose the acid & alkali resistant bowl option in those areas.

Ordering & spares

Choose your port size: 1/4″, 3/8″, 1/2″, 3/4" or 1"

Select bowl type: Standard polycarbonate with guard / Chemical-resistant / Aluminium.

Add elements: RED coalescing, GREEN carbon, 5 µm pre-filter (sold individually or as a 3-pack bundle).

Wall bracket, gauge and test point included.

FAQs

Does this set make my air “EN 12021 compliant” automatically?

It’s designed to help you meet typical limits, but true compliance depends on your whole system and must be confirmed by testing.

How often should we test?

At least every three months, and after any change in risk (new paints/solvents, compressor service, element changes).

When should I change the carbon element?

Every 3–6 months as a rule of thumb or immediately if any smell/odour breaks through.

Are polycarbonate bowls safe near solvents?

Solvent vapours can attack polycarbonate. Where present, specify the acid/alkali-resistant bowls.

Can you supply NPT threads?

Yes — specify at checkout or contact our team.

Does the system remove CO2 and Carbon Monoxide?

No, this filter system DOES NOT REMOVE CO2 or CO

Can I use normal airline for breathing Air?

No, you must use hose according to European standard of ‘REGULATION (EU) 2016/425 - personal protective equipment' SS-EN 14594: Respiratory protective devices and SS-EN 14593-1: Respiratory protective devices - Requirements, testing and marking.

Verified Flow Performance (from factory test report)

| Model | Port Size | Flow Rate | Max Flow Rate | Inlet Pressure | Outlet Pressure | Test Temperature |

|---|---|---|---|---|---|---|

| UFR02B-UMF02B-UMF02KB | ¼ BSP | 2057 L/min (≈ 123 m³/h) | 2104 L/min (≈ 126 m³/h) | 7.15 kg/cm² (≈ 7 bar) | 0.37 kg/cm² (≈ 0.36 bar) | +24.8 °C |

| UFR04B-UMF04B-UMF04KB | ½ BSP | 2237 L/min (≈ 134 m³/h) | 2238 L/min (≈ 134 m³/h) | 7.72 kg/cm² (≈ 7.6 bar) | 0.40 kg/cm² (≈ 0.39 bar) | +22.7 °C |

1. Factory Flow-Rate Certification

Each assembly is factory-tested by Shako Co Ltd under controlled conditions.

At 7 bar inlet pressure and outlet drop of 0.4 bar, the maximum clean-air flow is confirmed as:

¼″ BSP: ≈ 2057 L/min (123 m³/h)

½″ BSP: ≈ 2237 L/min (134 m³/h)

Certification dated August 2020, witnessed by Connexion Developments Ltd (UK Reg No 03502257).

Download the factory test certificate.

2. Independent Breathing-Air Quality Testing

Real-world testing August 2025 carried out by Griffin Air Systems Ltd, Clydebank (UK), on installed Connexion Developments 3-stage breathing-air filter regulator sets.

Recent sample reports show results comfortably within the BS EN 12021:2014 breathing-air quality limits:

| Parameter | EN 12021 Limit | Griffin Air Result (Example) |

|---|---|---|

| O₂ Content % | 20–22 % | 20.7 % |

| CO₂ (ppm) | ≤ 500 ppm | 325 ppm |

| CO (ppm) | ≤ 5 ppm | 0 ppm |

| Oil Mist mg/m³ | ≤ 0.5 mg/m³ | Pass |

| Dew Point | ≤ −11 °C (typical) | −8 °C |

| Pressure (bar) | 6–8 bar typical | 6.3 bar |

| Result | Pass | Pass |

Tests performed 29 August 2025 at McKinnon & Forbes Ltd, Paisley, verified by Griffin Air Systems (UK test report ref: PM10145/002).

Attention to Detail — Built In

From bowl guards and lockable regulators to readily available spares, every component is specified for reliability and ease of maintenance.

Spares, Always Ready

Keep operations running: RED coalescing, GREEN carbon and 5 µm elements are stocked for same-day dispatch.

3. Compliance Statement

All Connexion 3-stage breathing-air assemblies are built, tested and supported to help users maintain breathing-air quality consistent with BS EN 12021:2014 and HSE guidance on compressed-air systems.

Regular quarterly testing and filter-element maintenance are essential to ensure continued compliance.

Key Features

Port Sizes: Available in 1/4", 3/8", 1/2", 3/4 and 1" BSP threads; NPT threads optional

Pressure Range: 0.5 to 10 Bar; tested up to 15 Bar

Temperature Range: 0°C to +60°C

Filter Stages:

Stage 1: 5μ pre-filter removes particles >0.01mm and 90% water

Stage 2: 0.01μ coalescing filter captures remaining oil, water, and particles >0.00001mm

Stage 3: Activated carbon filter eliminates biological particles, oil vapours, and odours, achieving filtration down to 0.003ppm

Construction:

Polycarbonate bowls with safety twist lock and guard

Optional acid/alkali-resistant or aluminium bowls

Drain Options: Semi-automatic standard; manual drain available

Certifications: EN12021 compliant for breathable air

Additional Inclusions: Pressure gauge, blanking plug, two mounting brackets with screws, and full instructions

Technical Specifications

Dimensions: Width: 64mm; Height: 247mm; Depth: 192mm

Weight: 2.6 kg

Body Material: Aluminium

Seals: NBR

Media: Compressed Air

Customer Reviews

Suzanne: "This was by far the cheapest one and when ordered arrived the next day... these are better than the previous ones and about 30% cheaper too!"

Jonathan: "Very impressive... the filter status signal is a major advantage... air is completely clean and without any odour."

Steve: "Half the price of the metalwork ones and these are much better than expected for the price... quick next day delivery too."

Related Products

Breathing Air Filter Element Set: Includes pre-filter, coalescing, and activated carbon filters for 1/4", 3/8", and 1/2" units.

Coalescing Filter Element (0.01μ): Red filter for 1/4", 3/8", and 1/2" units.

Activated Carbon Filter Element: Green filter for 1/4", 3/8", and 1/2" units.

Order Now

Ensure the highest air quality standards in your operations. Order the UFR-UMFB-UMFKB 3-Stage Breathing Air Filter Regulator Set today and experience the difference in performance and reliability.