Direct Acting Solenoid Valve Guide: How They Work & Uses

What Makes Direct Acting Solenoid Valves Special

Think of a simple light switch. Flick it, and the light comes on instantly. That direct connection is the heart of a direct acting solenoid valve. Unlike their pilot-operated counterparts, which use the system's own pressure to help them work, direct acting valves rely solely on the electromagnetic force from the solenoid. This direct action makes them incredibly adaptable and popular for many uses.

This straight line between electrical signal and valve action gives direct acting valves some serious perks. First off, they're fast, reacting in milliseconds. This speed makes them perfect for situations needing quick, precise control, like automated manufacturing where timing is everything.

Their simplicity also means they’re tough and dependable. Fewer moving parts equals fewer chances of something breaking and less maintenance – a huge plus in industrial settings.

Imagine a water treatment plant where adding just the right amount of chemicals is crucial. A direct acting solenoid valve can quickly and reliably dispense the correct dose, ensuring consistent water quality. This precise control, combined with their compact size, makes them easy to fit into complex systems.

Another major advantage? Direct acting valves don't rely on system pressure. Unlike pilot-operated valves, they work great even at low pressures or in a vacuum. This opens up a world of possibilities, from delicate lab equipment to heavy-duty industrial machinery. And speaking of industry, the global solenoid valve market is booming, predicted to jump from USD 5,175.2 billion in 2024 to USD 7,016.7 billion by 2032. This growth shows how important these valves are becoming across many sectors. Discover more insights on the solenoid valve market

Finally, direct acting solenoid valves are cost-effective. Their straightforward design usually means lower upfront costs and simpler maintenance, adding up to lower overall expenses. This is especially helpful when you need a lot of valves, like in large irrigation systems or complex industrial processes. All these advantages make direct acting solenoid valves a powerful and practical solution for controlling fluid flow in a wide range of applications.

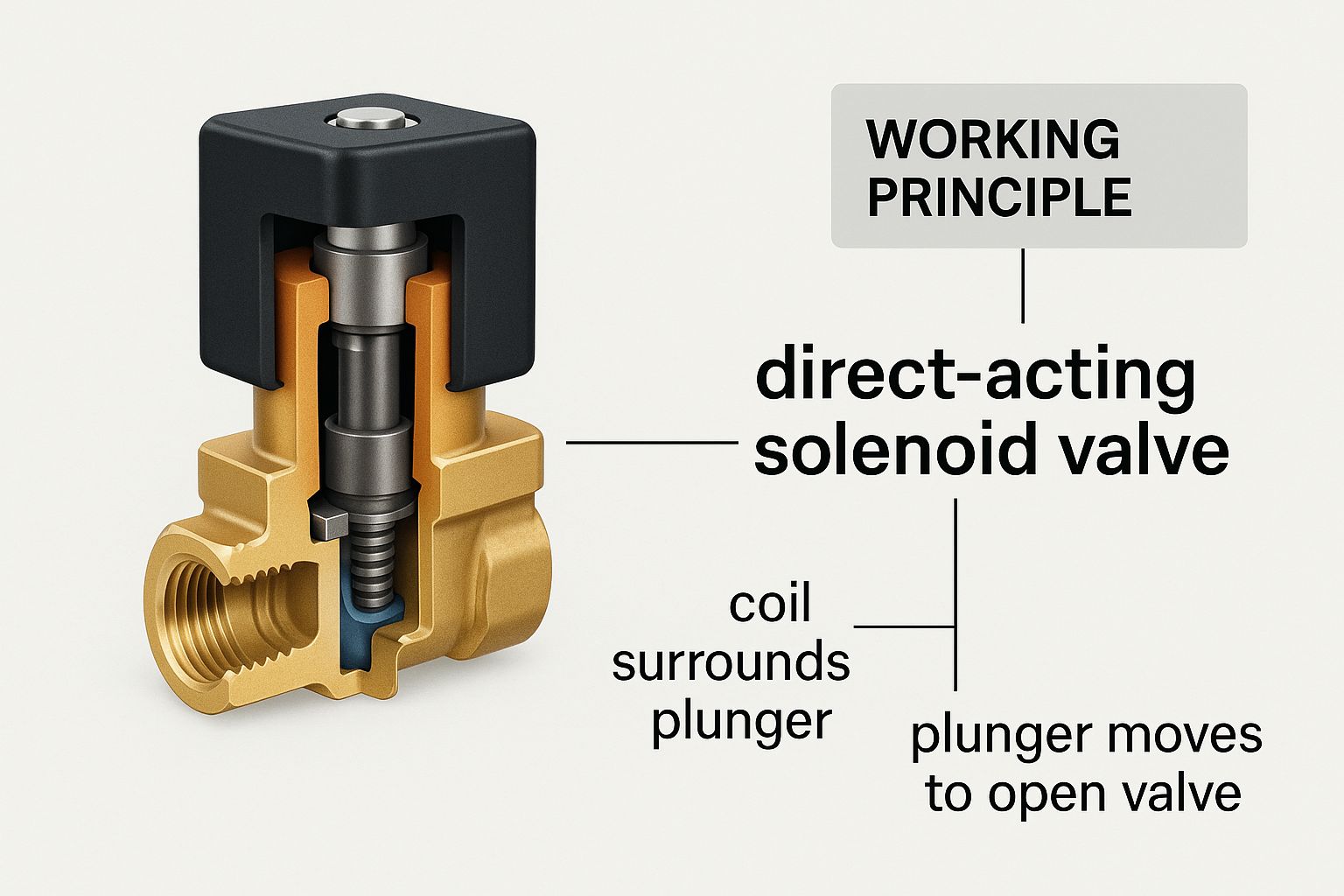

The Electromagnetic Magic Inside Your Valve

This infographic gives us a peek inside a direct acting solenoid valve. It's like an X-ray showing the coil, plunger, and how everything works together. You can clearly see how the coil, when powered up, creates a magnetic field that pushes or pulls the plunger to control the flow of liquid or gas.

Let's explore this electromagnetic interaction in more detail.

The Opening Act: Energizing the Coil

Think of the solenoid coil as an electromagnet. When electricity flows through it, a magnetic field appears, like a miniature, super-strong horseshoe magnet. This magnetic field attracts the plunger, a movable metal core within the valve. This attraction is the force that opens or closes the valve.

When you apply electricity to the coil, the magnetic field builds almost instantly. This field pulls the plunger, overcoming the force of a spring holding the valve closed. This movement opens the valve’s orifice, allowing fluid to flow through. This happens incredibly fast, often in milliseconds. This speed makes these valves perfect for applications needing precise timing.

The Closing Curtain: De-energizing the Coil

Switching off the electrical current causes the magnetic field to disappear. The spring, no longer held back by the magnetic pull, pushes the plunger back to its starting position. This closes the valve, stopping the flow. This simple on-off cycle is the foundation of countless systems, from your washing machine to complex industrial processes.

The Supporting Cast: Springs, Seals, and More

While the solenoid and plunger are the main components, other parts play vital supporting roles. The spring, for instance, isn't just there for show. Its tension dictates how much magnetic force is needed to open the valve. This affects the valve’s responsiveness and how much power it uses. Seals are equally important, preventing leaks and maintaining system pressure.

Listening for Clues: The Telltale Click

That distinctive "click" you sometimes hear from a solenoid valve? That’s the sound of the plunger hitting its stop. This seemingly insignificant sound can be a valuable diagnostic tool. A slow or muffled click might suggest a weak spring or a buildup of debris, indicating a need for maintenance.

Temperature's Impact

Temperature changes can also affect how well the valve performs. Extreme heat or cold can change the properties of the seals and even the magnetic field itself, possibly causing leaks or slower response times. Understanding these nuances helps you anticipate and address potential problems before they become major headaches.

Let's summarize some key differences between direct acting and pilot operated solenoid valves:

To help clarify the distinctions between these two valve types, the following table outlines the key differences:

Direct Acting vs Pilot Operated Solenoid Valve Comparison: Key differences in operation, performance characteristics, and applications between direct acting and pilot operated solenoid valves

| Feature | Direct Acting | Pilot Operated | Best Application |

|---|---|---|---|

| Operating Principle | Direct electromagnetic actuation of the plunger | Uses system pressure assisted by a pilot orifice | |

| Minimum Pressure Differential | Requires a minimum pressure difference for operation (except for "zero differential" types) | Can operate at zero or low pressure differential | Low pressure systems |

| Size and Flow Rate | Typically smaller, suitable for lower flow rates | Can handle larger flow rates | High flow applications |

| Power Consumption | Generally higher power consumption | Lower power consumption | Power-sensitive applications |

| Response Time | Faster response time | Slightly slower response time due to pilot stage | Applications requiring rapid switching |

| Cost | Generally less expensive | More expensive due to complex construction | Cost-sensitive, smaller systems |

| Maintenance | Simpler maintenance | More complex maintenance | Systems with easy access for maintenance |

This table summarizes the core differences, highlighting the strengths and weaknesses of each type. Direct acting valves excel in applications requiring speed and simplicity, while pilot operated valves are better suited for high-flow, low-pressure scenarios where energy efficiency is crucial.

Understanding the inner workings of a direct acting solenoid valve empowers you to choose the right valve for your needs and keep it running smoothly.

Performance Realities That Engineering Specs Don't Tell You

Datasheets for direct acting solenoid valves paint a rosy picture of performance under perfect conditions. But let's be honest, the real world rarely cooperates. Think of it like your car's advertised gas mileage – a nice starting point, sure, but your actual results depend on your driving habits and the road conditions.

Pressure Limits: More Than Just a Number

Datasheets list maximum operating pressures. But what happens when the pressure in your system isn't constant? Imagine a sudden pressure surge in a water main. If it exceeds the valve's burst pressure, the result could be a catastrophic failure. This is why understanding your system’s dynamic pressure – the real-time fluctuations – is so important.

Also, direct acting solenoid valves need a minimum pressure differential to operate correctly. Below this threshold, the valve might not open fully, restricting flow. It's a detail easily missed, but critical for reliable operation.

Flow Rates: The Impact of the Real World

Datasheets give you flow rate numbers, but those are often based on ideal conditions. Temperature plays a big role, particularly with thicker fluids. A valve designed for water might struggle with thick oil at low temperatures. Think about how oil gets sluggish in cold weather – that same principle applies inside the valve.

Debris can also wreak havoc on flow rates. A clogged orifice restricts flow, and it's a common issue in industrial settings. Regular maintenance and filtration are your best defense against this.

Response Times: Expect Some Variation

Datasheets specify response times, but real-world factors like voltage fluctuations and temperature can throw things off. Even a small voltage dip can slow down the valve, affecting system timing. Imagine a packaging line where a delayed valve closure leads to spilled product – a small delay with big consequences.

Power Consumption: Balancing Speed and Efficiency

High-performance direct acting solenoid valves often come with higher power consumption. It's a trade-off. If energy efficiency is a priority, consider the long-term operating costs.

Environmental Factors: The Silent Killers

Extreme temperatures, humidity, and corrosive environments can significantly shorten a valve's lifespan. A valve exposed to salt spray in a coastal location will corrode faster, requiring more frequent replacements. Choosing the right materials for the environment is crucial for long-term reliability.

Understanding these practical considerations helps you choose and operate your direct acting solenoid valve effectively, avoiding costly surprises and headaches down the road.

Where These Valves Excel In The Real World

Direct acting solenoid valves are the often-unseen workhorses powering countless applications. They quietly ensure everything from a smooth pour at the pub to the efficient operation of massive industrial systems. Their simple design, speed, and dependability make them a favorite among engineers across many different fields. Let's take a look at some real-world scenarios where these valves truly shine.

Precision and Quality Control: From Bottling Plants to Bubbly Drinks

Picture a bustling bottling plant where precise filling is paramount. Direct acting solenoid valves control the liquid flow with millisecond precision, guaranteeing consistent fill levels and minimizing waste. Their quick reaction time is essential for high-speed production lines, preventing costly spills and upholding product quality.

This same level of accuracy is vital in dispensing systems for carbonated beverages. These valves ensure the perfect blend of syrup and carbonated water for every single drink.

Enhancing Energy Efficiency in HVAC Systems

Modern HVAC systems depend on direct acting solenoid valves to regulate the flow of hot and cold water. This helps optimize energy use and maintain comfortable temperatures. The valves respond quickly to temperature fluctuations, ensuring efficient heating and cooling.

Their ability to operate at low pressures makes them perfect for adjusting flow in hydronic systems, leading to even greater energy savings.

Renewable Energy and the Rise of Direct Acting Valves

The growing focus on renewable energy, particularly in the UK, has opened up new applications for direct acting solenoid valves. In solar thermal systems, they control the flow of heat transfer fluid, maximizing energy capture and system efficiency.

They also play a critical role in the hydraulic systems of offshore wind farms, ensuring smooth operation and reliable performance even in harsh conditions. Historically, these valves have been important in the UK's industrial automation sector, especially in water treatment. The UK's emphasis on sustainability and energy efficiency has further increased the demand for these versatile components. Discover more insights on the solenoid valve market You might also find this interesting: solenoid valve for gas

Critical Control in Medical Applications

In medical equipment, precise control of gases and fluids is often a matter of life and death. Direct acting solenoid valves handle this critical task, ensuring patient safety and treatment effectiveness.

For example, in ventilators, these valves regulate oxygen flow, delivering life-sustaining breaths with precise timing and volume. Their reliability and ability to be sterilized make them essential in crucial medical devices.

When Direct Acting Valves Aren't the Ideal Choice

While incredibly versatile, direct acting solenoid valves are not always the best solution. In applications with high flow rates, pilot-operated valves offer better performance and energy efficiency. Truly understanding valve performance involves looking at application performance monitoring to observe nuances beyond standard specifications. If a system requires very low pressure differences, specialized zero differential direct acting valves or pilot-operated valves might be necessary. Recognizing the limitations of direct acting valves is just as important as understanding their strengths.

These examples showcase the wide array of applications where direct acting solenoid valves excel. Their compact size, straightforward design, and quick response make them essential components in countless systems, contributing to efficiency, safety, and reliability across numerous industries.

Smart Selection Strategy That Actually Works

Choosing the right direct acting solenoid valve doesn't have to be a daunting task. Think of it like choosing the right tool for a job. You wouldn't use a hammer to tighten a screw, would you? The same principle applies here. A valve designed for a gentle water flow won't be suitable for controlling high-pressure steam. This guide provides a practical, step-by-step approach to help you navigate the selection process with confidence.

Defining Your Needs: The First Step to Success

Before diving into technical specifications, take a moment to clearly define your application's needs. What kind of fluid will the valve be handling? Is it water, air, a specific type of gas, or perhaps something more specialized? What are the typical operating temperatures and pressures? What flow rate is required for your system? How quickly does the valve need to respond? Answering these fundamental questions lays the groundwork for a successful valve selection.

Pressure Differential: The Unsung Hero

One factor often overlooked is pressure differential, the difference in pressure between the inlet and outlet of the valve. Direct acting solenoid valves need a certain minimum pressure difference to operate correctly. If the differential is too low, the valve might not open fully or close completely, leading to performance issues and potential system disruptions. Imagine a door needing a certain push to open – too little force, and it gets stuck.

Media Compatibility: A Match Made to Last

The type of media – the substance flowing through the valve – plays a crucial role in determining the valve's lifespan. For instance, corrosive fluids require valves made of resistant materials, such as stainless steel. Choosing the wrong material is like using a paper cup for hot coffee – it simply won't hold up. Selecting the right material ensures long-term reliability and avoids premature wear, leaks, and costly downtime.

Environmental Considerations: Weathering the Storm

Don't forget about the environment! Temperature extremes, humidity, and vibrations can impact valve performance and longevity. If your valve will be exposed to harsh weather conditions, it needs appropriate protection. Considering these factors early on prevents future problems and ensures your valve can withstand the elements. Think about it like choosing the right clothing for the weather - you wouldn't wear a swimsuit in a blizzard!

Total Cost of Ownership: Thinking Long Term

While the initial price tag is important, consider the total cost of ownership. This includes installation, maintenance, and potential replacement costs. A slightly more expensive valve with a longer lifespan and lower maintenance requirements could be more economical in the long run. It’s like investing in a high-quality appliance – the upfront cost might be higher, but it pays off over time.

Sizing: Finding the Perfect Fit

Choosing the right valve size is crucial. An oversized valve leads to inefficiency and wasted energy, like using a firehose to water a small plant. An undersized valve, on the other hand, restricts flow and strains the system, like trying to drink a milkshake through a tiny straw. Finding the "just right" size that meets your flow requirements without oversizing is essential. Check out this helpful guide: choosing a solenoid valve for more detailed information.

Documenting Your Rationale: Leaving a Trail

After selecting a valve, document your reasoning. This creates a valuable record for future maintenance and troubleshooting. Explain why you chose that specific valve, including the factors you considered and any trade-offs you made. This documentation can be a lifesaver down the line.

Vendor Evaluation: Partnering for Success

Choosing a reputable vendor is just as crucial as choosing the right valve. Look for vendors with a proven track record, excellent customer support, and readily available spare parts. A reliable vendor is a valuable partner throughout the valve's lifecycle. Think of it like choosing a trusted mechanic – you want someone reliable and knowledgeable to keep your equipment running smoothly.

To help you in your selection process, here's a handy table summarizing key criteria:

Direct Acting Solenoid Valve Selection Matrix

| Valve Type | Pressure Range | Flow Rate | Media Types | Typical Applications |

|---|---|---|---|---|

| 2-Way Normally Closed | 0-10 bar | 0.5-5 L/min | Water, Air | Irrigation systems, basic on/off control |

| 2-Way Normally Open | 0-15 bar | 1-10 L/min | Oil, Gas | Fuel control, pneumatic systems |

| 3-Way | 0-20 bar | 2-20 L/min | Water, Air, Gas | Diverting flows, mixing applications |

| (This is an example table. Actual values will vary depending on specific valve models) |

This table provides a quick overview of different valve types and their typical applications. Remember to consult manufacturer datasheets for specific details.

By following this smart selection strategy, you'll choose a direct acting solenoid valve that not only meets your present needs but also delivers reliable, long-term performance. This approach maximizes your investment and minimizes future headaches, ensuring smooth and efficient operation for years to come.

Installation Wisdom From Engineers Who've Been There

Installing a direct acting solenoid valve is more than just connecting a few pipes and wires. Think of it like building a house – a solid foundation is essential. We've gathered insights from seasoned field engineers who've seen it all, from flawless setups to epic fails. Their experiences highlight the critical details that make the difference between smooth operation and costly downtime.

Orientation Matters: Fighting Gravity and Flow

Believe it or not, gravity plays a role in how your valve performs. The valve's orientation can impact flow rate and even lead to early wear and tear. Installing a valve upside down, for example, can trap debris and restrict flow. Imagine pouring a drink – the right angle ensures a smooth pour, while the wrong one leads to gurgling and spills. Always check the manufacturer's instructions for the recommended orientation for your specific valve.

Piping Perfection: Avoiding Premature Wear

The piping around your valve is like the roads leading to your house. Sharp bends and sudden changes in pipe diameter create turbulence and pressure fluctuations, stressing the valve and reducing its lifespan. Think of a river hitting a narrow gorge – the water becomes turbulent and erodes the banks. Smooth, gradual pipe transitions are key to minimizing stress and optimizing flow.

Electrical Connections: Preventing Future Headaches

Solid electrical connections are crucial. Loose connections can cause intermittent issues and even safety hazards. Using the correct wire gauge and ensuring tight connections prevents voltage drops and overheating. It’s like making sure a plug is securely in a socket – a loose connection can cause sparks and power outages.

Mounting Matters: Stability and Vibration

Secure mounting prevents excessive vibration, a major contributor to valve wear. Imagine a washing machine vibrating violently – it can loosen parts and cause damage. Use proper mounting brackets and ensure the valve is firmly in place to minimize vibrations and extend its life.

Thermal Cycling: Handling Temperature Swings

Temperature changes cause components to expand and contract, leading to stress and potential leaks. If your valve experiences significant temperature swings, consider flexible connectors to accommodate these changes. Think of bridge expansion joints that allow for movement without cracking.

Real-World Scenarios: Lessons Learned the Hard Way

One engineer shared a story where a tiny oversight during installation caused a major system shutdown. The valve was installed correctly, but a plastic shipping plug was left in the orifice, completely blocking the flow. Another engineer described how a loose electrical connection caused intermittent failures for months before the culprit was found. These real-world examples emphasize the importance of attention to detail. You might find this helpful: Solenoid Valve Installations and Maintenance Instructions

Pre-Installation Checklist: Avoiding Common Pitfalls

Here’s a quick checklist to avoid common mistakes:

- Verify valve orientation.

- Check piping for smooth flow.

- Ensure secure electrical connections.

- Use appropriate mounting brackets.

- Consider temperature changes.

- Double-check for obstructions.

By following these best practices, gleaned from years of experience, you can ensure your direct acting solenoid valve operates reliably and efficiently for years to come, saving you time, money, and frustration.

Maintenance Approaches That Make Financial Sense

This Wikipedia screenshot gives us a simple view inside a direct acting solenoid valve. Think of it as a blueprint highlighting the key parts – the coil, plunger, and orifice. See how the coil's magnetic field directly moves the plunger to control the flow? This direct action is what makes these valves so simple and reliable.

Recognizing the Real Value of Maintenance

Let's ditch the old-school idea of rigid maintenance schedules. Effective maintenance for direct acting solenoid valves isn't about checking boxes. It's about understanding how these workhorses wear down. I've talked to maintenance managers who've nailed valve reliability, and they all share a practical, value-driven approach.

Think of it this way: not all maintenance tasks are equal. Regularly checking for leaks? That's like getting your car's oil changed – it genuinely prolongs its life. Constantly disassembling a valve for inspection? That can actually cause more problems by damaging seals or introducing contaminants.

Early Warning Signs: Listening to Your Valves

These valves often give you subtle hints before a major breakdown. Changes in response time, odd noises, or fluctuating flow rates can all signal trouble brewing. It’s like your car making a strange noise – you wouldn't ignore it, right? Catching these early warnings allows for proactive maintenance, preventing expensive downtime.

Simple Adjustments, Big Impact: Optimizing Operations

Small tweaks to your system can significantly extend valve life. Reducing pressure surges or filtering out debris protects the valve from unnecessary stress. Think of it like driving your car gently – it reduces wear and tear.

Realistic Maintenance Schedules: Ditching the Generic Approach

One-size-fits-all maintenance recommendations just don't cut it. The best schedule depends on your specific setup and conditions. A valve handling clean water needs less attention than one dealing with harsh chemicals. Tailoring your schedule optimizes resources and minimizes downtime.

Spare Parts Strategy: Balancing Cost and Availability

A smart spare parts inventory is key. Too many spares tie up money; too few risk lengthy downtime. A cost-effective strategy involves identifying crucial parts and stocking a balanced inventory based on how quickly you can get replacements and how often they fail.

Troubleshooting Techniques: Diagnosing Problems Quickly

Rapid diagnosis is essential. We'll explore troubleshooting methods to help you pinpoint the root cause of problems, from electrical glitches to mechanical failures. This empowers your team to quickly resolve issues and minimize disruption.

Repair vs. Replace: Making the Smart Financial Decision

Sometimes, fixing a valve makes sense. Other times, replacing it is the better option. We'll look at factors to consider when making this call, helping you balance short-term repair costs with long-term reliability and overall cost.

Tracking Valve Performance: Measuring What Matters

Tracking key metrics like flow rate and response time gives you valuable insights into valve health. This data helps you spot trends, predict potential issues, and fine-tune your maintenance schedule. It’s like monitoring your car's oil pressure – vital information about your engine's condition.

By taking a practical, value-driven approach to maintenance, you can maximize the life of your direct acting solenoid valves, minimize downtime, and get the most out of your maintenance budget. This keeps your systems running smoothly and efficiently, contributing to your overall success.

Ready to delve deeper into the world of solenoid valves? Check out Solenoid Valve World for a wide selection of valves, expert advice, and dependable service.