Oil Solenoid Valve Mastery: Your Complete Technical Guide

Understanding Oil Solenoid Valves: The Foundation You Need

Oil solenoid valves play a vital role in countless hydraulic and pneumatic systems, especially those designed for oil. These electromagnetically controlled valves precisely manage the flow of oil, making them indispensable for applications requiring accurate, automated control. They essentially act as gatekeepers within your oil system, directing flow based on electrical signals. This electronic control provides significantly more precision than manual operation, a key benefit in today's complex systems.

How Oil Solenoid Valves Work

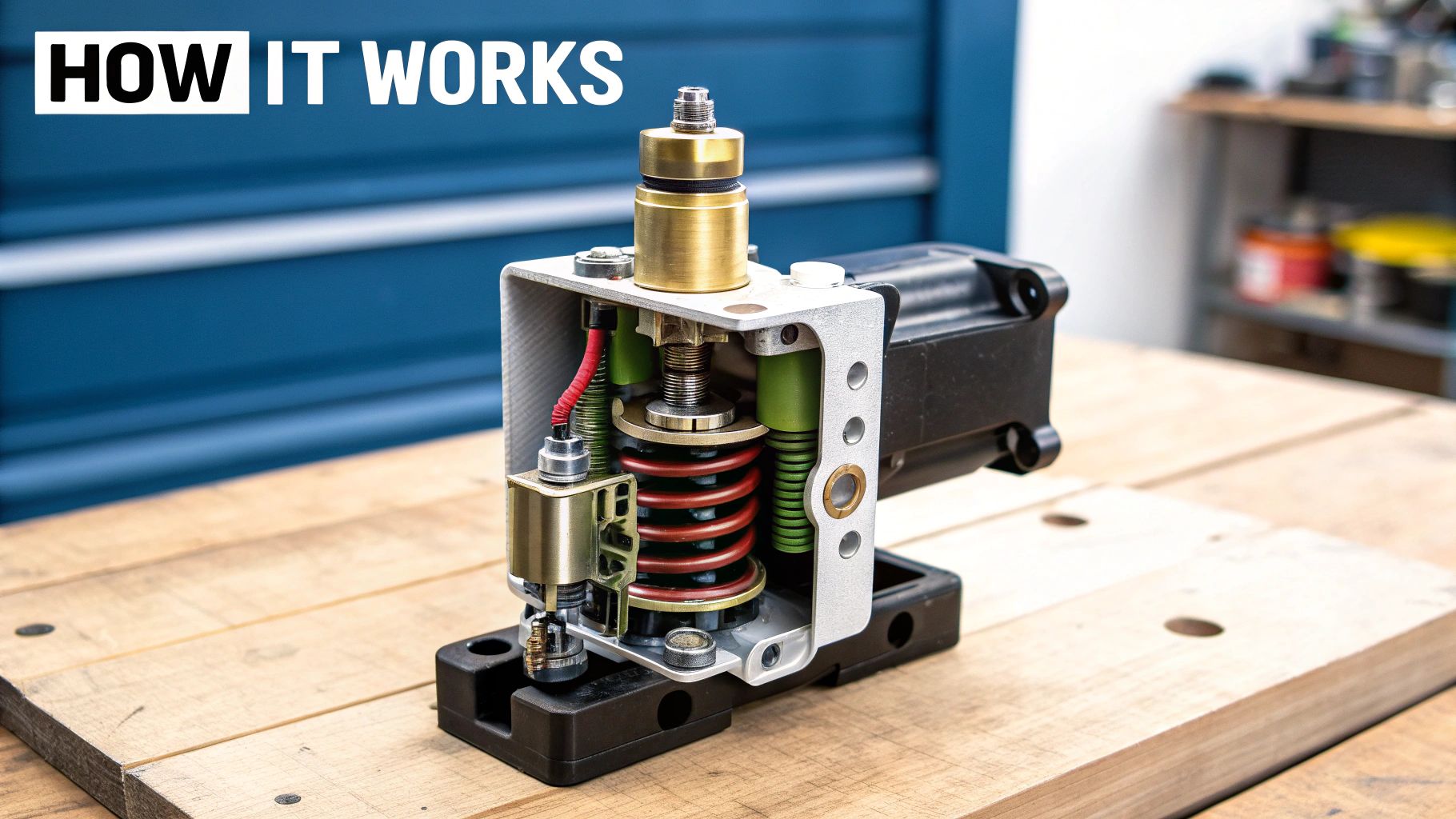

Oil solenoid valves operate on a fundamental principle: electromagnetism. When an electrical current runs through the solenoid coil, a magnetic field is generated. This magnetic field then interacts with a plunger or poppet, causing it to move and either open or close the valve. This seemingly straightforward mechanism underpins the control of intricate oil flow patterns in diverse machinery.

For instance, consider a hydraulic press used in a manufacturing setting. The oil solenoid valve functions as the switch, permitting oil to flow into the press cylinder. This flow extends the ram and applies the necessary force. When the electrical current to the solenoid is interrupted, the valve closes, halting the oil flow. This precise control is essential for consistent and safe operation.

Key Components and Configurations

Three primary components heavily influence the performance of an oil solenoid valve: the solenoid coil, the plunger mechanism, and the valve body. The solenoid coil's design dictates the magnetic field's strength and, consequently, the valve's responsiveness. The plunger's design affects how quickly and reliably the valve opens and closes. The valve body, often constructed from durable materials like brass or stainless steel, guarantees compatibility with the specific oil used and ensures long-lasting performance.

Furthermore, understanding different valve configurations is crucial for effective system design. Normally closed valves stay closed until energized, while normally open valves remain open until energized. Selecting the correct configuration, based on specific application needs, is paramount for both safety and efficiency. Normally closed valves are often favored in safety-critical systems, defaulting to a secure state if power is lost.

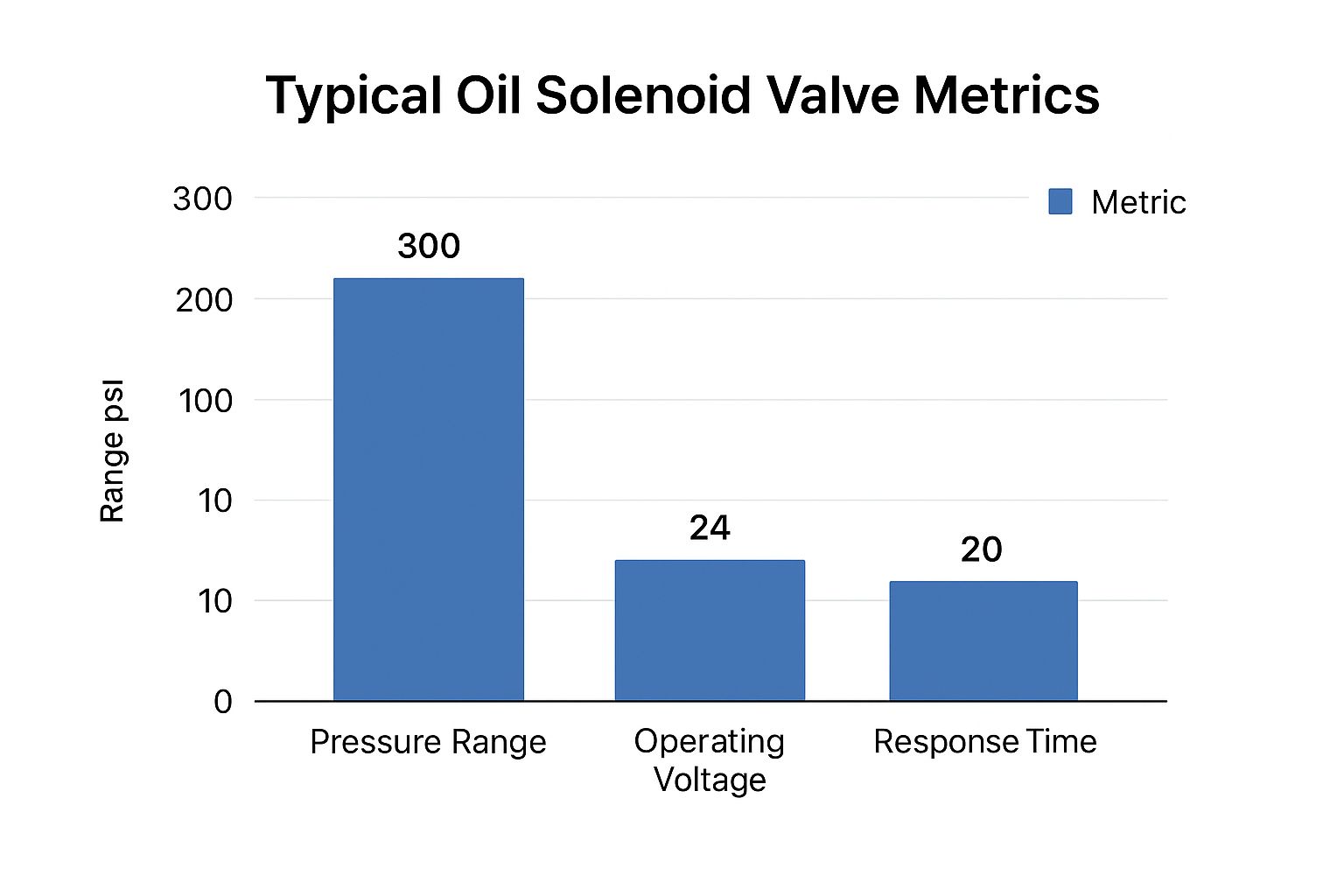

To illustrate typical performance metrics, the infographic below visualizes the pressure range, operating voltage, and response time of an oil solenoid valve.

As the infographic shows, a typical oil solenoid valve operates across a wide pressure range, utilizing a relatively low operating voltage and maintaining a rapid response time, typically measured in milliseconds. These combined characteristics make these valves incredibly versatile, suitable for even the most demanding applications. This precise and speedy control of oil flow makes these valves essential across numerous UK industries, from North Sea oil and gas production to manufacturing and hydraulic systems.

To further clarify the different types of oil solenoid valves available, the following table provides a comparison:

To assist in selecting the right valve for a given application, the following table offers a detailed comparison of various oil solenoid valve types.

Oil Solenoid Valve Types Comparison Comprehensive comparison of different oil solenoid valve configurations, operating principles, and typical applications

| Valve Type | Operating Mode | Response Time | Typical Applications | Advantages |

|---|---|---|---|---|

| Direct-acting | Directly opens/closes flow path | Fast (milliseconds) | Low-flow, low-pressure systems | Simple design, compact size |

| Pilot-operated | Uses a pilot valve to control main valve | Slower than direct-acting | High-flow, high-pressure systems | Handles larger flow rates |

| Internally piloted | Pilot valve integrated within main valve | Moderate response time | Medium-flow, medium-pressure systems | Compact and efficient |

This table highlights the key distinctions between direct-acting, pilot-operated, and internally piloted valves, illustrating their respective strengths and ideal applications. Each type offers unique benefits based on its operating mechanism and intended use. Selecting the appropriate type is crucial for optimized system performance.

Technical Specifications That Actually Matter

Beyond the marketing, the real test of an oil solenoid valve lies in its technical specifications. These details determine a valve's success or failure in demanding applications. This means understanding the key specs engineers focus on: pressure ratings, temperature ranges, and flow coefficients, particularly given oil's viscosity.

Decoding the Datasheet

Pressure ratings define the maximum pressure a valve can safely handle. Exceeding this limit risks leaks or catastrophic failures. The temperature range specifies the acceptable operating temperatures. Oil viscosity changes drastically with temperature, affecting valve performance. Choosing a valve with the right temperature range is crucial for reliable operation in varying weather.

Flow coefficients (Cv) quantify a valve's flow capacity. A higher Cv means greater flow. Oil's viscosity requires careful Cv selection to ensure adequate flow without excessive pressure drop. A valve with a low Cv could restrict oil flow in a high-demand hydraulic system. This careful spec consideration separates a reliable system from a problematic one.

Material Science and Longevity

An oil solenoid valve's lifespan depends heavily on its construction materials. Corrosion-resistant alloys and high-temperature sealing compounds are vital for withstanding harsh oil environments. These specialized materials prevent premature failure due to chemical attack or thermal degradation.

Industry standards like ATEX ratings for explosive atmospheres and API specifications for petroleum applications provide crucial guidance. Understanding these standards helps engineers interpret technical datasheets effectively. This knowledge allows you to select the right valve for your specific application, especially in regulated industries.

Beyond Theoretical Maximums

Manufacturers often emphasize maximum performance figures, but real-world conditions rarely reach these theoretical limits. Matching valve capabilities to your actual operational needs, not theoretical maximums, is vital for long-term reliability. Consistently operating a valve near its maximum pressure rating can shorten its lifespan.

You might be interested in: How to master vacuum systems with solenoid valves.

Practical Considerations

Understanding the nuances of oil solenoid valve specifications is key. Consider factors like response time, measuring how quickly a valve reacts to electrical signals. In high-speed applications, a fast response time is critical. Power consumption is also important, especially for battery-powered or energy-efficient systems.

Furthermore, consider the valve's mounting orientation and electrical connection requirements. These practical considerations ensure smooth system integration. Focusing on these practical aspects prevents common installation issues and ensures optimal performance. Attention to these seemingly minor details significantly impacts your system's effectiveness and longevity. Careful consideration of these specifications and real-world conditions will ultimately determine the success of your oil solenoid valve application.

Real-World Applications Across Industries

Oil solenoid valves are crucial components in various industries, providing precise, automated control over oil flow. Their ability to withstand high pressures and temperatures makes them perfect for demanding applications. Let's explore how these versatile valves contribute to diverse sectors.

Upstream Oil Production and Refineries

In upstream oil production, oil solenoid valves are essential in wellhead control systems, managing the flow of crude oil from the reservoir. They also contribute to pipeline automation, ensuring safe and efficient oil transport over long distances. This precise control is vital for maintaining optimal flow rates and preventing hazardous situations.

Refinery engineers rely on oil solenoid valves for process control. These valves regulate oil flow through various refining stages, impacting the final product's quality and safety. Precise oil flow control is essential for maintaining specific temperatures and pressures during chemical reactions.

Hydraulic Systems and Manufacturing

Oil solenoid valves are integral to hydraulic systems powering heavy machinery in construction, manufacturing, and other industries. They control hydraulic actuators, enabling precise operation of excavators, cranes, and factory automation equipment. This control is crucial for safe and efficient operation in demanding environments.

For example, in a hydraulic press, an oil solenoid valve controls oil flow to the press cylinder, enabling precise control of force and speed. Similarly, in a construction excavator, these valves control the boom, arm, and bucket movements, allowing operators to perform complex tasks with precision.

Renewable Energy and Beyond

The applications of oil solenoid valves extend to the renewable energy sector. In wind turbines, they are used in hydraulic pitch control systems, adjusting the turbine blades' angle to optimize energy capture and protect the turbine from high winds. This highlights their role in sustainable energy generation.

The UK market for oil solenoid valves is influenced by the nation's focus on sustainability and energy efficiency. The UK water treatment industry, driven by government initiatives, is a substantial market for these valves, especially given their precise flow control capabilities. Learn more about this market here. The North Sea oil and gas industry and the growing renewable energy sector, particularly offshore wind farms, further drive demand, relying on precise fluid control for effective operation.

Cost-Benefit Analysis and Operational Efficiency

Proper oil solenoid valve selection is crucial. The right valve significantly impacts operational efficiency, safety, and bottom-line results. A well-chosen valve can minimize downtime, reduce maintenance costs, and improve overall system performance.

Investing in a high-quality, durable oil solenoid valve might have a higher initial cost, but it can lead to long-term savings by reducing maintenance and replacement needs. Cost-benefit analysis is critical. By considering factors like lifespan, maintenance requirements, and potential downtime costs, businesses can make informed choices that optimize their return on investment. Choosing the right valve is an investment in reliable performance and long-term cost savings.

Navigating The UK Market Landscape

The UK market for oil solenoid valves presents a unique blend of opportunities and challenges. Brexit has significantly reshaped how these essential components are sourced and distributed within the UK. This shift has created new opportunities for domestic manufacturers to meet local demand. Evolving regulations also play a crucial role, influencing valve specifications and purchasing decisions across various sectors.

North Sea Oil and Evolving Demands

The North Sea oil industry significantly drives demand for specialized oil solenoid valves in the UK. As enhanced oil recovery techniques become more important, the need for sophisticated control systems increases. These systems rely on advanced oil solenoid valves capable of precise and reliable operation in demanding subsea environments. For instance, remotely operated vehicles (ROVs) utilized for subsea maintenance and inspection depend on these valves for essential hydraulic functions.

The broader shift towards Industry 4.0 is also influencing the oil and gas sector. Smart oil solenoid valves integrated with IoT (Internet of Things) platforms are becoming more common. This integration enables predictive maintenance and remote monitoring, optimizing performance and minimizing downtime. Potential problems can be identified and addressed proactively, preventing costly failures.

Brexit's Impact and Domestic Manufacturing

Brexit has undoubtedly impacted the UK's access to European suppliers. However, this has created new opportunities for UK manufacturers of oil solenoid valves. Domestic companies are now better positioned to compete within the UK market. They are actively developing innovative solutions to meet specific needs, investing in advanced manufacturing technologies to enhance competitiveness.

The UK's commitment to quality remains a key differentiator. British engineering has a longstanding reputation for excellence. UK manufacturers of oil solenoid valves maintain these standards, producing highly reliable and durable valves that meet stringent industry requirements. You might be interested in: How to master pneumatic systems with solenoid valves.

Competition and Global Standards

UK manufacturers face competition from global players. However, they are actively leveraging their strengths. These include a deep understanding of local market needs and a steadfast commitment to quality. They are also adapting to the global shift towards Industry 4.0 by incorporating smart technologies into their products.

The European, and therefore UK, solenoid valve market remains substantial. Europe held a 38.41% revenue share in 2023, highlighting its significant contribution to the global market. This growth is fueled by expansion across industries like oil and gas, where oil solenoid valves are essential for automation and precise fluid control. Find more detailed statistics here: https://www.grandviewresearch.com/industry-analysis/solenoid-valves-market-report. As the demand for automation and efficient fluid control rises, UK manufacturers are well-positioned for success. Their focus on quality, innovation, and adaptation will be crucial in this dynamic market.

Installation And Maintenance That Prevents Problems

Correct installation and proactive maintenance are essential for the reliable operation of any oil solenoid valve. Getting it right the first time can prevent costly downtime and ensure optimal performance throughout the valve's lifespan. This section offers best practices for installation and maintenance, compiled from the experience of field engineers and industry veterans.

Installation Best Practices

Installation errors often lead to premature valve failure. Addressing potential problems upfront can significantly improve long-term reliability. Here are the key steps for a successful installation:

Electrical Connections: Ensure correct wiring and secure connections to prevent voltage fluctuations or power loss, which can damage the solenoid coil. Double-check wiring diagrams and select appropriate connectors for your specific valve model.

Mounting Considerations: Securely mount the valve to minimize vibration. Excessive vibration can lead to premature wear and tear. Use appropriate mounting brackets and ensure correct alignment within the system.

System Integration: Carefully integrate the valve into the overall oil system. Pay close attention to flow direction and pressure requirements for compatibility with other system components. This prevents pressure surges and ensures smooth operation.

Preventing Common Installation Errors

A significant 80% of premature failures are attributed to avoidable installation errors. Here are some common pitfalls to avoid:

Over-tightening: Avoid over-tightening fittings, which can damage the valve body and cause leaks. Use a torque wrench to ensure proper tightness and prevent cracking.

Contamination: Keep the valve and surrounding pipes clean during installation. Debris introduced into the system can damage seals and internal components. Thoroughly flush the system before commissioning.

Incorrect Orientation: Install the valve in the correct orientation as specified by the manufacturer. Incorrect orientation can impair valve function and lead to premature failure.

Maintenance Protocols for Maximum Lifespan

Even with a perfect installation, regular maintenance is crucial for maximizing the lifespan of your oil solenoid valve.

Inspection Schedule: Establish a regular inspection schedule based on operating conditions and manufacturer recommendations. Frequent inspections can identify potential issues early, preventing more serious problems down the line.

Monitoring Techniques: Implement monitoring techniques to track valve performance and identify deviations from normal operation. This can include monitoring coil resistance, response times, and oil flow rates. Changes in these parameters can indicate developing problems.

Practical Maintenance Checks

Here are some practical maintenance checks to perform:

Coil Resistance: Regularly check coil resistance using a multimeter to detect potential coil burnout. Compare the measured resistance to the manufacturer's specifications.

Seal Integrity: Inspect seals for signs of wear or degradation. Promptly replace worn seals to prevent leaks and maintain system integrity.

Response Time Measurement: Monitor valve response time to ensure efficient operation. A slow response might indicate mechanical sticking or other issues.

Fluid Compatibility and Filtration

Using compatible fluids and maintaining proper filtration are vital for protecting your oil solenoid valve.

Fluid Compatibility: Ensure the oil used is compatible with the valve's materials and seals. Incompatible fluids can cause degradation and premature failure. Consult the manufacturer's guidelines.

Filtration Standards: Maintain adequate filtration to prevent contaminants from entering the valve. Use filters with the appropriate micron rating for your application. Change filters regularly to maintain optimal performance.

To assist with maintaining your oil solenoid valves, the following table provides a recommended maintenance schedule:

Oil Solenoid Valve Maintenance Schedule Recommended maintenance intervals and procedures for different operating conditions and environments

| Maintenance Task | Frequency | Severity Level | Tools Required | Expected Duration |

|---|---|---|---|---|

| Visual Inspection | Monthly | Low | None | 5 minutes |

| Coil Resistance Check | Quarterly | Medium | Multimeter | 10 minutes |

| Seal Inspection | Annually | High | Wrenches | 30 minutes |

| Response Time Test | Annually | Medium | Timer, pressure gauge | 20 minutes |

| Fluid and Filter Change | As per manufacturer recommendations | High | Wrenches, containers | 1 hour |

This table outlines key maintenance tasks, their recommended frequency, the severity level if neglected, the tools required, and the expected duration for each task. Regularly performing these checks will contribute significantly to the long-term health of your valves.

By following these installation and maintenance best practices, you can ensure the reliable and long-lasting performance of your oil solenoid valves, minimizing downtime and maximizing your return on investment. For further information on specialized applications, consider our guide on high-pressure solenoid valves.

Troubleshooting Problems Before They Cost You

When your oil solenoid valve malfunctions, downtime costs can quickly add up. A fast and accurate diagnosis is essential. This section explores the systematic troubleshooting methods used by experienced technicians to efficiently identify issues and restore your systems.

Recognizing the Early Warning Signs

Catching the subtle signs of a problem can save you significant time and money. Several common issues affect oil solenoid valves:

Coil Burnout: This often presents as a complete failure of the valve to actuate. You might also detect a burning smell or excessive heat from the coil.

Mechanical Sticking: A sticking valve can behave erratically, showing slow response times or intermittent operation. This disrupts the smooth operation of your oil system.

Seal Degradation: Look for oil leaks around the valve body, a telltale sign of seal failure. Leaking oil not only creates a mess but also affects valve performance.

Addressing these issues before they become major failures is vital for maintaining system uptime and avoiding costly repairs.

On-Site Diagnostic Procedures

Effective troubleshooting involves a step-by-step process. These diagnostic procedures help pinpoint the root cause:

Visual Inspection: Start by checking the valve for any visible damage, loose connections, or debris.

Electrical Measurements: Use a multimeter to measure the coil resistance. Compare your readings to the manufacturer’s specifications to detect potential coil issues. Low or no resistance suggests a short circuit, while high resistance may indicate an open circuit.

Pressure Testing: Check for pressure drops across the valve. A significant drop can point to a blockage or internal valve damage.

These on-site tests can quickly isolate the malfunction, saving you the cost of unnecessary component replacements.

Practical Guidance and Cost-Effective Solutions

Effective testing is key to an accurate diagnosis. Focus on electrical and pressure measurements.

Electrical Tests: Checking the voltage supply to the solenoid is the first step. If there's no voltage, trace the wiring back to the source of the issue. Testing coil resistance helps identify coil problems.

Pressure Tests: Use a pressure gauge to measure pressure before and after the valve. A noticeable drop across the valve indicates internal issues or blockage.

This practical guidance ensures accurate diagnostics, leading to effective and cost-effective solutions.

Safety First: Working with Pressurized Oil

Always prioritize safety when working with pressurized oil systems. Depressurize the system before any maintenance or troubleshooting. Wear appropriate safety glasses and gloves to protect yourself from oil splashes or leaks.

Repair or Replace: Making Informed Decisions

After identifying the problem, decide whether to repair or replace the valve. This decision often involves a cost-benefit analysis. For minor issues like a damaged coil, repair is usually the best option. For more significant internal damage, replacement might be the better long-term choice. Consider the valve's age, the repair costs, and the likelihood of future issues. For instance, if an older valve needs extensive repairs, replacement may be more cost-effective due to the risk of additional failures. Combining effective troubleshooting with practical guidance helps maintain optimal system performance and avoid unnecessary costs.

Key Takeaways

This section provides practical advice for getting the best performance and longest life from your oil solenoid valve. We'll cover best practices and real-world examples, giving you actionable checklists for valve selection, installation, and maintenance. You can put these checklists to work right away. Each key takeaway focuses on measurable improvements like better reliability, lower maintenance costs, and improved system performance.

Selecting the Right Valve: Focus on Specifications

Choosing the right oil solenoid valve is essential. The valve's technical specifications must match your system's needs.

This means paying close attention to critical parameters like pressure ratings. Make sure the valve can handle the maximum system pressure without leaking or failing. The temperature range is also crucial. It needs to accommodate how the oil's viscosity changes at different operating temperatures. Finally, the flow coefficient (Cv) has to be sufficient for proper flow without large pressure drops, keeping your system running smoothly.

For example, if your hydraulic system operates in cold conditions, you'll need a valve with a temperature range that considers how oil viscosity changes at lower temperatures. Likewise, a high-pressure system needs a valve with a matching pressure rating for safe, reliable operation.

Installation: Avoiding Costly Errors

Proper installation is critical. A surprising 80% of early valve failures are due to installation errors. Make sure you have accurate electrical connections, matching the wiring and connectors to the valve's specifications. Secure mounting reduces vibration, which can cause wear and tear. Just as importantly, ensure proper system integration, paying attention to flow direction and pressure compatibility. Ignoring these details can lead to expensive downtime and repairs.

Proactive Maintenance: Maximizing Valve Life

Regular maintenance protects your investment in long-term reliability. Set up a planned maintenance schedule that includes checks like coil resistance measurements with a multimeter, seal inspections, and response time monitoring. These proactive steps help you identify and fix potential problems early, minimizing downtime and maximizing the valve's lifespan. Also, be sure to check for fluid compatibility and maintain good filtration to prevent contamination and wear.

Troubleshooting: Efficient Diagnosis and Repair

Even with the best preventative maintenance, issues can still occur. A systematic troubleshooting approach is vital for quick and accurate diagnosis. Be familiar with the signs of common problems like coil burnout, sticking, and seal degradation. Knowing on-site diagnostic procedures, such as electrical measurements and pressure testing, helps you find the root causes, minimize downtime, and avoid unnecessary replacements. Remember to prioritize safety when working with pressurized oil systems; always depressurize the system before any maintenance work.

Making Informed Decisions: Repair vs. Replace

When a problem arises, you face a key decision: repair or replace? Base this decision on a thorough evaluation of the valve's condition, the damage, and the cost of each option. For minor problems, repair is usually the best choice. However, for more extensive damage or if the valve is nearing the end of its life, replacement is often smarter, preventing future problems and ensuring long-term system reliability.

Investing in quality oil solenoid valves and following these key takeaways will benefit you in the long run, ensuring smooth, efficient, and reliable system operation. Want to explore a range of high-quality oil solenoid valves and related components? Visit Solenoid Valve World today. We have a wide selection of valves for various applications, plus expert technical support to help you with selection and implementation.