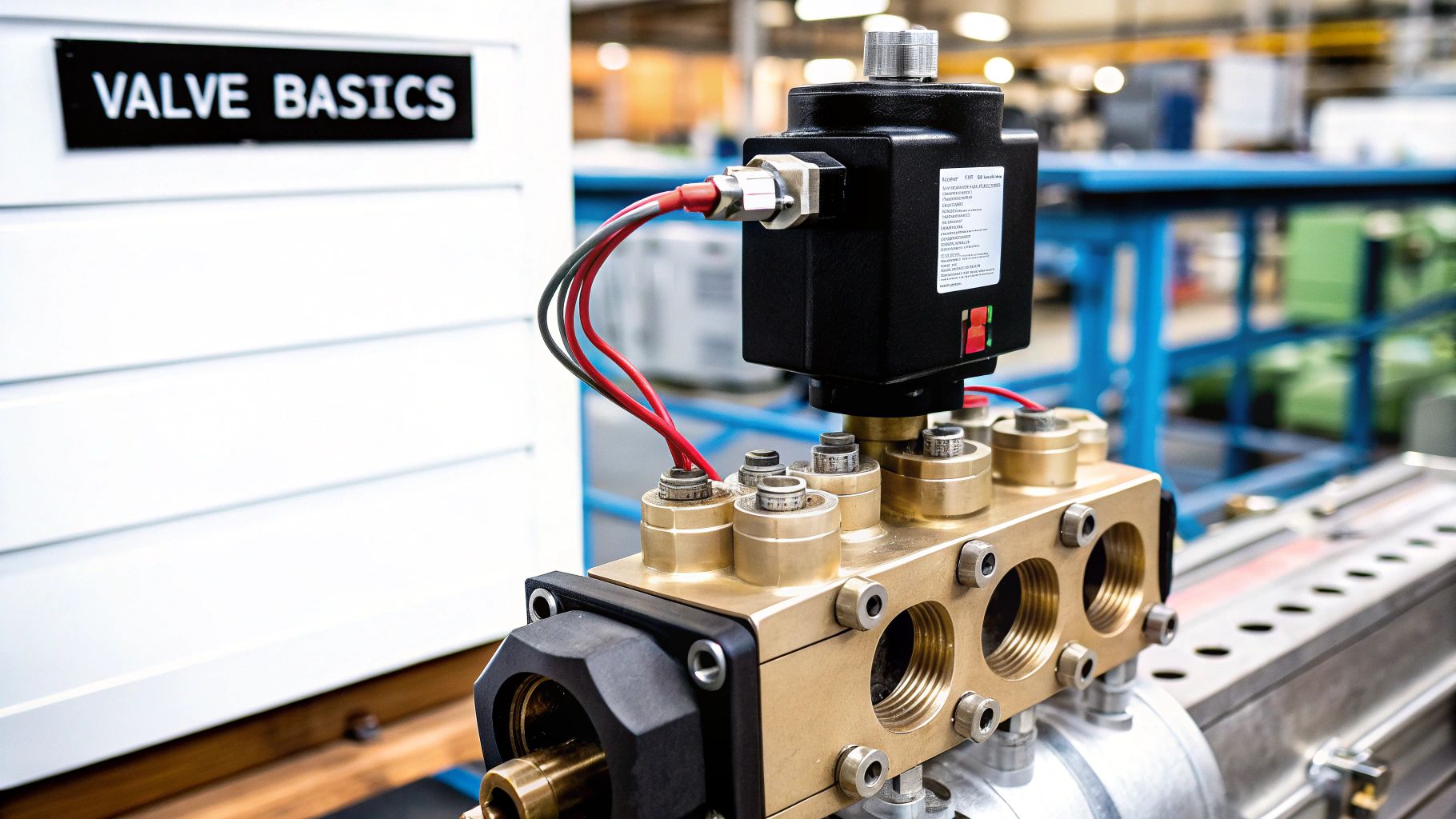

Pneumatics Solenoid Valve Guide: Essential Tips & Insights

At its core, a pneumatic solenoid valve is a clever electromechanical gatekeeper for compressed air. It takes a simple electrical signal and uses it to instantly open or close an air channel, acting as a critical translator between an electronic brain and real-world mechanical action.

Decoding the Pneumatic Solenoid Valve

Think of it like a light switch, but instead of completing an electrical circuit for a bulb, it directs compressed air to a machine. When you send an electrical current to the valve's solenoid—which is essentially a coil of wire—it generates a magnetic field. This magnetic force then moves a small internal component, often called a plunger or spool.

This tiny, near-instantaneous movement is all it takes. It physically opens or closes ports inside the valve body, either unleashing a powerful jet of compressed air or cutting it off completely. This simple, rapid action is what modern automation is built on. It’s the bridge between a control system, like a Programmable Logic Controller (PLC), and the physical "muscle" of a pneumatic cylinder that might be pushing, pulling, or clamping a part.

Why It Matters in UK Industries

This ability to precisely manage air flow makes the pneumatic solenoid valve an unsung hero across countless UK sectors. From the blistering speed of robotic arms on a car assembly line in the Midlands to the delicate sorting systems in food and beverage processing, these valves deliver the speed and reliability that British industry demands.

They are the essential components that enable automated equipment to perform tasks with high precision and incredibly fast, repeatable response times, forming the backbone of efficient manufacturing and logistics operations.

Without these little devices, the seamless, automated processes we now take for granted would grind to a halt. They are fundamental for:

- Automation: Powering everything from robotic arms and actuators to grippers on a production line.

- Process Control: Managing the flow of materials in packaging, sorting, and filling systems.

- Safety: Serving as a crucial component in emergency stop circuits by rapidly cutting off the air supply.

By turning a low-power electrical instruction into a powerful pneumatic force, these valves truly unlock the potential of compressed air in almost any industrial setting you can imagine.

How a Solenoid Valve Actually Controls Airflow

When you send an electrical signal to a pneumatic solenoid valve, you’re kicking off a lightning-fast chain reaction. That tiny electrical pulse gets transformed into a powerful, physical action—the controlled release of compressed air. It's a surprisingly straightforward process that hinges on a basic principle of physics: electromagnetism.

At the heart of the valve, a simple sequence plays out. An electrical current flows into the solenoid, which is nothing more than a tightly wound coil of copper wire. The instant that current hits, it creates a powerful, concentrated magnetic field. Think of it like flicking a switch on a tiny, incredibly strong electromagnet.

This magnetic field has one job: to act on a small, movable part called a plunger or armature. Because the plunger is made from a ferromagnetic material, it’s instantly and forcefully pulled towards the centre of the magnetic field. This small, linear movement is the key mechanical action that drives the entire valve.

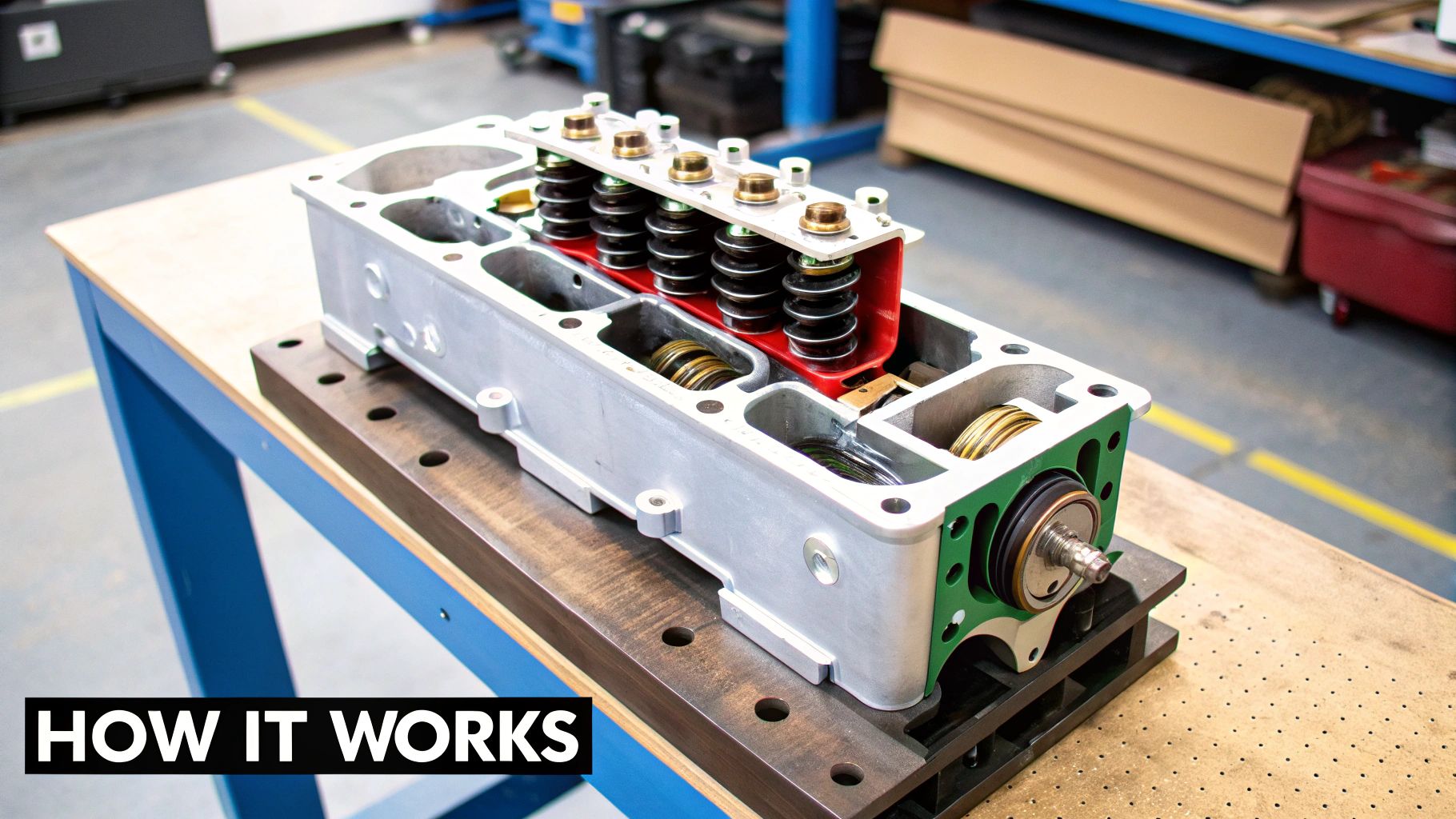

The Core Components Working in Harmony

To really get a feel for how a pneumatic solenoid valve operates, it helps to look at its four key players. Each has a specific job, and it’s how they work together that makes the valve such a reliable workhorse in any automated system.

The Solenoid Coil: This is the brains of the operation. When it gets the right voltage, it creates the magnetic field. Cut the power, and the field collapses just as quickly.

The Plunger (or Armature): This is the muscle. It’s the moving part that the coil’s magnetic force acts upon. A small spring is there to hold the plunger in its default position when the coil isn't energised.

The Valve Body: This is the skeleton holding everything together. It's a solid housing, usually made of metal or a tough polymer, that contains all the internal parts. It also has carefully machined channels, or ports, for the air to flow through.

Seals and Orifices: These are the gatekeepers. Small seals, often made from durable rubber or plastic, are fitted to the plunger. As the plunger shifts, these seals block or unblock the orifices (tiny openings) that connect the air channels, directing the flow of air exactly where it needs to go.

This perfectly coordinated dance happens in milliseconds. An electrical signal creates a magnetic field, the field moves the plunger, and the plunger opens or closes a path for compressed air. It’s a beautiful, efficient example of electromechanical engineering in action.

Direct-Acting vs Pilot-Operated Valves

While the basic principle of electromagnetism is always the same, solenoid valves apply this force in two different ways. The method used really comes down to the scale of the job—specifically, how much air you need to control.

A direct-acting valve is like using a hammer—simple, direct force gets the job done. A pilot-operated valve is like using a lever—it uses a small amount of effort to control a much greater force, making it more efficient for heavy lifting.

Direct-Acting Valves In a direct-acting valve, the solenoid does all the heavy lifting itself. When the coil is energised, it has to generate enough magnetic force to overcome the spring pressure and physically pull the plunger up, opening the main air passage directly.

- How it works: Brute force. The solenoid is the only thing moving the main seal.

- Best for: Lower flow applications where you need a super-fast response. They have a simpler design and don't need any minimum system pressure to work.

- Limitation: To control higher flow rates, they need bigger, more power-hungry coils. This can generate more heat and use more energy.

Pilot-Operated Valves A pilot-operated valve is a much smarter, two-stage system. It uses a small, efficient solenoid just to control a tiny "pilot" channel. When this little pilot channel opens, it lets a small amount of the system's own air pressure flow into a chamber above the main seal.

This redirected air pressure then acts on a much larger surface area, creating more than enough force to open the main valve passage. Essentially, the valve cleverly uses the system’s own power to do the hard work.

- How it works: Leverage. A small solenoid controls the system pressure, and that pressure then operates the main valve.

- Best for: High flow rate applications. They can control a huge volume of air with a tiny, low-power coil, making them highly energy-efficient.

- Limitation: They need a minimum operating pressure to function properly, because they rely on that pressure difference to open the main orifice.

Understanding this difference is vital when choosing a pneumatic solenoid valve. It has a direct impact on performance, energy use, and whether the valve is the right fit for your specific job.

Navigating the Different Solenoid Valve Types

Choosing the right pneumatic solenoid valve is a lot like picking the perfect tool for a job. Get it wrong, and you're in for a world of inefficiency and headaches. But get it right? You'll be rewarded with smooth, reliable performance every time.

Valves aren't a one-size-fits-all component. They’re organised by their function, which boils down to two key things: their port configuration (how many pathways for air they have) and their default state when the power is off.

Understanding this is crucial. A simple valve might just turn airflow on and off, but a more complex one can reverse the direction of a pneumatic cylinder, making it extend and then retract. Let's dig into these classifications to see how they solve real-world automation challenges.

Understanding Default States: Normally Open vs Normally Closed

Before we even count the ports, the most fundamental choice you'll make with any pneumatic solenoid valve is its default state. This simply means what the valve does when there's no electricity running to the solenoid coil. This decision has massive implications for your system's design, energy use, and safety.

Normally Closed (NC): This is the most common setup. In its resting state, an NC valve is closed, completely blocking the flow of compressed air. When you send an electrical current to the solenoid, it snaps open and lets the air through. Think of it as a gate that's shut by default and needs power to open.

Normally Open (NO): As the name suggests, a Normally Open valve does the exact opposite. With no power, it allows compressed air to flow freely through it. Energising the solenoid closes the valve and stops the flow. You'd use this in applications where something needs to be active most of the time, and the valve is only powered up to stop the process.

The choice between NC and NO often comes down to your system's fail-safe needs. If the power cuts out, do you need the air supply to be immediately cut off (choose NC), or should it keep flowing (choose NO)? Answering this question is a foundational step in designing a safe and effective system.

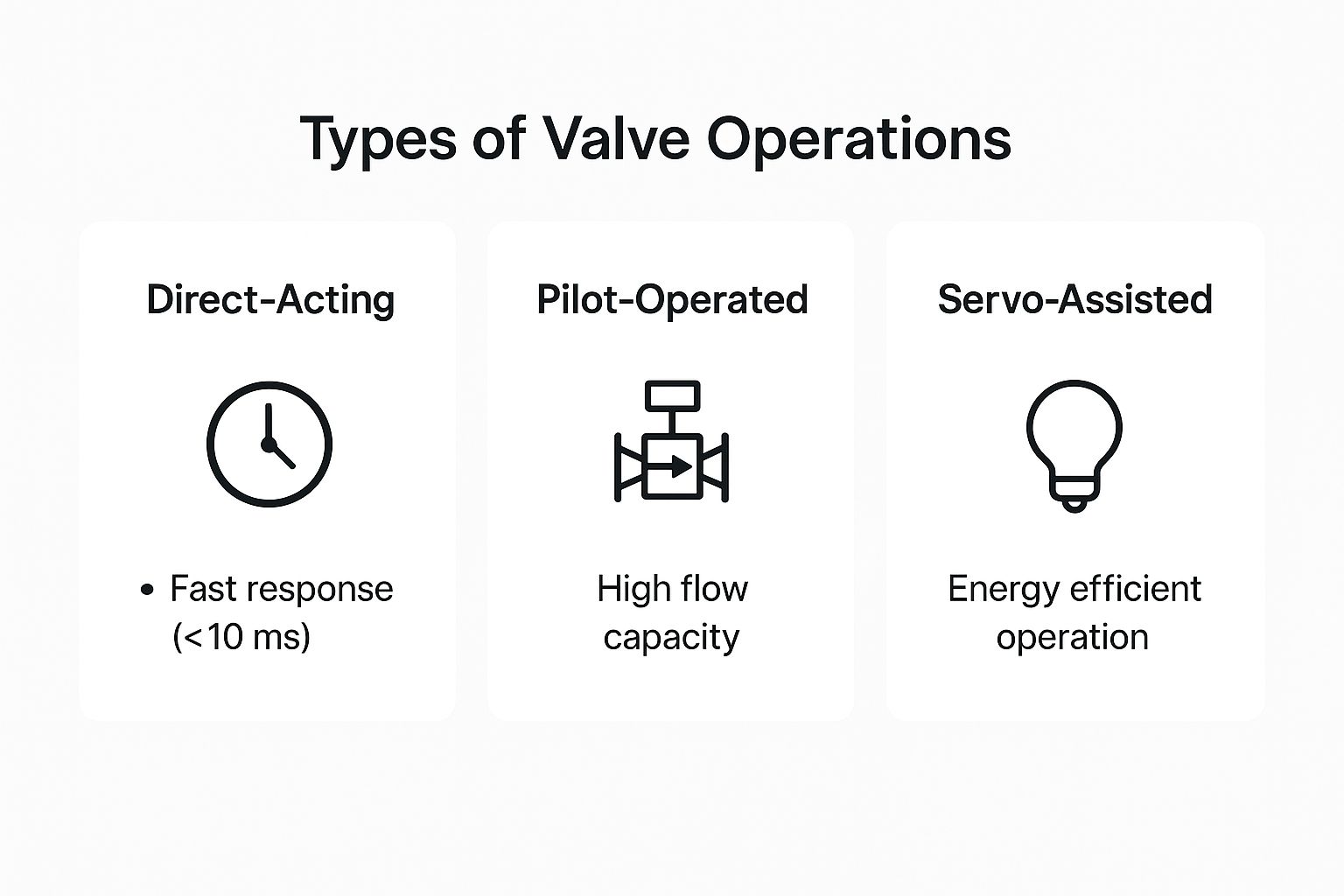

A Closer Look at Valve Operation Types

Beyond the default state, the way a valve is actuated also separates it into different categories, influencing its speed, power, and overall efficiency.

As you can see, there's a key trade-off here. Direct-acting valves give you raw speed, while pilot-operated models deliver superior flow control and energy efficiency for bigger jobs.

Functional Roles: 2-Way, 3-Way, and 5-Way Valves

The "way" number you see on a valve tells you how many working ports it has, which directly dictates what it can do. Each type is built for a different kind of task, from simple on-off switching to complex directional control.

To help you get your head around the options, here’s a quick comparison table.

Solenoid Valve Configurations at a Glance

This table breaks down the common pneumatic solenoid valve types to help you match the right valve to the right job.

| Valve Type (Ways/Positions) | Primary Function | Common Applications | Key Advantage |

|---|---|---|---|

| 2-Way Valve | On/Off control | Blowing debris, dispensing single bursts of air | Simplicity and direct control |

| 3-Way Valve | Pressurise and exhaust a single line | Controlling single-acting (spring-return) cylinders | Allows for controlled venting |

| 5-Way Valve | Reversing a double-acting cylinder | Operating robotic grippers, pneumatic presses | Full directional control (extend and retract) |

Let's break down what these configurations mean in practice.

2-Way Valves

The simplest of the lot, a 2-way valve has just two ports: an inlet and an outlet. Its only job is to start or stop the flow of air. It acts like a basic light switch and is most often a Normally Closed valve.

- Primary Function: On/Off control.

- Example Application: Firing a single, quick puff of air to blow dust off a part on a conveyor belt.

3-Way Valves

A 3-way valve steps things up with three ports: an inlet, an outlet, and an exhaust. This setup allows it to not only supply air to a device but also to safely vent that air when the valve switches off. This is absolutely essential for controlling single-acting cylinders, which rely on a spring for the return stroke.

- Primary Function: Pressurise and exhaust a single line.

- Example Application: Pushing a product off a production line using a spring-return pneumatic cylinder.

5-Way Valves

For motion control, the 5-way valve is the most versatile option. It has five ports: one pressure inlet, two outlet ports (A and B), and two corresponding exhaust ports. This is the industry standard for controlling double-acting cylinders, which need air pressure for both the extend and retract strokes. The valve expertly directs air to one side of the cylinder's piston while simultaneously venting the other side, and then reverses the process on command.

- Primary Function: Reversing the direction of a double-acting cylinder.

- Example Application: Operating a robotic gripper that needs pneumatic force to both open and close.

If you need to explore a wide range of pneumatic solenoid valves, checking out a specialised supplier can be incredibly helpful.

Where You'll Find These Valves in UK Industries

The real story of a pneumatic solenoid valve isn’t in a dry technical manual. It's written on the factory floors, in the logistics hubs, and across the critical infrastructure that keeps the UK running. These compact but powerful components are the unsung heroes in countless industrial processes.

They act as the crucial link, turning simple electrical signals into powerful, real-world actions. It's this ability to provide speed, precision, and unwavering reliability that gives British industries the edge they need to compete on a global stage.

To really get a feel for their impact, let's step away from the abstract and look at where they do their best work.

Driving Automation in Manufacturing and Logistics

Picture a state-of-the-art automotive plant in the West Midlands. You see a robotic arm, moving with a fluid, almost balletic grace, applying perfect welds to a car chassis. Every single movement, every application of pressure, is orchestrated by a bank of pneumatic solenoid valves firing in a flawless sequence. They are the reason that robot has such pinpoint accuracy and can repeat its task thousands of times without tiring, ensuring every vehicle rolling off the line meets the highest quality standards.

Now, let's head to a massive logistics hub somewhere along the M1 corridor. Thousands of parcels, all different shapes and sizes, are hurtling down conveyor belts. How are they all sorted so quickly and accurately? Often, the answer is pneumatic diverter arms, triggered in the blink of an eye by solenoid valves. A scanner reads a barcode, sends a signal to a specific valve, and wham—the valve actuates a cylinder to guide the parcel onto the right chute for its journey.

This is the kind of automation that powers modern e-commerce, and it’s all made possible by the near-instant response of a pneumatic solenoid valve.

Think of these valves as the nerve endings of an automated system. They take the digital 'thought' from a control system and create a physical 'reflex' on the production line. This enables tasks that would be utterly impossible for a person to perform at that speed and scale.

The applications in manufacturing are practically limitless:

- Packaging: Rapidly operating the machines that fill, seal, and label products in food and beverage plants.

- Assembly: Powering the pneumatic screwdrivers, grippers, and presses on electronics assembly lines.

- Quality Control: Activating reject gates to push faulty products off a production line without having to stop everything.

Critical Roles in Process Control and Public Services

But their influence doesn't stop at the factory gate. Solenoid valves are just as vital in sectors crucial for our public health and environment. Take the UK’s water treatment industry, for example—a sector dedicated to supplying safe, clean drinking water to millions.

Here, solenoid valves are essential for process control. They meticulously dose treatment chemicals, open and close massive butterfly valves to route water through different filtration stages, and manage the backwash cycles that keep filters clean and working efficiently. Their reliability is non-negotiable; a single valve failure could potentially compromise water quality or disrupt the entire supply.

This reliance on smart valve technology is only set to increase.

The UK solenoid valve market is projected to grow steadily, with a Compound Annual Growth Rate (CAGR) of around 4.3% between 2025 and 2035. A major driver for this is the national push towards sustainability and energy efficiency, especially in sectors like water treatment. As government directives to improve water quality intensify, so does the demand for smart, efficient components. You can find a deeper dive into this trend in the full market analysis.

From the sterile precision of a pharmaceutical lab to the raw power needed in a quarry, the pneumatic solenoid valve is an essential piece of the puzzle. It's the component that lets engineers turn a simple puff of compressed air into a finely controlled, powerful, and efficient industrial tool, shaping the productivity and innovation of countless UK industries.

Your Checklist for Selecting the Right Valve

Choosing the right pneumatic solenoid valve isn't just a simple purchase. It's a critical engineering decision that has a direct knock-on effect on your system's performance, efficiency, and safety. Get it wrong, and you could be looking at anything from sluggish operation and wasted energy to a catastrophic system failure and expensive downtime.

The secret is to look past the generic spec sheets and start asking pointed questions about what you really need. This practical checklist helps you turn confusing technical data into a clear path forward. By working through these criteria one by one, you'll be able to choose a valve that’s a perfect match for the job, guaranteeing reliability and peak performance.

Define Your Operational Requirements

First things first, you need to pin down exactly what the valve has to do. This means looking at the entire system it will be part of, not just the valve in isolation. A mismatch at this stage is the number one cause of performance headaches down the line.

Start with these fundamentals:

- What's the required flow rate? This is often shown as a Cv value (flow coefficient) and is arguably the most crucial factor. An undersized valve will starve your actuator of air, leading to slow or weak movement. You need to calculate the minimum Cv your system demands based on your target flow rate and acceptable pressure drop.

- What are your system's pressures? You must know both the minimum and maximum operating pressures. A pilot-operated valve, for example, needs a certain minimum pressure difference to even open, while pushing a valve past its maximum pressure rating is a serious safety risk.

- What is the media being controlled? While we're talking about pneumatics, the quality of your compressed air is key. Is it clean, dry, and lubricated, or does it carry moisture and debris? The air quality will dictate your choices for materials and filtration. For a better grasp of system needs, it's worth reviewing the pneumatic system basics.

Match the Valve to the Environment

Once you've defined the operational needs, think about where the valve is going to live. A valve that works perfectly in a cleanroom will fail in short order in a harsh, industrial washdown area.

A valve’s material composition is its first line of defence against its operating environment. Choosing a material that is incompatible with ambient conditions, such as temperature or corrosive elements, is a direct path to premature failure.

Consider these environmental and electrical points:

- Materials Compatibility: Will the valve be exposed to moisture, chemicals, or extreme temperatures? The body and seal materials must be up to the task. Brass is a great all-rounder, but for really tough applications, stainless steel offers superior corrosion resistance.

- Electrical Supply: What voltage and current (AC or DC) do you have available? Hooking up the wrong voltage is one of the quickest ways to fry a solenoid coil.

- Response Time: How fast does the valve need to open and close? For high-speed automation lines, a direct-acting valve might be essential. For less critical jobs, the slightly slower response of a pilot-operated valve is perfectly fine.

The market for these parts is strong and growing, particularly for specialised units. The UK's miniature solenoid valves market was valued at around USD 62.7 million in 2024 and is projected to reach USD 86.9 million by 2030. Stainless steel models are the big players, holding about 48.5% of the revenue share thanks to their durability, while lightweight plastic valves are the fastest-growing segment. You can dig into more details about this market growth on grandviewresearch.com. This trend highlights just how important it is to find a precisely specified valve for every unique job.

Installation and Maintenance That Prevents Downtime

A top-tier pneumatic solenoid valve is only as reliable as its installation and maintenance plan. Getting these steps right is what separates a dependable, long-lasting component from a recurring source of expensive downtime. Think of it as laying a solid foundation; without it, even the best-engineered valve is destined to fail.

Proper installation isn’t just about hooking up pipes and wires. It’s about creating the perfect operating environment from the very beginning. This proactive mindset is the key to preventing the common issues that so often plague pneumatic systems.

Perfecting the Installation Process

The first thing to get right is mounting the valve in the correct orientation. This isn't just a suggestion—it's crucial. Most solenoid valves are designed to work with gravity, which means the solenoid coil needs to be sitting vertically on top. If you install it sideways or upside down, the plunger might not seat properly, which can lead to poor performance or a much shorter lifespan.

Next up, your air supply. The air flowing through your valve has to be clean and dry. There’s no bigger enemy to a pneumatic solenoid valve than contaminants like dirt, rust, or moisture. These tiny particles can score internal surfaces, clog small orifices, and cause seals to break down, resulting in leaks or a valve that’s completely jammed. A quality filter-regulator unit upstream isn't just a good idea; it's essential insurance for your system.

It's estimated that a staggering 80% of all pneumatic system failures are caused by contaminated air. Keeping your air supply clean and dry is the single most effective thing you can do to protect your investment and avoid unexpected shutdowns.

Finally, be meticulous with the wiring. Applying the wrong voltage is the quickest way to burn out a solenoid coil. Always, always double-check that your power supply voltage matches what’s specified on the valve’s coil. You'll also want to make sure all your connections are secure to avoid those frustrating intermittent faults that are a nightmare to diagnose later.

A Simple Preventative Maintenance Checklist

Once your valve is installed, a simple maintenance routine will go a long way in maximising its life and catching small problems before they become big ones. You don't need a complex procedure; a basic "look, listen, and feel" check works wonders.

Here’s a straightforward checklist for your regular inspections:

- Listen for Unusual Noises: A healthy AC-powered valve might give off a faint hum, but if you hear loud buzzing or clicking, that’s a red flag. It often points to low voltage, some debris stopping the plunger from seating, or another internal issue.

- Visually Inspect for Leaks: Grab a soapy water solution and apply it around the fittings and valve body. Any bubbles will instantly give away air leaks that are wasting energy and costing you money.

- Check for Overheating: It's normal for a coil to get warm during operation. However, if it’s too hot to comfortably touch, it could be a sign of incorrect voltage or that the coil is working too hard because of a mechanical blockage.

- Confirm Secure Mounting and Wiring: Over time, vibrations can loosen fasteners and electrical connections. A quick visual check ensures everything is still tight and secure.

Proactive care is especially important in the UK, where automation in key industries is growing fast. For more in-depth guidance, have a look at our detailed guide on solenoid valve installations and maintenance instructions for expert, step-by-step advice.

As industrial automation continues to expand in sectors like oil & gas, water treatment, and renewable energy, the reliability of these components becomes paramount. By following these straightforward installation and maintenance practices, you can ensure your pneumatic solenoid valve delivers the dependable performance your operations need.

Frequently Asked Questions About Pneumatic Solenoid Valves

Even the most experienced engineers and technicians have questions when dealing with a pneumatic solenoid valve. These little workhorses are incredibly reliable, but knowing their quirks is the secret to fast troubleshooting and smart system design. Let's dig into some of the most common questions we get asked, with some clear, practical answers.

Getting to grips with these points will help you solve frequent issues and give you a much deeper, real-world understanding of how these valves tick. The end goal? Keeping your automated systems running without a hitch.

Direct-Acting vs Pilot-Operated: What's the Difference?

This is probably the most common point of confusion we see. The easiest way to think about it is comparing raw muscle against clever leverage.

A direct-acting valve uses the brute force of the solenoid's magnetic field to directly shift the valve open or closed. A pilot-operated valve is a bit smarter; it uses a tiny amount of air to operate a small pilot valve, which then uses the main system pressure to do the heavy lifting of opening the main valve.

The leverage in a pilot-operated valve means a small, energy-sipping coil can control a massive amount of airflow, making it perfect for bigger jobs. Direct-acting valves, on the other hand, are brilliantly simple and fast, which makes them ideal for applications that need quick responses at lower flow rates.

How Do I Choose the Right Cv Rating?

Getting the Cv rating, or flow coefficient, right is absolutely crucial. Get it wrong, and you'll starve your system of air. An undersized valve leads to sluggish, weak performance from pneumatic cylinders or air tools – it's a very common mistake.

To nail the right Cv, you need to know three key things:

- The required flow rate for your equipment (usually in SCFM).

- The pressure of the air going into the valve (inlet pressure).

- The pressure you need coming out of the valve (outlet pressure).

Armed with these figures, you can pop them into a manufacturer’s online calculator or a standard formula to find the minimum Cv your system needs. A good rule of thumb is to always choose a valve with a Cv that meets or slightly exceeds this number. This gives you a little headroom and ensures you've always got enough flow.

Why Is My Solenoid Valve Making a Loud Buzzing Noise?

A loud, angry buzzing or humming, especially from an AC-powered valve, is a definite red flag. It’s the valve’s way of shouting for help.

The usual suspects are incorrect voltage (often too low), a tiny piece of dirt or debris that’s stopping the plunger from seating properly, or a broken internal part like a shading ring. First, double-check that the supply voltage matches the coil's rating exactly. If that’s fine, the valve probably needs to be safely depressurised, taken apart, and given a thorough clean. If it's still buzzing after a clean-up, the coil or the whole valve might be on its way out and will need replacing to prevent it from burning out completely.

For a comprehensive selection of valves for any application, from air and water to gas and steam, the experts at Solenoid Valve World can provide UK-based technical support and next-day delivery. Explore our range today at https://solenoid-valve.world.