A Practical Guide to Types of Pipe Fittings

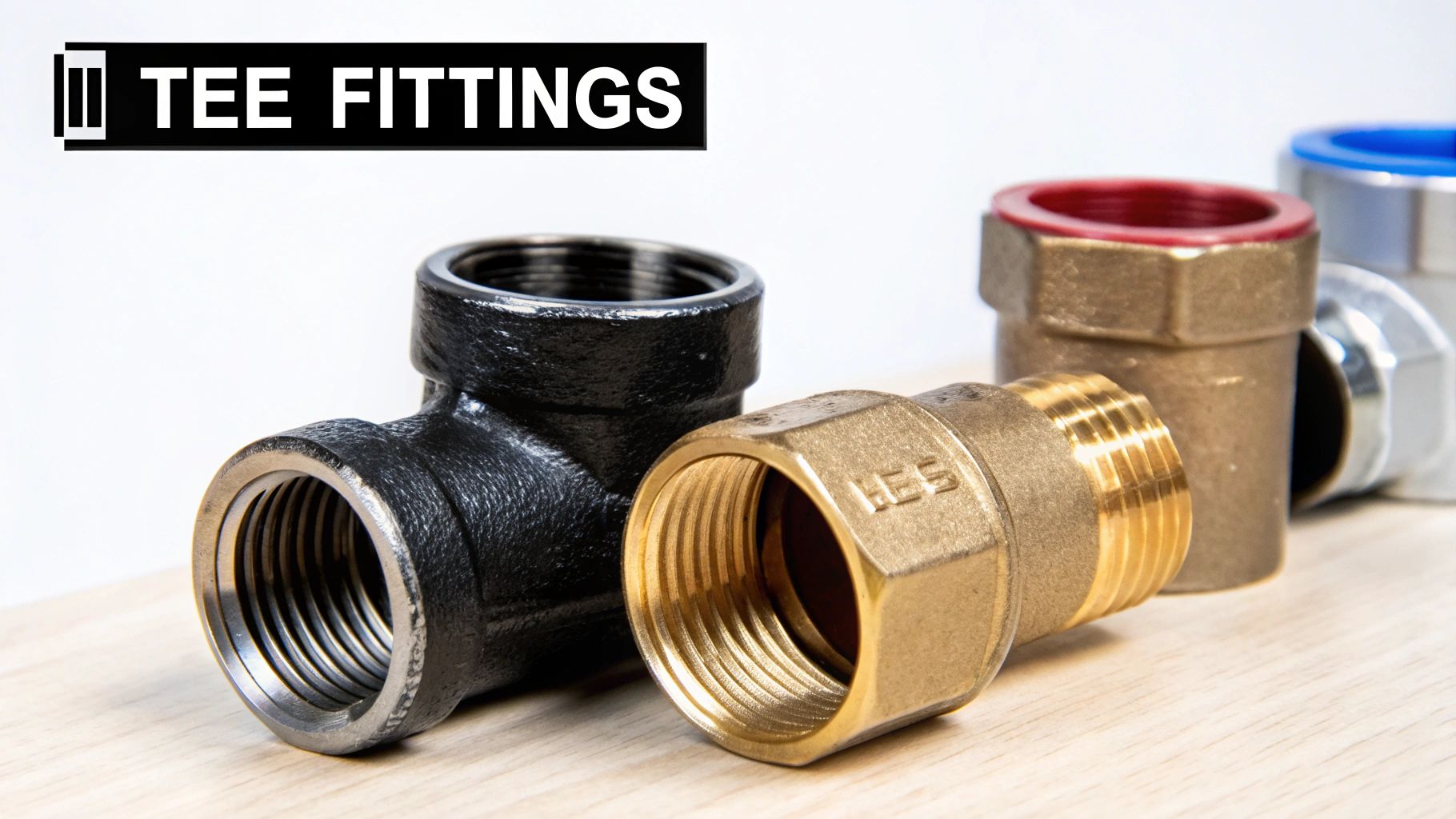

When you're dealing with plumbing or any kind of pipework, it's the small parts that often make the biggest difference. The world of piping is held together by a whole family of components called pipe fittings. These crucial connectors, like elbows, tees, and couplings, are what allow us to join pipes, snake them around corners, or change their size. They're the reason our systems work securely and, most importantly, without leaks.

What Are Pipe Fittings and Why Do They Matter?

Think of pipe fittings as the unsung heroes of any piping system. Whether it’s the simple network under your kitchen sink or a sprawling industrial setup, they play a vital role. Imagine trying to build something with only straight, disconnected rods – you wouldn't get very far. Fittings are like the joints of that structure, connecting individual pipes to create a complete, functional system.

But these aren't just simple connectors. Each fitting is a small piece of clever engineering, designed for a very specific job. Its shape and material determine its function, which usually falls into one of these key tasks:

- Changing Direction: Fittings like elbows are essential for redirecting the flow of water, gas, or other fluids around obstacles and corners.

- Connecting Pipes: Couplings and unions are used to create solid, leak-proof links between two separate pipes.

- Branching Flow: A tee fitting acts like a T-junction on a road, splitting one flow into two or merging two separate flows into one.

- Adapting Size: Reducers and bushings are the perfect solution for connecting a larger pipe to a smaller one, helping manage changes in pressure and flow.

- Terminating a Line: When you need to stop the flow completely, caps and plugs are used to safely seal off the end of a pipe.

The Foundation of System Integrity

Getting the types of pipe fittings right is absolutely critical for the safety and long-term health of the entire system. A simple mismatch in material can kick off corrosion, while using the wrong size could lead to a catastrophic leak. It’s simple, really: using a low-pressure fitting in a high-pressure line is just asking for trouble.

The real job of a pipe fitting isn't just to connect things. It’s about maintaining the integrity of the whole system, managing pressure, and guaranteeing a safe, leak-free operational life for the pipeline.

Beyond standard plumbing, you'll find fittings designed for very specific jobs. For example, you can find specialised fittings for landscape irrigation systems, which are often made from PVC or polyethylene to stand up to constant contact with soil and water.

Ultimately, once you understand what each fitting does, you'll stop thinking about just "joining pipes." Instead, you'll see it as strategically building a reliable and efficient network. That knowledge is key, whether you’re a seasoned engineer or a weekend DIY warrior.

To help you get started, here’s a quick rundown of the most common fittings and what they do.

Quick Guide to Common Pipe Fitting Types and Functions

This table breaks down the most common fittings you'll encounter and their primary role in a piping system. It's a great starting point for identifying what you need for your project.

| Fitting Type | Primary Function |

|---|---|

| Elbow | Changes the direction of flow (e.g., 90° or 45°). |

| Tee | Splits or combines flow from a three-way junction. |

| Coupling | Connects two pipes of the same size in a straight line. |

| Union | Connects two pipes but allows for easy disassembly. |

| Reducer | Joins two pipes of different diameters. |

| Cap | Seals the external threaded end of a pipe. |

| Plug | Seals the internal threaded opening of a fitting. |

Having a solid grasp of these basic types makes planning and executing any piping job much more straightforward.

Choosing the Right Metal Fitting Materials

While a fitting's shape tells you what it does, its material dictates where and how you can actually use it. In the world of plumbing and pipework, metal fittings are the undisputed workhorses, valued for their raw strength and ability to handle extreme conditions. They form the backbone of systems where failure simply isn't an option.

Picking the right metal isn't just a casual choice; it’s a critical decision. You have to weigh up the pressure, the temperature, the type of fluid moving through the pipes, and even the surrounding environment. Let's break down the three most common metals—steel, copper, and brass—to see why each has its own unique place in the industry.

Steel: The Heavy-Duty Champion

Think of steel fittings as the structural I-beams of the piping world. Known for their incredible strength and sheer durability, steel fittings are the go-to for high-pressure and high-temperature jobs. You'll find them everywhere in industrial processing plants, power stations, and huge infrastructure projects where the system is under constant, immense stress.

There are a few different flavours of steel used for various types of pipe fittings:

- Carbon Steel: This is your most common and budget-friendly option. It offers fantastic strength and works brilliantly in non-corrosive environments, making it the standard for industrial manufacturing and fire sprinkler systems.

- Stainless Steel: Add a bit of chromium into the mix, and you get stainless steel, which boasts superior resistance to rust and corrosion. This makes it perfect for food processing, pharmaceuticals, and marine applications where cleanliness and chemical resistance are non-negotiable.

- Galvanised Steel: This is simply carbon steel that’s been coated in a protective layer of zinc. The zinc coating acts as a sacrificial barrier against corrosion, making galvanised fittings a common sight in outdoor water supply lines and construction frameworks.

Given its strength, it's hardly a surprise that steel dominates the UK market. In 2024, steel fittings pulled in the largest revenue share at around 40.46%. This trend is set to continue, thanks to ongoing infrastructure and construction projects across the country.

Copper: The Reliable Residential Standard

If steel is the industrial powerhouse, then copper is the trusted professional you call for residential and commercial plumbing. For decades, copper fittings have been the gold standard for drinking water lines and central heating systems throughout the UK, and for very good reasons.

Copper has a unique set of talents. It’s highly resistant to corrosion from water, giving it a long and reliable service life. On top of that, its natural biostatic properties mean it actively inhibits bacterial growth—a huge plus for any system carrying drinking water.

Copper’s excellent thermal conductivity makes it exceptionally efficient for hot water systems. It transfers heat effectively, which is why it's the preferred material for pipes connecting to boilers and radiators.

What's more, copper is relatively soft and easy to work with. This allows plumbers to create secure, leak-proof joints with simple soldering, a reliability that has cemented its place in pretty much every home.

Brass: The Versatile and Durable All-Rounder

Brass is an alloy, primarily a mix of copper and zinc. By blending these two metals, brass gets the best of both worlds: copper's corrosion resistance paired with zinc's strength and durability. This combination makes brass fittings incredibly versatile.

Their main advantage is fantastic resistance to corrosion, especially from mineral-heavy water that can be tough on other metals. This makes them a first-class choice for drinking water applications, particularly for taps and valves that are constantly exposed.

Beyond that, brass is a robust material that can handle moderate pressures and temperatures without breaking a sweat. It's also easy to machine, which allows for precise, tight-sealing threads.

Because of this versatility, you’ll often find brass used for:

- Potable Water Systems: Fittings, valves, and tapware.

- Gas Lines: Its durability and leak-proof nature make it suitable for low-pressure gas distribution.

- Pressure Management: Brass is a common material for components that control system pressure. For safety and efficiency, you can also explore our detailed guide on pressure reducing valves for air and water.

Ultimately, the choice between steel, copper, and brass really boils down to the specific demands of the job. Steel brings unmatched strength for heavy industry, copper provides reliable and safe performance for homes, and brass delivers versatile durability for a huge range of applications.

When to Use Modern Plastic Pipe Fittings

While metal fittings have a long-standing reputation for raw strength, modern plastic fittings have carved out a huge space in the plumbing world for very different reasons. They bring an unbeatable combination of affordability, total immunity to corrosion, and incredibly simple installation to the table. This has made them the go-to choice for a massive range of residential and light commercial jobs.

When you hear "plastic fittings," two materials probably jump to mind: PVC and its tougher cousin, CPVC. Although they look quite similar, they're engineered for completely different tasks. Getting to grips with what each one does best is absolutely essential for building a safe, reliable system that lasts.

The shift towards these materials isn't just a hunch; it's backed by some serious market data. PVC and CPVC fittings make up a huge slice of the UK market. In fact, polyvinyl chloride (PVC) alone is responsible for an 83.68% revenue share in 2024. Its sheer versatility and low cost are driving this trend, with experts forecasting a 5.2% annual growth rate through to 2033. You can dive deeper into the UK's PVC and CPVC pipe fittings market outlook to see the full picture.

This popularity really underscores why it’s so critical to know which plastic to use, and when.

PVC: The Versatile Cold Water Specialist

Polyvinyl Chloride, or PVC, is one of the most recognised types of pipe fittings out there. You can’t miss its classic brilliant white or grey colour in any DIY store or on a building site. At its core, PVC is designed for low-pressure and low-temperature work.

Think of PVC as the perfect partner for any pipe run where the water will always be cool. Its smooth inner surface cuts down on friction for better flow and, crucially, it will never rust or suffer from the mineral scale that can clog up metal pipes over the years.

You’ll typically find PVC fittings used for:

- Cold Potable Water Lines: Bringing fresh, cold water to the taps and toilets in a house.

- Drainage and Waste Systems: Its ability to resist chemicals makes it a solid choice for carrying household waste away without breaking down.

- Irrigation and Sprinkler Systems: Being so light and easy to connect makes it ideal for laying out complex watering systems outdoors.

The single most important thing to remember about standard PVC is its heat limit. It is simply not made for hot water. If you expose it to high temperatures, it will soften, lose its shape, and eventually fail, leading to major leaks and water damage.

CPVC: Handling the Heat Safely

This is exactly where Chlorinated Polyvinyl Chloride, or CPVC, comes in. That extra "C" in its name stands for "chlorinated," a simple chemical tweak that gives it a whole new set of skills. The chlorination process grants CPVC a much higher temperature resistance than its standard PVC relative.

If PVC is the cold water specialist, then CPVC is the trusted choice for hot water systems. It holds its shape and pressure rating at temperatures that would make PVC warp and fail. This makes it a safe and widely approved material for running both hot and cold water through the same plumbing system.

You can usually spot CPVC by its light cream or off-white colour—a handy visual clue that it’s built for higher temperatures.

Key uses for CPVC fittings include:

- Hot and Cold Water Distribution: It's the standard plastic for residential supply lines that need to carry hot and cold water safely.

- Industrial Liquid Handling: Its excellent chemical resistance also sees it used in certain industrial settings to handle various corrosive fluids.

At the end of the day, the choice between PVC and CPVC is straightforward but non-negotiable. For any pipework that will only ever deal with cold water, drainage, or outdoor irrigation, PVC is a reliable and cost-effective solution. But the second hot water enters the equation, you must switch to CPVC to guarantee safety and performance. Getting this simple distinction right is the key to preventing costly failures and building a plumbing system designed to last.

Understanding How Fitting Shapes Control Flow

If a fitting's material is its personality, then its shape is its job description. Every bend, branch, and opening is specifically engineered to do something—change direction, split the flow, or connect two different pipes. To really get a handle on the different types of pipe fittings, you need to see them less as simple components and more as tools that actively manage the fluid inside a system.

Think of it like building a custom road network for water or gas. You wouldn't just use straight sections; you'd need intersections, corners, and on-ramps to create an efficient system. That's exactly what pipe fittings do. Let's break down the most common shapes and what they're used for.

Elbows: The Direction Changers

Elbows are some of the most common fittings out there. Their job is simple but vital: to change the direction of a pipe run. They are the corners of your piping system, letting you navigate around obstacles, turn up walls, or squeeze into tight spots.

You'll mainly come across two angles:

- 90-Degree Elbow: This creates a sharp, right-angle turn. It's perfect when you need to make an abrupt change, like running a pipe along a floor and then straight up a wall. A handy variation, the street elbow, has one male and one female end, which saves space by cutting out the need for an extra fitting.

- 45-Degree Elbow: This fitting provides a gentler, more gradual turn. It’s often used for slight directional adjustments, helping to reduce the friction and pressure drop you'd get from a sharper 90-degree bend.

Choosing between a 90° and 45° elbow isn't just about the physical angle; it’s about managing how the fluid behaves. A sharp turn creates more turbulence, whereas a gentler one keeps things moving along smoothly.

Tees: The Flow Dividers

A tee fitting looks exactly like the letter "T". It has one inlet and two outlets set at 90-degree angles to the main line. Its main role is to act as a junction, either splitting one flow into two separate streams or merging two flows into one.

You’ll find tees everywhere, from home plumbing where a main water line needs to branch off to supply a sink and a toilet, to more complex industrial systems. An "equal tee" means all three openings are the same size. A "reducing tee" has a smaller branch port, so you can connect a smaller pipe to the main run.

Reducers: The Size Translators

So, what do you do when you need to connect a large pipe to a smaller one? You grab a reducer. These fittings are critical for handling changes in pipe diameter, which directly impacts the flow rate and pressure of the fluid.

Reducers aren't just simple connectors; they're engineered to create a smooth, controlled transition between pipe sizes. This is key to minimising turbulence and preventing a sudden pressure drop that could throw the whole system out of whack.

There are two main styles:

- Concentric Reducers: These are cone-shaped, with both ends aligned along the same centreline. They are typically used in vertical pipe runs because they keep the flow profile even.

- Eccentric Reducers: These have a flat side, which means the smaller outlet's centreline is offset from the larger one. This flat design is essential for horizontal pipes, as it stops air or sediment from getting trapped where the pipes connect.

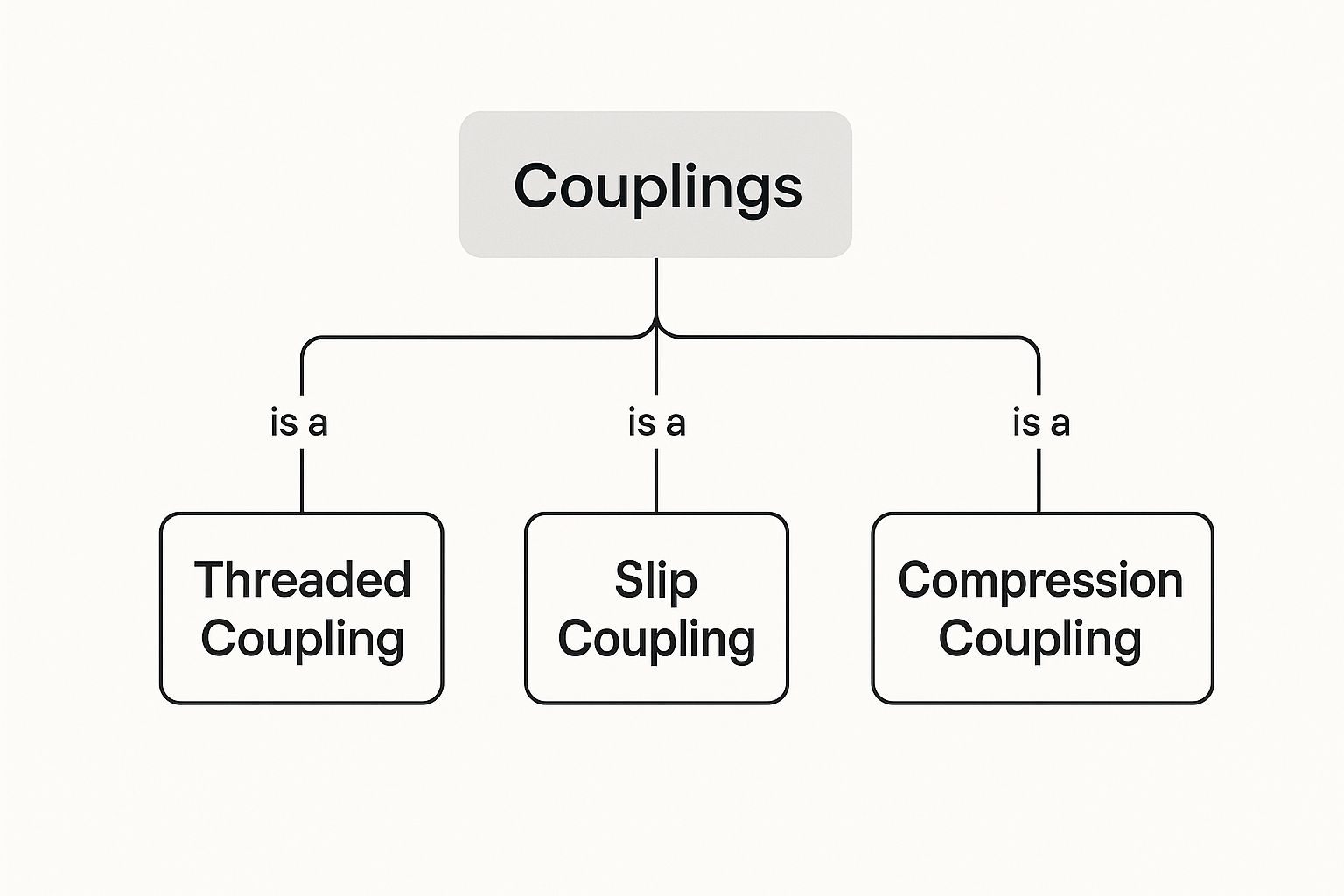

Couplings and Unions: The Straight Connectors

Couplings are fittings made to join two pipes of the same size in a straight line to make a longer run. They are simple, effective, and usually create a semi-permanent seal.

A slip coupling, for instance, is a clever fitting for repairs. It has no internal stop, so it can slide completely over a pipe. This makes it invaluable for fixing a small, damaged part of a long pipe without having to replace the entire length.

Unions do a similar job to couplings—joining two pipes—but with one major difference: they are designed to be taken apart easily. A union is made of three parts: two ends that attach to the pipes and a central nut that pulls them together. This setup is perfect for spots where you might need to do maintenance, as you can separate the pipes without any cutting.

This concept map breaks down the core functions of different coupling types.

The visualisation clearly shows how different couplings—threaded, slip, and compression—are all specialised to connect pipes, but achieve it in distinct ways for different needs.

Caps and Plugs: The Line Terminators

Finally, when you need to stop the flow completely, you'll use a cap or a plug. These fittings are essential for sealing the end of a pipe, whether it's a temporary measure during construction or a permanent termination point.

A cap fits over the male (external) threads of a pipe, like a lid on a jar. In contrast, a plug is inserted into the female (internal) threads of a fitting. Both get the job done, creating a secure, leak-proof seal that stops contaminants from getting in and makes sure the line is safely closed off.

How to Select the Correct Fitting Size and Thread

Getting the right size and thread for your pipe fittings is one of those areas where you really have to be precise. Get it wrong, and you’re looking at nagging leaks, a loss of pressure, or even a total system failure. It’s a foundational step that secures the integrity of your entire project.

This guide will walk you through how to get it right, every single time. We'll cut through the jargon around UK sizing and threading standards, making sure your new parts are a perfect, leak-free fit.

Understanding Sizing Standards

When you pick up a pipe fitting, its size isn't as simple as just taking a tape measure to it. In the UK and across Europe, we use a system called Nominal Pipe Size (NPS), or sometimes Diameter Nominal (DN), to standardise things.

The most important thing to grasp is that the nominal size, for instance a "1-inch pipe," isn't a direct measurement. It's a reference number that points to a specific set of standard dimensions for the inside and outside diameters.

A 1-inch pipe doesn't actually measure one inch anywhere you check it. This is a massive point of confusion and a common reason people order the wrong types of pipe fittings. Always have a proper sizing chart handy to cross-reference the nominal size with the actual outside diameter (OD). That's how you confirm you have a match.

Male vs Female Connections

Next up is identifying the connection type, which is much more straightforward. It all comes down to basic mechanics:

- Male Fittings: These have threads on the outside.

- Female Fittings: These have threads on the inside.

A male fitting screws directly into a female one to create the connection. Think of a cap fitting over a male thread, whereas a plug screws into a female thread. Simple as that.

The Critical Role of Thread Types

Once you've sorted the size and connection, the final piece of the puzzle is the thread standard. Here in the UK, the dominant standard is British Standard Pipe (BSP). But—and this is a big but—BSP comes in two different types. Mixing them is a guaranteed recipe for leaks.

BSPT (British Standard Pipe Tapered): On a BSPT fitting, the threads are tapered, meaning they get narrower along their length. The seal is formed when the male and female threads are tightened, physically wedging themselves together to create a pressure-tight joint. You’ll always need to use a thread sealant to make sure this connection is completely leak-proof.

BSPP (British Standard Pipe Parallel): As the name implies, the threads here are parallel, or straight. The threads themselves don't actually form the seal. Instead, the seal comes from a bonded washer or an O-ring that gets compressed between a shoulder on the male fitting and the face of the female fitting.

While BSP is the go-to in the UK, you might sometimes stumble upon NPT (National Pipe Taper) threads, especially on equipment imported from the USA. It's vital to know these two standards are not compatible. To avoid headaches, it’s worth understanding the key differences between NPT and BSPT.

UK Pipe Thread Standards Compared

To make things crystal clear, here’s a quick comparison of the two main thread types you’ll encounter in the UK.

| Feature | BSPT (Tapered) | BSPP (Parallel) |

|---|---|---|

| Thread Shape | Tapered along the length. | Straight or parallel. |

| Sealing Method | Threads wedge together. Requires sealant. | Washer or O-ring compresses. |

| Primary Use | High-pressure lines where a permanent seal is vital. | Lower-pressure systems or where disassembly is likely. |

| Common Name | Tapered Thread | Parallel Thread |

Nailing down the size, connection gender, and thread standard is the cornerstone of a successful and leak-free installation. Take the time to get these details right from the start.

The Future of the UK Pipe Fitting Industry

You might think the world of pipe fittings is a bit traditional, built on tried-and-tested standards that haven’t changed in decades. But that couldn't be further from the truth. The UK market is being actively reshaped by major economic and environmental shifts, changing the game for the types of pipe fittings needed and creating new hurdles—and opportunities—for our domestic manufacturers.

A massive driver for this change is the UK’s unwavering commitment to hitting net-zero carbon emissions. This national mission is pouring huge sums of money into green energy infrastructure, from brand-new hydrogen networks to sprawling renewable energy plants. These projects don't just need any old fittings; they require highly specialised, tough components, often made from steel, that can handle new types of fuels and much higher operational pressures. This has opened up a whole new market.

Green Energy and Trade: A New Landscape

This green transition offers a clear path for long-term growth. While the UK's manufacturing of steel tubes and fittings has dipped recently—declining at a compound annual rate of about 4.2% in the five years to 2025—the shift to green energy is a huge opportunity on the horizon. You can read more about the steel tube and pipe manufacturing industry on ibisworld.com.

At the same time, the post-Brexit trade environment has added its own layer of complexity. It's certainly created some supply chain headaches, but it has also sparked a renewed focus on building up the UK's own manufacturing muscle. This has given local producers a real chance to step up, innovate, and plug the gaps in the market.

Innovations in Materials and Manufacturing

It isn't just market forces at play; technology is also pushing the industry into the future. The next chapter will be all about smarter, more sustainable materials and advanced production techniques that boost performance and efficiency.

We’re seeing exciting developments in a few key areas:

- Advanced Composites: New materials are being developed that are lighter, stronger, and more resistant to corrosion than traditional metals, offering great alternatives for certain jobs.

- Smart Fittings: Imagine fittings with built-in sensors that monitor pressure, temperature, and flow in real time. This allows for predictive maintenance, catching potential problems before they lead to system failures.

- 3D Printing (Additive Manufacturing): The ability to print custom-designed or obsolete fittings on demand is a game-changer. It slashes waste and delivers quick fixes for complex repairs or one-off projects.

In the end, the future of the UK pipe fitting industry hinges on one thing: adaptability. Success will come down to those who embrace sustainable practices, invest in advanced manufacturing, and develop the specialised components needed to build our next generation of energy and infrastructure systems.

Common Questions About Pipe Fittings

Even when you've got a good handle on the different types of pipe fittings, a few questions always seem to pop up on the job. Getting the right answer can be the difference between a project that runs smoothly and one that causes a real headache. Here are some of the most common queries we see.

What's the Real Difference Between a Coupling and a Union?

Think of it in terms of permanence versus convenience. A coupling is designed to join two pipes together in a way that’s more or less permanent. You wouldn't install one expecting to take it apart easily.

A union, on the other hand, also connects two pipes but it’s built with a central nut. This clever three-part design means you can easily separate and then reconnect the pipes without having to cut anything. It’s perfect for any part of your system where you know you'll need to do maintenance down the line.

Can I Mix Metal and Plastic Fittings?

You can, but you absolutely must use a specialised transition fitting to avoid some serious problems. If you connect dissimilar metals directly, like copper to galvanised steel, you’ll trigger galvanic corrosion which will eat away at the metal over time.

When you're joining a metal pipe to a plastic one, you need a specific adapter. This fitting will usually have a brass thread for the metal side and a plastic solvent or push-fit end for the plastic pipe. This is the only way to guarantee a secure, leak-proof seal without risking damage to your materials.

How Do I Know a Fitting's Pressure Rating?

The pressure rating is almost always marked right on the fitting itself, either stamped into the metal or moulded into the plastic. You'll typically see it listed in PSI (pounds per square inch) or Bar.

It is absolutely crucial to make sure this rating is higher than the maximum operating pressure of your system. For systems that need careful pressure control, it's also a good idea to understand how a pressure relief valve works as part of the bigger picture.