What are Coalescing & Carbon Filters and their Role in Breathing Air Systems?

When it comes to compressed air and breathing air systems, air quality is not just a performance issue—it’s a matter of safety and compliance. One of the most critical components in maintaining ultra-clean, breathable air is the coalescing filter. This advanced filtration device plays a vital role in removing microscopic contaminants from compressed air, ensuring that the air supply remains safe, clean, and suitable for sensitive applications—including those involving human respiration.

What Is a Coalescing Filter?

A coalescing filter is a specialised air filter designed to remove aerosols, fine oil mists, water vapour, and sub micron particles from compressed air. Unlike standard particulate filters, coalescing filters capture extremely small droplets and solid contaminants—often as small as 0.01 microns—by causing them to coalesce or gather together into larger droplets that can then be drained away.

These filters are essential in applications requiring high-purity air, as they effectively remove impurities that can compromise downstream equipment, processes, or—in the case of breathing air systems—human health.

How Does a Coalescing Filter Work?

Coalescing filters use multiple layers of fine, porous media—typically fibreglass or synthetic fibres—to trap particles and aerosolised liquids. As air flows through the filter element:

Tiny oil and water droplets are intercepted by the fibres.

These droplets combine (coalesce) into larger drops.

Gravity pulls the larger drops to the bottom of the filter, where they are collected and automatically or manually drained.

The result is clean, dry air that is free from harmful oil mists, bacteria, and fine particles.

Coalescing Filters in Breathing Air Systems

Breathing air systems—used in medical, pharmaceutical, diving, firefighting, and industrial paint spray applications—require air that is free from oil, moisture, and other airborne contaminants. Coalescing filters are an essential part of the multi-stage filtration process in these systems.

Typical breathing air systems include:

Particulate filters for removing solid particles

Coalescing filters for removing aerosols and oil/water vapours

Activated carbon filters for removing odours and gaseous contaminants

Breathing Air Filter Regulator sets.

In this setup,

1. The pressure regulator and 5μ pre-filter combination is the primary defence removing particles larger than 0.01mm and 90% of any water.

2. The 0.01μ coalescing filter acts as the secondary defence that traps remaining oil, water and particles larger than 0.00001mm.

3. Then finally activated carbon filter that traps any biological particles and any remaining oil vapour and odours giving technically absolutely clean air to give filtration down to 0.003ppm for the highest demanding air applications and provides safe, breathable air for the spray booth.

Protecting users from inhaling toxic substances and ensuring compliance with safety standards such as EN 12021.

Why Coalescing Filters Matter in Pneumatic and Compressed Air Systems

In many pneumatic systems, especially those involving solenoid valves, actuators, and sensors, contamination can cause blockages, wear, and premature failure. Coalescing filters play a preventive role by:

Extending equipment life

Reducing maintenance needs

Improving system efficiency

At Solenoid-Valve.World, we understand the importance of clean air in automation and industrial systems. Whether you're outfitting a simple pneumatic circuit or a complex breathing air solution, our selection of compressed air treatment components is engineered for high performance and reliability.

Key Benefits of Using Coalescing Filters

Removes oil mist and water vapour down to 0.01 microns

Essential for clean breathing air systems

Protects sensitive pneumatic equipment

Helps meet ISO 8573-1 air quality classes

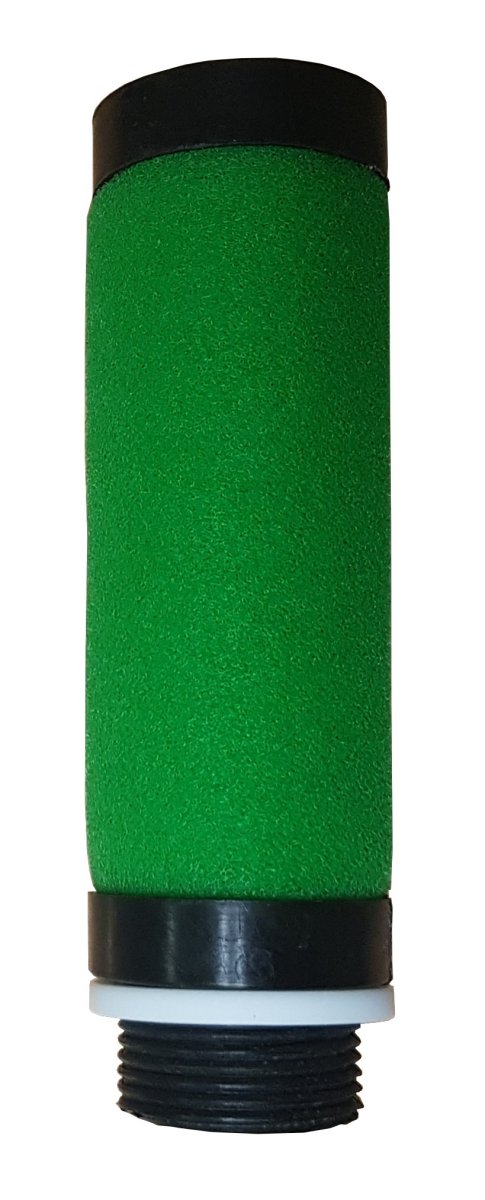

What Is an Activated Carbon Filter and How It's Used in Breathing Air Systems

Introduction to Activated Carbon Filters

Activated carbon filters, also known as activated charcoal filters, are widely used in industrial and commercial applications to remove gases, vapours, and chemical contaminants from air and fluid streams. These filters use highly porous carbon material with a vast surface area to adsorb impurities through a physical-chemical process.

In compressed air systems, activated carbon filters play a crucial role in purifying air by removing oil vapours, odours, and volatile organic compounds (VOCs). Their effectiveness makes them essential in high-purity environments such as breathing air systems and pneumatic control systems involving sensitive components like solenoid valves.

How Activated Carbon Filters Work

Activated carbon is processed at high temperatures to open up millions of micro-pores. When contaminated air passes through an activated carbon filter, gaseous impurities adhere to the carbon’s surface through adsorption. Unlike absorption (where substances are soaked in), adsorption involves the binding of pollutants onto the filter’s surface without chemical alteration.

These filters do not remove particulate matter; instead, they specialise in capturing vapour-phase impurities. For this reason, they are often used in conjunction with particulate and coalescing filters in multi-stage purification systems.

Activated Carbon Filters in Breathing Air Systems

Breathing air systems are used in industries like pharmaceuticals, food processing, chemical manufacturing, and confined-space operations, where clean, odourless, and contaminant-free air is vital for worker safety and process integrity.

In these systems:

Primary filters remove bulk particles and moisture.

Coalescing filters eliminate oil aerosols and finer particles.

Activated carbon filters serve as a final purification stage, removing oil vapours, hydrocarbons, odours, and harmful gaseous contaminants. (But not Carbon Monoxide)

This layered approach ensures that the breathing air meets stringent standards such as EN 12021 or ISO 8573-1 Class 1 for air quality.

Integration with Solenoid Valve Systems

Solenoid valves rely on clean, dry, and oil-free compressed air to operate reliably. Contaminants like oil vapour or volatile gases can degrade seals, clog internal passages, and cause premature valve failure. Activated carbon filters ensure the pneumatic air used in solenoid-controlled automation systems is free from chemical contaminants.

This is particularly important in:

Medical gas supply systems

Laboratory air controls

Precision pneumatic applications

By combining activated carbon filtration with solenoid valve technologies, industries can enhance both safety and equipment longevity.

Applications and Industries

Activated carbon filters in breathing air and pneumatic systems are commonly used in:

Chemical manufacturing

Paint booths and spray applications

Pharmaceutical production

Food and beverage packaging

Confined space air supplies

Firefighting and emergency response SCBA systems

In each case, these filters play a central role in maintaining clean and safe air for both human respiration and pneumatic automation.

Choosing the Right Filter for Your System

When selecting an activated carbon filter for a breathing air system or solenoid valve setup, consider the following:

Flow rate requirements

Maximum pressure rating

Filter life expectancy and saturation indicators

Compliance with applicable air quality standards

Leading suppliers like Solenoid-Valve.World offer a range of pneumatic valves, fittings, and components compatible with air purification systems, making it easy to integrate activated carbon filtration into your operation.

Conclusion

Activated carbon filters are essential components in both breathing air systems and pneumatic systems utilising solenoid valves. Their ability to remove harmful vapours and odours ensures safety, compliance, and reliability across a range of industrial applications. Whether you're maintaining worker safety or protecting sensitive equipment, incorporating activated carbon filtration is a smart, compliant, and effective solution.

Available in various flow rates and pressure ratings Find the Right Components at Solenoid-Valve.World

Looking to improve the air quality in your compressed air system or ensure breathable air compliance?

Browse our selection of pneumatic filters, coalescing + activated carbon elements, and solenoid valve solutions at Solenoid-Valve.World.

Our expert support and wide range of components help you build cleaner, safer, and more reliable systems.