Pneumatic Air Line Rapid Push In Fittings

Pneumatic push-in fittings are essential components in compressed air systems, enabling fast, leak-free connections between tubes and pneumatic components. At Solenoid-Valve.World, we offer a wide range of push-in pneumatic fittings that ensure reliability, efficiency, and ease of installation across various industrial applications.

Why Choose Push In Pneumatic Fittings?

Fast and Tool-Free Installation

Push-in fittings allow you to connect and disconnect tubing without tools. This saves time during setup, maintenance, or reconfiguration.

Features.

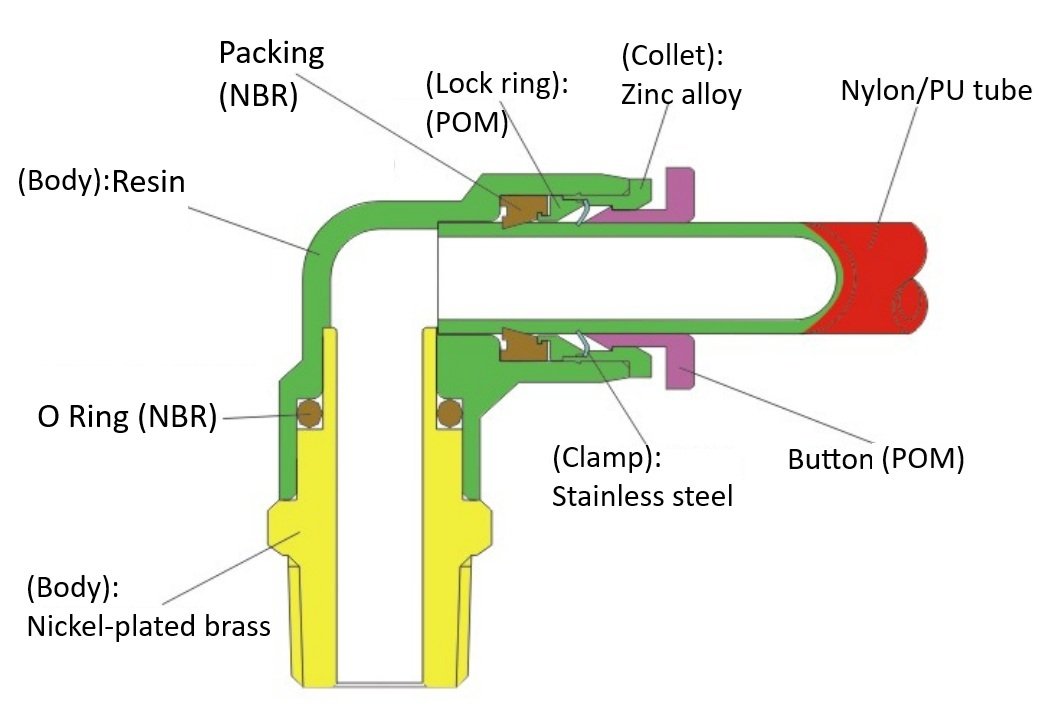

Quick connect pneumatic fittings are used for pneumatic tubing systems.

Fittings come in a variety of models to meet all your pneumatic system requirements.

Even after installation, the tubing direction can still be freely adjusted.

Nickel plated brass body resists corrosion and contamination.

All BSPT, R threads are supplied with thread sealant ready for use.

All BSPP, G threads are supplied with NBR O rings ready to use.

Technical Parameters:

Working pressure: 10 Bar (1 MPa - 150 psi)

Negative pressure Vacuum: -1 Bar ( -100kPa - -29.5 in Hg)

Maximum pressure: 15 Bar (1.5 MPa - 217 psi)

Temperature: -20C to +70C (-4F to +150F)

Leak-Free and Secure Connections

High-quality seals and tight tolerance machining provide a secure, leak-proof fit, ideal for maintaining optimal air pressure in your system.

How to use a Push In Fitting.

How to install airline push in fittings.

Make sure you have the correct tube and thread type and size for your application.

Check that the fittings and tubing are free from any internal debris or contamination.

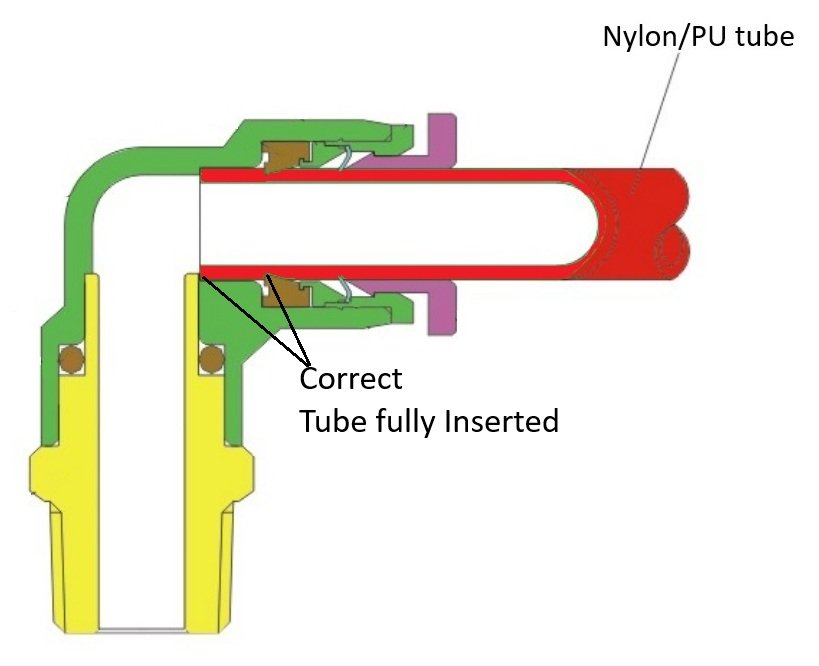

The airline tube is easy to install, simply push the tube into the Button (release ring) until it stops. You should feel the tube push past the retaining claws and seal then suddenly stop.

The retaining claws will automatically clamp around the tube keeping it secure.

How to remove airline push in fittings.

Check that the airline is not under pressure, if the tube feels stiff or feels solid when squeezed it is probably under pressure. A safety shut off vent valve can be installed for next time to avoid this.

Push the button ring inwards (towards the fitting) - this releases the retaining claws and you should be able to remove the tube.

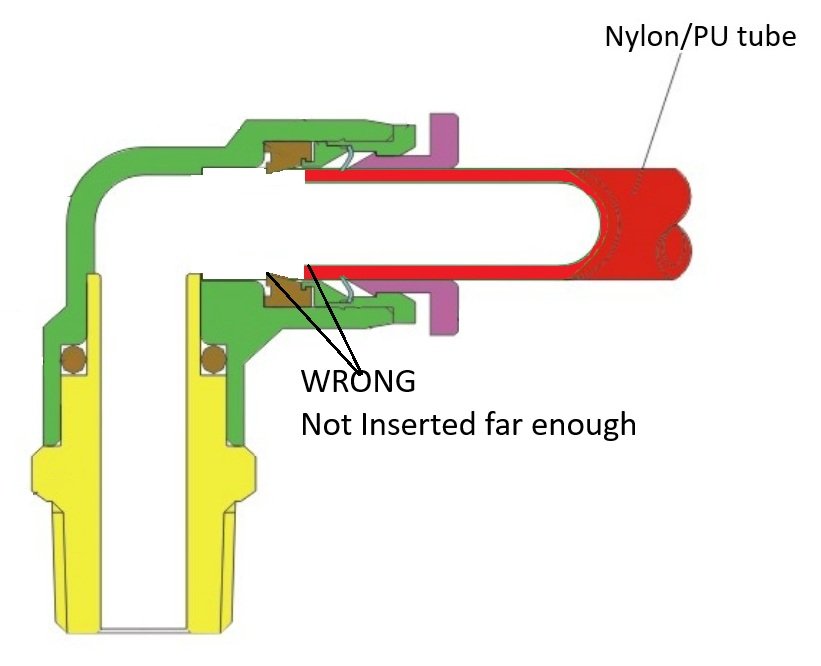

Why is my airline fitting leaking after installation?

This is a common problem if the tube has not been fully inserted into the rapid airline fitting.

Turn off the air supply and vent the air system, to avoid hose whip if the tube releases under pressure.

Push the tubing further into the fitting until it stops. If the tube will not move inwards, remove tube check for any debris, cut 1 inch of tube off the end and reinsert.

If the problem persists, check that you have correct tube and fitting size. (not mixed imperial / metric)

Replace the fitting and try again. If this solves the problem remember to discard the old fitting to avoid repeating the problem.

The picture on the left shows the tube only partially inserted causing air leakage.

Versatility Across Industries

From automation to packaging and food processing, push-in fittings suit a wide array of systems that rely on compressed air.

Types of Pneumatic Push-In Fittings

Stud & Union Push-In Fittings

Ideal for connecting tubes in a straight line, minimising flow restriction.

Elbow and Swivel Elbow Fittings

Perfect for tight spaces and directional changes, these fittings allow rotation and reduce stress on tubing.

Tee and Y Push-In Fittings

Split airflow efficiently with our push-in T and Y connectors, made for branching air lines without compromising pressure.

Multi Port Fittings

Multiple port fittings and manifold systems to connect and divert into several airlines without needing to use several fittings at one point, reducing size and costs.

Caps and Reducers

Blanking caps, plugs enable quick end point shut off and reducing fittings to reduce tube size quickly and efficiently.

Flow and Speed Control fittings

Allow for easy installation of flow control via variable restriction to reduce cylinder or actuator speed to save levels.

Technical Features and Materials

Durable Construction

Our pneumatic fittings are made from nickel-plated brass, PBT, and stainless steel, offering corrosion resistance and longevity.

Suitable for Various Tubing Types

Compatible with polyurethane (PU), nylon (PA), and polyethylene (PE) tubing, available in metric and imperial sizes.

Working Pressure and Temperature

Operating Pressure: 0 to 10 bar (depending on model)

Operating Temperature: -20°C to +70°C

Always check specific product specs for exact performance ratings.

Applications of Push-In Fittings

Industrial Automation

Ensure fast pneumatic connections for sensors, actuators, and valves in automated assembly lines.

HVAC Systems

Use push-in fittings in control systems for heating, ventilation, and air conditioning where space and ease of maintenance matter.

Pneumatic Conveyors

Reliable air line fittings for transferring materials using compressed air in manufacturing and food processing.

How to Select the Right Push-In Fitting

Step 1: Determine Tube Size and Material

Ensure compatibility with your tubing's outer diameter and material (PU, PA, or PE).

Step 2: Consider System Pressure and Temperature

Match fittings to your pneumatic system’s working conditions for safety and performance.

Step 3: Choose the Appropriate Shape

Select straight, elbow, tee, or bulkhead based on layout and space constraints.

Why Buy from Solenoid-Valve.World?

Wide Selection: Stocking various fitting types and sizes for immediate dispatch.

High Quality: Sourced from trusted manufacturers, ensuring industrial-grade reliability.

Expert Support: Our team helps you choose the right fitting for your application.

Worldwide Shipping: Delivering pneumatic fittings globally at competitive rates.

Need Help Finding the Right Fitting?

Our pneumatic specialists are ready to assist. Visit our online store to browse our full selection or contact us for tailored advice.

Air Fittings Features and Benefits:

Strong PBT and nickel plated brass body

Efficient stainless steel tube grip

Robust easy to handle nickel plated brass release sleeve

Efficient NBR O ring sealing

PTFE pre-coated male thread sealing.

View Our Range